2 | www.jema.as

Contents

Contents .........................................................................................................................................2

Introduction ....................................................................................................................................4

EU Declaration of conformity ..........................................................................................................5

Conditions for use...........................................................................................................................6

General information ........................................................................................................................7

Delivery ..................................................................................................................................7

Storage...................................................................................................................................7

Noise level measuring.............................................................................................................7

Type plate ..............................................................................................................................8

Construction ...........................................................................................................................8

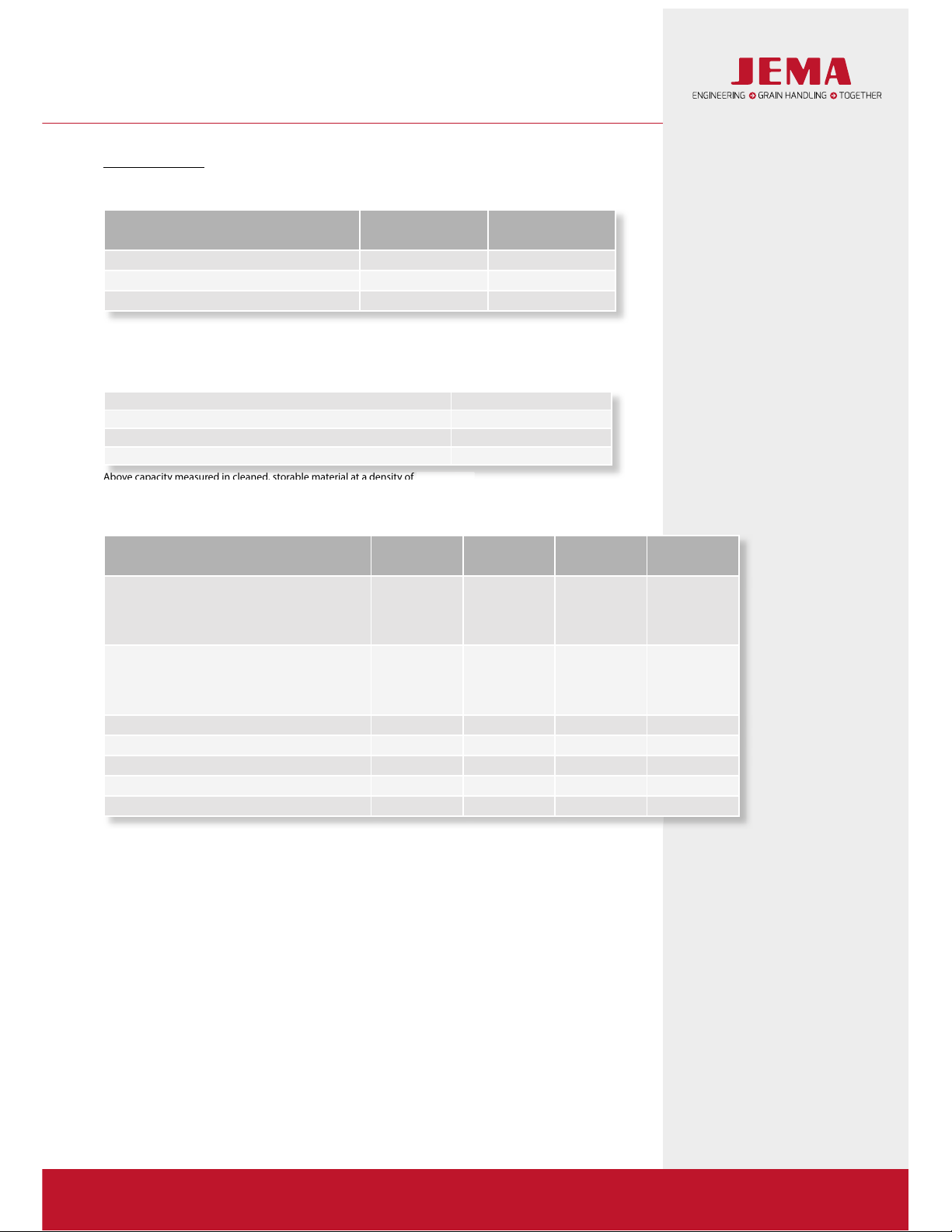

Capacity .................................................................................................................................9

Technical specifications – power consumption ......................................................................10

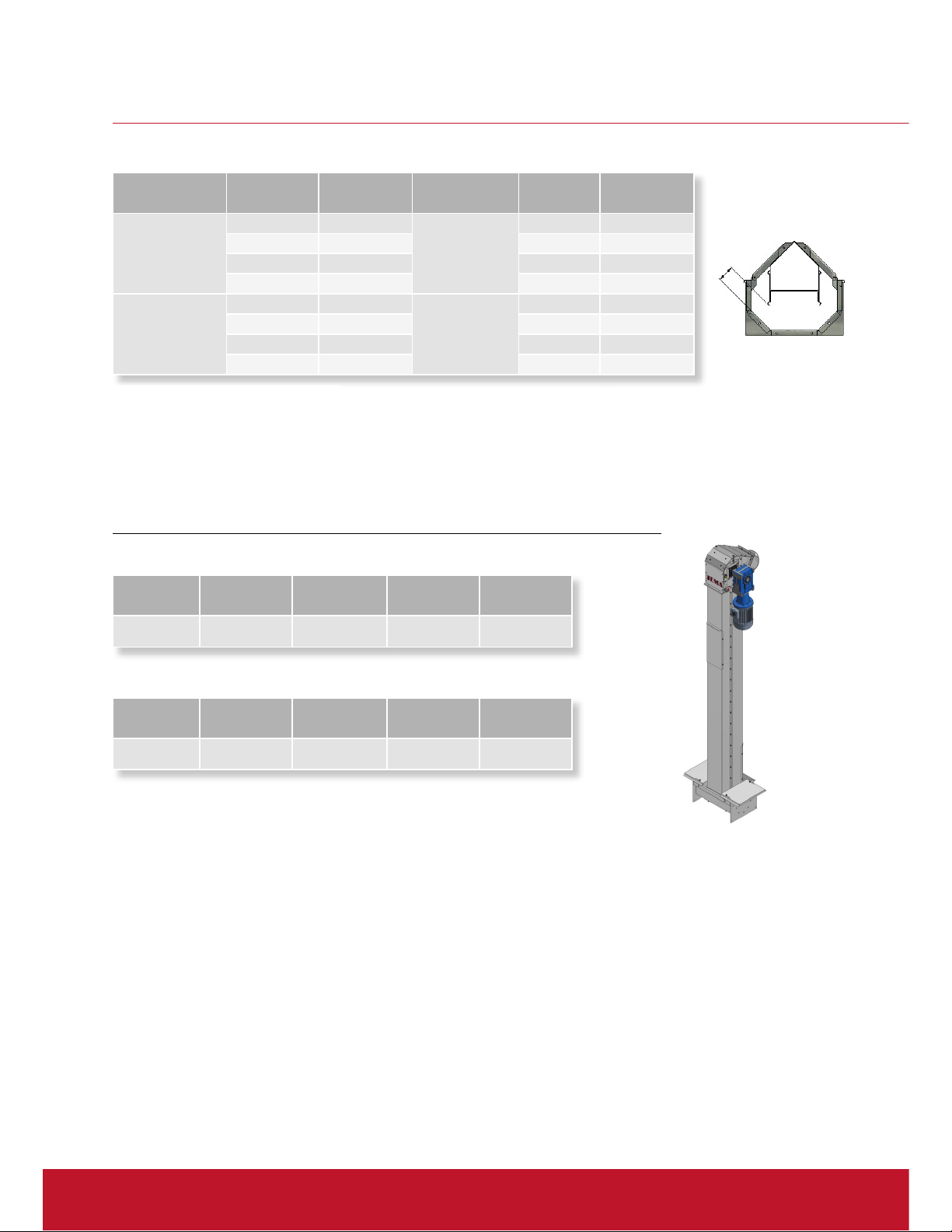

Elevator head .......................................................................................................................12

Elevator extension ................................................................................................................12

Elevator boot .......................................................................................................................13

Scale drawing T20/T40 .........................................................................................................14

Scale drawing T20/T40 with 90° bend ..................................................................................15

Upon receipt.........................................................................................................................16

Warning labels......................................................................................................................16

Foundation...........................................................................................................................17

Lifting equipment ................................................................................................................17

Lifting instructions ................................................................................................................18

Weight table – individual components T20/T40.....................................................................19

Weight table T20/T40...........................................................................................................21

Weight table T20 with 90° bend ...........................................................................................22

Weight table T40 with 90° bend ...........................................................................................23

Assembly ......................................................................................................................................24

Sealing .................................................................................................................................25

Elevator bottom section ........................................................................................................26

Elevator top section..............................................................................................................27

Elevator with auger trough d135 ..........................................................................................29

Elevator with 90° bend .........................................................................................................30

Fitting of gear motor ............................................................................................................31

Elevator extensions...............................................................................................................32

Elevator chain.......................................................................................................................33

Assembly of elevator ............................................................................................................35

Potential equalization ...........................................................................................................36

Height attachment................................................................................................................37

Support of increasing elevator ..............................................................................................38

Upstart ................................................................................................................................39

Elevator stops – faultfinding .................................................................................................39

Maintenance .................................................................................................................................40

Gear motor...........................................................................................................................40

Elevator chain.......................................................................................................................41

Rubber slats .........................................................................................................................41

Bearings ...............................................................................................................................41