Jefferson JEFHTG2S-230 User manual

User Manual

v.1.1

JEFHTG2S-230

2

USER MANUAL

JEFHTG2S-230

2000W HEAT GUN

www.jeffersontools.com

3

USER MANUAL

JEFHTG2S-230

2000W HEAT GUN

www.jeffersontools.com

1. Contents

Important: Please read all these instructions before operating this product and save these instructions. This manual has been

compiled by Jefferson Tools and is an integrated part of the product with which it is enclosed and should be kept with it for future

reference. Make careful note of safety instructions, warnings and cautions. This product should only be used for its intended

purpose. Failure to do so may cause damage and/or personal injury and will invalidate the warranty.

This manual describes the purpose for which the product has been designed and contains all the necessary information to ensure

its correct and safe use. We recommend that this manual is read before any operation or before performing any kind of adjustment

to the product and prior to any maintenance tasks. By following all the general safety instructions contained in this manual you will

help to ensure operator safety and extend the potential lifespan of the equipment.

All photographs and drawing in this manual are supplied by Jefferson Tools to help illustrate the operation of the product. Whilst

every effort has been made to ensure accuracy of information contained in this manual our policy of continuous improvement

determines the right to make modifications without prior warning.

1. Contents 3

2. Introduction & Specification 4

3. Safety Guidelines 5

4. Operation Guide 7

5. Applications 8

6. Maintenance & Troubleshooting 8

Limited Warranty Statement 9

EC Declaration of Continuity 11

4

USER MANUAL

JEFHTG2S-230

2000W HEAT GUN

www.jeffersontools.com

2. Introduction

This heat gun has been designed for stripping paint, soldering pipes, shrinking PVC, welding and bending plastic as well as

general drying and thawing purposes.

WARNING! Read this manual and general safety Instructions carefully before using the appliance, for your own safety. Your power

tool should only be passed on together with these instructions.

Technical Specifications:

Voltage: 230V ~ 50HZ

Power supply: 2000 W

Air temperature / Flow: [I] 450° 300L/min

[II] 600° 500L/min

12

3

4

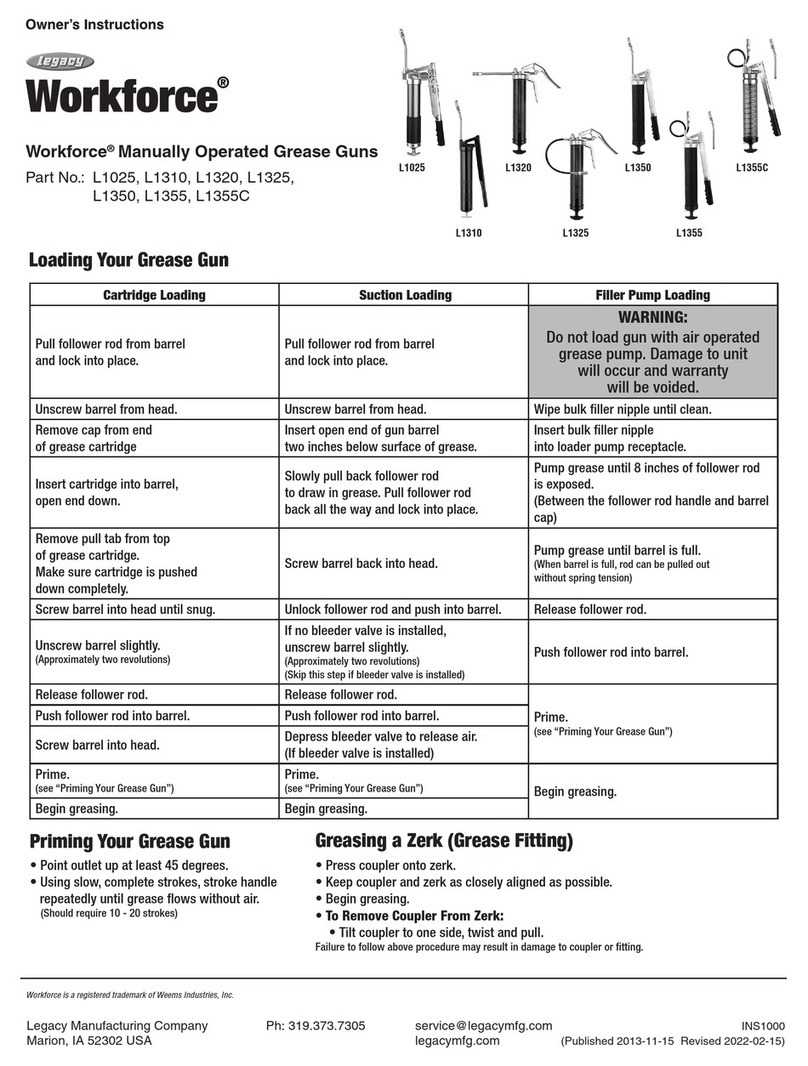

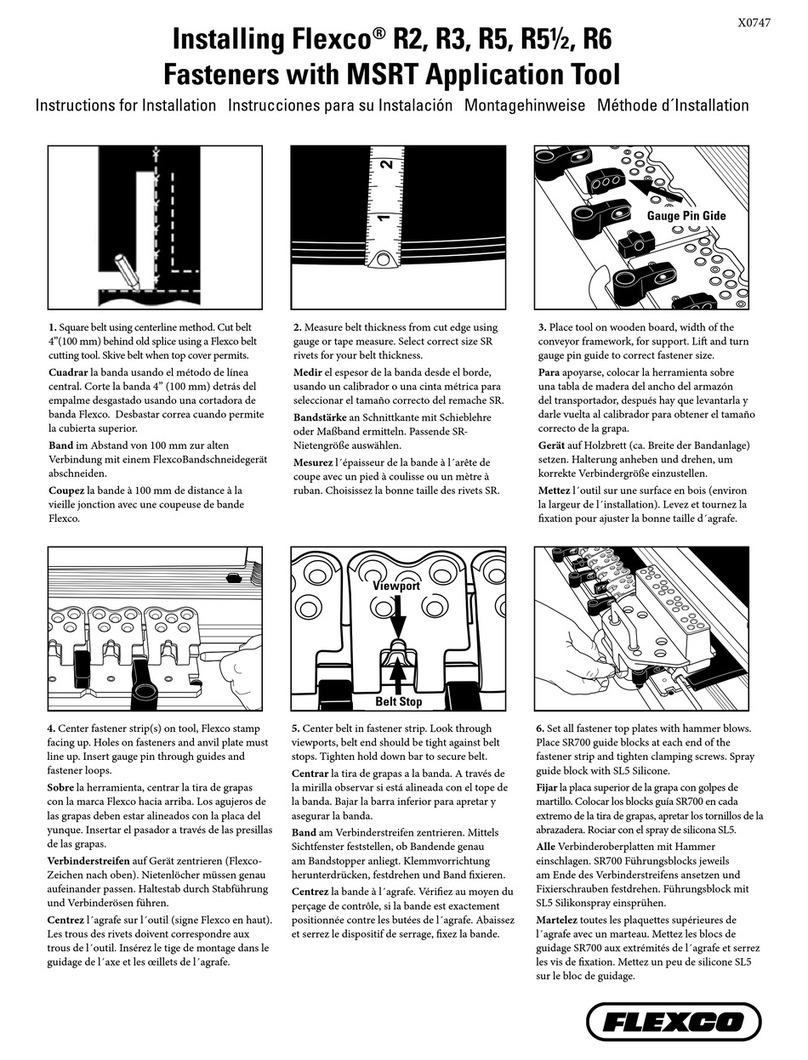

Number Description

1Nozzle

2Trigger Switch

Settings:

O - OFF

I - Low Setting: 450˚C - 300L/Min Airow

I I - High Setting: 600˚C - 500L/Min Airow

3Ventilation Cover

4Hanging Hook

5

USER MANUAL

JEFHTG2S-230

2000W HEAT GUN

www.jeffersontools.com

Please read all the safety warnings and all instructions carefully before use. Failure to follow all the warnings and instructions may

result in electric shock, re and/or serious injury. Save all warnings and instructions for future reference. The term “power tool” in

the warnings refers to your mains operated (corded) power tool or battery operated (cordless) power tool.

Work area

• Keep work area clean and well lit. Cluttered and dark areas invite accidents.

• Do not operate power tools in explosive atmospheres, such as in the presence of ammable liquids, gases or dust. Power

tools create sparks which may ignite the dust or fumes.

• Keep children and bystanders away while operating a power tool. Distractions can cause you to lose control.

Electrical safety

• Power tool plugs must match the ratings on the outlet. Never modify the plug in any way. Do not use any adapter plugs with

earthed (grounded) power tools. Unmodied plugs and matching outlets will reduce risk of electric shock.

• Avoid body contract with earthed or grounded surfaces such as pipes, radiators, ranges and refrigerators. There is an

increased risk of electric shock if your body is earthed or grounded.

• Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the risk of electric shock.

• Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep cord away from heat, oil,

sharp edges or moving parts. Damaged or entangled cords increase the risk of electric shock.

• When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

• If operating a power tool on a damp location is unavoidable, use a residual current device (RCD) protected supply. Use of an

RCD reduces the risk of electric shock.

Personal safety

• Stay alert, watch what you are doing and use common sense when operating a power tool. Do not use a power tool while

you are tried or under the inuence of drugs, alcohol or medication. A moment of inattention while operating power tools may

result in serious personal injury.

• Use safety equipment. Always wear eye protection. Safety equipment such

as dust mask, non-skid safety shoes, hand hat, or hearing protection used

whenever conditions require will reduce personal injuries.

• Avoid accidental starting. Ensure the switch is in the off position before

plugging in.

• Carrying power tools with your nger on the switch or plugging in power tools

that have the switch on invites accidents.

• Remove any adjusting key or wrench before turning the power tool on. A

wrench or a key left attached to a rotating part of the power tool may result in

personal injury.

• Do not overreach. Keep proper footing and balance at all times. This enables better control of the power tool in unexpected

situations.

• Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and gloves away from moving parts. Loose

clothes, jewellery or long hair can be caught in moving parts.

• If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and properly

used. Use of these devices can reduce dust related hazards.

3. Safety Guidelines

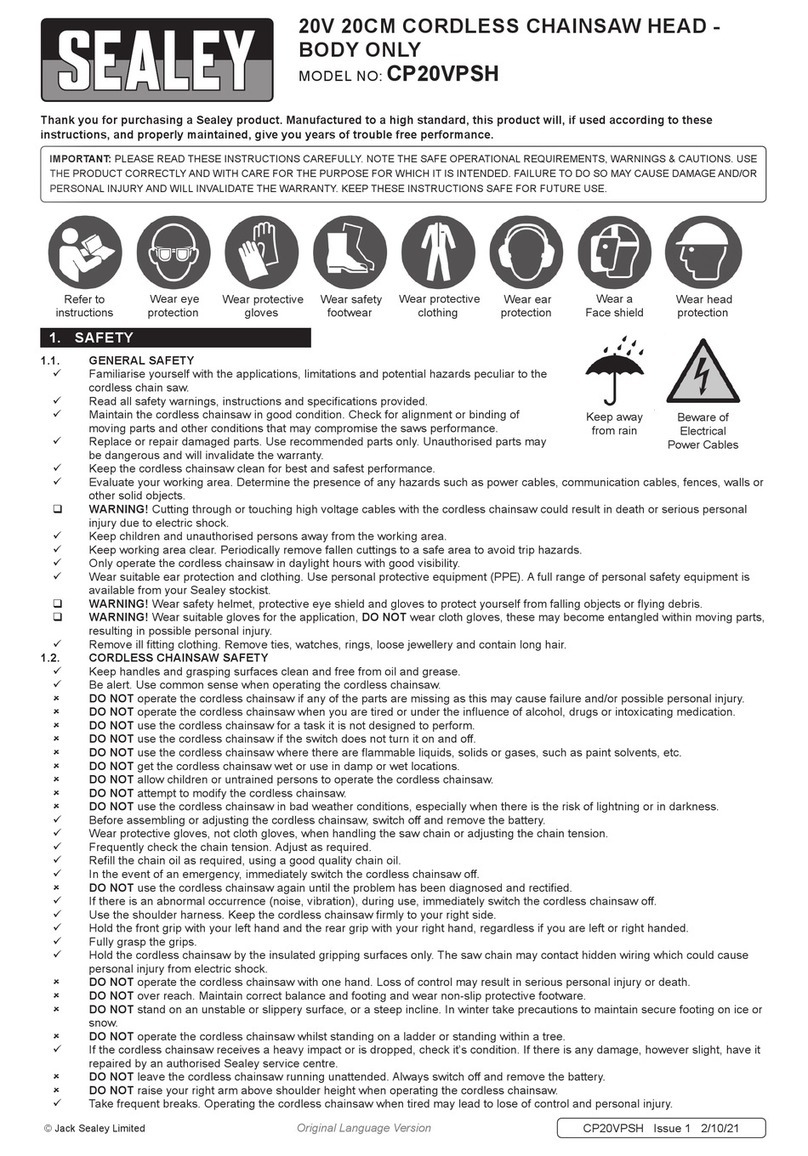

YELLOW & GREEN

EARTH WIRE

BROWN

LIVE

WIRE

BLUE

NEUTRAL

WIRE

CABLE

RESTRAINT

FUSE RATING

13 AMP

6

USER MANUAL

JEFHTG2S-230

2000W HEAT GUN

www.jeffersontools.com

Power tool use and care

• Do not force the power tool. Use the correct power tool for your application. The correct power tool will do the job better and

safer at the rate of which it was designed.

• Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be controlled with the switch is

dangerous and must be repaired.

• Disconnect the plug from the power source before making any adjustments, changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of starting the power tool accidentally.

• Store idle power tool out of the reach children and do not allow persons unfamiliar with the power tool of these instructions to

operate the power tool. Power tools are dangerous in the hands of untrained users.

• Maintain power tools. Check for misalignment or sticking of moving parts, breakage of parts and other condition that may

affect the power tool’s operation. If damaged, have the power tool repaired before use. Many accidents are caused by poorly

maintained power tools.

• Keep cutting tools sharp and clean. Properly maintained cutting tools with cutting edges are less likely to stick and are easier

to control.

• Use the power tool, accessories and tool bits etc., in accordance with these instructions and in the manner intended for the

particular type of power tool, taking into account the working conditions and the work to be performed. Use of the power tool

for operations different from intended could lead to a hazardous situation.

Servicing

Have your power tool serviced as required by a qualied repair person if replacement parts are required repair using only Jefferson

approved components. Contact your nearest Jefferson Dealer for further information.

Additional Safety Instructions For Heat Guns

• Do not place your hand over the air vents or block the vents in any way.

• The nozzle and accessories of this tool become extremely hot during use. Let these parts cool down before touching.

• Always switch the tool off before putting it down.

• Do not leave the tool unattended while it is switched on.

• A re may arise if the appliance is not used with care.

• Heat may be conducted to combustible materials that are out of sight. Do not use in a damp atmosphere, where ammable

gases may be present or near combustible materials.

• Allow the tool to cool fully before storing.

• Ensure adequate ventilation as toxic fumes may be produced.

• Do not use as a hairdryer.

• Do not obstruct either the air intake or nozzle outlet, as this may cause excessive heat build up resulting in damage

• Do not direct the hot air blast at other people.

• Do not touch the metal nozzle as it becomes very hot during use and remains hot for up to 30 minutes after use.

• Do not place the nozzle against anything while using or immediately after use.

• Do not poke anything down the nozzle as it could give you an electric shock. Do not look down the nozzle while the unit is

working because of the high temperature being produced.

• Do not allow paint to adhere to the nozzle or scraper as it could ignite after some time.

7

USER MANUAL

JEFHTG2S-230

2000W HEAT GUN

www.jeffersontools.com

Always observe the safety instructions and applicable regulations.

Use only one hand to hold the tool, do not place your other hand over the air vents

Prior to operation :

• Mount the correct accessory for the application.

• Set the desired air temperature.

Switching On and Off

To switch the tool on, set the on/off switch to position [I] or [II] (low or high).

Some smoke may be emitted after switching on; this does not indicate a problem.

To switch the tool off, set the switch to the Low Setting [I] and let it run for a few minutes. Then set the on/off switch to position

[0]. Let the tool cool down before moving or storing it.

Temperature Settings.

Turn ON/OFF switch to [I] or [II] (low or high) depending on temperature you need. The heat gun will start to buzz.

Stripping Paint

• Mount an appropriate accessory

• Set a high air temperature

• Switch the tool on

• Direct the hot air onto the paint to be removed

• When the paint softens, scrape the paint away using a hand scraper

• Do not strip metal window frames, as the heat may be conducted onto the glass and crack it.

• When stripping other window frames, use a glass protection nozzle.

• Do not keep the tool directed at one spot too long to prevent igniting the surface.

• Avoid collecting paint on the scraper accessory (if included), as it may ignite. If necessary, carefully remove paint debris from

the scraper accessory using a knife.

• Do not use this tool to remove paint containing lead. The peelings, residue and vapors of paint may contain lead, which is

poisonous. Any pre-1960 building may have been painted in the past with paint containing lead and covered with additional

layers of paint.

• Once deposited on surfaces, hand to mouth contact can result in the ingestion of lead.

• Exposure even to low levels of lead can cause irreversible damage to the brain and nervous system. Young and unborn

children are particularly vulnerable.

• When removing paint., ensue that the work area is enclosed. Preferably wear a dust mask.

• Do not burn the paint. Use the scraper and keep the nozzle at leaf 25 mm away from the painted surface. When working in a

vertical direction, work downwards to prevent paint from falling into the tool and burning.

• Dispose of all paint debris safely and ensure that the work area is thoroughly cleaned after completing the work.

Stationary use

• This tool can also be used in stationary mode.

• Unfold the Hang Hook and place the tool onto the workbench.

• Secure the cable to prevent pulling the tool off the workbench.

• Carefully switch the tool on.

• Make sure that the nozzle always points away from you and any bystanders.

• Make sure not to drop anything into the nozzle.

Cool Down Period

The nozzle and accessory become very hot during use. Let them cool down before attempting to move or store the tool.

To reduce the cooling time, set the on/off switch to position [I] and let it run for a few minutes.

Switch the tool off and let it cool down for at least 30 minutes.

4. Operation Guide

8

USER MANUAL

JEFHTG2S-230

2000W HEAT GUN

www.jeffersontools.com

Attention! Before performing any work on the equipment, pull the power plug.

Maintenance

Your Power Tool has been designed to operate over a long period of time with a minimum of maintenance. Continuous

satisfactory operation depends upon proper tool care and regular cleaning.

Lubrication

Your power tool requires no additional lubrication.

Cleaning

• Keep the ventilation slots of the machine clean to prevent overheating of the engine.

• Regularly clean the machine housing with a soft cloth, preferably after each use.

• Keep the ventilation slots free from dust and dirt.

• If the dirt does not come off use a soft cloth moistened with soapy water.

• Never use solvents such as petrol, alcohol, ammonia water, etc. These solvents may damage the plastic parts.

6. Maintenance & Troubleshooting

The air temperature can be adjusted to suit a wide range of applications. The table below suggests settings for different

applications.

[I] Low Setting Applications:

• Drying paint, varnish color shade samples, ller, adhesives, construction joints and stucco forms

• Drying wet timber prior to lling

• Removing stickers

• Joining adhesives-Large-surface gluing with contact adhesives, activation of pressure-sensitive adhesives, acceleration of

bonding processes, releasing of bonding points as well as releasing or bonding of edge band or veneer.

• Waxing and de-waxing

• Shrinking PVC wrapping and insulation tubes

• Defrosting of icy stairs and steps, door locks, trunk lids, car doors or water pipes, as well as for defrosting refrigerators and

ice boxes

[II] High Setting Applications:

• Welding of thermoplastic polymer, ooring materials of PVC and linoleum, PVC-coated fabric, tarpaulins and foils

• Bending plastic pipes and sheets

• Soldering plumbing joints, tin, special silver solder, SMD elements, cable lugs

• Loosening rusted or tightly fastened nuts and bolts

• Removing old and even thick coatings of oil paint , lacquer, varnish and synthetic plaster

• Disinfection-With hot air of 600°, you can quickly rid animal sties/stables of bacteria .Woodworm infestation can be controlled

(Caution: Danger of re! Do not heat up the wooden surface excessively).

5. Applications

9

USER MANUAL

JEFHTG2S-230

2000W HEAT GUN

www.jeffersontools.com

Jefferson Professional Tools & Equipment, or hereafter "Jefferson" warrants its customers that its products will be free of defects

in workmanship or material. Jefferson shall, upon suitable notication, correct any defects, by repair or replacement, of any parts

or components of this product that are determined by Jefferson to be faulty or defective.

This warranty is void if the equipment has been subjected to improper installation, storage, alteration, abnormal operations,

improper care, service or repair.

Warranty Period

Jefferson will assume both the parts and labour expense of correcting defects during the stated warranty periods below.

All warranty periods start from the date of purchase from an authorised Jefferson dealer. If proof of purchase is unavailable from

the end user, then the date of purchase will be deemed to be 3 months after the initial sale to the distributor.

1 Year

JEFHTG2S - 230 - 2000W Heat Gun

90 Days

• All replacement parts purchased outside of the warranty period

Important: All parts used in the repair or replacement of warranty covered equipment will be subject to a

minimum of 90 days cover or the remaining duration of the warranty period from the original date of purchase.

Warranty Registration / Activation

You can register and activate your warranty by visiting the Jefferson Tools website using the following address:

www.jeffersontools.com/warranty and completing the online form.

Online warranty registration is recommended as it eliminates the need to provide proof of purchase should a warranty claim be

necessary.

Warranty Repair

Should Jefferson confirm the existence of any defect covered by this warranty the defect will be corrected by repair or

replacement at an authorized Jefferson dealer or repair centre.

Packaging & Freight Costs

The customer is responsible for the packaging of the equipment and making it ready for collection. Jefferson will arrange

collection and transportation of any equipment returned under warranty. Upon inspection of the equipment, if no defect can be

found or the equipment is not covered under the terms of the Jefferson warranty, the customer will be liable for any labour and

return transportation costs incurred. These costs will be agreed with the customer before the machine is returned.

*Jefferson reserve the right to void any warranty for damages identified as being caused through misuse

Warranty Limitations

Jefferson will not accept responsibility or liability for repairs made by unauthorised technicians or engineers. Jefferson's liability

under this warranty will not exceed the cost of correcting the defect of the Jefferson products.

Jefferson will not be liable for incidental or consequential damages (such as loss of business or hire of

substitute equipment etc.) caused by the defect or the time involved to correct the defect. This written warranty is the only

express warranty provided by Jefferson with respect to its products.

Any warranties of merchantability are limited to the duration of this limited warranty for the equipment involved. Jefferson is not

responsible for cable wear due to flexing and abrasion. The end user is responsible for routine inspection of cables for possible

wear and to correct any issues prior to cable failure.

LIMITED WARRANTY STATEMENT

10

USER MANUAL

JEFHTG2S-230

2000W HEAT GUN

www.jeffersontools.com

Claiming Warranty Coverage

The end user must contact Jefferson Professional Tools & Equipment (Tel: +44 (0) 1244 646 048) or their

nearest authorised Jefferson dealer where final determination of the warranty coverage can be ascertained.

Step 1 - Reporting the Defect

Online Method:

• Visit our website www.jeffersontools.com/warranty and complete the Warranty Returns form. You can complete the form

online and submit it to us directly or download the form to print out and return by post.

Telephone Method:

Contact your Jefferson dealer or sales representative with the following information:

• Model number

• Serial number (usually located on the specification plate)

• Date of purchase

A Warranty Returns form will be sent to you for completion and return by post or fax, together with details of your nearest au-

thorised Jefferson repair centre. On receipt of this form Jefferson will arrange to collect the equipment from you at the earliest

convenience.

Step 2 - Returning the Equipment

It is the customer's responsibility to ensure that the equipment is appropriately and securely packaged for collection, together

with a copy of the original proof of purchase. Please note that Jefferson cannot assume any responsibility for any damage

incurred to equipment during transit. Any claims against a third party courier will be dealt with under the terms & conditions of

their road haulage association directives.

Please note: Jefferson will be unable to collect or process any warranty requests without a copy of the original proof of purchase.

Step 3 - Assessment and Repair

On receipt, the equipment will be assessed by an authorised Jefferson engineer and it will be determined if the equipment is

defective and in need of repair and any repairs needed are covered by the warranty policy. In order to qualify for warranty cover all

equipment presented must have been used, serviced and maintained as instructed in the user manual.

Where repair is not covered by the warranty a quotation for repair, labour costs and return delivery will be sent to the customer

(normally within 7 working days). Note: If the repair quotation is not accepted Jefferson Professional Tools & Equipment will in-

voice 1 hour labour time at £30 per hour plus return carriage costs (plus VAT).

In cases where no fault can be found with the equipment, or, if incorrect operation of the equipment is

identified as the cause of the problem, a minimum of 1 hour labour at £30 per hour plus carriage costs will be

required before the equipment will be despatched back to the customer.

Any equipment repaired or replaced under warranty will normally be ready for shipment back to the customer within 7 working

days upon receipt of the equipment at an authorised Jefferson Repair centre (subject to part availability). Where parts are not im-

mediately available Jefferson will contact you with a revised date for completion of the repair.

General Warranty Enquiries

For any further information relating to Jefferson warranty cover please call +44 (0) 1244 646 048 or send your enquiry via email to

Disclaimer:

The information in this document is to the best of our knowledge true and accurate, but all recommendations or suggestions are made without

guarantee. Since the conditions of use are beyond their control, Jefferson Tools® disclaim any liability for loss or damage suffered from the use of

this data or suggestions. Furthermore, no liability is accepted if use of any product in accordance with this data or suggestions infringes any patent.

Jefferson Tools® reserve the right to change product specifications and warranty statements without further notification. All images are for

illustration purposes only.

11

USER MANUAL

JEFHTG2S-230

2000W HEAT GUN

www.jeffersontools.com

EC Declaration of Conformity

We, Jefferson Professional Tools & Equipment, as the authorised European

Community representative of the manufacturer, declare that the following equipment

conforms to the requirements of the following Directives:

2014/35/EU - Low Voltage Directive

2014/30/EU - Electromagnetic Compatibility

Equipment Category: 2000W Heat Gun / Hot Air Gun

Product Name/Model: JEFHTG2S-230

Signed by: Stephen McIntyre

Position in the company: Operations Director

Date: 10 February 2017

This technical document is held by: Jimmy Hemphill

Technical file holder's address as shown below

Name and address of manufacturer or authorised representative:

Jefferson Tools,

Herons Way,

Chester Business Park,

Chester,

United Kingdom,

CH4 9QR

12

USER MANUAL

JEFHTG2S-230

2000W HEAT GUN

www.jeffersontools.com

Jefferson Tools,

Herons Way,

Chester Business Park,

Chester,

United Kingdom,

CH4 9QR

Tel. +44 (0)1244 646 048

Email: [email protected]

Before attempting to use this product please read

all the safety precautions and operating instructions

outlined in this manual to reduce the risk of fire,

electric shock or personal injury.

IMPORTANT! SAFETY FIRST!

Other Jefferson Tools manuals

Jefferson

Jefferson JEFARIVT02H User manual

Jefferson

Jefferson JEFHOSRLH15-1/2 User manual

Jefferson

Jefferson JEFLUGGUN03 User manual

Jefferson

Jefferson JEFUNIPCPGR User manual

Jefferson

Jefferson JEFHOSRL15-3/8HVP User manual

Jefferson

Jefferson JEFTRCH09ILSG User manual

Jefferson

Jefferson JEFBGSSTDADJ User manual