IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS AND

CAUTIONS. USE THIS PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE

DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

WARNING! Ensure Health & Safety, local authority, and general

workshop practice regulations are adhered to when using this tool.

WARNING! Familiarise yourself with the specific applications and limitations of

this tool, as well as any potential hazards.

This tool should be used in conjunction with inspection maintenanceprocedures

recommended in the vehicle manufacturer’s manual.

Ensure that this tool is the correct tool for the task.

Ensure that the vehicle is properly supported with axle stands before working

under the vehicle.

Ensure that there is adequate lighting prior to using this tool.

A range of inspection lamps are available from your local Sealey dealer.

Keep children and unauthorised persons away from the working area.

Keep the force screw well lubricated during operation to ease removal and

insertion of bushes.

DO NOT use this tool for any purpose other than that for which it is designed.

DO NOT use air tools with this tool.

DO NOT use this tool if any parts are missing or damaged, as this may cause

failure and/or personal injury.

DO NOT use this tool when you are tired, or under the influence of alcohol,

drugs or intoxicating medication.

When not in use, store in a safe, dry location.

Thank you for purchasing a Sealey Product. Manufactured to a high standard this product will, if used according to these instructions and properly

maintained, give you years of trouble free performance.

1. SAFETY INSTRUCTIONS

2. INTRODUCTION & APPLICATIONS

3. OPERATION

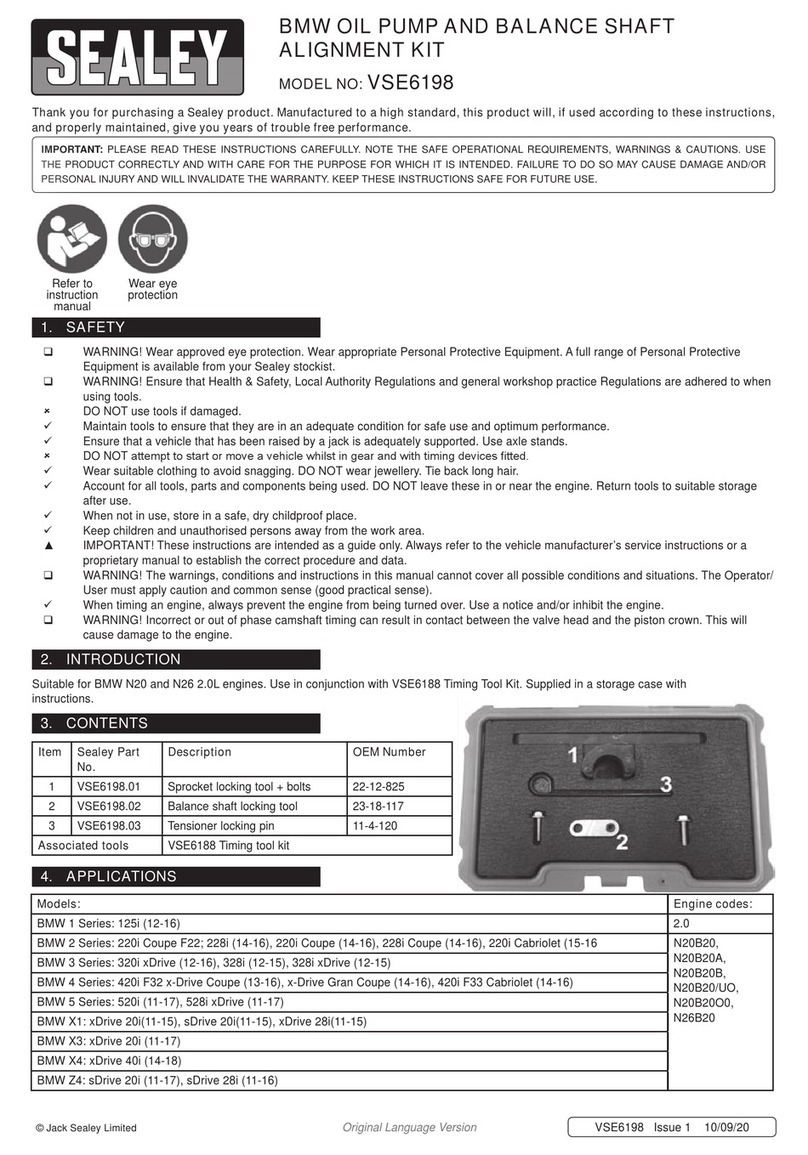

Suitable for the removal/installation of the front lower control arm bush on BMW 3 Series. Can be used in-situ without removing the arm from the

vehicle. When installing the new bushes, they must be held compressed while being pressed into the suspension control arm which this tool is

designed for. Supplied in carry-case.

APPLICATIONS: BMW 330xi: E90, E91, E92 3 Series (2005-2013)

Original Language Version VSE5586 Issue:1 - 11/10/13

INSTRUCTIONS FOR:

FRONT LOWER CONTROL ARM BUSH TOOL -

BMW 3 SERIES

MODEL No: VSE5586

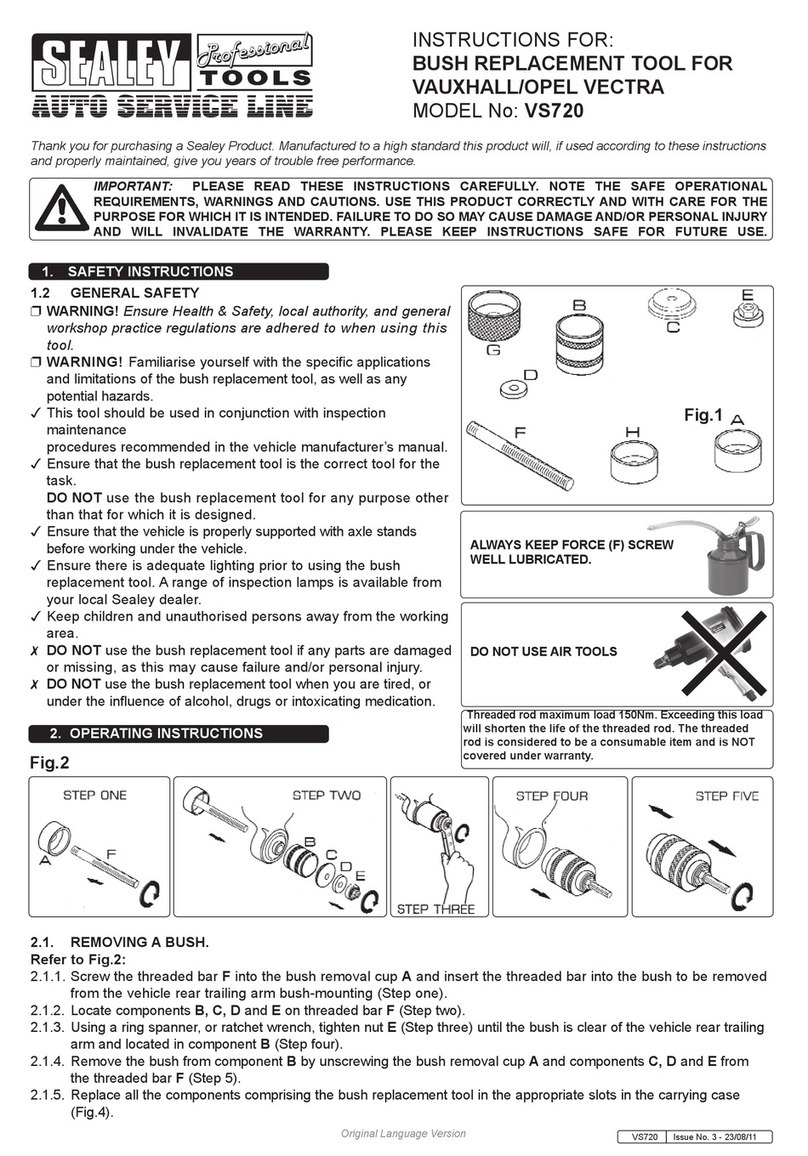

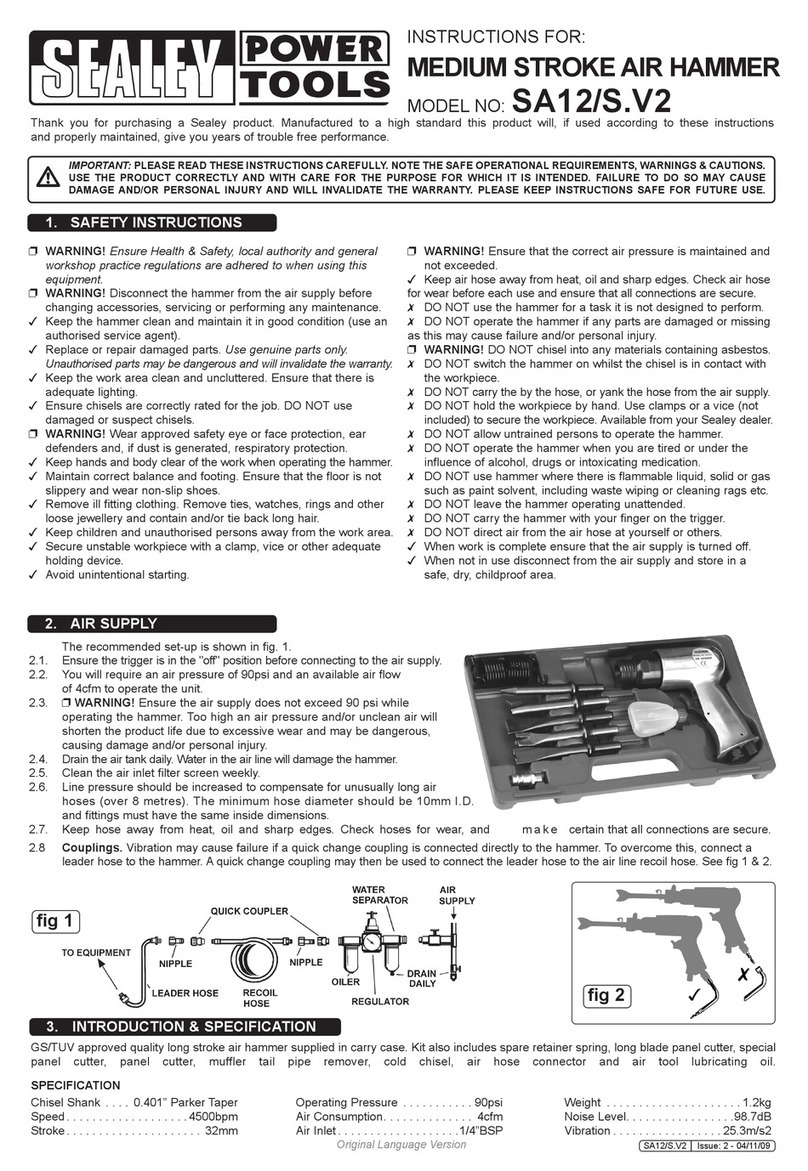

Fig.2 Fig.3

3.1. REMOVING BUSH (Figs.2 & 3)

3.1.1. Place force screw (5) through adaptor plate (3).

3.1.2. Hold the adaptor adaptor sleeve (6) against the suspension arm and push the force screw through the centre of the bush.

3.1.3. Placetheopenfaceoftheadaptorcupplate(7)againsttheothersideofthebushandruntheforcescrewnut(5)upthethreaduntilnger

tight.

3.1.4. Apply a 15mm spanner to the head of the force screw and a 19mm socket to the force screw nut.

3.1.5. Tighten the force screw nut, forcing the bush from the suspension arm.

Fig.1

© Jack Sealey Limited

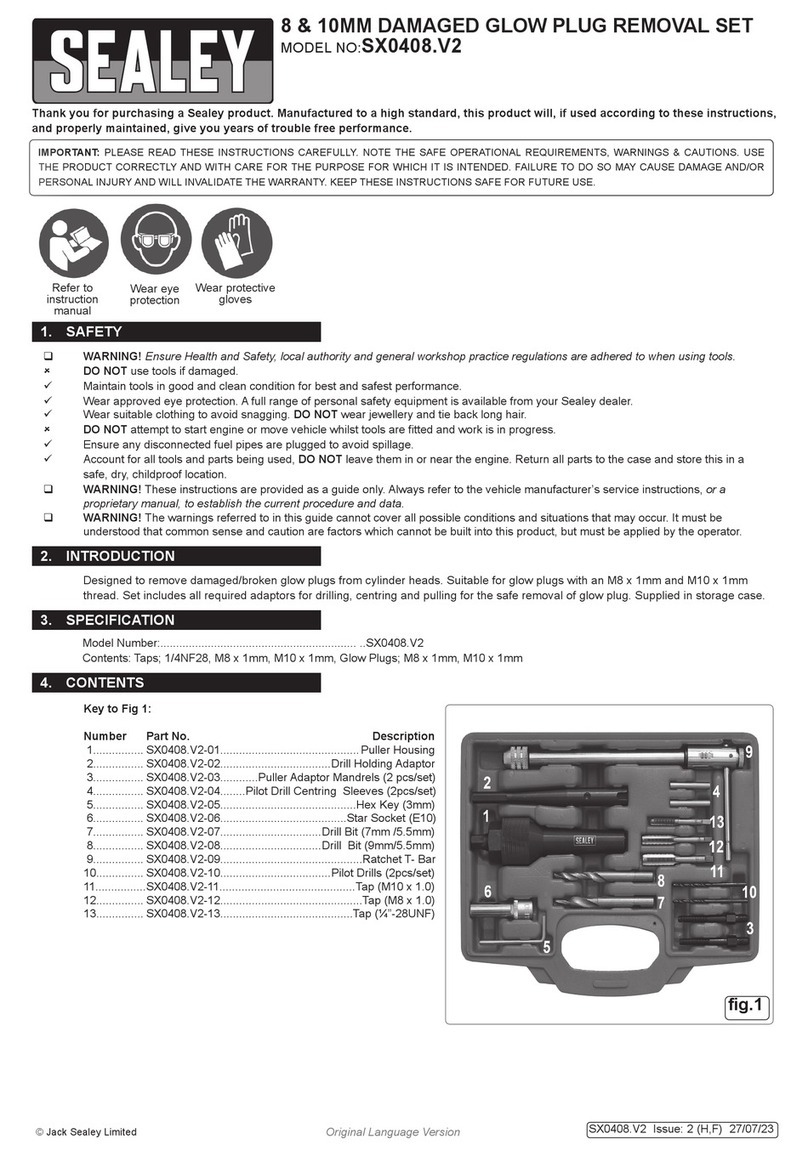

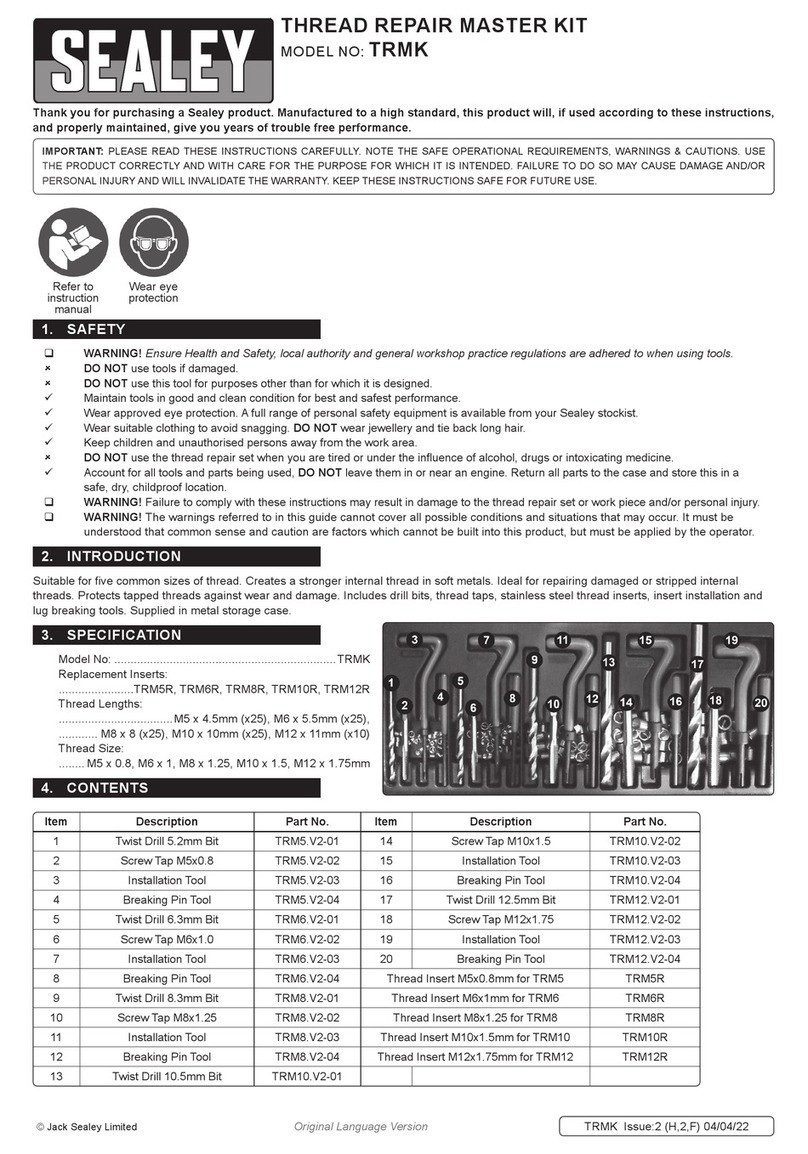

Item: Part No: Description:

1 VSE5568.01 Press Clamp Assembly

2 VSE5568.02 Force Screw Nut

3 VSE5568.03 Adaptor Plate

4 VSE5568.04 Adaptor Ring

5 VSE5568.05 Force Screw

6 VSE5568.06 Adaptor sleeve

7 VSE5568.07 Adaptor cup plate