operating

and

maintenance instructions Model JC III

page 7 of 12

PRODUCTS CORPORATION

33

ANDERSON ROAD, MIDDLET

OWN, CONNECTICUT 06457-4926

UNITED ST

A

TES OF AMERICA

TEL. 203-347-7271 F

AX. 203-347-6978

6234007::

3Prior to use or daily, perform the following test.

3.1 Make

sure the control trigger is working correct

-

ly. Depress the trigger and the tool should acti-

vate. Release the trigger and the tool should

deactivate. If the tool malfunctions, remove it

from service and report the problem to your su-

pervisor immediately.

4 Making the cut.

4.1 Position

the dehider in the area where the cutting

is to be done.

4.2 Squeeze

the trigger fully to

start the air motor and

make the cut.

4.3 When

desired cut is finished, release the

trigger

.

(This will stop the blades from oscillating.)

4.4 Withdraw the JC III from the carcass.

MAINTENANCE INSTRUCTIONS

IMPORTANT: ALWAYS DISCONNECT THE COMPRESSED

AIR SUPPLY IN ACCORDANCE WITH OSHA’S LOCKOUT/

TAGOUT

PROCEDURES (29 CFR 1910.147) WHEN

INST

ALL-

ING OR REMOVING THE BLADE. ALWAYS DISCONNECT

THE COMPRESSED AIR SUPPLY IN ACCORDANCE WITH

OSHA’S LOCKOUT/TAGOUT PROCEDURES (29 CFR

1910.147) BEFORE PERFORMING ANY MAINTENANCE OR

REPAIRS.

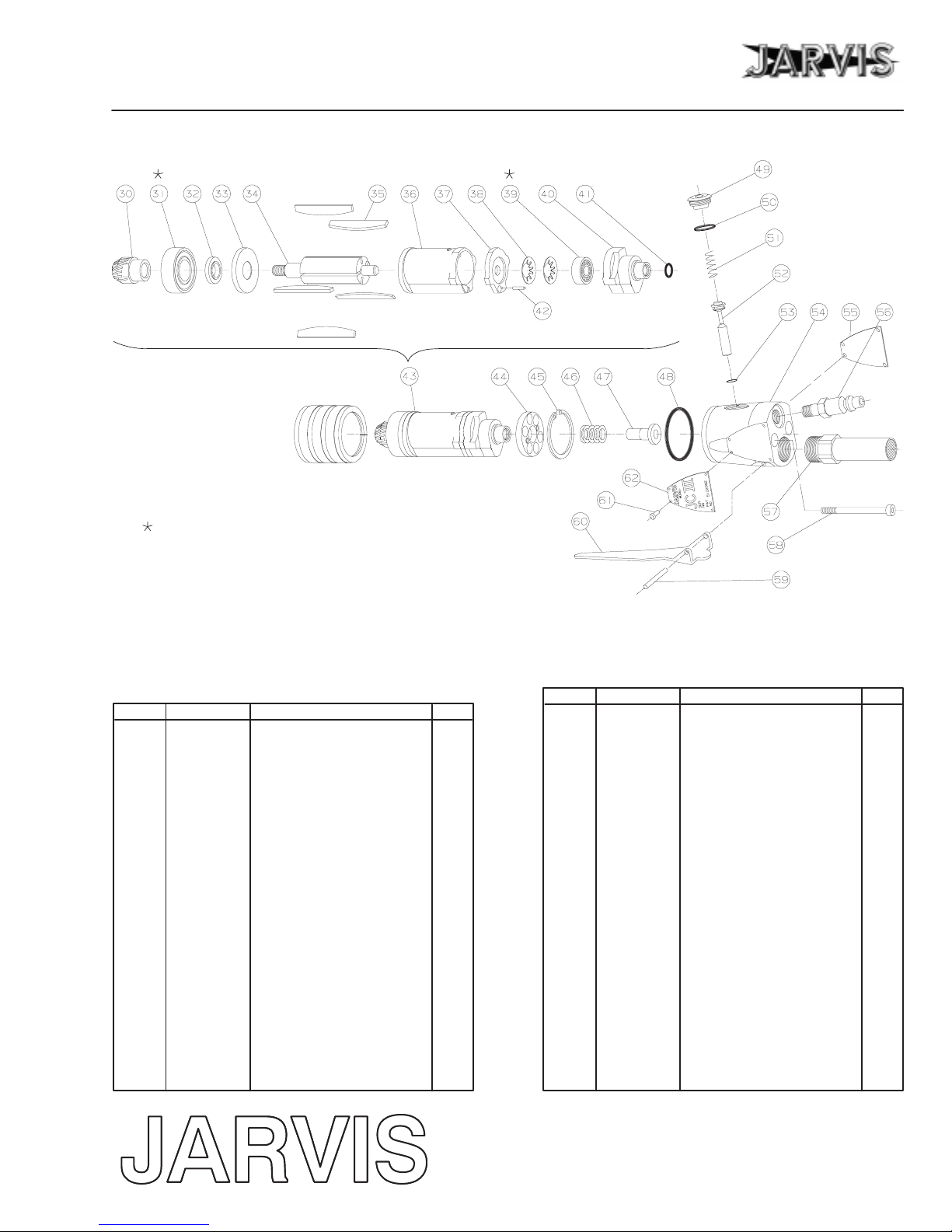

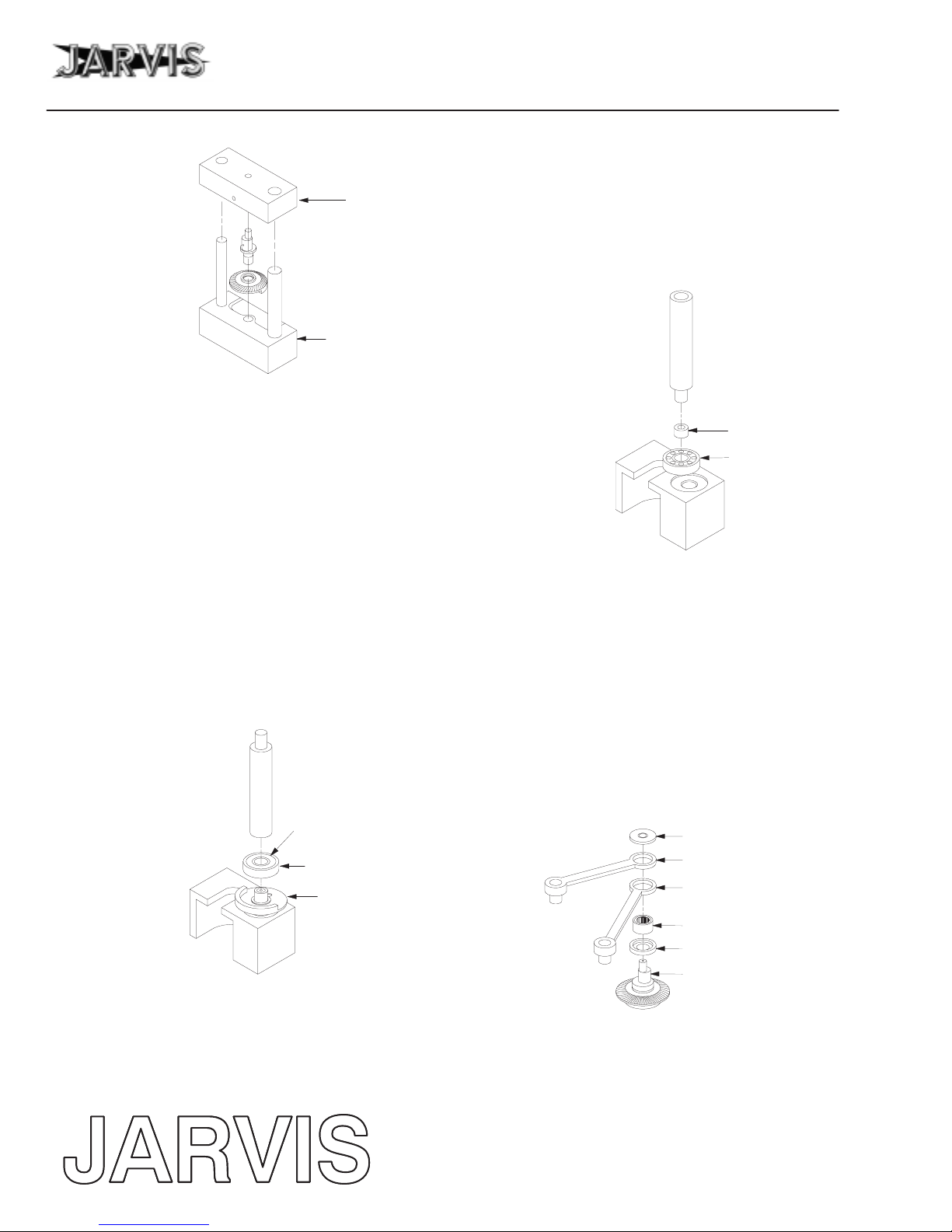

Refer

to the parts diagrams on pages 4-5 for

r

eferenced

items.

Refer

to the fixtur

e

diagrams above and the assembly/di

-

sassembly

diagrams within the text

for r

efer

enced fixtur

e

items.

1Three times per shift.

1.1 Grease all three grease fittings using Jarvis

Grease

Gun (part no. 8038001) and Jarvis Grease

(part no. 1062003 - Lubriplate FML-2).

1.1.1 Grease fittings (items 2 “A” and 2 “C”) with

two (2) pumps of grease.

1.1.2 Ensure

that grease is getting into the

eccentric

drive shaft (item 15), grease fitting (item 2

“B”) with four (4) pumps of grease.

2One time per shift.

2.1 Flush the air motor by squirting about 10 drops

of

Jarvis

air mist oil directly into the air inlet and

running the motor for about five seconds.

3One time per day.

W

ear cut pr

otective gloves when handling blades.

3.1 Make

sure that the compressed air supply is at the

proper

pressure and

that the lubricator oil is up to

the

full mark. (Use

JARVIS

Air Mist Lubricator

Oil;

if using a conventional air mist lubricator:

set

the

feed rate at 5 drops per minute; if

using

a mi

-

cro fog air mist lubricator*: set the feed rate at

100

drops per minute). *

Almost all air mist

lubri

-

cators ar

e micr

o fog air mist lubricators.

3.2 Remove cover screw (item 1).

3.3 Remove

items (3-8) by pulling up on and

turning

the blade set (item 8).

3.4 Push

bushing (item 26) in towards housing (item

24) to remove spacer (item 9).

3.5 Remove bushing (item 26).

3.6 Clean the dehider housing cover (item 11). Do

not

r

emove the cover

, mer

ely clean the

accessible

part of the cover.

3.7 Clean the blades with soap and water.

3.8 Sharpen the blades if necessary.

3.9 Spray or dip the dehider blades in USDA ap-

proved oil.

3.10 Grease the eccentric drive shaft (item 15)

through grease fitting (item 2 “B”) until grease

appears

through the dehider housing cover

(item

11).

3.11 Grease

the housing (item 24)

through grease fit

-

ting (item 2 “C”). Two (2) pumps of grease

should be sufficient.

3.12 Run the dehider without the blades for approxi-

mately one minute.

3.13 Insert bushing (item 26) into housing (item 24).

3.14 Place

spacer (item 9) into

dehider housing cover

(item 11).