Jegs 79012 User manual

Installation Instructions for 79012

Low Profile Transmission Jack

1000 lb. Max Capacity

Maximum Height 23”

Minimum Height 8.5”

Warning

Read all safety warnings and instructions.

Save all warnings and instructions for future reference.

Failure to heed these markings may result in personal injury and/or property damage:

1. Study, understand, and follow all instructions before operating this device.

2. Do not exceed 1000 lb. rated capacity.

3. Use only on hard, level surfaces.

4. Adequately support the vehicle before starting repairs.

5. Use of this product is limited to the removal, installation, and transportation in the lowered position, of transmissions,

transfer cases, and transaxles.

6. Do not adjust safety valve.

7. Wear ANSI-approved safety goggles and heavy-duty work gloves during use.

8. Keep clear of load while lifting and lowering.

9. Lower load slowly.

10. Do not use for aircraft purposes.

11. Inspect before every use; do not use if parts loose or damaged.

12. Do not alter the jack or use attachments and/or adapters that are not supplied by the manufacturer.

13. The warnings, precautions, and instructions discussed in this manual cannot cover all possible conditions and

situations that may occur. The operator must understand that common sense and caution are factors, which cannot be

built into this product, but must be supplied by the operator.

14. The brass components of this product contain lead, a chemical known to the State of California to cause cancer,

birth defects (or other reproductive harm). (California Health & Safety Code § 25249.5, et seq.)

Save these instructions!

Setup

Read the ENTIRE IMPORTANT SAFETY INFORMATION section at the beginning of this manual including all text

under subheadings therein before set up or use of this product.

WARNING! TO PREVENT SERIOUS INJURY: Remove load from the jack before any procedure on this page.

Note: For additional information regarding the parts listed in the following pages, refer to Parts List and Diagram.

Assembly

1. Connect a Support (41) to each corner of the

Saddle (32) using a Bolt (39) and Washer (40).

2. Thread a Wing Nut (37) onto the threaded end of

the Chain Hook (38) with its wings facing the hook.

3. Slide a Washer (31) onto the threaded end of the

Chain Hook.

4. Insert the threaded end of the Chain Hook

through the hole on the bracket on the Saddle, as

shown.

5. Secure the Chain Hook to the Saddle’s bracket

using Washer (31) and Wing Nut (37).

1-800-345-4545 jegs.com

Checking/Filling Hydraulic Fluid

IMPORTANT! Before first use:

1. Remove the Oil Fill Plug.

2. Check hydraulic oil level and fill to 1/4" below the fill port as needed.

3. Replace the Oil Fill Plug.

4. Thoroughly test the Jack for proper operation. If it does not work properly, bleed air from its hydraulic system as

described in Bleeding, below.

Bleeding

1. Follow the Checking/Filling Hydraulic Fluid instructions above.

2. Turn the Release Valve counterclockwise to open it.

3. Pump the Handle up and down quickly several times to purge air from the system.

4. Check hydraulic oil level and fill to 1/4" below the fill port as needed.

5. Replace the Oil Fill Plug and close the Release Valve by turning it clockwise.

Operation

Read ENTIRE IMPORTANT SAFETY INFORMATION section at beginning of this manual including all text under

subheadings therein before set up or use of this product.

Removing a Transmission

1. Before every use, check and/or fill Hydraulic Fluid.

2. Once the vehicle is raised and secured on a lift, clear the area underneath the vehicle of people and tools.

3. Remove the Chain and set aside.

4. Move the Transmission Jack underneath the transmission.

5. Close the Release Valve.

6. Pump the Handle to raise the Transmission Jack.

7. Stop just below the transmission and align the Saddle to the Transmission with the Tilt Knobs.

8. Continue raising the Saddle up to the transmission to determine where you will need to adjust the Supports. All four

Supports need to grip and make contact with the transmission.

9. After determining where they need to be set, loosen the threaded bolts on each Support, and adjust it to the proper

setting for the transmission. Tighten the bolts.

10. Raise the unit again to make contact with the transmission, making sure all of the Supports are in firm contact.

11. Hook the chain on the open bracket, wrap the Chain securely around the transmission, and hook the chain hook

through the other end. Tighten the Chain Hook securely to tighten the chain.

12. Once it is securely fastened, release the bolts holding the transmission in place.

13. Make sure the area is clear of people and tools, and verify that the transmission is securely held in place. Then,

slowly open the Release Valve to lower the Transmission Jack.

14. Move the Transmission Jack from under the vehicle and perform your desired maintenance.

Replacing a Transmission

1. Move the Transmission Jack so that the transmission is lined up properly with its connection points.

2. Close the Release Valve.

3. Pump the Handle to gradually raise the Transmission Jack, while guiding it into place.

4. Secure the transmission into place using its hardware.

5. Double-check to make sure the transmission is securely installed.

6. Disconnect the Chain and remove it.

7. Clear the area near the Transmission Jack, and slowly open the Release Valve to lower the Jack.

8. Move the Transmission Jack clear of the vehicle.

1-800-345-4545 jegs.com

Maintenance and Servicing

Procedures not specifically explained in this manual must be performed only by a qualified technician.

WARNING!

TO PREVENT SERIOUS INJURY FROM TOOL FAILURE: Do not use damaged equipment. If abnormal noise or

vibration occurs, have the problem corrected before further use.

1. BEFORE EACH USE, inspect the general condition of the equipment. Check for:

• loose hardware,

• misalignment or binding of moving parts,

• visibly leaking hydraulic fluid,

• cracked or broken parts, and

• any other condition that may affect its safe operation.

2. Before each use and after the inspection, thoroughly test the Jack for proper operation prior to its actual use. If the

Jack appears not to be working properly, follow Bleeding instructions.

3. Periodically, inject grease into the Zerk fitting on the main platform of the Transmission Jack.

4. Change the hydraulic oil at least once every three years:

a. With the Jack fully lowered, remove the Oil Filler Plug on the side of the Housing.

b. Tip the Jack to allow the old hydraulic oil to drain out of the Housing completely, and dispose of the old hydraulic oil

in accordance with local regulations.

c. With the Jack upright, completely fill the Housing with a high quality hydraulic oil (not included) until the oil just

begins to run out of the Oil Fill Hole.

d. Open the Release Valve and pump the Handle to bleed air from the system.

e. Reinstall the Oil Filler Plug.

5. Wipe dry with a clean cloth. Then, store the Jack in a safe, dry location out of reach of children and other non-

authorized people.

Troubleshooting

WARNING!

TO PREVENT SERIOUS INJURY: Use caution when troubleshooting malfunctioning jack. Stay clear of supported load.

Completely resolve all problems before use. If solutions presented in Troubleshooting guide do not solve the problem,

have a qualified technician inspect and repair jack before use. After jack is repaired: Test it carefully without a load

by raising and lowering it fully, checking for proper operation, BEFORE RETURNING JACK TO OPERATION.

DO NOT USE A DAMAGED OR MALFUNCTIONING JACK!

POSSIBLE SYMPTOMS

Jack will

not lift at its

weight

capacity

Saddle

lowers

under

load

Pump

stroke

feels

spongy

Saddle will

not lift all

the way

Handle

moves

up when

Jack is

under

load

Oil leaking

from Filler

Plug

PROBABLE SOLUTION

(Make certain that the Jack is not supporting a load

while attempting a solution.)

X

X

Check that Release Valve is closed fully.

Bleed air from the system.

X

X

X

Valves may be blocked and may not close fully. To flush the

valves:

1.1. Lower the Saddle and securely close the Release Valve.

2.Manually lift the Saddle several inches.

3. Open the release valve and force the Saddle

down as quickly as possible.

X

X

X

Jack may be low on oil. Check the oil level and refill if needed.

Jack may require bleeding - see instructions

X

Unit may have too much hydraulic oil inside, check fluid level

and adjust if needed.

1-800-345-4545 jegs.com

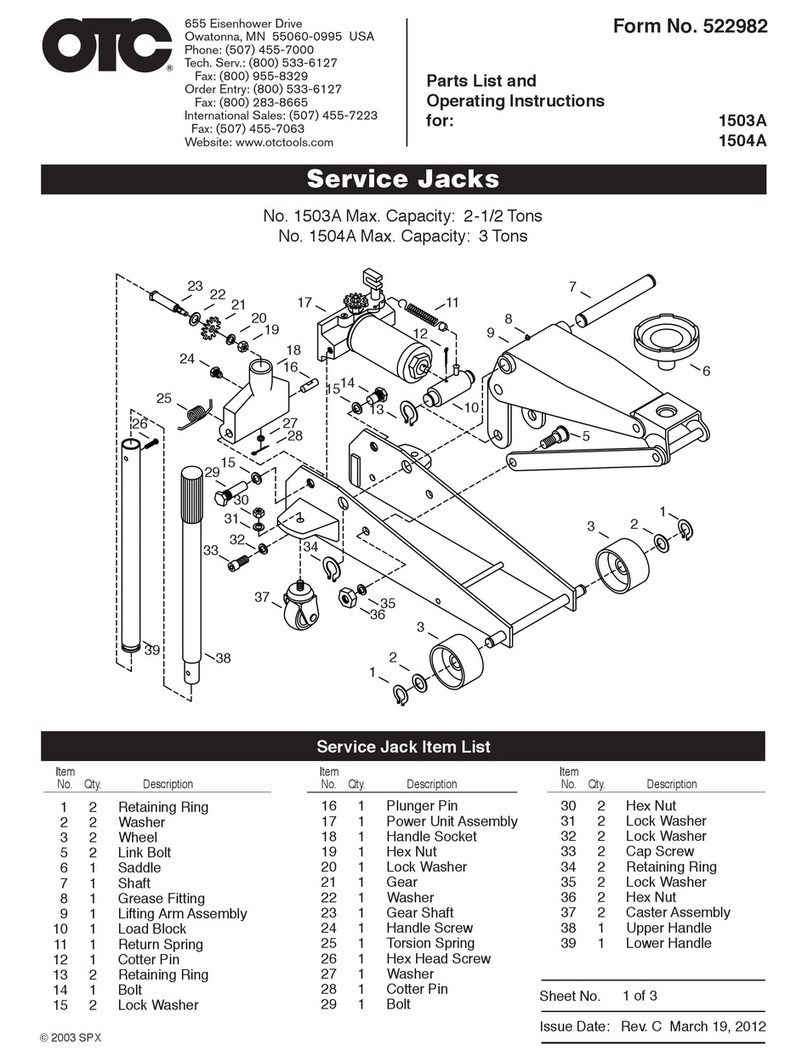

Parts List and Diagram

Part

Description

Qty

Part

Description

Qty

1

Bolt M6x16

16

22

Spring Pin Ø4.5x25

2

2

Caster

4

23

Shaft

1

3

Snap Ring “C”Ø22

2

24

Bearing

4

4

Washer Ø6

18

25

Shaft

1

5

Lock Washer Ø6

16

26

Nut M10

2

6

Nut M6

16

27

Snap Ring “c”Ø18

4

7

Hex Bolt M8x20

2

28

Shaft

1

8

Lock Washer Ø8

2

29

Short Screw Rod

1

9

Washer Ø8

2

30

Nut M12

1

10

Base Assembly

1

31

Washer Ø12

3

11

Hydraulic Pump Unit

1

32

Support

1

12

Long Shaft

1

33

Shaft

1

13

Split Pin 6x45

1

34

Tight Nut M10

1

14

Lifting Arm Assembly

1

35

Shaft

1

15

Long Connecting Rod

2

36

Chain

1

16

Snap Ring “c”Ø16

6

37

Wing Nut M6

2

17

Shaft

1

38

Hook

1

18

Shaft Sleeve

2

39

Bolt M10x16

8

19

Short Connecting Rod

2

40

Washer Ø10

14

20

Long Screw Rod

1

41

Shifting Stand

4

21

Turning Plate

1

42

Handle Assembly

1

1-800-345-4545 jegs.com

Other Jegs Jack manuals