Page 2 of 5

Cleaner Spray Nozzle Adjustment Procedure

Tools Required

- 3/4” or 19mm open end wrench

- 7/8" or 22mm open end wrench

- Large towel or several rags

Incorrect Spray Nozzle Adjustment Procedure – Do Not Use!

When performing the adjustment incorrectly, the user will over tighten the ball socket jam nut and hit the stem and

ball with too much force with a hammer or blunt object to adjust the spray nozzle spray to the lane surface. This

will put stress on the bottom jam nut, breaking off the threads of the nut withinthe cleaner rail assembly.

Correct Spray Nozzle Adjustment Procedure

Proper adjustment of the spray nozzle assembly will prevent breakage of the threads of the bottom socket ball nut

inside the cleaner rail assembly. Adjustment will also ensure that the lane cleaner solution gets sprayed onto the

lane surface in the correct area without overspray into the gutters, squeegee and duster cloth.

Place the Authority22 into the operating position and push the lane machine out onto the lane surface at least 12

inches (305mm) out past the foul line. Do not apply power to the Authority22 at this time. Open the covers of the

machine and locate the spray nozzle body to be adjusted.

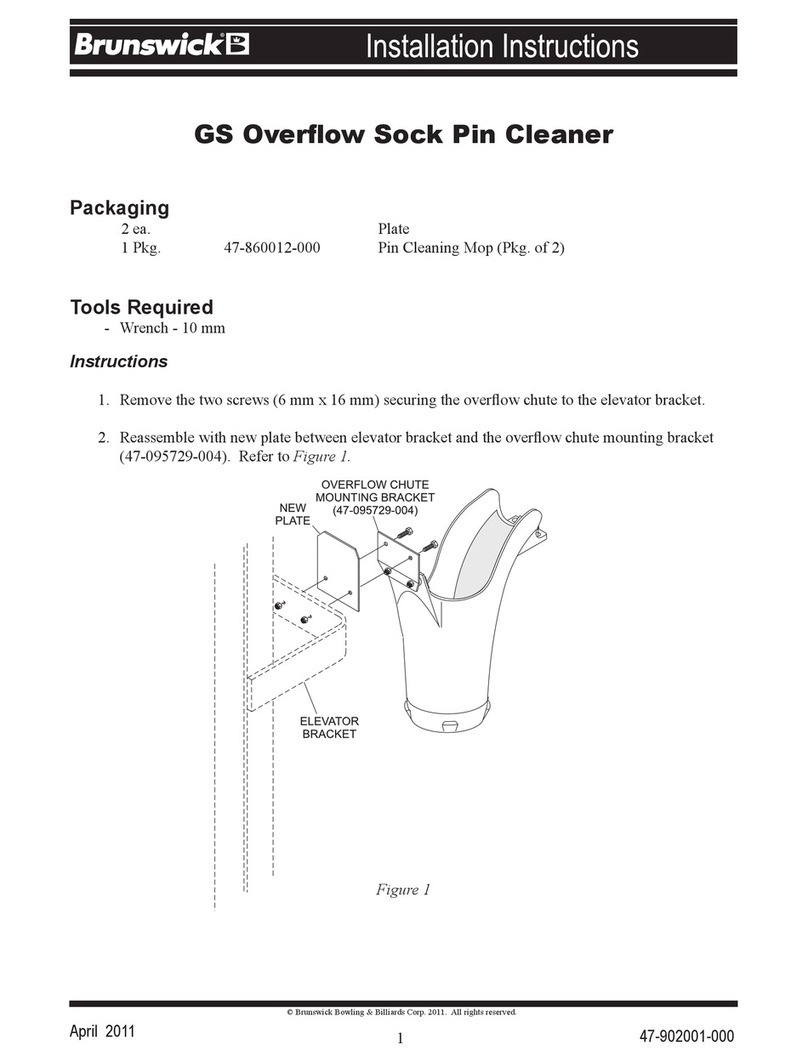

Step 1

To adjust, hold the bottom ball socket nut of the assembly firmly in place with a 3/4” or 19mm open end wrench.

Do not let the nut turn. If the nut turns and is threaded too far down into the rail, the threads could be broken off.

While holding the bottom nut in place, loosen the jam nut on the ball and stem using a 7/8"or 22mm open end

wrench. Slightly tighten the jam nut by hand and move the stem of the assembly to the desired point at which you

want the fan of the spray to be delivered to the lane surface. Tighten the jam nut with the 7/8" or 22mm open end

wrench. It may take several adjustments to get the correct alignment of the ball and stem and spray nozzle to the

lane surface. Follow Step 2 below to check the cleaner spray pattern to the lane surface.

Step 2

Have a large towel or several rags nearby to soak up cleaner as the cleaner pump is run. Apply power to the

Authority22. Using the Graphical User Interface, (GUI) select “Maintenance,” “Diagnostics,” “Cleaning,” and

“Cleaner Pump.” Press “OK” to run the cleaner pump. The pump will run for 20 seconds, you can stop the pump

prior to the 20 seconds if “OK” is pressed again. Watch where the cleaning solution is applied to the lane surface;

adjust so that there is complete coverage of the lane surface without spraying into the gutter sections of the lane.

Wipe up all excess cleaner from the lane surface and readjust if necessary.