WARNING!!

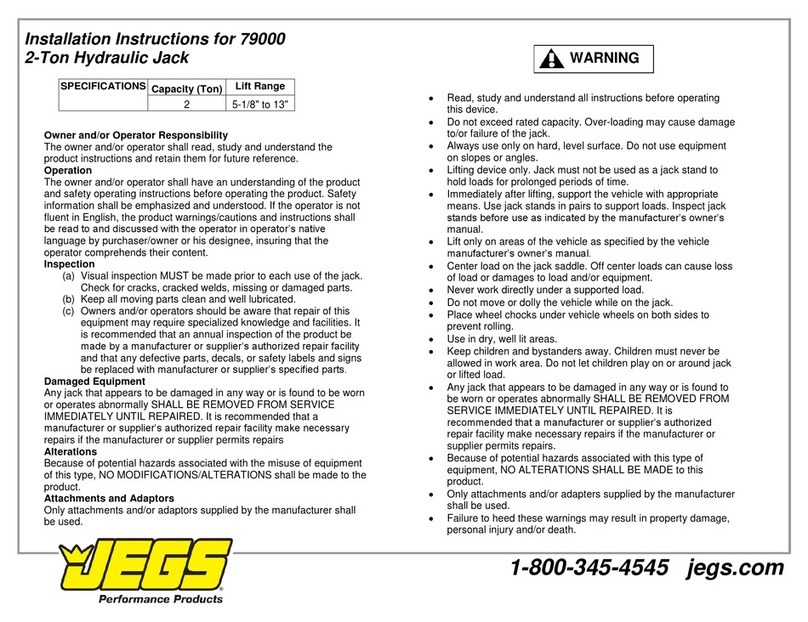

Read, study and understand all instructions before operating this device.

Do not exceed rated capacity. Over-loading may cause damage to/or failure of the jack.

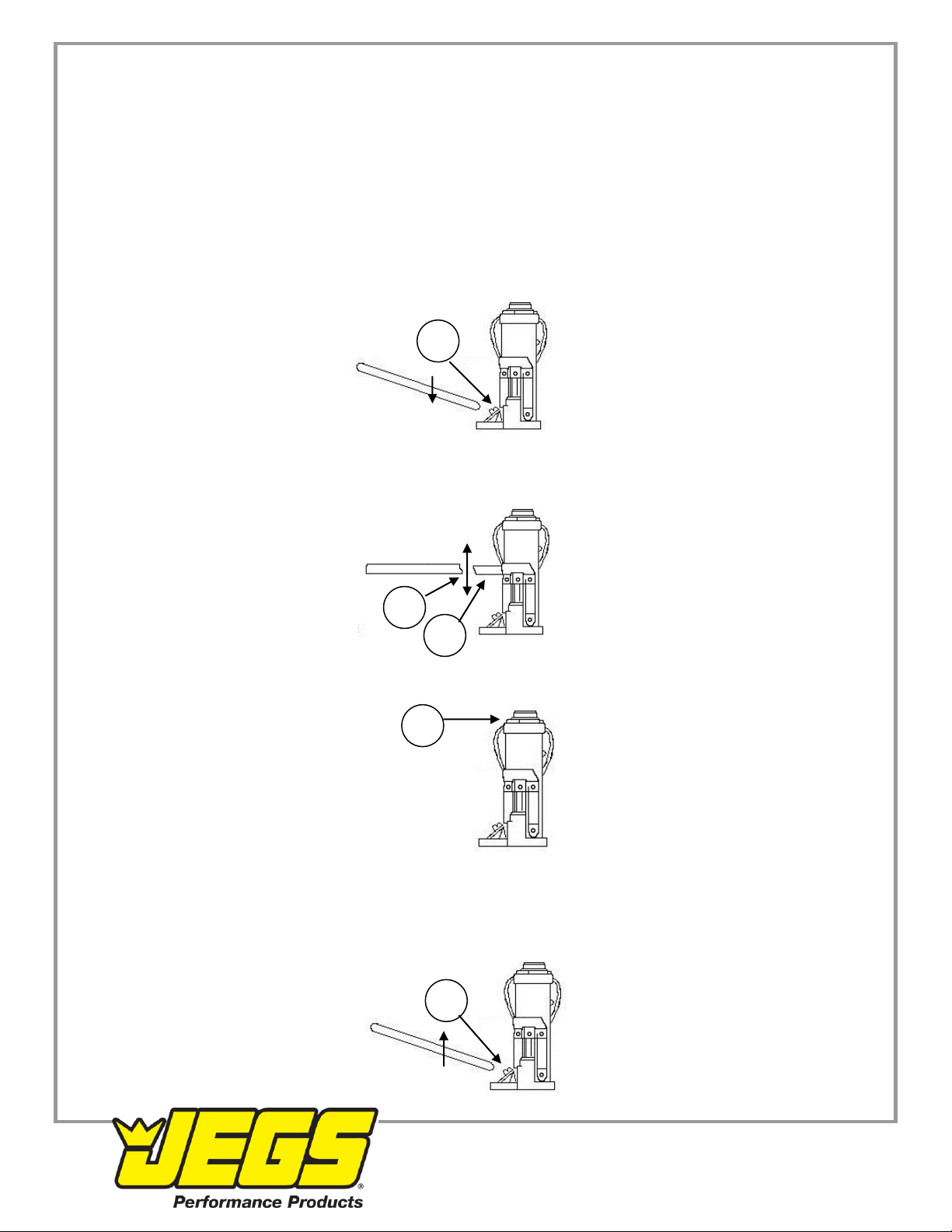

Always use only on hard, level surface. Do not use equipment on slopes or angles.

Lifting device only. Jack must not be used as a jack stand to hold loads for prolonged periods of time.

Immediately after lifting, support the vehicle with appropriate means. Use jack stands in pairs to support

loads.

Inspect jack stands before use as indicated by the manufacturer’s owner’s manual.

Lift only on areas of the vehicle as specified by the vehicle manufacturer’s owner’s manual.

Center load on the jack saddle. Off center loads can cause loss of load or damages to load and/or

equipment.

Never work directly under a supported load.

Do not move or dolly the vehicle while on the jack.

Place wheel chocks under vehicle wheels on both sides to prevent rolling.

Use in dry, well-lit areas.

Keep children and bystanders away. Children must never be allowed in work area. Do not let children

play on or around jack or lifted load.

Any jack that appears to be damaged in any way or is found to be worn or operates abnormally SHALL

BE REMOVED FROM SERVICE IMMEDIATELY UNTIL REPAIRED. It is recommended that a

manufacturer or supplier’s authorized repair facility make necessary repairs if the manufacturer or

supplier permits repairs.

Because of potential hazards associated with this type of equipment, NO ALTERATIONS SHALL BE

MADE to this product.

Only attachments and/or adapters supplied by the manufacturer shall be used.

Failure to heed these warnings may result in property damage, personal injury and/or death.