Jegs 81532 User manual

Installation Instructions for 81532 & 81533

Hydraulic Porta-Power Ram Jack Kit

4 & 10 Ton

IMPORTANT!

PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFETY INSTRUCTIONS AND WARNINGS.

USE THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED.

FAILURE TO DO SO MAY CAUSE DAMAGE TO PROPERTY AND/OR SERIOUS PERSONAL INJURY. PLEASE

KEEP THIS INSTRUCTION MANUAL SAFE FOR FUTURE USE.

1. SAFETY INSTRUCTIONS AND WARNINGS

1.1 The maximum ram capacity is 4 (10) ton. DO NOT exceed this rated capacity.

1.2 When extension tubes are used, the rated capacity is always reduced by 50% for each tube connected.

1.3 The maximum spreader capacity is 0.5 ton. And maximum ram toe and plunger toe capacity is 0.5 ton (4 ton jack

kit) or 0.8 ton (10 ton jack kit). DO NOT exceed these rated capacities when using these attachments.

1.4 DO NOT use this equipment as a vehicle lifting device or as a vehicle support.

1.5 Keep children and unauthorized persons away from the work area.

1.6 Remove loose clothing. Remove ties, watches, rings and other loose jewelry, and contain long hair.

1.7 Always wear ANSI approved safety goggles when operating the repair kit.

1.8 Keep proper balance and footing, do not overreach and wear nonslip footwear.

1.9 Only use this equipment on a surface that is stable, level, dry and not slippery, and capable of sustaining the load.

Keep the surface clean, tidy and free from unrelated materials and ensure that there is adequate lighting.

1.10 When using this equipment, open the breather valve (P09). Close it when not in use.

1.11 DO NOT allow the piston rod (R03) of ram to extend so far as to exceed the maximum ram stroke.

1.12 When coupler valves are disconnected, always use dust cap to keep the hydraulic system clean.

1.13 DO NOT drop any heavy objects onto the hose and DO NOT twist the hose. Always keep the hose clean to avoid

damage to the hose and couplers.

1.14 Keep the equipment away from heat or fire, as this may cause damage or weaken the seals.

1.15 DO NOT operate this equipment when you are tired or under the influence of alcohol, drugs or any intoxicating

medication.

1.16 DO NOT allow untrained persons to operate the equipment and DO NOT make any modifications to it.

1.17 DO NOT expose the equipment to rain or any other kind of bad weather.

1.18 Use a qualified person to maintain the equipment in good condition. Keep it clean for best and safest performance.

1.19 If the equipment is in need of repairing and/or there are any parts that need to be replaced, have it repaired by

authorized technicians and only use the replacement parts supplied by the manufacturer.

1.20 WARNING: The warnings, cautions and instructions discussed in this instruction manual cannot cover all possible

conditions and situations that may occur. It must be understood by the operator that common sense and caution

are factors which cannot be built into this product, but must be supplied by the operator.

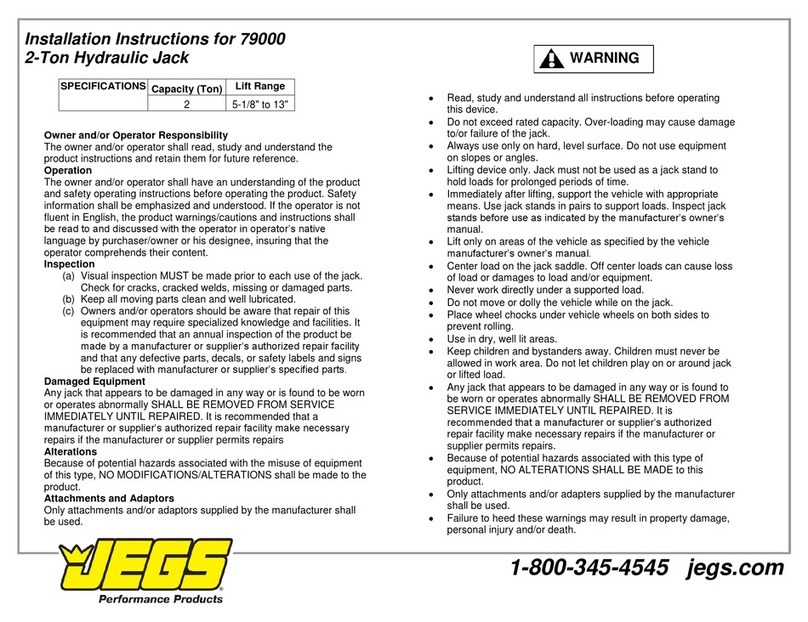

2. SPECIFICATIONS

Rated capacity: 4 Ton 10 Ton

Rump output pressure: 56.5MPa 63MPa

Ram min height: 267mm 322mm

Stroke: 120mm 130mm

Oil being filled: 350g 500g

1-800-345-4545 jegs.com

3. OPERATING,INSTRUCTIONS

3.1 Connect the hydraulic ram, hose and pump unit together, ensure that you have securely fastened the couplers

before pumping.

Warning: Inspect before each use. Do not use if bent, broken, leaking, damaged components or any suspect parts are

noted and/or it has been subjected to a shock load

3.2 Open the breather valve (P09).

3.3 Firmly close the release valve (P15) by turning it clockwise.

3.4 Adjust the ram slowly to make the load coaxial with the ram.

NOTE: The pump can be used in any position from horizontal to vertical. Always keep the hose end of the pump

downward when it is not horizontal.

3.5 Pump the handle (P39) up and down to supply pressure.

3.6 When work is done, SLOWLY and CAREFULLY turn the release valve counterclockwise (never more than one

turn) to release the pressure until ram retracts to desired position.

3.7 Close the breather valve.

4. MAINTENANCE

4.1 When not in use, store the equipment in a dry location with the pump piston (P34) and the ram fully retracted.

4.2 Periodically check the ram and pump piston for signs of rust or corrosion. Clean exposed areas with a clean oiled

cloth.

Warning: Never use sandpaper or abrasive material on these surfaces!

4.3 A coating of light lubricating oil to pivot points, axles and hinges will help to prevent rust and assure that pump

assemblies move freely. Periodically lubricate the pivot points, axles and hinges with a light lubricating oil as

needed.

4.4 With ram fully lowered, set pump unit in its normal, level position. Remove the oil filler screw (P07) to check the

hydraulic oil level. If it is not adequate add high quality hydraulic jack oil as necessary.

Warning: DO NOT use brake fluid or any other improper fluid and avoid mixing different types of oil when adding

hydraulic oil.

4.5 To ensure best performance and longer equipment life, replace the complete hydraulic oil at least once a year. With

ram fully lowered, remove the oil filler screw (P07) and drain the oil into a suitable container. Ensure that no dirt

gets into the system. Set the pump in its normal level position, fill with approved hydraulic jack oil, then replace the

oil filler screw (P07).

Note: Dispose of hydraulic oil in accordance with local regulations.

4.6 When equipment efficiency drops, purge away air from hydraulic system: Tum the release valve counterclockwise

by 1-1/2 tums, with ram fully retracted and release valve open, pump the handle rapidly for 10-20 times.

4.7 It is recommended that an annual inspection be done by qualified technicians.

5. TROUBLESHOOTING

Symptom

Possible Causes

Corrective Action

Ram won't lift load

Release valve not tightly closed

Overload condition

Air trapped in system

Firmly close release valve

Remedy overload condition

Purge away air from system

Ram won't maintain load

Release valve not tightly closed

Hydraulic unit malfunction

Firmly close release valve

Replace ram and/or pump

Ram won't lower after unloading

Reservoir overfilled

Linkages binding

Drain oil to proper level

Clean & lubricate moving parts

Ram won’t extend to full stroke

Oil level low

Add hydraulic oil

Poor performance

Oil level low

Air trapped in system

Add hydraulic oil

Purge away air from system

1-800-345-4545 jegs.com

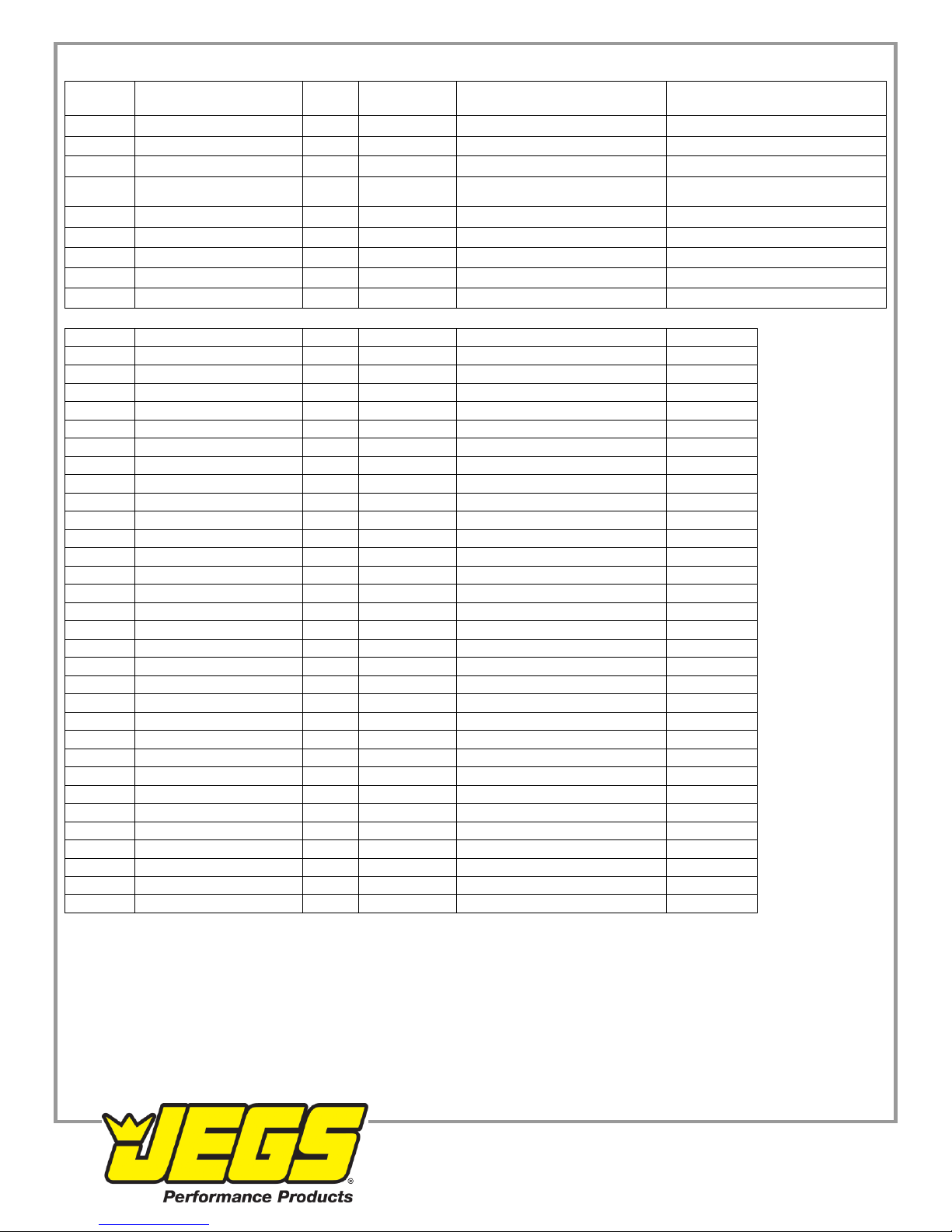

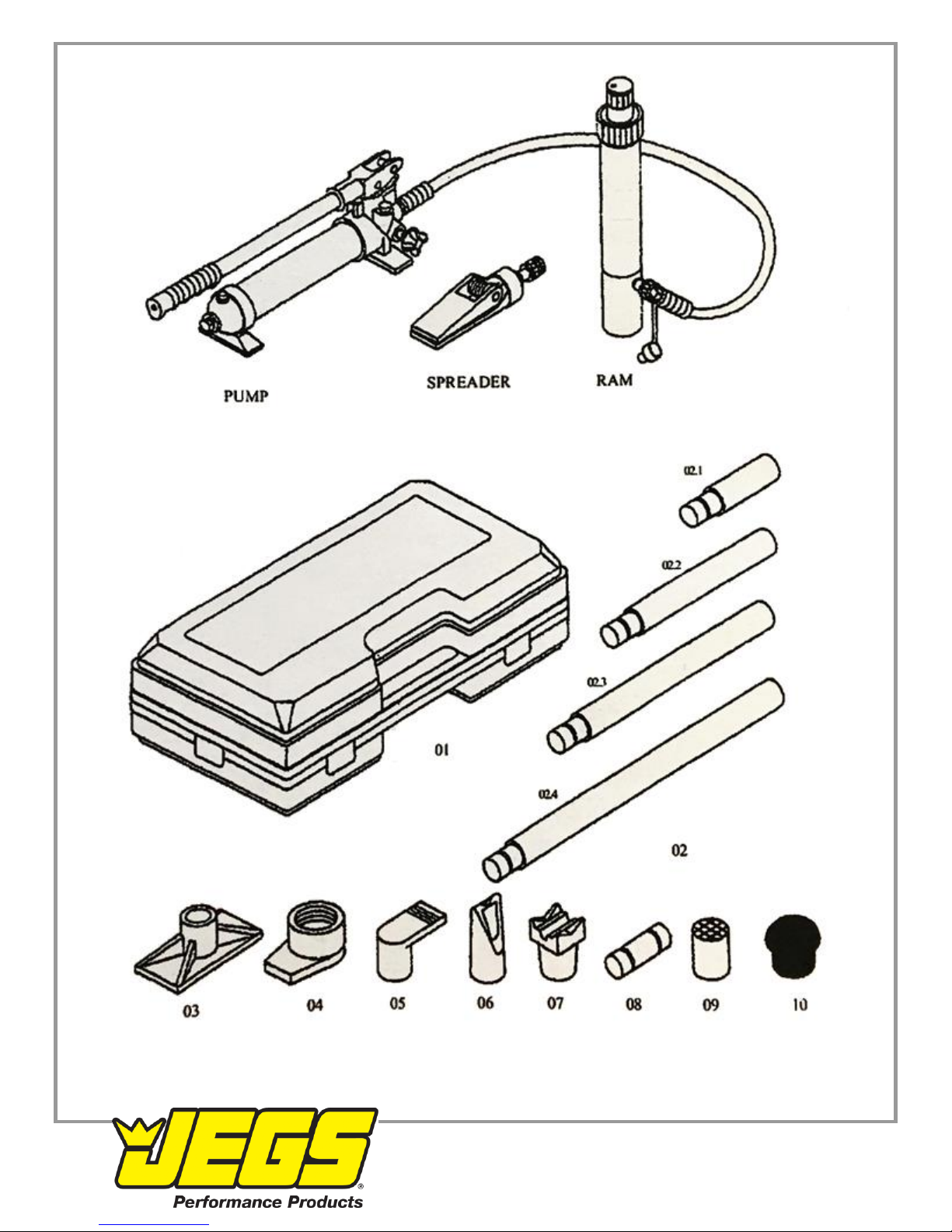

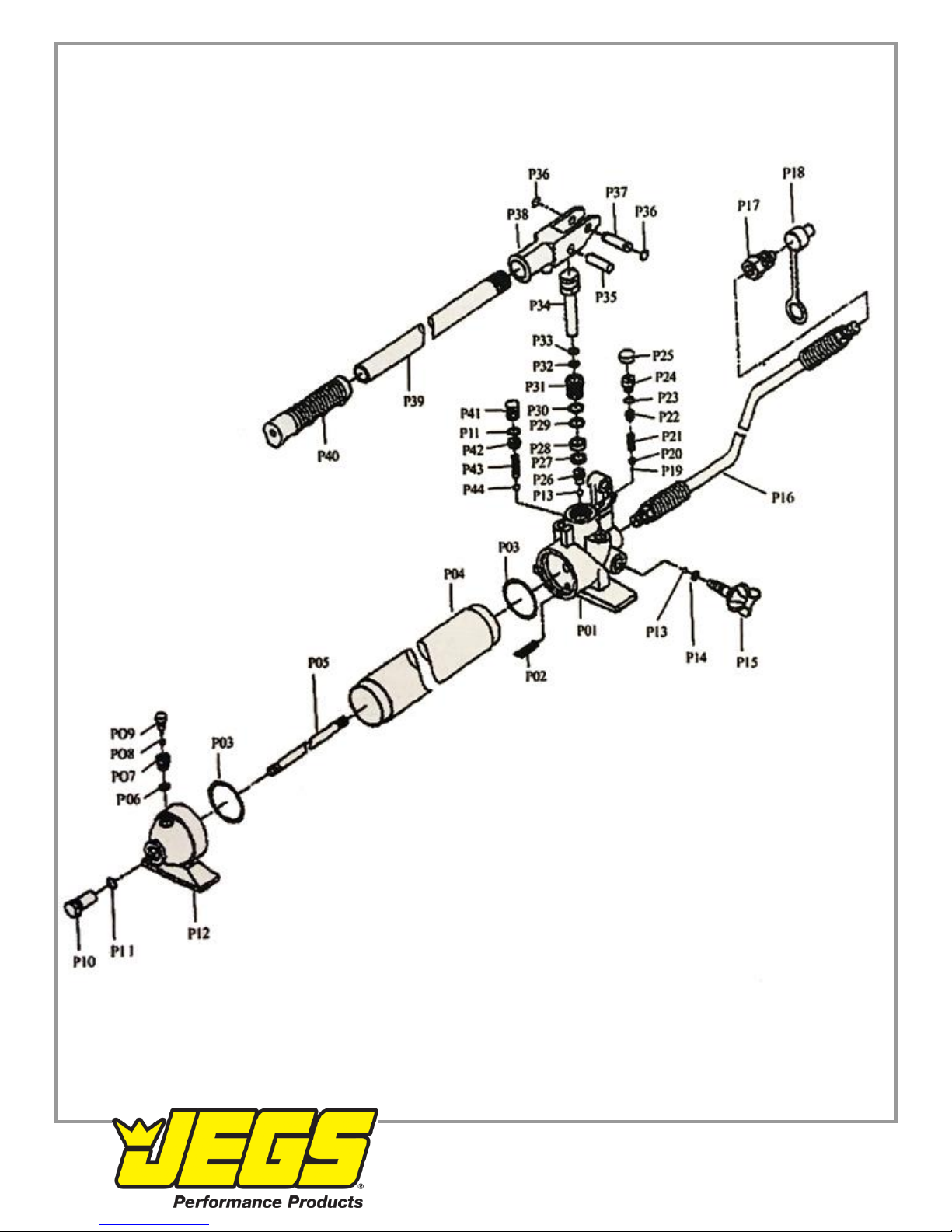

Part No.

Description

Qty

Part No.

Description

Qty

01

Case

1

10

Rubber head

1

02

Tube

5 (4)

P01

Valve block

1

03

Flat base

1

P02

Oil filter

1

04

Ram toe

1

P03

O-ring

2

05

Plunger toe

1

P04

Reservoir

1

06

Wedge head

1

P05

Tie rod

1

07

V-base

1

P06

Nylon ring

1

08

Male connector

1

P07

Oil filler screw

1

09

Serrated saddle

1

P08

Sealing

1

P09

Breather valve

1

P41

Screw

1

P10

Screw

1

P42

Screw

1

P11

O-ring

4

P43

Spring

1

P12

Pump foot

1

P44

Ball

1

P13

Ball

2

R01

Cover

1

P14

O-ring

1

R02

Circlip

1

P15

Release valve

1

R03

Piston rod

1

P16

Hydraulic hose

1

R04

Circlip

1

P17

Coupler

1

R05

Bushing

1

P18

Hose dust cover

1

R06

Nylon ring

1

P19

Ball

1

R07

Sealing ring

1

P20

Ball cap

1

R08

Circlip

1

P21

Spring

1

R09

Nut

1

P22

Screw

1

R10

Spring

1

P23

O-ring

1

R11

Screw

1

P24

Screw

1

R12

Protection cap

1

P25

Screw protector

1

R13

Ring for ram

1

P26

Screw

1

R14

Cylinder

1

P27

Nylon ring

1

R15

Screw

1

P28

Sealing ring

1

S1

Pin

1

P29

O-ring

1

S2

Circlip

2

P30

Nylon ring

1

S3

Movable jaw

1

P31

Screw

1

S4

Spring

1

P32

O-ring

1

S5

Fixed jaw

1

P33

Nylon ring

1

S6

Piston

1

P34

Piston

1

S7

Cup seal

1

P35

Pin

1

S8

O-ring

1

P36

Retaining ring

2

S9

End cap

1

P37

Pin

1

S10

Coupling ring

2

P38

Handle socket

1

S11

Coupling bolt

2

P39

Handle

1

S12

Dust cap

2

P40

Handle sleeve

1

6. PARTS LIST

1-800-345-4545 jegs.com

1-800-345-4545 jegs.com

1-800-345-4545 jegs.com

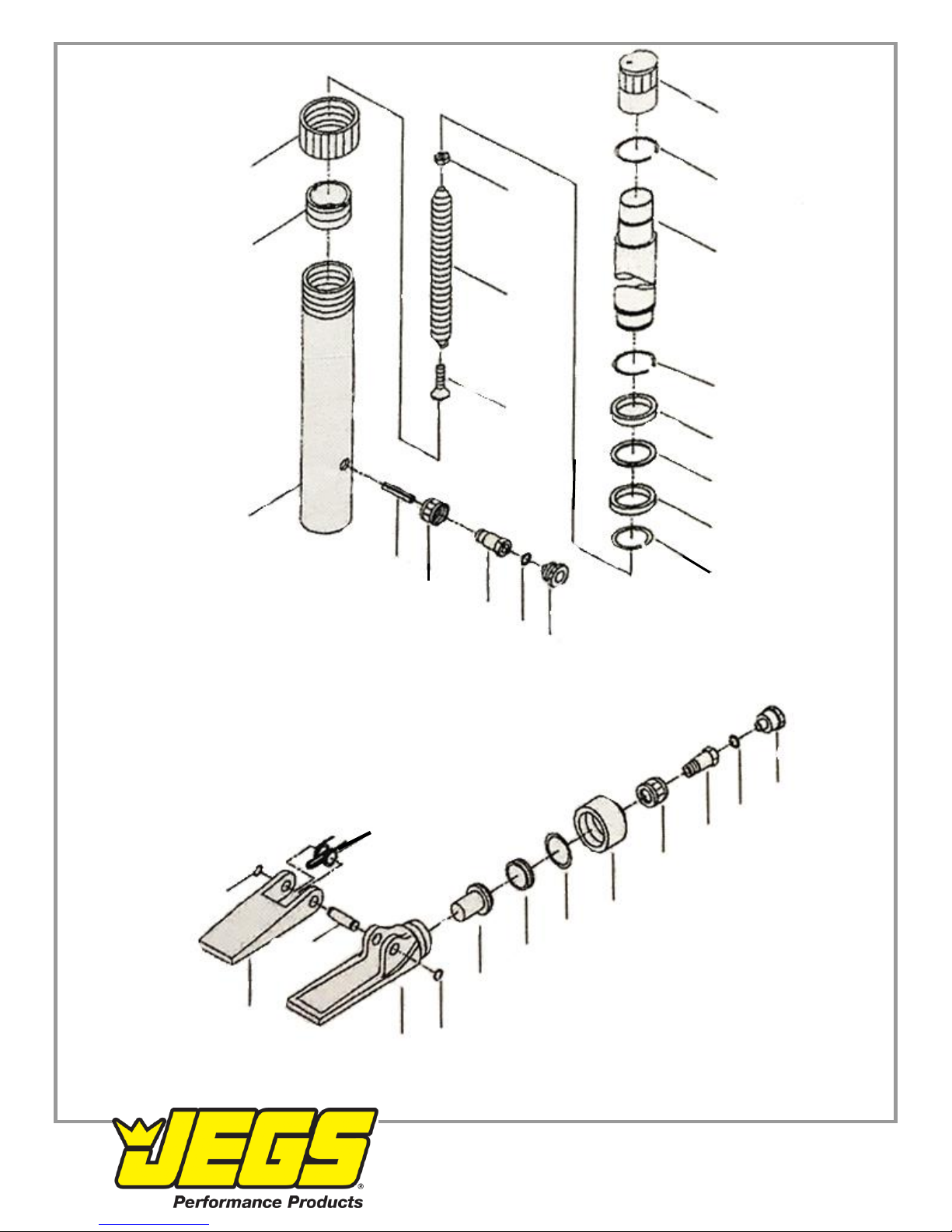

R01

R12 R02

R09

R13 R03

R10

R04

R11

R05

R06

R14

R07

R15 R08

S10

S11

P11

S12

S12

S4 P11

S11

S10

S2

S9

S8

S1

S7

S6

S3

S2

S5

1-800-345-4545 jegs.com

This manual suits for next models

1

Table of contents

Other Jegs Jack manuals

Popular Jack manuals by other brands

Mega

Mega N10-3 Operation and maintenance instructions

Rescue 42

Rescue 42 TeleCrib Strut Jack manual

Borum

Borum BPROAJ22T owner's manual

Stromberg Carlson Products

Stromberg Carlson Products JET-5000 installation instructions

Arcan

Arcan BLACKLINE SAJ35TB quick start guide

Atlas Equipment

Atlas Equipment RJ-8000 Installation & operation manual