Jegs 79000 User manual

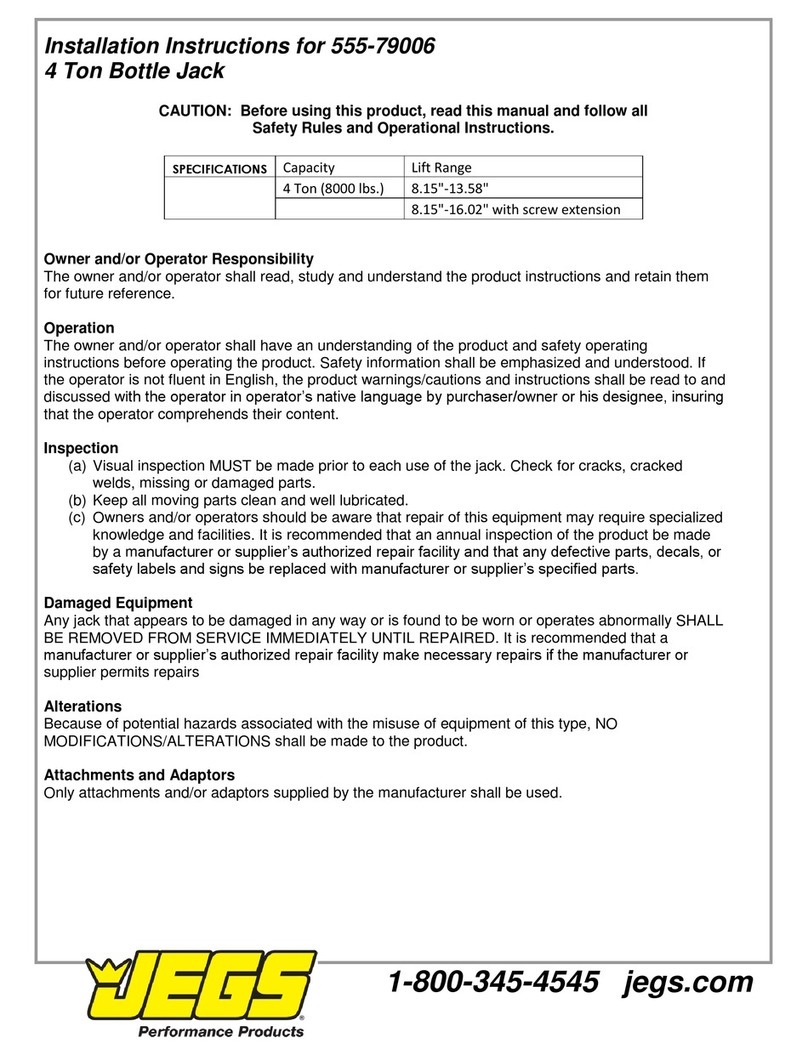

Installation Instructions for 79000

2-Ton Hydraulic Jack

SPECIFICATIONS

Capacity (Ton)

Lift Range

2

5-1/8" to 13"

1-800-345-4545 jegs.com

Owner and/or Operator Responsibility

The owner and/or operator shall read, study and understand the

product instructions and retain them for future reference.

Operation

The owner and/or operator shall have an understanding of the product

and safety operating instructions before operating the product. Safety

information shall be emphasized and understood. If the operator is not

fluent in English, the product warnings/cautions and instructions shall

be read to and discussed with the operator in operator’s native

language by purchaser/owner or his designee, insuring that the

operator comprehends their content.

Inspection

(a) Visual inspection MUST be made prior to each use of the jack.

Check for cracks, cracked welds, missing or damaged parts.

(b) Keep all moving parts clean and well lubricated.

(c) Owners and/or operators should be aware that repair of this

equipment may require specialized knowledge and facilities. It

is recommended that an annual inspection of the product be

made by a manufacturer or supplier’s authorized repair facility

and that any defective parts, decals, or safety labels and signs

be replaced with manufacturer or supplier’s specified parts.

Damaged Equipment

Any jack that appears to be damaged in any way or is found to be worn

or operates abnormally SHALL BE REMOVED FROM SERVICE

IMMEDIATELY UNTIL REPAIRED. It is recommended that a

manufacturer or supplier’s authorized repair facility make necessary

repairs if the manufacturer or supplier permits repairs

Alterations

Because of potential hazards associated with the misuse of equipment

of this type, NO MODIFICATIONS/ALTERATIONS shall be made to the

product.

Attachments and Adaptors

Only attachments and/or adaptors supplied by the manufacturer shall

be used.

Read, study and understand all instructions before operating

this device.

Do not exceed rated capacity. Over-loading may cause damage

to/or failure of the jack.

Always use only on hard, level surface. Do not use equipment

on slopes or angles.

Lifting device only. Jack must not be used as a jack stand to

hold loads for prolonged periods of time.

Immediately after lifting, support the vehicle with appropriate

means. Use jack stands in pairs to support loads. Inspect jack

stands before use as indicated by the manufacturer’s owner’s

manual.

Lift only on areas of the vehicle as specified by the vehicle

manufacturer’s owner’s manual.

Center load on the jack saddle. Off center loads can cause loss

of load or damages to load and/or equipment.

Never work directly under a supported load.

Do not move or dolly the vehicle while on the jack.

Place wheel chocks under vehicle wheels on both sides to

prevent rolling.

Use in dry, well lit areas.

Keep children and bystanders away. Children must never be

allowed in work area. Do not let children play on or around jack

or lifted load.

Any jack that appears to be damaged in any way or is found to

be worn or operates abnormally SHALL BE REMOVED FROM

SERVICE IMMEDIATELY UNTIL REPAIRED. It is

recommended that a manufacturer or supplier’s authorized

repair facility make necessary repairs if the manufacturer or

supplier permits repairs.

Because of potential hazards associated with this type of

equipment, NO ALTERATIONS SHALL BE MADE to this

product.

Only attachments and/or adapters supplied by the manufacturer

shall be used.

Failure to heed these warnings may result in property damage,

personal injury and/or death.

WARNING

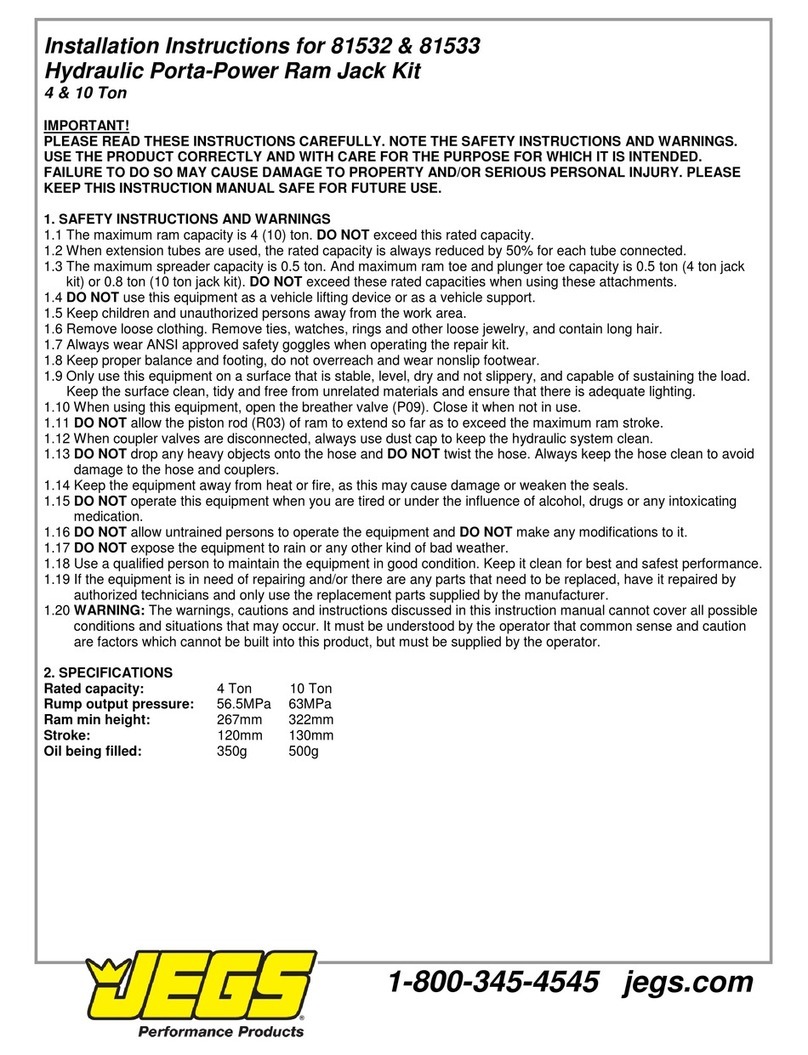

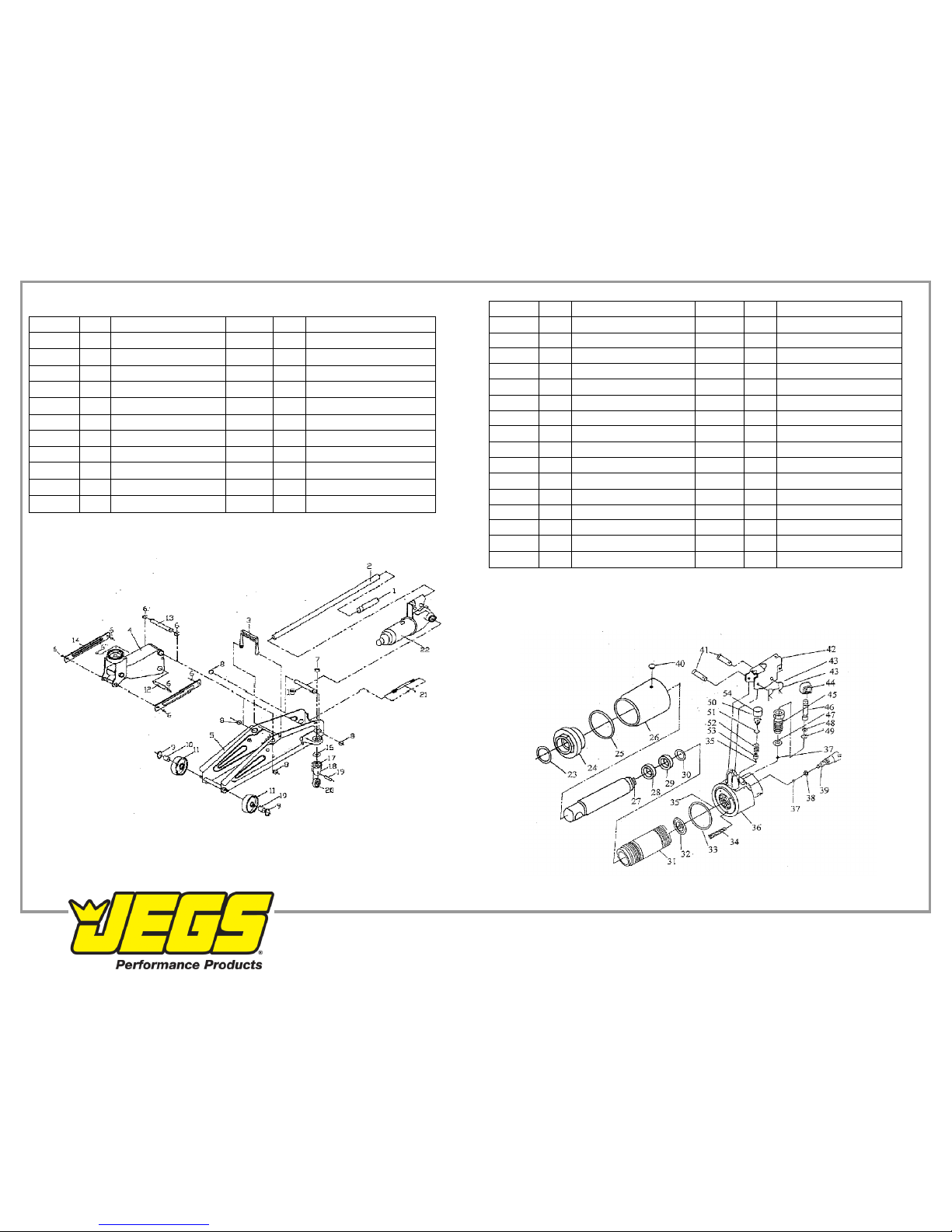

Main Jack Parts List

Main Jack Parts Diagram

Power Unit Parts List

Part #

Qty

Description

Part #

Qty

Description

1

1

Cap & Release Valve

12

1

Cross Head Pin

2

1

Handle

13

1

Spindle, Lifting Arm

3

1

Portable Handle

14

2

Radius Link

4

1

Lifting Arm

15

1

Anchor Bolt

5

1

Side Board

16

2

Steel Ball Bearing

6

8

Circlip

17

2

Bolt, Caster Wheel

7

2

Nut

18

2

Fork, Caster Wheel

8

4

Circlip

19

2

Spindle, Caster Wheel

9

2

Flat Washer

20

2

Caster Wheel

10

2

Spacer, Front Wheel

21

1

Return Spring

11

2

Front Wheel

22

1

Hydraulic Unit Assembly

Part #

Qty

Description

Part #

Qty

Description

23

1

Top Nut O-Ring

39

1

Release Valve

24

1

Top Nut

40

1

Filler Plug

25

1

Small Nylon Washer

41

2

Connector Pin

26

1

Oil Reserve

42

1

Operating Link

27

1

Ram

43

2

Split Pin

28

1

Collar

44

1

Spring Clip

29

1

Cup Seal Ram

45

1

Pump Cylinder

30

1

O-Ring Seal

46

1

Piston

31

1

Cylinder

47

1

Copper Washer

32

1

Copper Washer

48

1

Back Up Ring

33

1

Large Nylon Washer

49

1

O-Ring

34

1

Screen Filter Body

50

1

Overload Valve Screen

35

2

Steel Ball 3/16”

51

1

Overload Valve O-Ring

36

1

Power Unit Casting

52

1

Spring Overload Valve

37

2

Steel Ball ¼”

53

1

Spring Guard

38

1

Release Valve O-Ring

54

1

Cap

1-800-345-4545 jegs.com

Power Unit Parts Diagram

Problem

Possible Cause

Remedy

Saddle won’t rise

Lifts only half way

Lifts, then lowers out

of control

Erratic lift.

1. Release valve open.

2. Oil Exhausted.

3. Defective suction

and/or exhaust valve.

4. Packing worn out or

defective.

1. Insufficient oil.

1. Air in system.

2. Defective suction

and/or release valve.

3. Defective piston

packing.

1. Defective plunger

packing and/or valve.

1. Tighten release

valve.

2. Fill tank with oil.

3. Check for dust

or foreign

matter inside

and clean.

4. Replace

packing.

1. Check oil

supply and fill.

1. Open oil plug

on the front of

cylinder. Hold

saddle down.

Open release

valve and pump

handle several

times.

2. Clean valves

and adjust

valve contact.

3. Replace the

piston packing.

1. Clean valves

and/or packing.

1-800-345-4545 jegs.com

Operation

Prior to each use, visually inspect jack. Check for cracks, cracked welds, and

missing and/or damaged parts. Any jack that appears to be damaged in any of

these ways must not be used.

To Lift

(d) Turn the release valve clockwise to the closed

position. Do not over tighten.

(e) Consult the vehicle owner’s manual to determine the

location of jack points and position the jack under the

prescribed lift point. Be sure to set the vehicle parking

brake and lock the wheels.

(f) Be sure that the vehicle and the jack are on a hard,

level surface.

(g) Begin lifting by pumping the handle up and down.

(h) Always use jack stands in pairs to support loads at

locations recommended by the vehicle manufacturer.

Jacks are not designed to maintain heavy loads for

prolonged periods of time.

(i) Turn the release valve slowly counterclockwise to

lower the vehicle onto jack stands.

To Lower

(a) Turn the release valve clockwise to the closed

position. Do not over tighten.

(b) Pump the handle up and down to lift vehicle off jack

stands.

(c) Remove the jack stands. Do not get under or let

anyone under the vehicle while lowering.

(d) Turn the release valve slowly counterclockwise to

lower the vehicle onto the ground.

Maintenance

(a) Visual inspection MUST be made prior to each use of jack.

Check for cracks, cracked welds, missing or damaged parts.

(b) Keep all moving parts clean and well lubricated.

(c) Owners and/or operators should be aware that repair of this

equipment may require specialized knowledge and facilities. It

is recommended that an annual inspection of the product be

made by a manufacturer or supplier’s authorized repair facility

and that any defective parts, decals, or safety labels and signs

be replaced with manufacturer or supplier’s specified parts.

Troubleshooting

1-800-345-4545 jegs.com

Check and refill oil

Use hydraulic jack oil only. Do not use brake or transmission

fluids or regular motor oil or any other fluids as they may

damage the seals.

(a) Turn the release valve counterclockwise to allow ram

to fully retract. It may be necessary to apply force to

the saddle for complete lowering.

(b) With the jack in the level position, remove the oil fill

plug. Stand jack in a vertical position with the handle

socket down. The oil should be level with the bottom

of fill hole. If not, top off. Do not overfill. Always fill

with new, clean hydraulic jack oil.

(c) Replace oil fill plug and check jack operation.

(d) Purge air from system as required.

Air Purge Procedure

During shipment or after refilling oil, air may get into the

hydraulic system causing poor lift performance. Purge system

for better performance.

(a) Turn the release valve fully counterclockwise to fully

open the release valve.

(b) Pump handle rapidly several times

(c) Turn the release valve clockwise to close the release

valve.

(d) Pump the handle until the lift arm reaches maximum

height and continue to pump several times to remove

trapped air in the ram.

(e) Turn the release valve counterclockwise in one full

turn and lower lift arm to the lowest position. Use

force on saddle if necessary.

(f) Carefully and slowly pinch oil fill plug to release

trapped air.

(g) Turn the release valve clockwise to closed position

and check for proper pump action. It may be

necessary to perform the above steps more than

once to assure air is completely evacuated.

Other Jegs Jack manuals

Popular Jack manuals by other brands

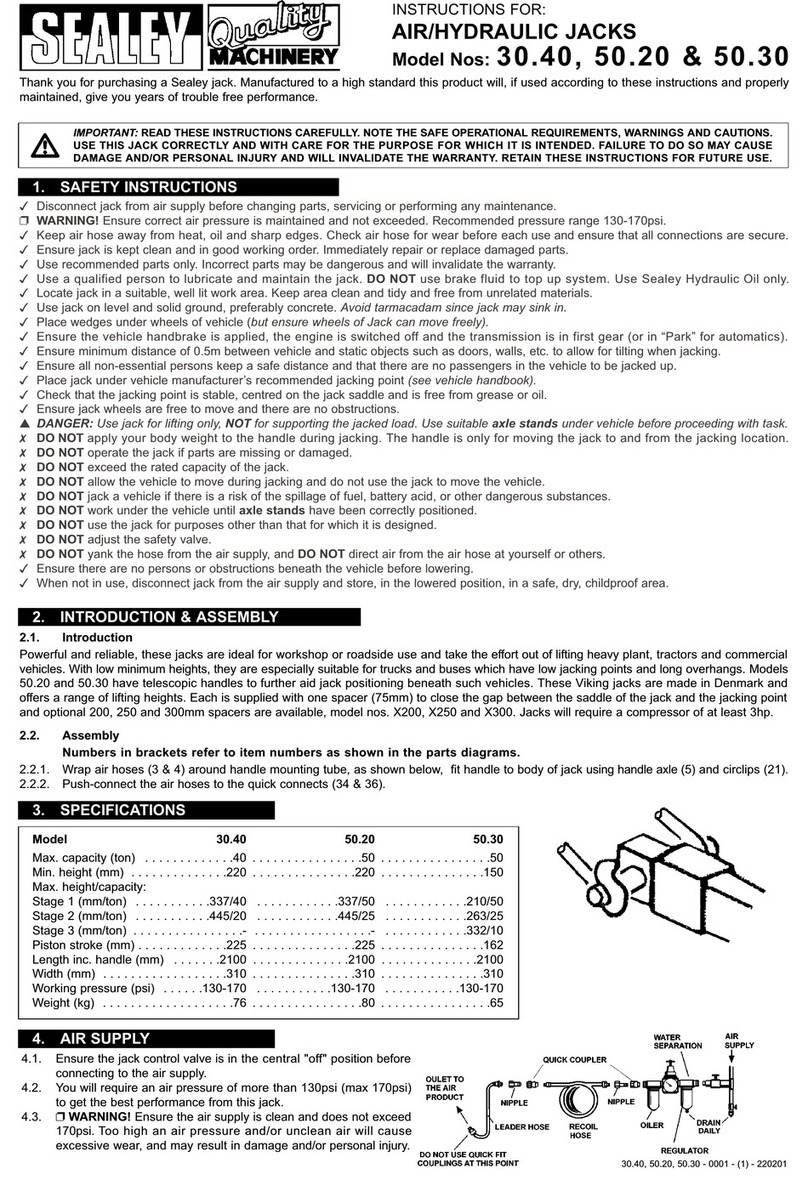

Sealey

Sealey Quality Machinery 30.40 instructions

Daytona

Daytona DS300SB Owner's manual & safety instructions

Vigor

Vigor V 2477 operating instructions

Cornwell Tools

Cornwell Tools CSE-ATV operating manual

Beta

Beta 3050/K Operation manual and instructions

Omega Lift Equipment

Omega Lift Equipment 22101C operating instructions

Sunex HD

Sunex HD 66037A owner's manual

Westward

Westward 1VW32 Operating instructions manual

Bannon

Bannon 55828 owner's manual

Lippert Components

Lippert Components LCI owner's manual

Clarke

Clarke CTJ1250AC Operation & maintenance instructions

Clarke

Clarke STRONG-ARM CTJ2500QLGB Operating & maintenance instructions