Metallic supports included

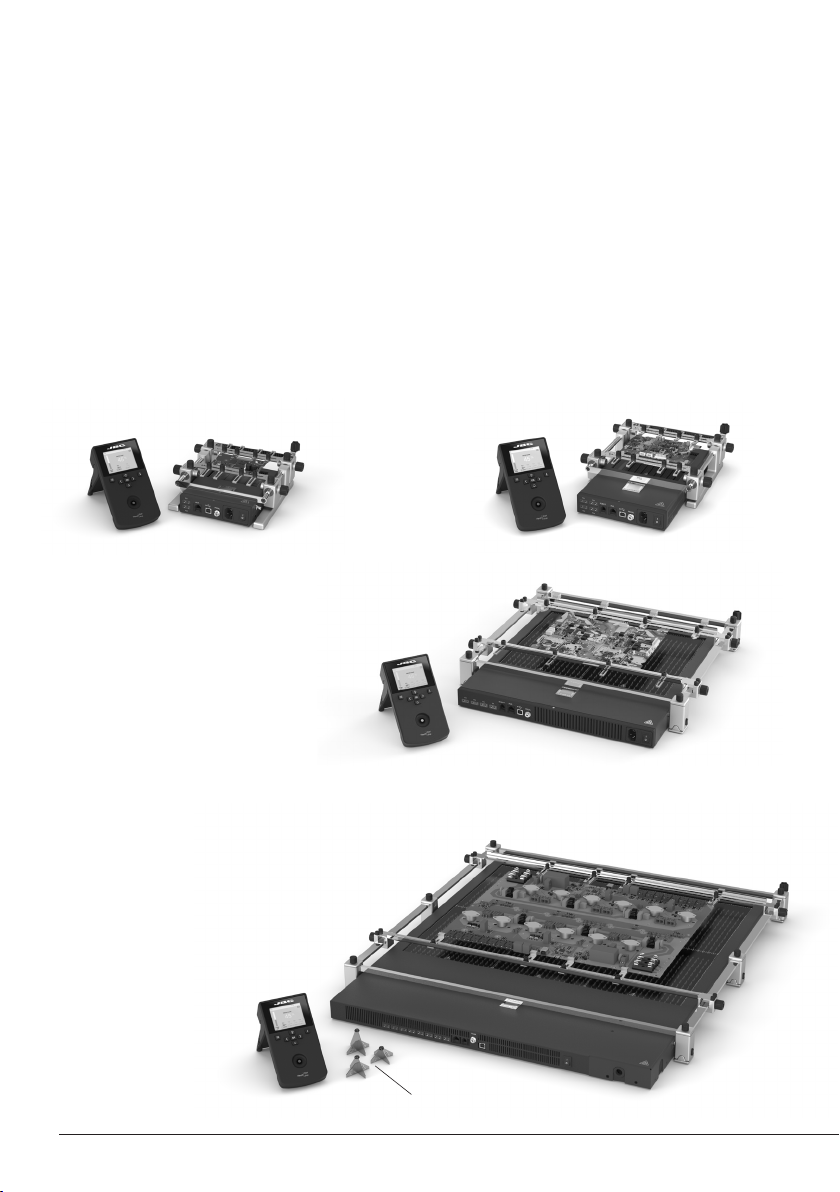

PHNK Nano Preheater Set

- Heating area:

108 x 70 mm / 4.25 x 2.75 in

- Thermocouple connections: 2x

- Clearance PCB to preheater:

22, 45 or 65 mm / 0.87, 1.77 or 2.56 in

PHSK Small Preheater Set

- Heating area:

130 x 135 mm / 5.12 x 5.31 in

- Thermocouple connections: 4x

- Clearance PCB to preheater::

22, 45 or 65 mm / 0.87, 1.77 or 2.56 in

PHBK Large Preheater Set

- Heating area:

360 x 277 mm / 14.2 x 10.9 in

- Thermocouple connections: 4x

- Clearance PCB to preheater:

28, 38 or 48 mm / 1.10, 1.50 or 1.89 in

PHXK XL Preheater Set

- Heating area:

510 x 610 mm / 20.07 x 24 in

- 6 independent work zones, each:

255 x 203 mm / 10.04 x 8 in

- Thermocouple connections: 8x

- Clearance PCB to preheater:

28, 38 or 48 mm / 1.10, 1.50 or 1.89 in

Preheater Sets

JBC offers preheater sets for different PCB sizes. For small, medium, large and extra large PCBs. The

set includes preheater with its console and PCB support.

Accessories

8