Working with the shredder

1. Safety and technical remarks

1.1. The user should be 18 years old or more.

1.2. The machine should be positioned on a horizontal. Firm surface.

1.3. User must wear safety gloves (not provided with this unit), ear-protection and safety goggles.

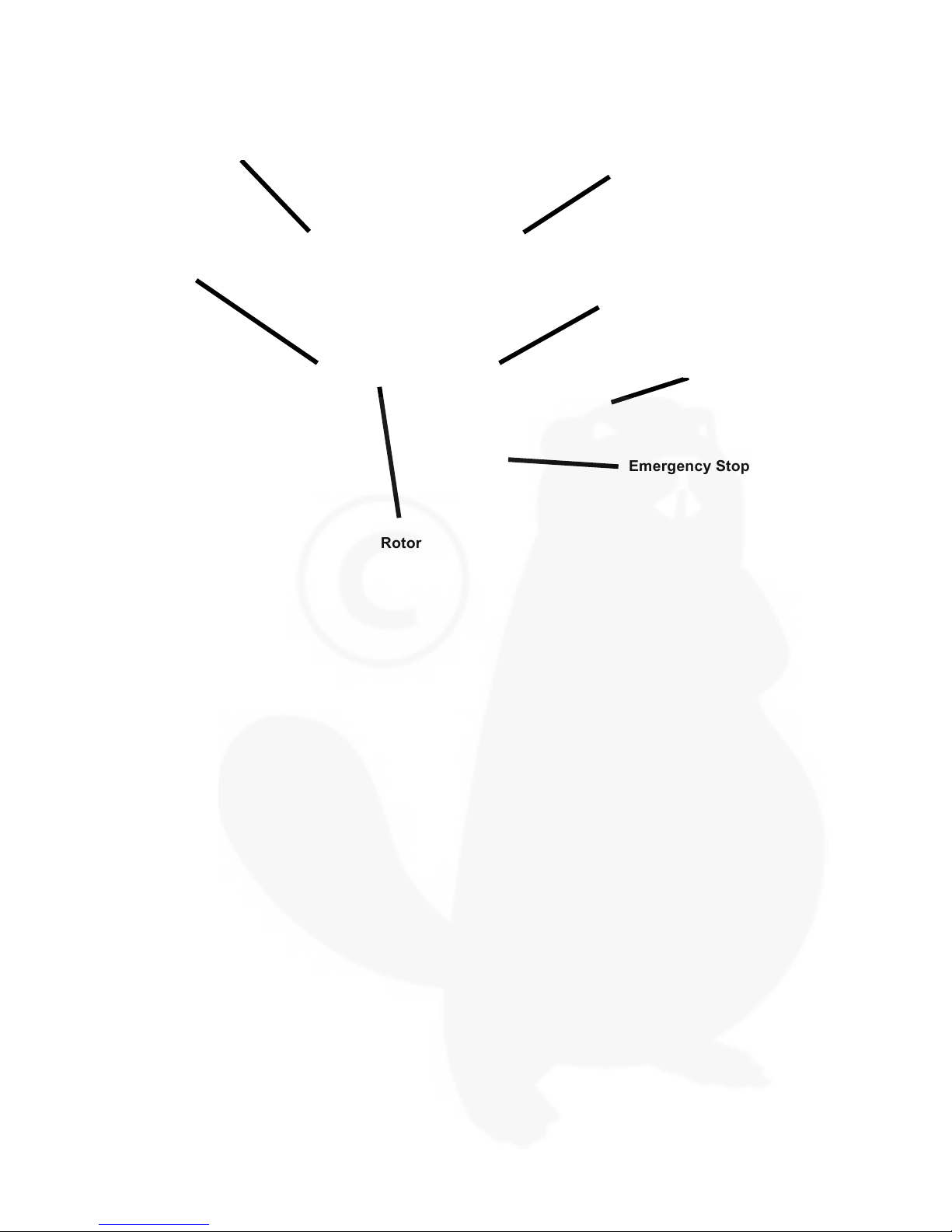

(fig.4)

1.4. When working in a confined space, always make sure there is sufficient ventilation and

lighting, in order to reduce the risk of suffocation and injury.

1.5. Only one person at a time should operate the machine.

1.6. Pieces jamming the input tube can only be removed safely when the engine is stopped and

blocked. If necessary, unbolt and tip the input and output tubes to facilitate access to the

rotor. Use a wooden pole to remove pieces stuck in the rotor. Never use your

hands.(fig.6-8)

1.7. Never leave the machine running unattended.

1.8. Changing the blades of the rotor or the counter blade and checking blade bolts should only

be done when the engine and rotor are stopped, the spark plug cap is removed and the

rotor is blocked.

1.9. After one hour of use always check that all bolts and nuts are still tightened properly. If not,

tighten them again or bring the machine back to your dealer/service-point.

1.10. Use only original parts for maintaining your shredder, otherwise the warranty will be void.

1.11. The shredder can only be repaired by a skilled dealer/service-point.

1.12. The shredder exceeds 90 dBA during operation. Therefore all users and onlookers must

wear ear-protection.

1.13. Before use, make secure that the bolts on the fixed blade are firmly fixed. Check after one

hour that the bolts still are firmly fixed (just first time).