Jefferson JEFARIVT02H User manual

OLYMPUS

User Manual

v.1.1

JEFARIVT02H

AIR-HYDRAULIC

BLIND RIVETER

3

USER MANUAL v1.1

JEFARIVT02H

AIR-HYDRAULIC BLIND RIVETER

www.jeffersontools.com

CONTENTS

Contents 3

About This Document 3

Introduction 4

Specications 4

Equipment Identication 4

Safety Guidelines 5

Connecting to The Air Supply 6

Operation 6

Maintenance 7

Troubleshooting 8

Hand Arm Vibration 9

Environmental Protection 9

Parts List 10

Parts Diagram 11

Limited Warranty Statement 12

EU Declaration Of Conformity 14

ABOUT THIS DOCUMENT

This manual has been compiled by Jefferson Tools and is an integrated part of the product with which it's enclosed

and should be kept with it for future reference. Please read all of the information supplied in this User Manual before

operating this product.

This manual describes the purpose for which the product has been designed and contains all the necessary

information to ensure its correct and safe use. We recommend that you read the information supplied before carrying

out any maintenance or repair. By following all the general safety instructions contained in this manual you will help

to ensure operator safety and extend the potential life span of the equipment.

All photographs and drawings in this manual are supplied by Jefferson Tools to help illustrate the operation of the

product. Whilst every effort has been made to ensure accuracy of information contained in this manual our policy of

continuous improvement determines the right to make modifications without prior warning.

The information contained in this Instruction Manual is designed to assist you in the safe operation and maintenance

of the equipment Some illustrations in this Instruction Manual may show details or attachments that differ from those

on your own model. Contact your nearest Jefferson Dealer if you are unsure about any information included in this

manual or require any additional information about the safe use, operation maintenance, or repair of this equipment.

4

USER MANUAL v1.1

JEFARIVT02H

AIR-HYDRAULIC BLIND RIVETER

www.jeffersontools.com

INTRODUCTION

A powerful, heavy duty trigger-operated Air Hydraulic Riveter for aluminium, steel, stainless steel and structural blind

rivets from 3/16” to 1/4”. With hardened steel jaw assembly and air-actuated vacuum rivet shaft collector. Durable

grip for added comfort and hanging loop for use with balancer.

Supplied with three riveting nozzles: 4.8mm(3/16") • 5.6mm(7/32") • 6.4mm(1/4"); two spanners and oil can in a

durable carry case.

SPECIFICATIONS

Model Number: JEFARIVT02H

Air Consumption: 4cfm

Maximum Operating Pressure: 90psi

Air Inlet Size: 1/4" BSP

Sound Power: 82 dB(A)

Measured vibration emission value (a): 0.4 m/s²

Uncertainty value (k) 0.54 m/s²

Nozzles: 4.8mm(3/16") • 5.6mm(7/32") • 6.4mm(1/4")

Weight: 1.9kg

* Sound Power Level:

The figures quoted in this table are emission (sound power) levels and are not necessarily safe working levels. Whilst there is a correlation between the emission and exposure

levels, this can not be used reliably to determine whether or not further precautions are required. Factors that influence the actual level of exposure to the work-force include the

characteristics of the work room, the other sources of noise, the number of machines and other adjacent processes, and the length of time for which an operator is exposed to

the noise. Also the permissible exposure level can vary between regions. This information, however, will allow the user of the machine to make a better evaluation of the hazard

and risk.

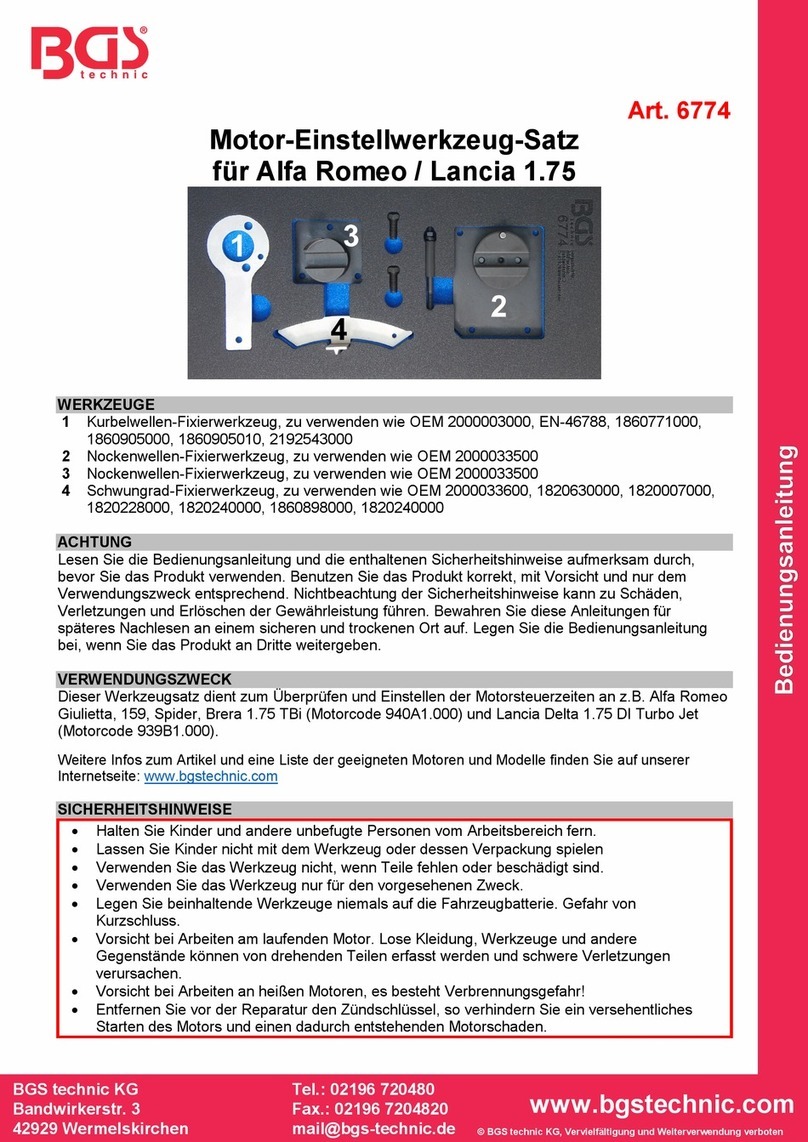

EQUIPMENT IDENTIFICATION

Trigger

Hook

Spent Mandrel Bottle

Nosepiece

Shutoff Valve

Air Cylinder Body

Oil Resevoir

Air Cylinder / Oil Reservoir Cap

5

USER MANUAL v1.1

JEFARIVT02H

AIR-HYDRAULIC BLIND RIVETER

www.jeffersontools.com

SAFETY GUIDELINES

Please read and ensure that you understand all of the operating instructions, safety

precautions and warnings in this Instruction Manual before operating or maintaining this

equipment. An accident can often be avoided by recognizing a potentially hazardous

situation before it occurs, and by observing the appropriate safety procedures. Never use

this equipment or modify it in any way that has not been specically recommended by the

manufacturer.

GENERAL EQUIPMENT SAFETY

• Familiarise yourself with the use, application and potential hazards associated with this equipment before use .

• Ensure all Health & Safety regulations are adhered to when using this equipment.

• Ensure that the riveter is operated by a capable and responsible person who is familiar with the user guidelines.

• Never operate the riveter when you are tired or under the inuence of alcohol, drugs or intoxicating medication.

• Disconnect the riveter from the air supply before changing accessories, servicing or performing any maintenance.

• Ensure that the equipment is well-maintained and kept clean condition.

• Check equipment condition prior to use. Replace or repair damaged parts before use. Use Jefferson approved

genuine parts only. Unauthorised parts may be dangerous and will invalidate the warranty.

• Only use in a suitable working environment. Keep the area free from unrelated materials and ensure that there is

adequate lighting. Do not operate near children or animals.

• Always wear approved eye (or face) and hand protection when operating the riveter.

• Maintain correct balance and footing at all times. Do not over reach, ensure the oor is not slippery, wear non-

slip shoes.

• Keep the air hose away from heat, oil and sharp edges. Check air hose for wear before each use and ensure that

all connections are secure before use.

• Remove ill tting clothing, ties, watches, rings, loose jewellery before use. Contain or tie back long hair.

• Wear appropriate protective clothing and keep hands and body clear of working parts.

• Keep the riveter away from your body and at a safe distance from others.

• Secure any non-stable workpieces with a clamp, vice or other adequate holding device.

• Ensure that spent rivet stems are disposed of correctly and do not cause a hazard.

• Ensure correct air pressure is maintained and not exceeded (check specications).

• The recommended working pressure for the riveter is 85-90psi.

• Avoid unintentional starting.

• Never use the riveter for a task it is not designed to perform.

• This tool is designed for riveting metal, primarily in workshops and garages. We do not recommend any other

use. Do not modify the equipment for other uses or try to enhance beyond its capacity.

• Do not operate the riveter if any parts are damaged or missing as this may cause failure and/or personal injury.

• Never carry the riveter by the hose, or pull the hose from the air supply.

• Do not use the riveter in wet or damp environments or areas where there is heavy condensation.

• Never direct air from the air hose at yourself or others.

• When not in use, disconnect from the air supply and store in a safe, dry, childproof location.

WARNING:

No responsibility is accepted for incorrect use of this equipment. Incorrect use can result in damage to the equipment

and danger to the user. Warranty will be void in the event of incorrect use. The warnings, cautions and instructions

discussed in this instruction manual cannot cover all possible conditions and situations that may occur. It must be

understood by the operator that common sense and caution are factors which cannot be built into this product, but must

be supplied by the operator.

6

USER MANUAL v1.1

JEFARIVT02H

AIR-HYDRAULIC BLIND RIVETER

www.jeffersontools.com

CONNECTING TO THE AIR SUPPLY

IMPORTANT: Ensure the air supply is clean and does not exceed the maximum operating pressure for this

equipment (90psi). Unclean air supply and high pressure can cause excessive wear, and may be dangerous, causing

damage and/or personal injury.

Please refer to the diagram shown in Fig.1 below for an example of a recommended connection set-up for this

equipment:

•Ensure the riveter air valve (or trigger) is not depressed before connecting to the air

supply.

•To operate safely and efciently the riveter requires a suitable air pressure between

85-90psi , and an air ow according to the specication above.

• For optimal performance ensure that the air tank is drained daily. Water in the air

line will damage the riveter and invalidate your warranty.

• Clean air inlet lter weekly to ensure a constantly clean air supply.

• Line pressure should be increased to compensate for unusually long air hoses (over

8 metres). The minimum hose diameter should be 1/4” I.D. and ttings must have the

same inside dimensions.

•Ensure that the hose is kept away from heat, oil and sharp edges at all times.

Check hoses for wear, and make certain that all connections are secure before use.

•To avoid excessive vibration during use, ensure that quick couplings are not

connected directly to the riveter Vibration may cause failure if a quick change

coupling is connected directly to the riveter. Use a leader hose to connect the riveter

to the air line as shown in Fig.2. Contact your nearest Jefferson Dealer for advice on

the equipment and airline setup and suitable components.

OPERATION

IMPORTANT: Ensure that you have read, understood and apply the safety instructions prior to using this equipment.

Fitting the required nozzle:

•Fit the supplied spanner over the nozzle and turn it anti-clockwise to

remove it as shown in Fig.3.

•Fit the correct size nozzle for the rivet to be used and screw back into

the frame head and tighten with the spanner.

NOZZLE

Fig.1

Fig.2

Fig.3

7

USER MANUAL v1.1

JEFARIVT02H

AIR-HYDRAULIC BLIND RIVETER

www.jeffersontools.com

Fig.4

Fig.5

Fig.6 Fig.7

Fig.8 Fig.9

Operation

Ensure the air valve is in the closed position before connecting the air

supply:

•Open the shut-off valve by sliding the knurled ring upwards as shown

in the diagram to the right.

•Insert the desired size rivet into the nozzle, ensuring the appropriate

nozzle is tted rst.

•Insert the rivet into the workpiece as far as it will go and squeeze the

trigger.

•The rivet will be compressed and the spent mandrel will be sucked into

the spent mandrel bottle.

•When the spent mandrel bottle is full, close the shut-off

valve, unscrew, empty and replace as shown in Fig.4.

MAINTENANCE

IMPORTANT: Ensure you disconnect the tool from the air supply system before attempting any maintenance.

General Maintenance

•Ensure that the riveter is kept in good clean condition. Check condition prior to use. Do not use the equipment if

damage is detected. Contact Jefferson tools for advice on repair and replacement parts.

•Maintain the tool with care. •Keep the equipment well oiled for optimum performance.

Lubrication

• Lubricate the air tool daily with a suitable high quality air tool oil

(for example SAE 10). Please refer to the parts diagram shown on

pg.10 for reference.

• Unscrew and remove the frame head (Part #38) and cylinder cap

(Part #1A) using 2x Ø5.1mm rods as shown in Fig.5. Remove the

air piston (Part #7A). Using the oil can supplied, ll the reservoir

with oil until the oil level reaches the o-ring (Part #18). Inspect,

clean or replace the oil seal as required during this procedure.

• Re-t the cylinder cap and reassemble the jaw housing and

adjust the length to match the spanner gauge (Part #63) and x

the frame head as shown in Fig.9.

Jaw Replacement

•After a period of use the jaws on the riveter will wear and

require replacement.

•To replace, rst remove the nozzle and frame head using

the spanners supplied as shown in Fig.6.

•Undo and remove the jaw housing from the jaw housing (Fig.7 - Fig.8)

•Remove the worn jaws and replace with a new set. If the

jaw pusher and spring fall out, put the spring back rst and

then the jaw pusher followed by the jaws.

•Fit the frame head and tighten.

•When the jaws are replaced check that the jaw distance

from the main body is 84mm using the guide on the

spanner as shown in Fig.9.

Oil Level

8

USER MANUAL v1.1

JEFARIVT02H

AIR-HYDRAULIC BLIND RIVETER

www.jeffersontools.com

TROUBLESHOOTING

Factors That May Inhibit Performance:

•Loss of power or erratic action may be caused by reduced compressor output, an excessive drain on the air line,

moisture or restrictions in air pipes or the use of hose connections of improper size.

•Grit or gum deposits in the tool may cut power and can be corrected by cleaning the air strainer and ushing out

the tool with gum solvent oil or an equivalent de-greaser.

•If all outside conditions are in order, disconnect the tool from the air supply, disassemble and replace any worn or

damaged parts with Jefferson approved parts.

•Clean all parts, reassemble the tool and lubricate.

•Store the tool in a safe, dry, secure environment.

Symptom Possible Causes Solution

Rivet jammed. 1. Wrong size for rivet/nozzle.

2. Filings jammed in jaw housing.

3. Filings jammed in nozzle.

1. Use correct size nozzle for the rivet.

2. Snap off rivet head, dismantle jaw housing

and pull out the rivet mandrel. Use an

airline to blow out the lings, oil and

reassemble the jaw housing.

3. Clean out the nozzle.

No suction. 1. The shut-off valve has not been

opened.

1. Open shut-off valve.

Air leaking. 1. Loose screws.

2. Damaged O-rings.

1. Tighten screws.

2. O-rings must be replaced.

Tool runs slow or suffers a

loss of power.

1. Air line is loose.

2. Exhaust port is blocked.

3. Operating pressure is too low.

1. Re-install and tighten air line.

2. Clean out exhaust port.

3. Increase the operating pressure to 85-

95psi. If the pressure exceeds 105-110psi,

the safety valve will be activated.

9

USER MANUAL v1.1

JEFARIVT02H

AIR-HYDRAULIC BLIND RIVETER

www.jeffersontools.com

HAND ARM VIBRATION

Risk of Hand Arm Vibration Injury.

This tool may cause Hand Arm Vibration Syndrome if its use is not managed adequately.

This tool is subject to the vibration testing section of the Machinery Directive 2006/42/EC.

This tool is to be operated in accordance with these instructions.

Measured vibration emission value (a): 0.4 m/s²

Uncertainty value (k): 0.54 m/s²

Please note that the application of the tool to a sole specialist task may produce a different average vibration

emission. We recommend that a specic evaluation of the vibration emission is conducted prior to commencing with

a specialist task.

A health and safety assessment by the user (or employer) will need to be carried out to determine the suitable

duration of use for each tool.

NB: Stated Vibration Emission values are type-test values and are intended to be typical. Whilst in use, the actual

value will vary considerably from and depend on many factors. Such factors include; the operator, the task and the

inserted tool or consumable.

NB: ensure that the length of leader hoses is sufcient to allow unrestricted use, as this also helps to reduce

vibration. The state of maintenance of the tool itself is also an important factor, a poorly maintained tool will also

increase the risk of Hand Arm Vibration Syndrome.

Health surveillance

We recommend a programme of health surveillance to detect early symptoms of vibration injury so that management

procedures can be modied accordingly.

Personal protective equipment

We are not aware of any personal protective equipment (PPE) that provides protection against vibration injury that

may result from the uncontrolled use of this tool. We recommend a sufcient supply of clothing (including gloves) to

enable the operator to remain warm and dry and maintain good blood circulation in ngers etc.

Please note that the most effective protection is prevention, please refer to the Correct Use and Maintenance section

in these instructions. Guidance relating to the management of hand arm vibration can be found on the HSC website

www.hse.gov.uk - Hand-Arm Vibration at Work.

ENVIRONMENTAL PROTECTION

Recycle any packaging and unwanted materials instead of disposing of them as waste. All tools,

accessories and packaging should be sorted, taken to a recycling centre and disposed of in a

manner which is compatible with the environment.

When the product becomes completely unserviceable, reaches the end of its working life and

requires disposal, drain off any uids (if applicable) into approved containers and dispose of the

product and the uids according to local regulations.

10

USER MANUAL v1.1

JEFARIVT02H

AIR-HYDRAULIC BLIND RIVETER

www.jeffersontools.com

PARTS DIAGRAM

11

USER MANUAL v1.1

JEFARIVT02H

AIR-HYDRAULIC BLIND RIVETER

www.jeffersontools.com

PARTS LIST

# Description # Description

1A CYLINDER CAP 34 SPRING PIN

2RUBBER BASE 35 O-RING (2.57-6.13-1.78)

3A AIR CYLINDER BODY 36 O-RING (13.8-18.6-2.4)

5NUT 37 NOZZLE 1/4"

6WASHER 37A NOZZLE 7/32"

7A AIR PISTON 37B NOZZLE 3/16"

7WASHER 38 FRAME HEAD

8O-RING (72.62-79.68-3.53) 39 JAW HOUSING

9O-RING (1.78-5.34-1.78) 40 JAW FOR NOZZLES

10 O-RING (7.6-12.84-2.62) 41 JAW PUSHER FOR NOZZLES

11 O-RING (9.8-13.6-1.9) 42 JAW HOUSING COUPLER

11A O-RING 43 SPRING

13 TUBE 44 PISTON SHAFT

14 ROD 45 INT TOOTH WASHER

15A STEM NUT 46 CASE LOCK NUT M10

17 BACK-UP RING 49 OIL SEAL WASHER

18 O-RING (11.8-16.6-2.4) 50 HEXAGON SOCKET SCREW

19 STEM 51 HOOK

20 MUFFLER 53 OIL CYLINDER BODY

21 PAD 54 PISTON ROD

22 O-RING 12.74x1.78 55 O-RING

23 CAGE 56 SPRING

24 SPRING 57 O-RING (24.7-31.7-3.5)

25 VALVE 58 FRAME CAP NUT

26 VALVE CAP 59 BOTTLE

27 RETAINING RING 60 O-RING (37.7-44.7-3.5)

28 VALVE PISTON 61 BOTTLE ADAPTOR

29 HANDLE BODY ASS'Y 61A SILENCER

30 O-RING (4.47-8.03-1.78) 62 SPANNER

31 TRIGGER INSERT 63 SPANNER GAUGE

32 TRIGGER HEAD 64 OIL CAN

33 TRIGGER (SO) 65 VALVE

12

USER MANUAL v1.1

JEFARIVT02H

AIR-HYDRAULIC BLIND RIVETER

www.jeffersontools.com

LIMITED WARRANTY STATEMENT

Jefferson Professional Tools & Equipment, or hereafter "Jefferson" warrants its customers that its products will be free of defects in workmanship

or material. Jefferson shall, upon suitable notication, correct any defects, by repair or replacement, of any parts or components of this product

that are determined by Jefferson to be faulty or defective.

This warranty is void if the equipment has been subjected to improper installation, storage, alteration, abnormal operations, improper care, service

or repair.

Warranty Period

Jefferson will assume both the parts and labour expense of correcting defects during the stated warranty periods below.

All warranty periods start from the date of purchase from an authorised Jefferson dealer. If proof of purchase is unavailable from the end user, then

the date of purchase will be deemed to be 3 months after the initial sale to the distributor.

1 Year

JEFARIVT02H AIR-HYDRAULIC BLIND RIVETER

90 Days

• All replacement parts purchased outside of the warranty period

Important: All parts used in the repair or replacement of warranty covered equipment will be subject to a minimum of 90 days cover or the

remaining duration of the warranty period from the original date of purchase.

Warranty Registration / Activation

You can register and activate your warranty by visiting the Jefferson Tools website using the following address:

www.jeffersontools.com/warranty and completing the online form. Online warranty registration is recommended as it eliminates the need to

provide proof of purchase should a warranty claim be necessary.

Warranty Repair

Should Jefferson confirm the existence of any defect covered by this warranty the defect will be corrected by repair or replacement at an

authorized Jefferson dealer or repair centre.

Packaging & Freight Costs

The customer is responsible for the packaging of the equipment and making it ready for collection. Jefferson will arrange collection and

transportation of any equipment returned under warranty. Upon inspection of the equipment, if no defect can be found or the equipment is not

covered under the terms of the Jefferson warranty, the customer will be liable for any labour and return transportation costs incurred. These costs

will be agreed with the customer before the machine is returned.

*Jefferson reserve the right to void any warranty for damages identified as being caused through misuse

Warranty Limitations

Jefferson will not accept responsibility or liability for repairs made by unauthorised technicians or engineers. Jefferson's liability under this

warranty will not exceed the cost of correcting the defect of the Jefferson products.

Jefferson will not be liable for incidental or consequential damages (such as loss of business or hire of substitute equipment etc.) caused by

the defect or the time involved to correct the defect. This written warranty is the only express warranty provided by Jefferson with respect to its

products.

Any warranties of merchantability are limited to the duration of this limited warranty for the equipment involved.

Jefferson is not responsible for cable wear due to flexing and abrasion. The end user is responsible for routine inspection of cables for possible

wear and to correct any issues prior to cable failure.

13

USER MANUAL v1.1

JEFARIVT02H

AIR-HYDRAULIC BLIND RIVETER

www.jeffersontools.com

Claiming Warranty Coverage

The end user must contact Jefferson Professional Tools & Equipment (Tel: +44 (0) 1244 646 048) or their nearest authorised Jefferson dealer where

final determination of the warranty coverage can be ascertained.

Step 1 - Reporting the Defect

Online Method:

• Visit our website www.jeffersontools.com/warranty and complete the Warranty Returns form. You can complete the form online and submit it

to us directly or download the form to print out and return by post.

Telephone Method:

Contact your Jefferson dealer or sales representative with the following information:

• Model number

• Serial number (usually located on the specification plate)

• Date of purchase

A Warranty Returns form will be sent to you for completion and return by post or fax, together with details of your nearest authorised Jefferson

repair centre. On receipt of this form Jefferson will arrange to collect the equipment from you at the earliest convenience.

Step 2 - Returning the Equipment

It is the customer's responsibility to ensure that the equipment is appropriately and securely packaged for collection, together with a copy of

the original proof of purchase. Please note that Jefferson cannot assume any responsibility for any damage incurred to equipment during

transit. Any claims against a third party courier will be dealt with under the terms & conditions of their road haulage association directives.

NOTE: Jefferson will be unable to collect or process any warranty requests without a copy of the original proof of purchase.

Step 3 - Assessment and Repair

On receipt, the equipment will be assessed by an authorised Jefferson engineer and it will be determined if the equipment is defective and in need

of repair and any repairs needed are covered by the warranty policy. In order to qualify for warranty cover all equipment presented must have been

used, serviced and maintained as instructed in the user manual.

Where repair is not covered by the warranty a quotation for repair, labour costs and return delivery will be sent to the customer (normally within 7

working days).

NOTE: If the repair quotation is not accepted Jefferson Professional Tools & Equipment will invoice 1 hour labour time at £30 per hour plus

return carriage costs (plus VAT).

In cases where no fault can be found with the equipment, or, if incorrect operation of the equipment is identified as the cause of the problem, a

minimum of 1 hour labour at £30 per hour plus carriage costs will be required before the equipment will be despatched back to the customer.

Any equipment repaired or replaced under warranty will normally be ready for shipment back to the customer within 7 working days upon receipt

of the equipment at an authorised Jefferson Repair centre (subject to part availability). Where parts are not immediately available Jefferson will

contact you with a revised date for completion of the repair.

General Warranty Enquiries

For any further information relating to Jefferson warranty cover please call +44 (0) 1244 646 048 or send your enquiry

Disclaimer:

The information in this document is to the best of our knowledge true and accurate, but all recommendations or suggestions are made without

guarantee. Since the conditions of use are beyond their control, Jefferson Tools® disclaim any liability for loss or damage suffered from the use of

this data or suggestions. Furthermore, no liability is accepted if use of any product in accordance with this data or suggestions infringes any patent.

Jefferson Tools® reserve the right to change product specifications and warranty statements without further notification. All images are for

illustration purposes only.

14

USER MANUAL v1.1

JEFARIVT02H

AIR-HYDRAULIC BLIND RIVETER

www.jeffersontools.com

EU DECLARATION OF CONORMITY

We, Jefferson Professional Tools & Equipment, as the authorised European Community representative of the manufacturer, declare

that the following equipment conforms to the requirements of the following:

Directive / Standard / Regulation Description:

2006/42/EC (as amended) Machinery Directive

EN ISO 11148-1 Hand-held non-electric power tools - Safety Requirement Part 1:

Assembly Power Tools for Non-Threaded Mechanical Fasteners (ISO

11178-1:2011)

EN ISO 20643:2008+A1:2012 Principles for evaluation of vibration emission

EN ISO 15744: 2008 Hand-held non-electric power tools. Noise measurement code.

Engineering method (grade 2)

Equipment Category: Riveter

Model Number(s): JEFARIVT02H - Air-Hydraulic Blind Riveter

Sound Power: 82 dB(A)

Measured vibration emission value (a)

Uncertainty value (k)

0.4 m/s²

0.54 m/s²

Signed by: Stephen McIntyre

Position in the company: Operations Director

Date: 23 October 2020

Technical file holder's address as shown below

Name and address of manufacturer

or authorised representative:

Jefferson Tools, Herons Way, Chester Business Park,

Chester, United Kingdom, CH4 9QR

Telephone: +44 (0)1244 646 048 Fax: +44 (0)1244 241 191

Email: [email protected]

Jefferson Tools,

Herons Way,

Chester Business Park,

Chester,

United Kingdom,

CH4 9QR

Tel. +44 (0)1244 646 048

Email: [email protected]

IMPORTANT! SAFETY FIRST!

Before attempting to use this product please read

all the safety precautions and operating instructions

outlined in this manual to reduce the risk of fire,

electric shock or personal injury.

www.jeffersontools.com

Table of contents

Other Jefferson Tools manuals

Jefferson

Jefferson JEFUNIPCPGR User manual

Jefferson

Jefferson JEFHOSRL15-3/8HVP User manual

Jefferson

Jefferson JEFHTG2S-230 User manual

Jefferson

Jefferson JEFBGSSTDADJ User manual

Jefferson

Jefferson JEFTRCH09ILSG User manual

Jefferson

Jefferson JEFLUGGUN03 User manual

Jefferson

Jefferson JEFHOSRLH15-1/2 User manual

Popular Tools manuals by other brands

Alemlube

Alemlube 600A Service instructions

NORDFOREST

NORDFOREST Titan 80 operating manual

Makita

Makita DCO140 instruction manual

BGS technic

BGS technic 6774 instruction manual

FEDERAL PACIFIC

FEDERAL PACIFIC PSE Supplement to Inspection and Maintenance Recommendations

Binks

Binks STEADI-GRIP 80-295 Service manual