CLEANBLAST PORTABLE

CONTENTS

iii

Inspect Before You Connect

Acceptance Criteria

INSPECT

Inspect

IS IT CLEAN

Is it Clean?

CLEAN

Clean

Connect CONNECT

Fiber Optic Connectors

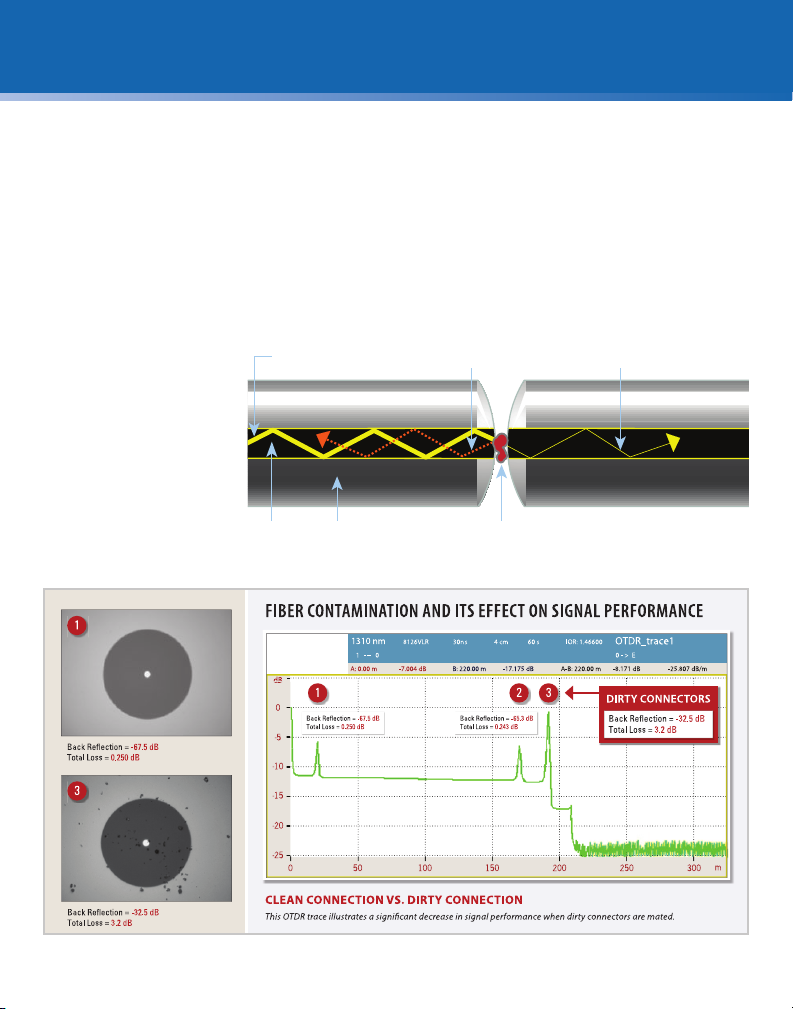

Effect on Signal Performance

Proactive vs. Reactive Inspection

Inspection: Westover FBP Probe

Cleaning: CleanBlast – Portable

Appendix A: Inspection Tips Guide

Appendix B: Cleaning Tips & Adapters Guide

System Status LED's

Solvent Refill

Troubleshooting

Replacing Air Filters

6.4-inch LCD

Optional Configurations

Safety Information

Warranty Information

Ordering Information

Single-mode Connectors.......................................................................15

Multimode Connectors ...........................................................................15

Bulkhead Inspection..................................................................................12

Patch Cord Inspection..............................................................................13

Zones and Acceptance Criteria..........................................................14

Grading Process ............................................................................................14

Bulkhead Cleaning......................................................................................16

Patch Cord Cleaning.........................................................................17

Good Fiber Connection...........................................................................18

Fiber Connections.......................................................................................18

Single Fiber Connectors.............................................................................5

Dirty Connection and Its Effect On Signal Performance ....6

The Problem.......................................................................................................4

The Equipment.................................................................................................4

The Solution .......................................................................................................4

Proactive Inspection.....................................................................................7

Reactive Inspection.......................................................................................7

FBP Probe Overview.....................................................................................8

CleanBlast Overview.....................................................................................9

Inspection Tip Reference Guide ........................................................26

Cleaning Tips Reference Guide..........................................................27

System Status Indicators........................................................................19

Solvent Refill Procedures........................................................................20

Troubleshooting Tips................................................................................22

Replacing Air Filters Procedures .......................................................21

6.4-inch TFT LCD...........................................................................................10

90-degree Handset and Backplane Wand .................................11

Safety Information for Cleaning Solvent.....................................23

General Information ..................................................................................24

CleanBlast – Portable Kit and Units ................................................25

Parts and Solvents.......................................................................................25