JDE Gallery 310 User manual

175535500

Quick Reference Guide

Gallery 310

08.2010

2

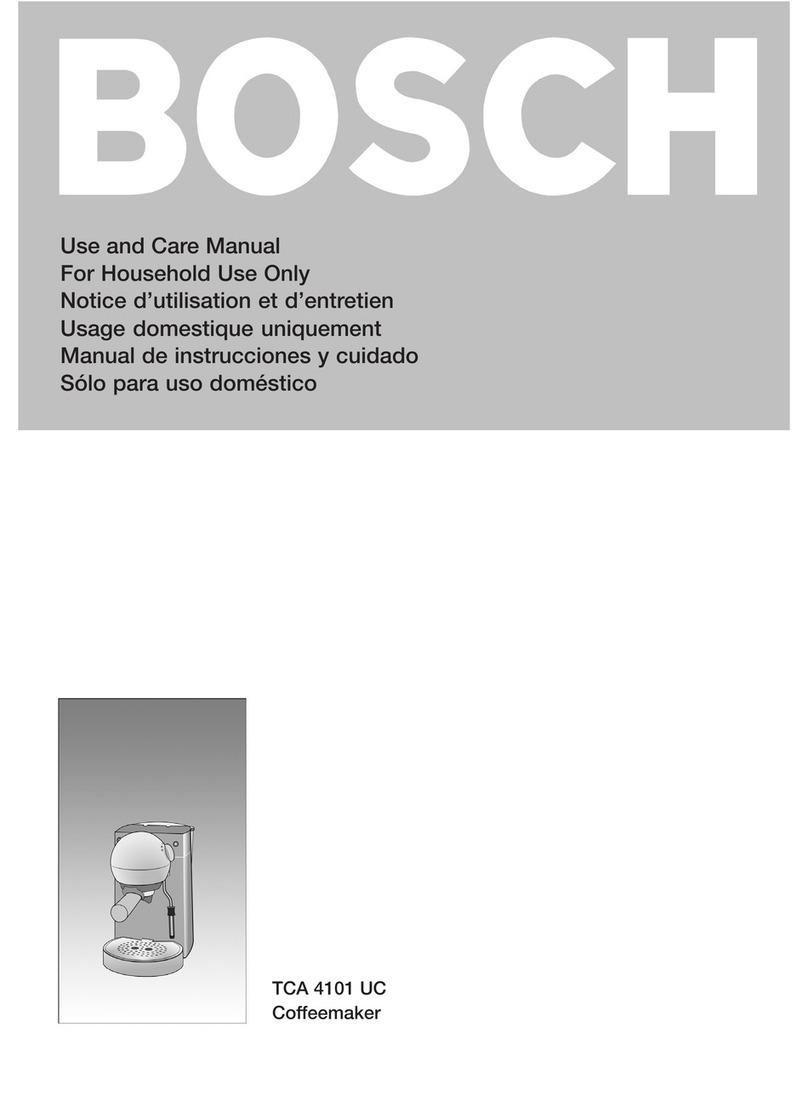

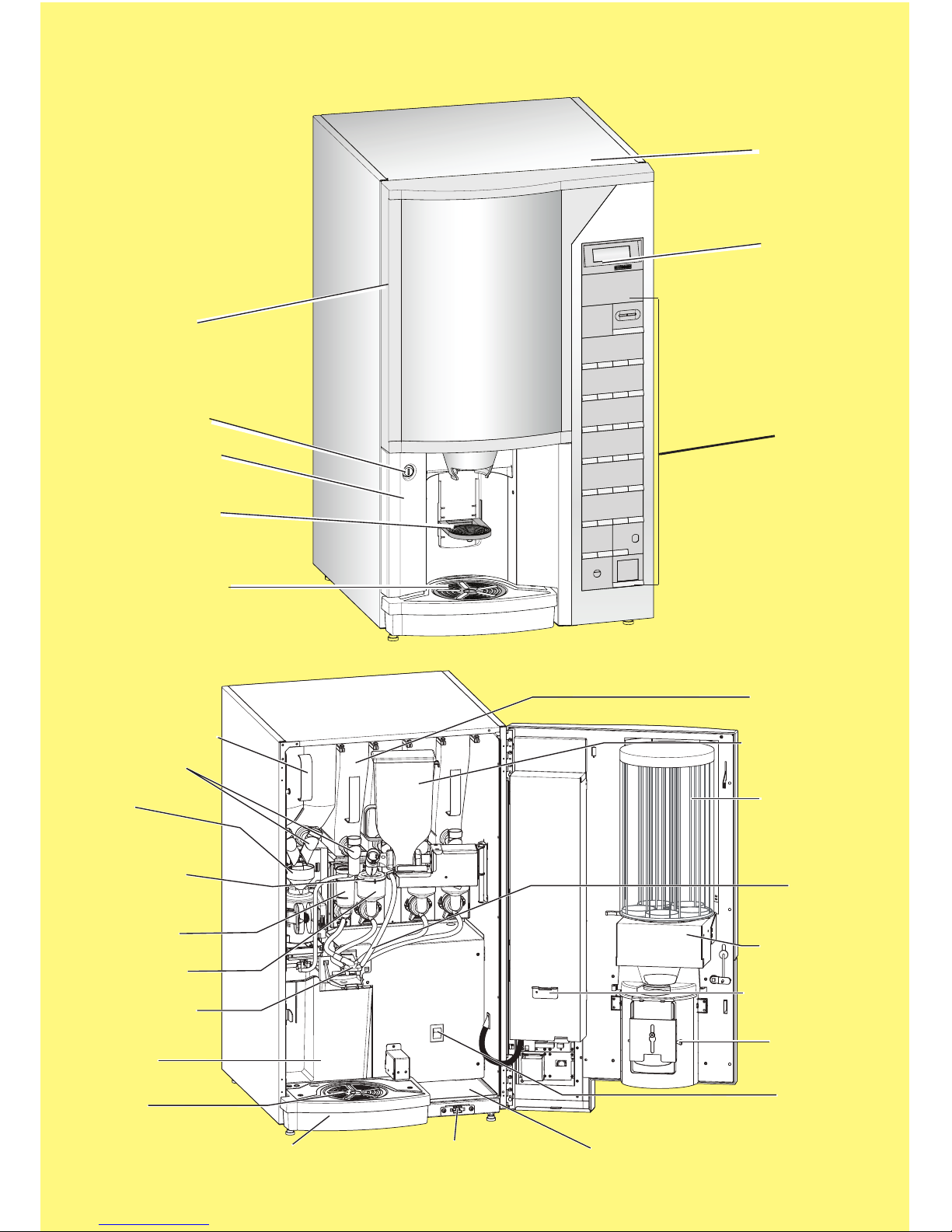

Description of the Machine Components

Cabinet

Door

Door lock

Cup station

Cup carrier

Jug platform

Cabinet

Display

Operator

panel

Instant ingredient

canister

Instant ingredient

canister in side

Cup Magazine

Instant

dispensing

hoses

Cup dispenser

Support bracket f.

canister in side

Retaining pin

for cup carrier

Main switch

Freshbrew

ingredient canister

Outlet spouts

Brewer

Hood for

mixing funnel

Diffuser /

Coffee mixer

Mixing funnel

Dispense head

Solid waste

container

Drip grid

Base trayDoor switchDrip tray

3

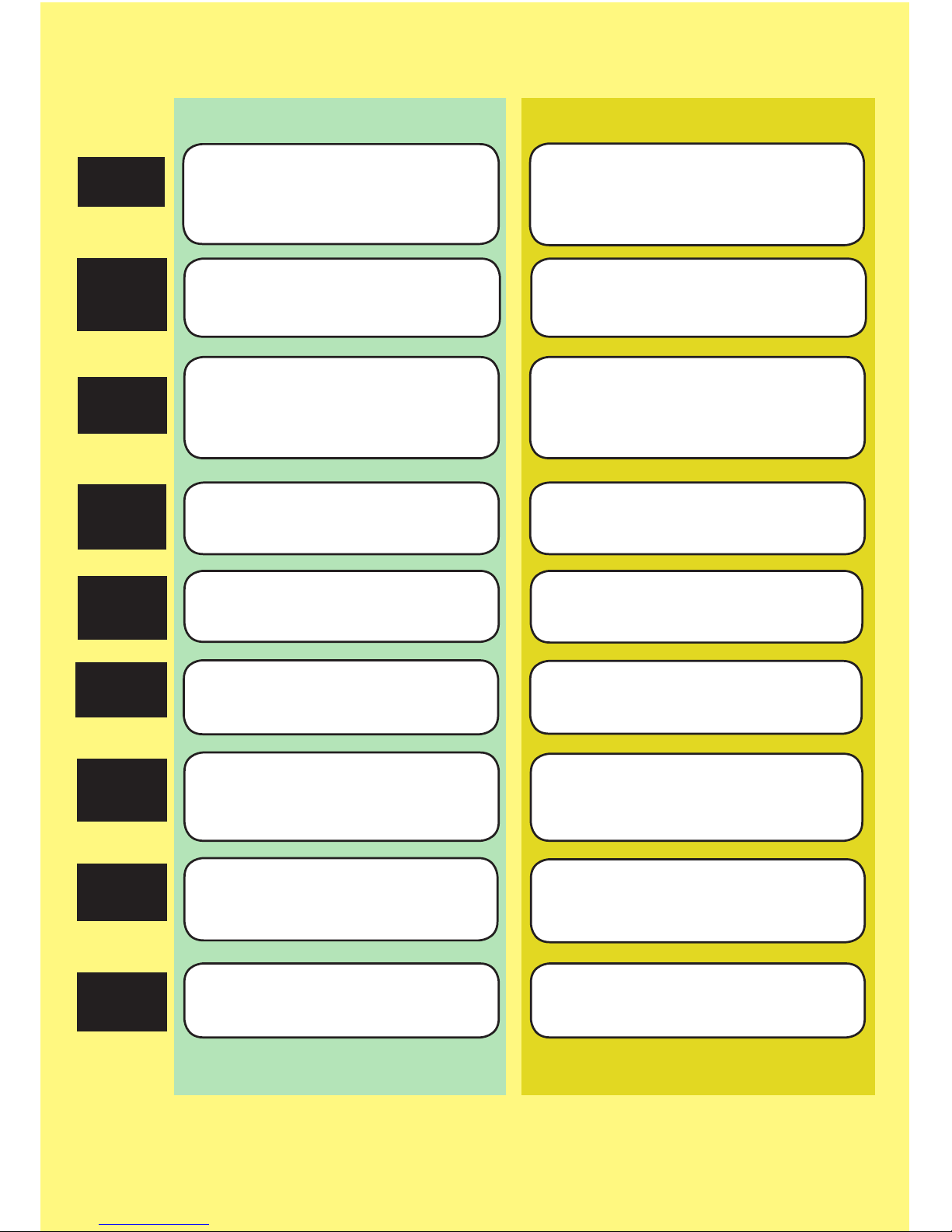

Reference Card Error Types

Display Possible cause Possible action

message

Base tray

full

Drip tray

full

Energy

saving

mode

No SB1 cyl.

pressure

Out of

service

Rinse in

progress ...

SB Piston

error

SB Scraper

error

Temperature

low

If it was impossible to remedy the fault, or other type of display message is shown,

please contact the service.

Empty and clean base tray. Wipe it dry.

Empty and clean drip tray. Wipe dry

sensor.

The machine returns to vend mode,

when a selection button is pressed.

When the water is heated sufficiently, the

machine is ready to dispense drinks.

Remove blocking object from uppper

valve of brewer cylinder.

Turn the machine off and on.

Wait until machine has finished the

automatic rinse function.

Clean the brewer unit.

Clean the brewer unit.

Wait until the water is heated sufficiently

(maximum 13 minutes).

Base tray is full.

Drip tray is full.

An energy saving period is active.

Upper valve in brewer cylinder is

blocked.

Machine has a problem.

Rinse program is in progress.

The movement of the brewer piston is

obstructed.

The movement of the brewer scraper

is obstructed.

The machine has been turned on

recently.

4

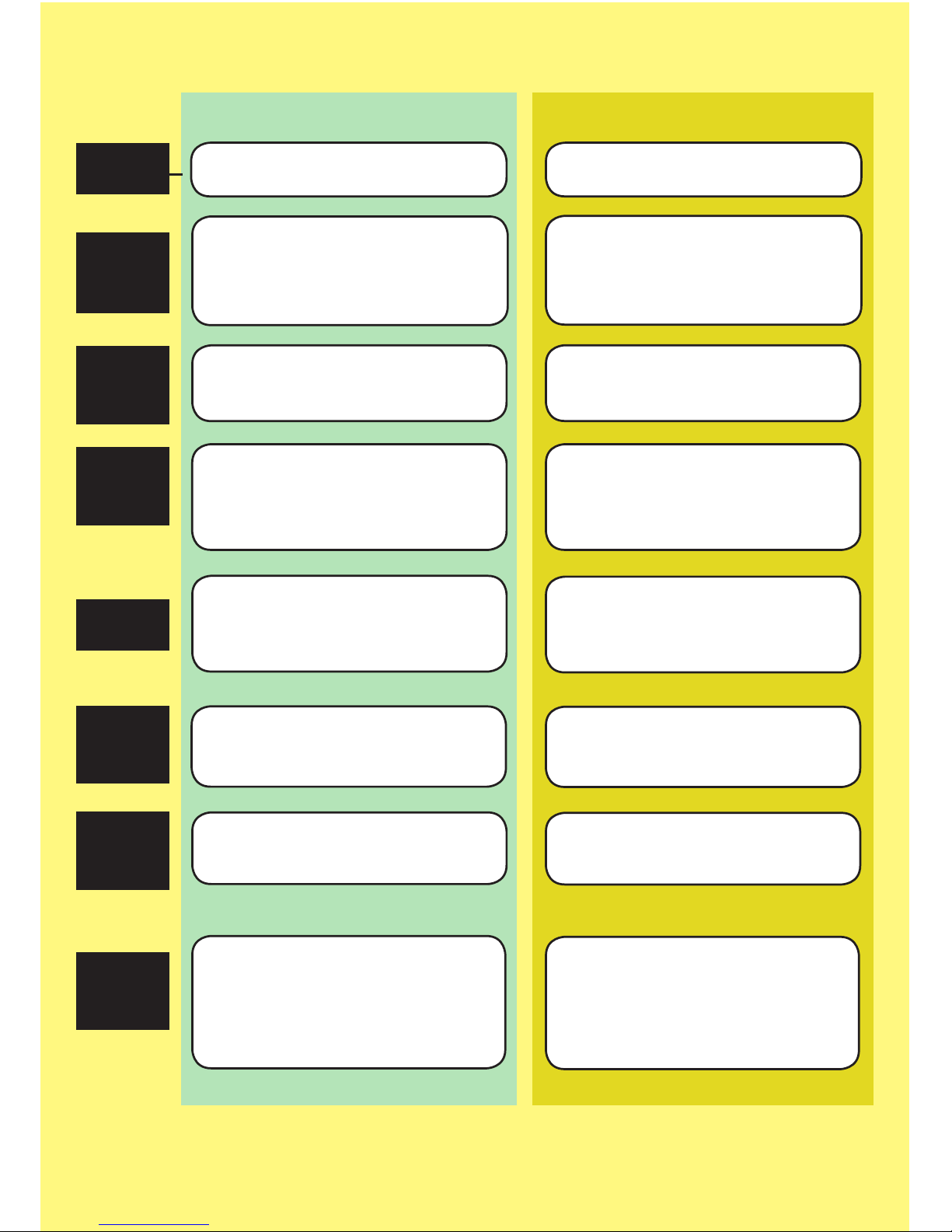

Reference Card Error Types (continued)

Error Possible cause Possible action

types

If it was impossible to remedy the fault, please contact the service.

Coins have difficulties being accepted.

Wrong ingredients used

Canisters or hoses in dispense head

switched by mistake.

Freshbrew unit or dispensing system

dirty.

Freshbrewer unit is not correctly

assembled.

Waste containers/trays or components

of dispensing system placed

incorrectly.

Sensor of drip tray is soiled.

The door is not properly closed.

The drip tray or base tray is full.

Mixing funnel(s) blocked or leak in

system.

Missing sealing ring in mixing funnel.

Mixing funnels or the coffee/tea filter

are blocked.

The ingredient spouts are closed.

Ingredient canister is empty.

Coupling not fitted in canister.

Ingredient sticking to auger drive

mechanism.

Press the coin return button.

Use correct ingredients.

Ensure that canisters and hoses are

locatated in correct positions.

Ensure that components are clean.

Assemble the freshbrewer unit

correctly.

Ensure that solid waste container,

trays, canisters, mixing funnels and

dispensing hoses are positioned in

correct places.

Clean sensor.

Ensure that the door is closed.

Empty, clean and dry trays and

sensors.

Switch machine off and on.

Replace or clean blocked part(s).

Fit sealing ring in mixing funnel.

Clean or replace blocked the parts.

Open ingredient spouts.

Refill the canister

Ensure that coupling is fitted in

canister.

Remove canister, clean auger drive

mechanism and reinsert.

Coins

sticking

Wrong

flavour of

drink

Freshbrewer

unit mal–

function

Liquid

escaping

from

machine

Machine out

of function

Mixing

system

overflows

No drinks

are

dispensed

Only water

is

dispensed

5

Regular Cleaning *)

17

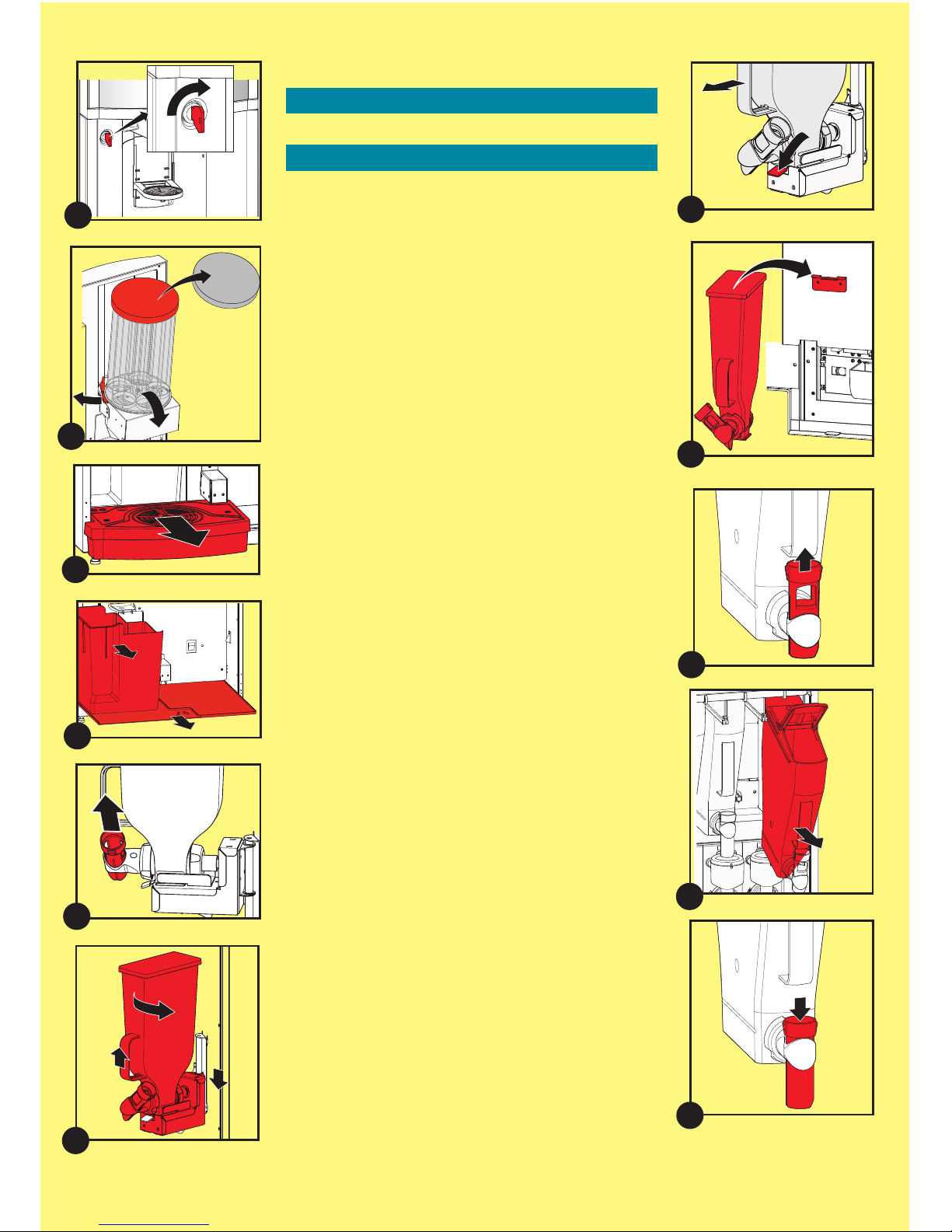

Opening the machine

• Open the door by turning key clockwise (1).

Cup magazine and ingredient canisters

Cup magazine

•Activate the locking clip of the cup dispenser

and tilt the cup dispenser forwards (2).

•Remove the lid and ll the cup magazine with

cups.

•Put the lid back on and tilt back the cup

dispenser.

Instant ingredient canisters

•Lift and take out the drip tray and place it

outside of the machine (3).

•Pull slightly forwards the solid waste container

and the base tray to prevent pollution (4).

•If an ingredient canister is present in side of

machine:

- close the outlet spout of the ingredient canister

(5).

- take hold of bracket for canister, raise it slightly

upwards and swing it out with canister (6).

- press the green release lever on bracket for

canister and remove the canister (7).

- hang the canister on its support bracket (8).

- remove the lid and fill the canister.

- put the lid back on and let the canister stay on

the support bracket (8).

•Close the outlet spouts of the other canisters

(9).

•Take the canisters by the handles and pull

them forwards to the end stop in guiding

rails (10). The lids are automatically triggered

open.

•If required, the canisters can be removed by

lifting canisters upwards and pulling forwards

over the end stops in guiding rails.

•Fill the ingredient canisters with ingredients.

•Press the lid slightly down and push back the

ingredient canisters.

•Open the outlet spouts of the canisters (11).

9

8

4

(see overleaf)

2

3

5

*) All parts to be cleaned are designed

in a blue colour. All parts of action are

supplied in a green colour.

6

10

11

6

Regular Cleaning (continued)

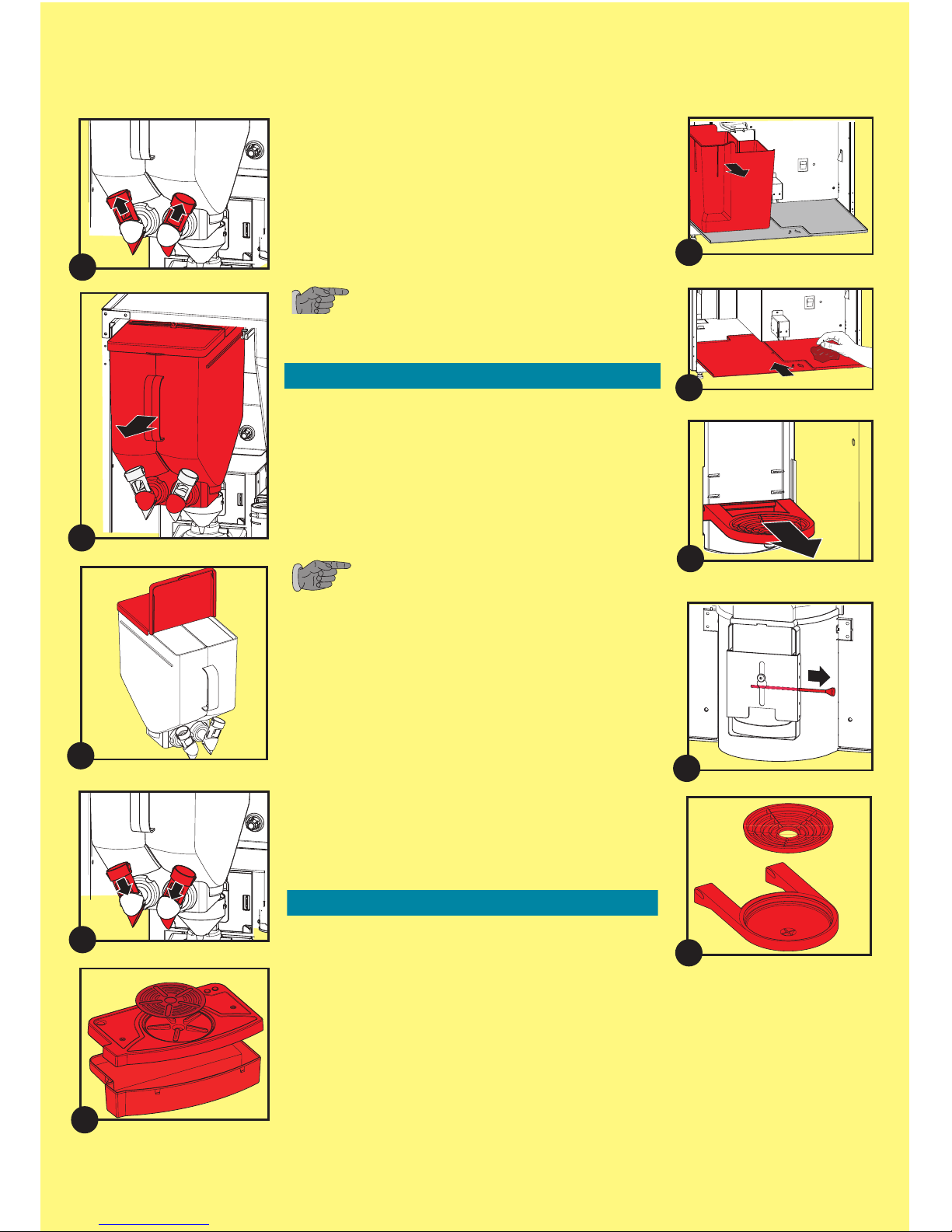

Freshbrew ingredient canister

•Close the outlet spouts of the canister (12).

•Pull forwards and take out the freshbrew

ingredient canister (13).

•Open the lid and ll the canister with coffee

(14).

•Close the lid.

•Push back the canister in place.

Check to make sure that it is locked in

place

•Open the outlet spouts of the canister (15)

Cleaning parts

Drip tray, solid waste container and base

plate

•Remove the drip grid and the lid from the

drip tray (16).

•Empty the drip tray (16).

•Clean the drip tray and its parts.

•Clean the parts in hot water with cleaning

agent, and wipe the parts dry.

Wipe the sensors in the lid dry (16a).

•Take out the solid waste container. Empty

the container and insert a new liner (17).

•Wipe clean the base tray.

Push the base tray back in place (18).

Cup carrier

It is recommended to have the cup carrier

as an exchange kit (hygiene kit).

•Remove cup carrier:Take hold of the

cup carrier with your right hand (19) and

remove the corresponding retaining pin

(20), situated on the rear side of the cup

station, with your left hand.

•Clean the drip grid and the tray (21) in hot

water with cleaning agent and dry parts.

Cleaning inside and outside

•Clean the door and housing inside and

outside, and finally the bottom with a clean,

damp cloth.

14

19

16

13

12

15

17

18

20

21

a

7

Regular Cleaning (continued)

25

Mounting the cleaned parts

•Remount all parts.

If present, relocate ingredient canister in side:

- insert it in its bracket in the side of the

machine (22).

- lift up the bracket with ingredient canister and

swing it back on proper place.

- open the outlet spout of the ingredient

canister (23).

Ensure that solid waste container is

mounted correctly. Front side facing

forward.

There is the risk of being scalded by

hot water.

Observe the safety precautions in the

operator manual.

•Have an empty jug (min. 1.5 l) ready to place

on the jug platform.

•Turn to the display and perform a machine

rinse using the preselection buttons (24).

- Press "1" to start the [Rinse]-function.

- Close the door and place the jug on the jug

platform (25).

•Follow the information on the display.

•Wait until the program has nished.

•Repeat the rinse procedure min. once more.

•Press the button 'Esc' until the machine

leaves the programming mode.

•Remove and empty the jug.

Last check

•Clean the machine with a damp cloth on the

outside. Clean also the jug platform.

•Perform a test dispensing with a drink with

milk and sugar.

(see overleaf)

-----SHORTCUTS-----

*(1)=Rinse (3)=Counter

(2)=Test (4)=Menu

(1) (2) (3) (4)

23

*) All parts to be cleaned are designed

in a blue colour. All parts of action are

supplied in a green colour.

22

24

8

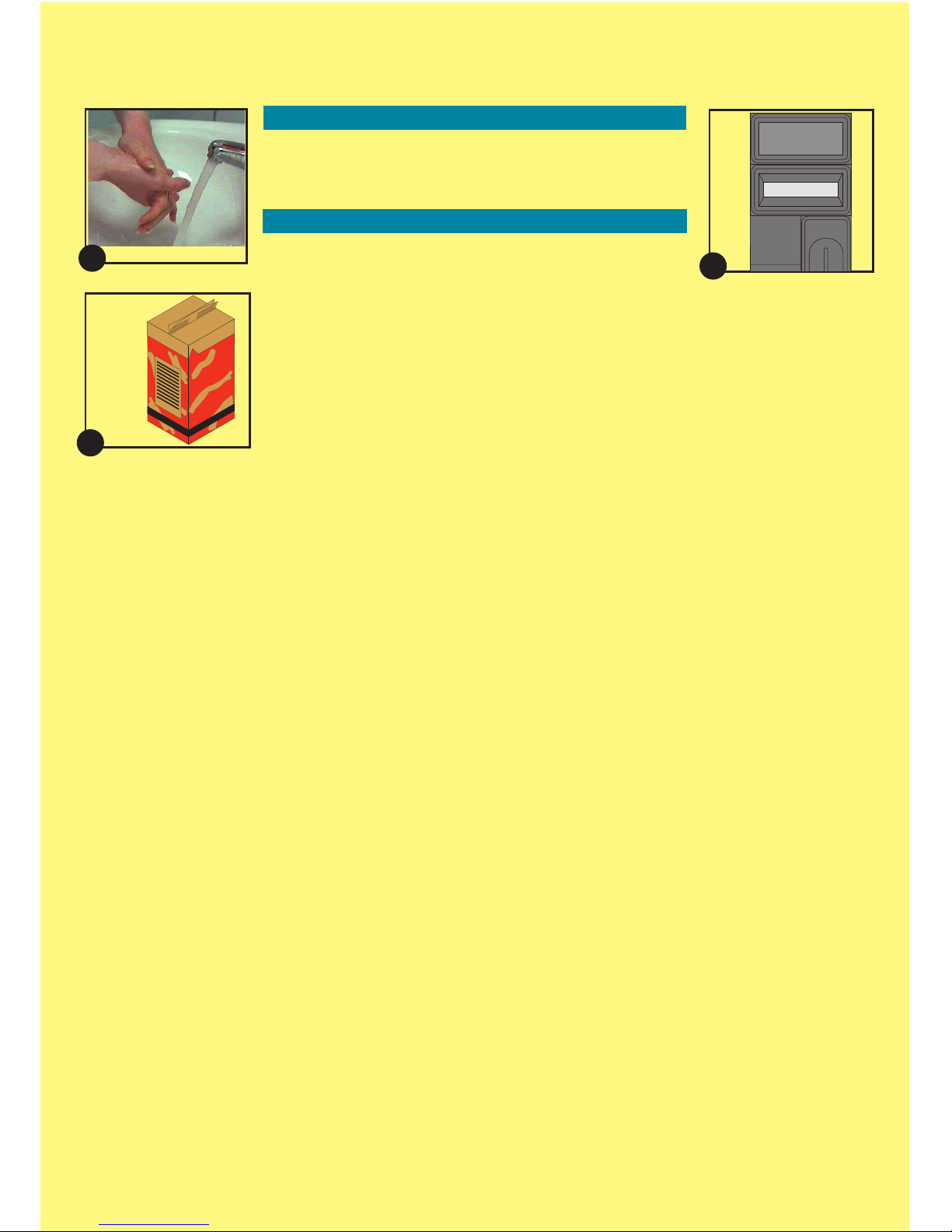

Deep Cleaning *)

(see overleaf)

Opening the machine

•Open the door by turning key clockwise (1).

Filling cups and ingredients

•Load cups (see Regular cleaning).

•Lift and take out the drip tray and place it

outside of machine (2).

•Pull forwards the solid waste container and

the base tray to prevent pollution (3).

Instant ingredient canisters

•If a canister in side of machine present:

- close the outlet spout of the ingredient

canister (4).

- remove the canister (5) (see Regular

cleaning).

- hang the canister on its support bracket and

fill canister (6). Let the canister stay on its

support bracket (see Regular cleaning).

•Close the outlet spouts of the other instant

ingredient canisters (7).

•Pull the ingredient canisters forwards and ll

with ingredients (8) (see Regular Cleaning).

•Wipe clean the shelf under the instant

ingredient canisters with a clean and moist

cloth.

•Leave the outlet spouts closed, and push

canisters back in place.

Freshbrew ingredient canister

•Close the outlet spouts (9).

•Pull and take out the freshbrew ingredient

canister (10) (see Regular Cleaning).

•Open lid and ll coffee canister with coffee.

•Close lid, and push canister back in place.

Check to make sure that it is locked in

place.

•Open the outlet spouts (11).

*) All parts to be cleaned are designed in a blue

colour. All parts of action are supplied in a

green colour.

1

8

2

3

4

5

6

7

9

10

11

9

Deep Cleaning (continued)

(see overleaf)

Cleaning parts

It is recommended to have an exchange kit

(hygiene kit), see operator manual.

Soak all parts, which will be disassembled,

at least for 15 minutes in a bucket with hot

water with cleaning agent**.

•Turn machine off at the main switch (12).

Instant ingredient mixer units

•Remove the mixing funnel hoods (13a).

•Remove mixer units: Loosen locking ring by

pressing release lever (13b) anti-clockwise,

and pull out mixing funnel leaving the hoses

back on.

•Remove sealing rings (14a).

•Pull off the whipper wheels (14b).

•Remove and clean the powder traps (15).

Diffuser / Coffee whipper

•Remove brewer hose from diffuser (16).

•Remove the hood for diffuser and the upper

sealing ring (16).

•Remove diffuser (16): turn clockwise, and

pull out diffuser leaving the outlet hose back

on.

•Remove the lower sealing ring.

•If diffuser is acting as a coffee mixer, pull

off the whipper wheel (16).

Dispense head and freshbrew unit

•Remove the outlet hoses from the dispense

head (17).

•Unclip and remove the drip tray with drain

hose under the dispense head (18).

•Remove the dispense head by turning the

winghead stud and lifting off the dispense

head (19).

•Disassemble mixing funnels, hoses, and

dispense head before soaking the parts.

•Disassemble parts of freshbrew unit in the

sequence indicated on page overleaf.

13 17

15

18

19

14

a

b

12

16

a

b

**) For cleaning and descaling: refer to the

HACCP guidelines.

10 (see overleaf)

Disassembling the freshbrew unit

The illustrations to be read row by row

1) from left to right, and

2) from top to bottom

11

Drip tray

•Remove the lid from the drip tray (20) and

empty the drip tray.

•Clean the drip tray and its parts (see regular

cleaning)

Wipe sensor in the lid dry (20a).

Solid waste container and base tray

•Take out solid waste container (21). Empty

container and insert a new liner.

•Remove the base tray from machine (22)

and clean it.

Cup carrier

•Remove retaining pin (23) and cup carrier

(24) (see Regular Cleaning).

• Clean the complete cup carrier (25a,b) (see

Regular Cleaning).

Cleaning inside and outside

•Clean the door and housing inside and

outside, and finally the bottom with a clean,

damp cloth.

•Flush all parts, which have been soaking,

thoroughly with clean and warm water.

Check that no dirt or cleaning agent

remains on the parts.

•Dry all parts with a dry cloth.

Mounting the cleaned parts

•Remount all parts (as to freshbrew unit, see

overleaf).

•Open the outlet spouts of all the instant

ingredient canisters (26)(27).

•Turn the main switch of machine on (28).

Ensure that solid waste container is

mounted correctly. Front side facing

forward.

Rinsing and last check

There is the risk of being scalded by

hot water. Observe the safety precau-

tions in the operator manual.

•Rinse machine twice (see Regular Cleaning).

•Clean exterior of the machine (damp cloth).

•Perform a test dispensing by pressing a

selection button e.g. coffee with milk and

sugar.

Deep Cleaning (continued)

28

(see overleaf)

25

23

a

b

24

22

21

a

26

20

26

12

Reassembling the freshbrew unit

The illustrations to be read row by row

1) from left to right, and

2) from top to bottom

13 (see overleaf)

2

13

xxxxx

Coffee

HACCP Guidelines

Directives

•For correct operation of the machine, at least

the mentioned guidelines must be taken into

consideration. The operator is held responsible for

the correct operation.

HACCP guidelines

Handling of coffee and ingredients

•Ensure hygienic handling:

- wash hands, preferably with a disinfectant (1)

- use hygienic gloves

- after cleaning, do not touch surfaces of parts that

may come into contact with food

- always use a clean cloth when cleaning

- keep the working area tidy.

•Check the package for integrity and damage (2).

•Store the coffee and ingredients dry, cool and dark.

•Use the packages within the recommended time

period (see the "best before"-date on the package).

•Always use packages according to the "rst-in-rst-

out"-principle.

•Thoroughly close an opened package to keep the

quality and preventing contamination.

•Coffee and ingredients should be stored separated

from cleaning products.

•The ingredient container should be cleaned

occasionally (see operator manual).

•Do not ll more coffee or ingredients than needed

until the next cleaning.

Cleaning the machine

•Observe the cleaning instructions.

•Clean the machine preferably at the end of the day

•After cleaning, dispense and check a drink (see

"Last check").

•Fill in the cleaning record card.

•When the display indicates an error message (3),

observe the display messages on the reference

card.

•Only use the recommended cleaning agents that

have been approved for the food industry (slightly

disinfecting, preferably liquids, tabs, possibly grains.

Avoid powders).

14

HACCP Guidelines (continued)

Descaling

•Depending on the hardness of water, the metal

parts of the filter plate holder must be cleaned after

approx. 1000 drinks.

Replacement

•Depending on the hardness of water, the nylon

brewer filter or the gasket for a metal brewer

filter must be replaced after a certain number of

vends, even if apparantly still efficient, see operator

manual.

Filing

•After opening, write the date of opening on the

package.

•File the "best before"-date of the package used to

fill the machine.

•File service and maintenance reports.

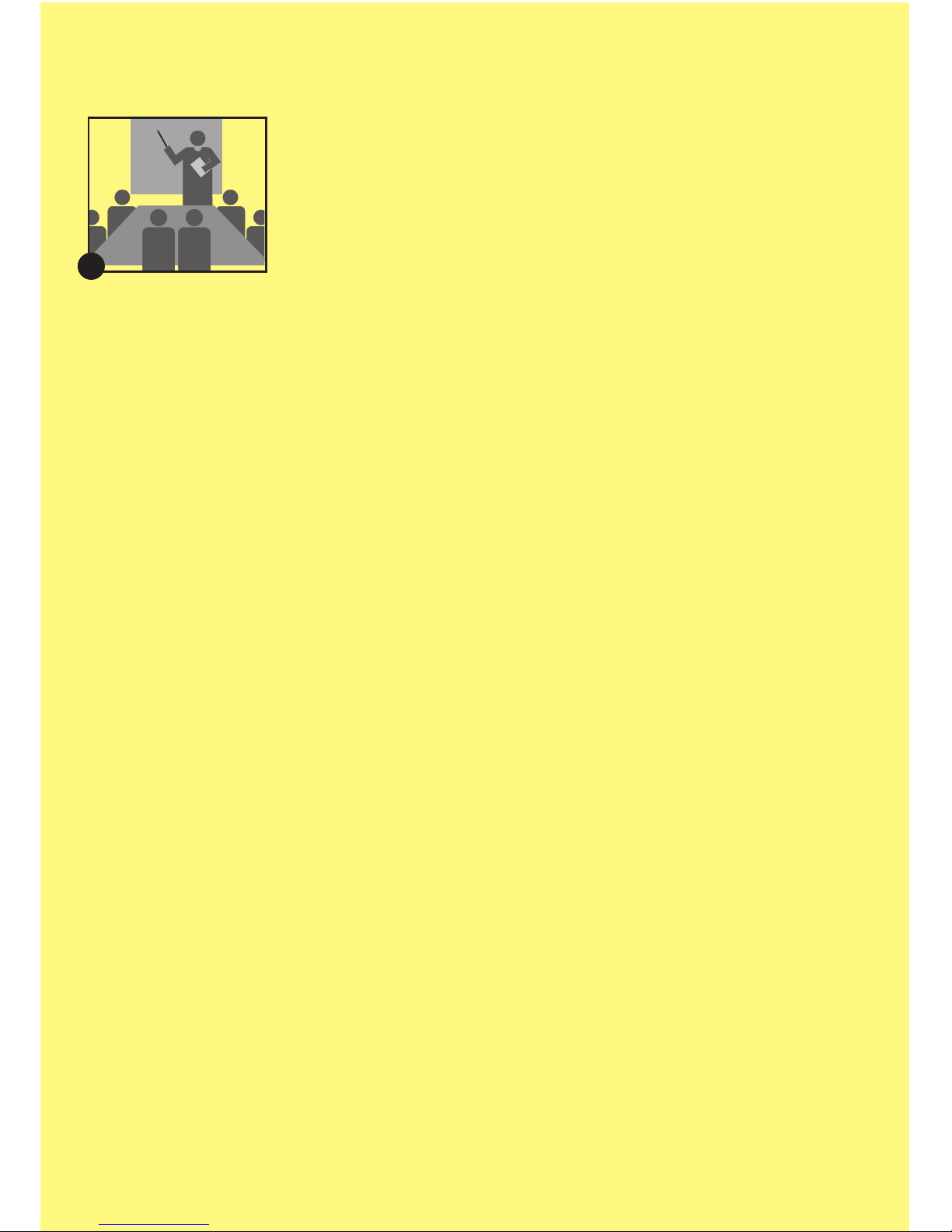

Training

•Train staff on HACCP guidelines (4).

•Implement the activities in the work schedules.

•For further questions please contact your service

representative.

4

15

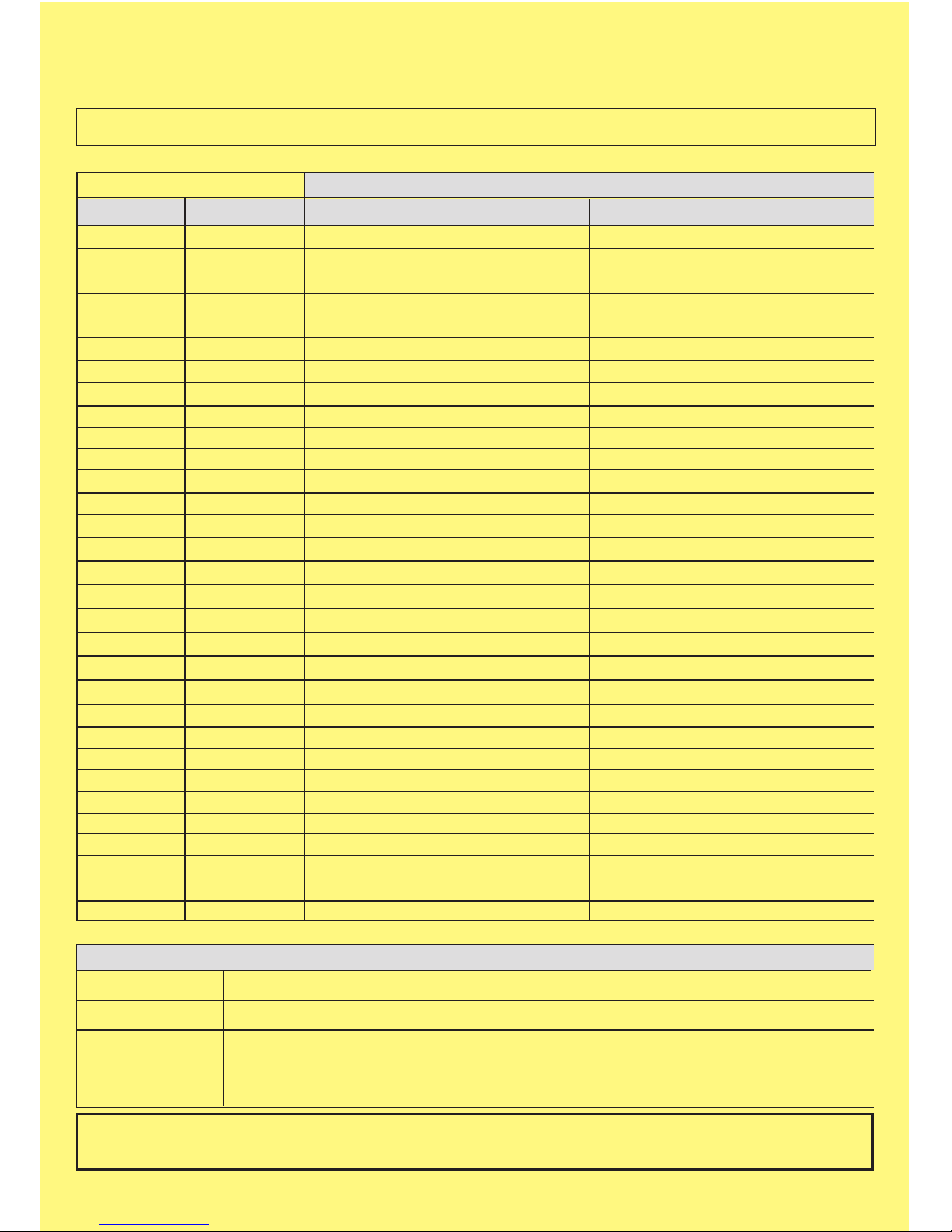

Cleaning Record Card

Declaration: Thismachinehasbeencleanedincompliancewiththecleaninginstruc-

Signature

Date Time Regular cleaning Weeky cleaning

Monthly management check

Date

Signature

Comment

KEEP THIS CARD WITH THE GALLERY 310 MACHINE

(and file when completed)

Table of contents

Other JDE Coffee Maker manuals

JDE

JDE PROFESSIONAL CAFITESSE QUANTUM TOUCH User manual

JDE

JDE Cafitesse 300 User manual

JDE

JDE schaerer Barista Pro BF BiB User manual

JDE

JDE PRMSS-001 User manual

JDE

JDE L'OR Supreme User manual

JDE

JDE EXCELLENCE COMPACT User manual

JDE

JDE Sprso Giro User manual

JDE

JDE EXCELLENCE COMPACT BLACK User manual

JDE

JDE Cafitesse 120 Next Generation User manual