4

Catalogue

1.The General Introduction ......................................................................................5

2.Proper usage............................................................................................................6

Modification...........................................................................................................6

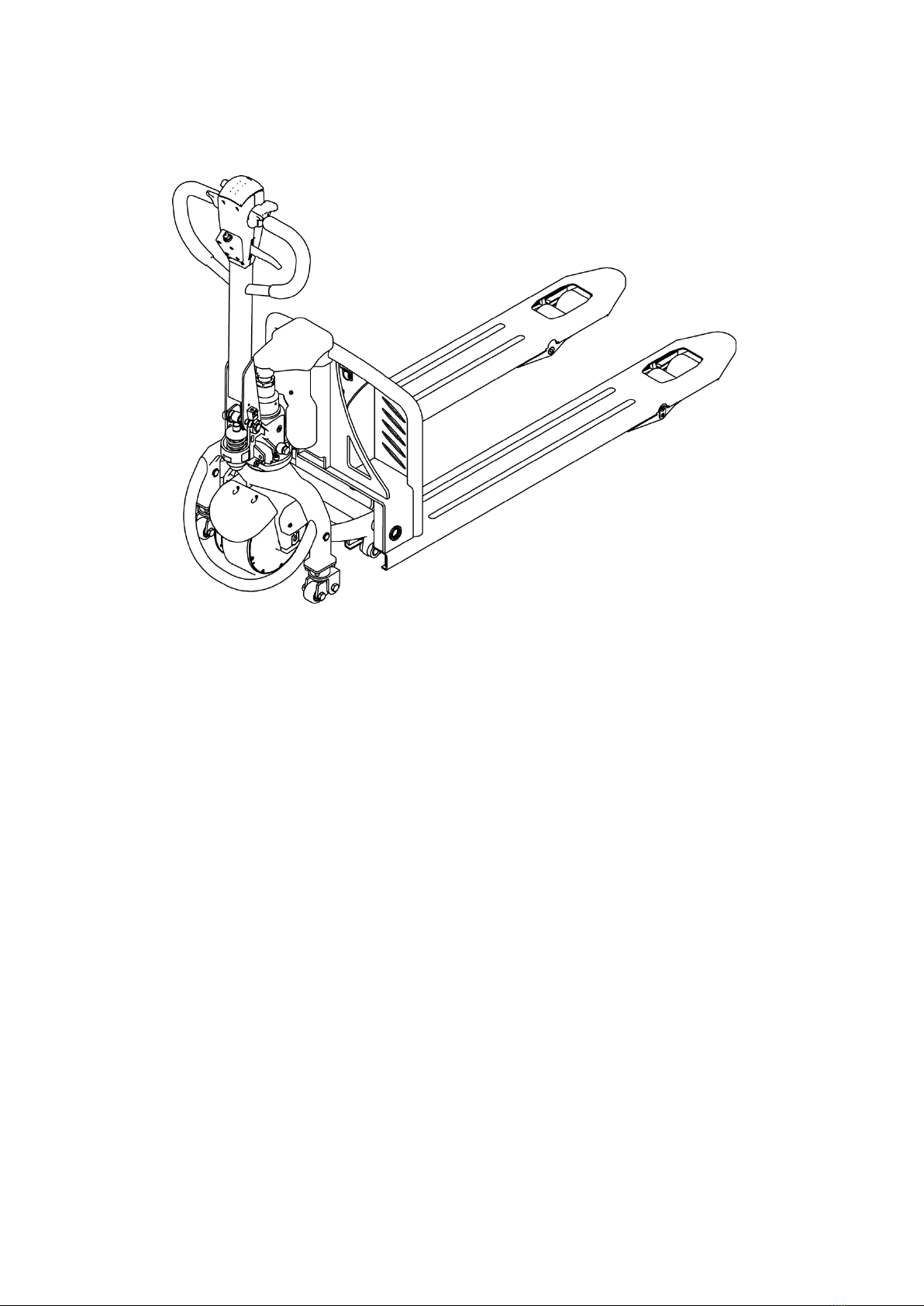

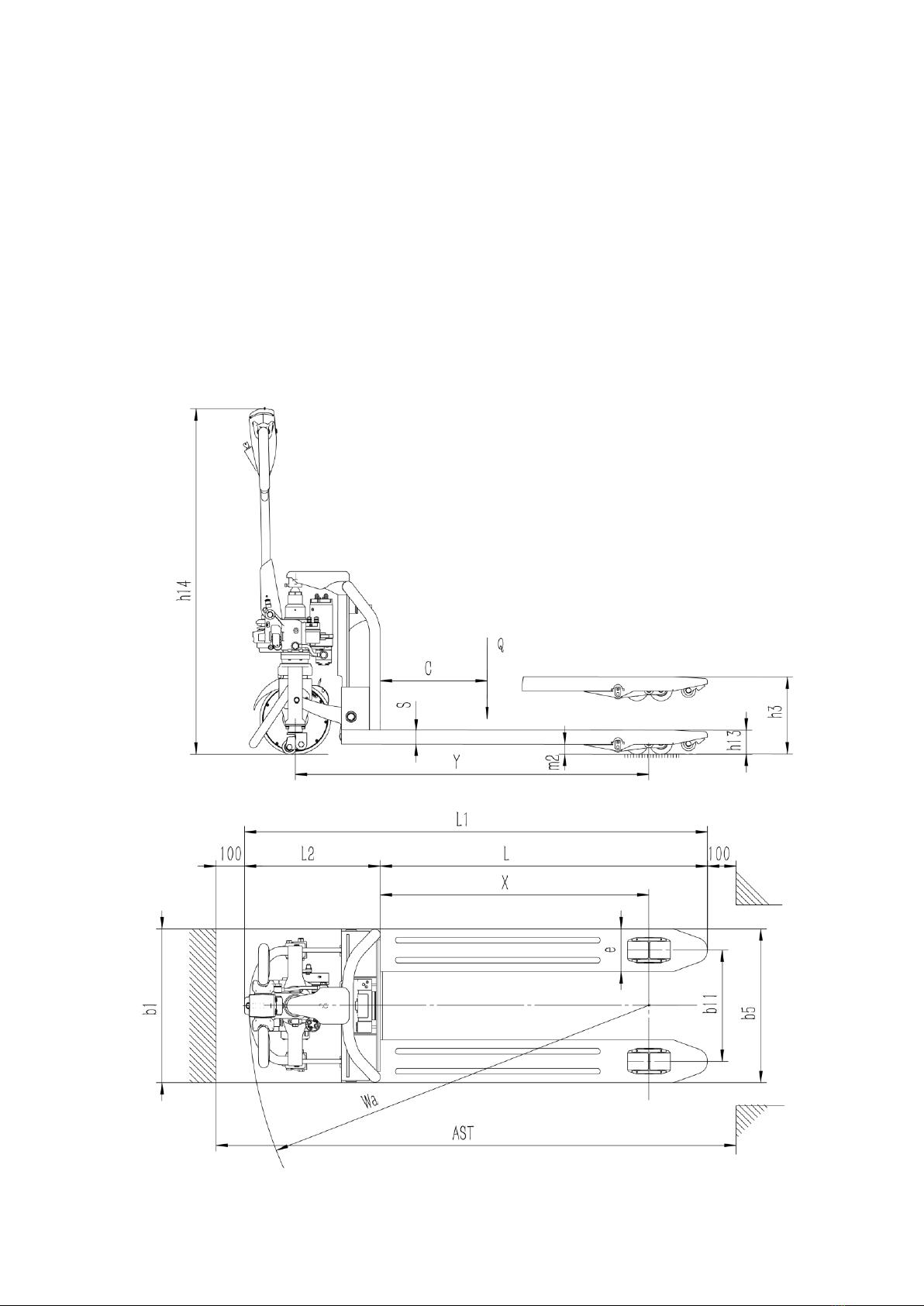

3.Introduction of the product......................................................................................7

3.1Model overview................................................................................................7

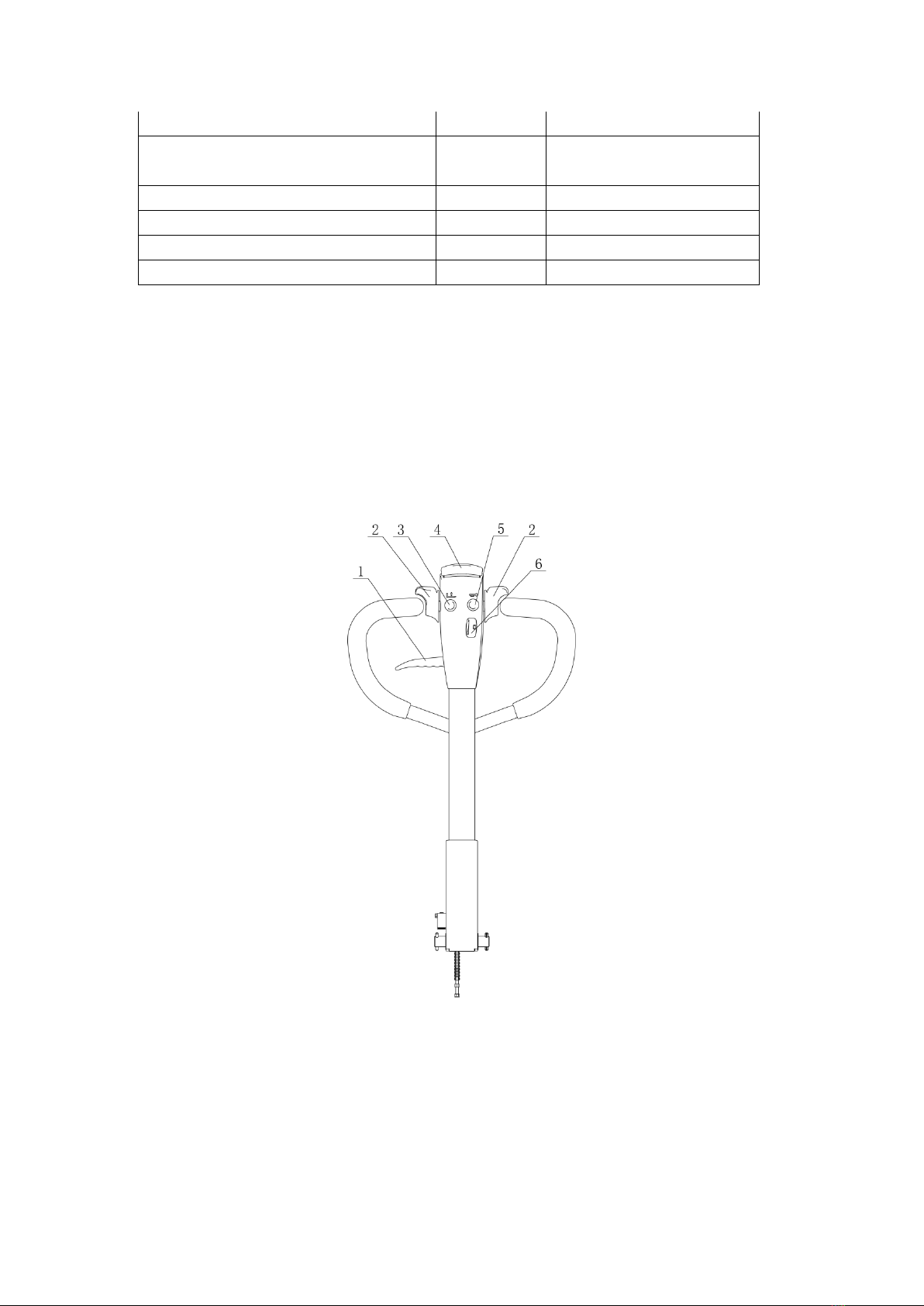

4.Operating principle ................................................................................................9

Operating mechanism diagram:...........................................................................9

5.Operating principle ..............................................................................................10

5.1Running system..............................................................................................10

5.2Steering system ..............................................................................................10

5.3 Brake structure and brake schematic diagram...........................................10

5.4 Operating System ..........................................................................................12

5.5 Electric System ..............................................................................................12

5.6 Hydraulic principle .......................................................................................12

6. Electrical schematic diagram ............................................................................13

6.1Electrical schematic diagram ........................................................................13

7. Hydraulic Scheme ................................................................................................14

7.1Hydraulic Scheme ..........................................................................................14

8.Operating Instruction ..........................................................................................15

8.1 Operation .......................................................................................................15

8.2Emergency reverse function .........................................................................17

8.3 The use of the horn and the reversing horn ...............................................17

8.4 Battery capacity display ...............................................................................17

8.5 operation........................................................................................................17

9.Safety operation and matters needing attention ...........................................18

9.1 Repair and Maintenance...............................................................................18

9.2 Routine Maintenance ....................................................................................19

9.3 Professional Maintenance Manual...............................................................19

9.4 battery maintenance, charging and maintenance. .....................................22

10.Safety Caution......................................................................................................26

10.1 General rule .................................................................................................26

10.2 Storage and transportation........................................................................26

10.3 Check before using......................................................................................27

10.4Safety operation regulation ........................................................................27

11.Service Manual....................................................................................................31

11.1 Troubleshooting.......................................................................................31

11.2 Preparation before repair ..........................................................................32

11.3Check the amount of hydraulic oil..............................................................32

11.4 Complete repair, the preparation before using........................................32

12.After Sales Service..............................................................................................33