2

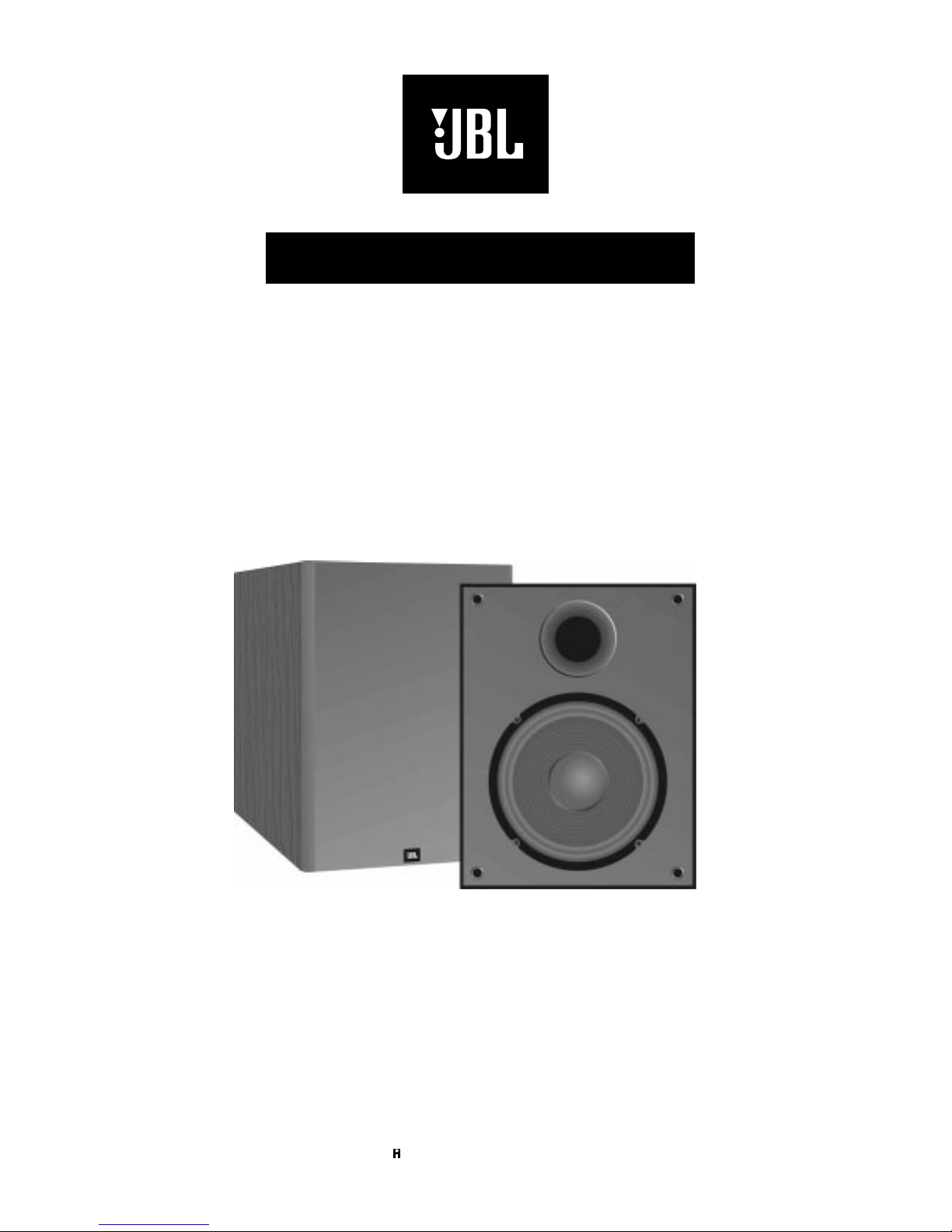

Powered Subwoofer TLX PS12

WARRANTY

This amplifier is warranted against defects in material

and workmanship for a period of one year from date of

shipment, when installed in accordance with the owners

manual in a clean, dry, interior home environment. THIS

AMPLIFIER IS NOT SUITABLE FOR OPERATION

OUTSIDE OR IN HARSH ENVIRONMENTS. During the

warranty period, the manufacturer will, at its option, either

repair of replace products which prove to be defective.

For warranty service or repair, this product must be

properly packed and returned to a service facility

designated by the manufacturer. Buyer shall prepay

shipping charges to the designated facility and the

manufacturer shall pay shipping charges to return the

product to buyer. However, Buyer shall pay all shipping

charges, duties and taxes for products returned to the

manufacturer from another country.

The manufacturer does not warrant that the operation of

the product will be uninterrupted or error-free. The Buyer

must determine the suitability of the product for his or her

purposes.

LIMITATION OF WARRANTY

The foregoing warranty shall not apply to defects

resulting from improper or inadequate maintenance by

Buyer, Buyer-supplied interfacing, unauthorized

modification or misuse, operation outside of the

environment specifications for the product including

inadequate ventilation, or improper site preparation,

installation, or maintenance.

NO OTHER WARRANTY IS EXPRESSED OR

IMPLIED. THE MANUFACTURER SPECIFICALLY

DISCLAIMS THE IMPLIED WARRANTIES OF

MERCHANTABILITYAND FITNESS FOR A PARTICULAR

PURPOSE.

EXCLUSIVE REMEDIES

THE REMEDIES PROVIDED HEREIN ARE BUYERS

SOLE AND EXCLUSIVE REMEDIES. THE

MANUFACTURER SHALL NOT BE LIABLE FOR ANY

DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES, WHETHER BASED ON

CONTRACT, TORT, OR ANY OTHER LEGAL THEORY.

SAFETY SYMBOLS

The following symbols are used throughout this manual

and in the product. Familiarize yourself with each of the

symbols and its meaning before servicing this amplifier.

Instruction manual symbol. The product will be

marked with this symbol when it is necessary for

the user to refer to the instruction manual in order

to protect the unit against damage.

Indicates dangerous voltages are present. Be

extremely careful.

The

CAUTION

sign denotes a

hazard. It calls attention to a

procedure which, if not correctly

performed or adhered to, could result in damage to or

destruction of the amplifier. Do not proceed beyond a

CAUTION

sign until the indicated conditions are fully

understood and met.

The

WARNING

sign denotes a

hazard. It calls attention to a

procedure which, if not correctly

performed or adhered to could

result in injury or loss of life. Do not proceed beyond a

WARNING

sign until the indicated conditions are fully

understood and met.

GENERAL SAFETY CONSIDERATIONS

THIS UNIT DOES NOT HAVE A POWER SWITCH;

HAZARDOUS VOLTAGES ARE PRESENT WITHIN THE

UNIT WHENEVER IT IS PLUGGED IN.

This still applies

when the over-temperature thermostat opens, as it may

automatically reset at any time.

There are voltages and hot components at many points

in the amplifier which can, if contacted, cause serious injury.

Be extremely careful. Any adjustments or service

procedures that require operation of the amplifier out of its

enclosure should be performed only by trained service

personnel.