jenway 570 User manual

pH, mV and Temperature Meter

Model 570

Instruction Manual

570 350/Rev B/05-17

3

Safety

Please read this information carefully prior to installing or using this

equipment.

1. The unit described in this manual is designed be to operated only by trained

personnel. Any adjustments, maintenance and repair must be carried out as

dened in this manual, by a person qualied to be aware of the hazards

involved.

2. It is essential that both operating and service personnel employ a safe system

of work, in addition to the detailed instructions specied in this manual.

3. Other than for those items dened in the maintenance procedures herein

there are no user serviceable items in this instrument. Removal of covers and

attempted adjustment or service by unqualied personnel will invalidate the

warranty and may incur additional charges for repair.

4. References should always be made to the Health and Safety data supplied

with any chemicals used. Generally accepted laboratory procedures for safe

handling of chemicals should be employed.

5. If it is suspected that safety protection has been impaired in any way, the unit

must be made inoperative and secured against any intended operation. The

fault condition should immediately be reported to the appropriate servicing

authority.

Merci de lire attentivement ces informations avant d’installer ou d’utiliser

cet appareil.

1. L’appareil décrit dans ce manuel est conçu pour être utilisé uniquement

par des personnes formées. Tout réglage, maintenance ou réparation doit

être effectué comme décrit dans ce manuel, par une personne qualiée

consciente des risques encourus.

2. Il est essentiel que les personnes utilisant et intervenant sur cet appareil

respectent les règles de sécurité de travail, en plus des instructions détaillées

précisées dans ce manuel.

3. En-dehors des éléments décrits dans les procédures de maintenance ci-

incluses, cet appareil ne contient aucun élément réparable par l’utilisateur.

L’enlèvement des capots et les tentatives de réglage ou de réparation par des

personnes non qualiées invalide toute garantie et entraîne un risque de frais

de réparation supplémentaires.

4. Toujours se référer aux ches techniques de santé et de sécurité

accompagnant tout produit chimique utilisé. Respecter les procédures de

laboratoire généralement acceptées pour la manipulation en toute sécurité

des produits chimiques.

5. Si l’utilisateur suspecte qu’un problème quelconque puisse mettre en

cause la sécurité, l’appareil doit être rendu inopérant en empêchant son

utilisation. Communiquer la défaillance constatée au service de maintenance

compétent.

Bitte lesen Sie diese Hinweise vor Installation oder Gebrauch dieser

Ausrüstung sorgfältig durch.

1. Das in diesem Handbuch beschriebene Gerät darf nur von geschultem

Personal bedient werden. Alle Anpassungen, Wartungsarbeiten und

Reparaturen müssen entsprechend der Vorgaben in diesem Handbuch und

von einer kompetenten Person, die mit den damit verbundenen Gefahren

vertraut ist, durchgeführt werden.

2. Es ist wichtig, dass sowohl das Bedienungs- als auch das Service-Personal

zusätzlich zu den detaillierten Anweisungen in diesem Handbuch ein sicheres

Arbeitssystem einsetzen.

3. Mit Ausnahme der Teile, deren Wartungsverfahren in diesem Handbuch

beschrieben sind, enthält dieses Gerät keine weiteren Teile, die vom Benutzer

gewartet werden können. Das Entfernen von Abdeckungen und Versuche

von hierfür unqualiziertem Personal, Anpassungen oder Wartungsarbeiten

durchzuführen, haben zur Folge, dass die Garantie verfällt und können

zusätzliche Reparaturkosten auslösen.

4. Es ist jederzeit auf die sicherheitsrelevanten Daten sämtlicher verwendeter

Chemikalien Bezug zu nehmen. Alle dazu vorhandenen Informationen,

Hinweise und Warnungen zur Handhabung, Lagerung, Verwendung und

Entsorgung müssen genauestens beachtet werden. Allgemein anerkannte

Labormethoden zum sicheren Umgang mit Chemikalien sollten eingesetzt

werden. Es ist jederzeit angemessene Sicherheitsausrüstung und persönliche

Schutzausrüstung zu verwenden.

5. Besteht der Verdacht, dass die Sicherheitsvorrichtungen in irgendeiner Weise

beschädigt wurden, muss das Gerät außer Betrieb genommen und gegen

weiteren Gebrauch gesichert werden. Die Störung sollte der zuständigen

Serviceeinrichtung unverzüglich gemeldet werden.

4

Leggere attentamente queste istruzioni prima di installare o utilizzare il

dispositivo.

1. L’unità descritta nel presente manuale è stata realizzata per essere utilizzata

solo da personale che ha ricevuto l’apposita formazione. Qualsiasi operazione

di regolazione, manutenzione e riparazione deve essere effettuata sulla

base di quanto indicato nel presente manuale da personale qualicato

consapevole dei rischi connessi.

2. È fondamentale che il personale operativo e il personale addetto alla

manutenzione utilizzino un

sistema di lavoro sicuro, oltre a seguire le istruzioni specicate nel presente

manuale.

3. Oltre a quelli indicati nelle procedure di manutenzione, all’interno di questo

dispositivo non sono

presenti altri elementi sui quali è possibile effettuare interventi. La rimozione

delle protezioni e qualsiasi

tentativo di regolazione o di manutenzione posto in essere da personale non

qualicato invaliderà la

garanzia. In questi casi, sarà necessario pagare un importo per le riparazioni

effettuate.

4. È sempre necessario fare riferimento ai dati sulla salute e sulla sicurezza

forniti con le sostanze chimiche utilizzate. Tutte le informazioni, i consigli e

gli avvertimenti disponibili sulla manipolazione, la conservazione, l’uso e lo

smaltimento devono essere rispettati attentamente. Adottare le procedure di

laboratorio generalmente accettate per la gestione delle sostanze chimiche.

Utilizzare sempre attrezzature protettive personali e di sicurezza adeguate.

5. Nel caso in cui si sospetti che la salute possa essere pregiudicata in qualsiasi

modo, disattivare l’unità per renderla inutilizzabile. Qualsiasi condizione

di errore deve essere immediatamente segnalata al responsabile per la

manutenzione.

Lea esta información atentamente antes de instalar o utilizar este equipo.

1. La unidad descrita en este manual está diseñada para que solamente la utilice

personal con formación. Cualquier operación de ajuste, mantenimiento y

reparación debe llevarse a cabo del modo indicado en este manual y debe

realizarla una persona cualicada que sea consciente de los peligros que

implica.

5

2. Es fundamental que tanto los operarios como el personal de servicio utilicen

un sistema de trabajo seguro, así como las instrucciones detalladas que se

especican en este manual.

3. Cualquier elemento que no se encuentre entre los denidos en los

procedimientos de mantenimiento aquí descritos no podrá utilizarse en este

instrumento. La extracción de las tapas y los intentos de ajuste o reparación

por parte de personal no cualicado invalidarán la garantía y pueden incurrir

en cargos adicionales por reparación.

4. Siempre deberían consultarse los datos sobre Salud y Seguridad que se

suministran con cualquier producto químico que se utilice. Deben respetarse

atentamente todas las indicaciones, recomendaciones y advertencias

disponibles en relación con la manipulación, el almacenamiento y la

eliminación de los productos. Es necesario llevar a cabo los procedimientos

de laboratorio de aceptación generalizada para la manipulación segura

de productos químicos. Se deben utilizar en todo momento los equipos

adecuados de seguridad y protección personal.

5. Si existe la sospecha de que las medidas protectoras de seguridad han

quedado dañadas en cualquier modo, la unidad debe inutilizarse y protegerse

contra toda operación que se intente llevar a cabo. El estado de fallo debe

comunicarse inmediatamente a la autoridad de servicio de mantenimiento y

reparación pertinente.

6

7

Contents

Page

SECTION 1 - Introduction 8

1.1 INSTRUMENT DESCRIPTION 8

1.2 INSTRUMENT SPECIFICATION 8

SECTION 2 – Installation 9

2.1 UNPACKING 9

2.2 INSTALLATION 9

2.3 DISPLAY AND CONTROLS 10

SECTION 3 – Temperature Adjustment 12

3.1 MANUAL TEMPERATURE ADJUSTMENT 12

3.2 AUTOMATIC TEMPERATURE CORRECTION (ATC) 12

SECTION 4 – Calibration and Measurement 13

SECTION 5 – Care and Maintenance 15

5.1 BATTERY REPLACEMENT 16

SECTION 6 – Accessories and Spare Parts 17

6.1 OPTIONAL ACCESSORIES 17

6.2 SPARES 17

SECTION 7 – Service and Support 18

7.1 SERVICE 18

7.2 TECHNICAL SUPPORT 18

SECTION 8 – Declaration of Conformity 19

SECTION 1 - Introduction

1.1 INSTRUMENT DESCRIPTION

Model 570 is a general purpose handheld pH, mV and temperature meter

offering 2 point calibration and automatic buffer recognition. This model

simultaneously displays either temperature compensated pH readings or

electrode potential and temperature.

1.2 INSTRUMENT SPECIFICATION

Model 570

Type pH, mV and temperature

Waterproof Yes (IP67)

pH Range -2 to 16pH

pH Resolution 0.01pH

pH Accuracy +/- 0.02pH

mV Range -1000 to 1000mV

mV Resolution 1mV

mV Accuracy +/-1mV

ATC 0 to 100°C

Temperature Range -39.9 to 149.9°C

Temperature Resolution 0.1°C

Temperature Accuracy +/-0.4°C (-10 to 70°C)

No. of Calibration Points 2

Automatic Buffer Recognition Yes – 4, 7 and 10 pH

Auto Shut Off 10 mins

Operating Temperature 0 to 100°C

Battery Life (hours) 2500

pH Connector BNC

Temperature Connector Waterproof Lumberg

screw-locking type

Dimensions (l x w x d) 141 x 71 x 32mm

Weight 230g

Instrument Warranty 2 years

Electrode/Temperature probe Warranty 6 months

8

SECTION 2 - Installation

2.1 UNPACKING

Remove the 570 meter from the packaging and ensure the following items

are included:

Model 570 pH and temperature meter (570 271)

Epoxy bodied combination pH electrode (924 001)

Temperature probe (170 101)

pH 4, 7 and 10 buffer sachets

3 x AAA alkaline batteries (tted)

Instruction manual (570 350)

Jenway Foreign Manual CD (JENMANCD)

2.2 INSTALLATION

Connect the electrode to the BNC socket on the instrument and remove the

protective cap covering the electrode. Connect the temperature probe to the

connector on the instrument and remove the protective sheath. Press the

ON/OFF key to turn the instrument on.

9

2.3 DISPLAY AND CONTROLS

The pH meter has an LCD display which displays either the temperature

compensated pH readings or electrode potential and temperature

simultaneously. The keypad used for this meter enables an easy and effective

way of calibrating and performing a measurement.

1. Display showing pH or electrode potential and temperature reading

2. Connector for temperature probe

3. BNC connector for pH electrode

4. UP arrow Key for adjusting values

5. DOWN arrow Key for adjusting values

6. On/Off key

7. MODE key to change the display between pH or mV and temperature

(single press), changing between °C and °F units (long press)

8. Calibration and Backlight key for calibrating the instrument and

switching on the backlight respectively

Fig. 2.3.1 – Display and Controls

10

1

3

2

4

6

7

85

The instrument will switch off automatically after 10 minutes of inactivity

(i.e. no key presses). To disable the auto-off function press and hold the Up

arrow key whilst switching the unit on. “Auto-off disable” will be displayed

across the screen. When the unit is turned off the auto-off function will be

re-enabled.

To change the instrument temperature units between °C and °F, press and

hold the MODE key for 3 seconds.

When the instrument is turned on a single press of the CAL and backlight key

will turn the backlight on. Another press will switch the backlight off. When

the backlight is on it will automatically turn off after 10 seconds. If the low

battery icon is showing the backlight function will not work.

If mV is selected instead of pH the instrument will read the voltage generated

by a pH, redox or ion type electrode within the range of ±1000mV.

11

SECTION 3 - Temperature Adjustment

Model 570 is supplied with a temperature probe enabling automatic temperature

compensation to be used. If the probe is disconnected then manual temperature

compensation can be used instead.

3.1 MANUAL TEMPERATURE ADJUSTMENT

If the temperature probe is disconnected ‘MANUAL’ will be displayed above

the temperature value. To manually adjust the temperature press or hold the

Up or Down arrow keys to adjust the temperature in whole degrees.

Note that manual temperature adjustment can only be performed if the

temperature probe is not connected.

3.2 AUTOMATIC TEMPERATURE CORRECTION (ATC)

When the temperature probe is connected the 570 meter will automatically

detect the connection and the temperature will be displayed continuously on

the screen. The pH reading will be automatically compensated depending on

the temperature of the sample being measured. The ATC range is 0 to 100°C

(32 to 212°F). If the temperature probe is removed the temperature will be

displayed for 10 seconds.

‘Hi Temp Err’ is displayed if the readings are above 100°C.

‘Lo Temp Err’ is displayed if the readings are below 0°C.

12

SECTION 4 - Calibration and Measurement

Before performing a measurement the instrument must be calibrated. It is

recommended that the instrument is calibrated daily to achieve consistent and

accurate results. Model 570 has a 2 point calibration process. The rst calibration

point MUST be buffer pH 7.00. The second calibration point depends on the

acidity of the solution which is to be measured. For samples with a pH around

5 the second calibration point should be 4.01 pH buffer. For samples with a pH

around 8 the second calibration point should be 10.01pH buffer. Always rinse

the pH and temperature probes in de-ionised water before placing in each buffer

solution. If the ATC probe is connected the instrument automatically compensates

for the resulting change in electrode response due to temperature during the

calibration process.

Press the ON/OFF key to switch the instrument on. If the temperature probe

is not connected ‘MANUAL’ will be displayed above the temperature value. If

manual temperature adjustment is being used, the temperature of the solution

must be measured using a thermometer so that the temperature can be manually

adjusted.

Place the pH electrode and temperature probe into 7.00 pH buffer solution and

allow the reading to stabilise. Stir then press and hold down the CAL key for 3

seconds. Auto-Cal will ash up on the display and then the current reading will be

displayed. Once the reading has stabilised press the CAL key, rinse the electrode

and temperature probe in deionised/distilled water and place them into 4.01 pH

or 10.01 pH solution and allow the reading to stabilise, again stir the solution to

remove any air bubbles. To nish press the CAL key, ‘Calibrated Ok’ will ash up

and the display will show the solution value of the buffer.

To abort the calibration point at any point press the ON/OFF key and the meter will

revert back to any previous calibration values.

During the calibration process the instrument will automatically detect the buffer

solution. However if you know the exact pH value for the buffer at a given

temperature (temperature coefcient) you can change the offset BS (buffer

solution 7.00pH) and slope BS (buffer solution 4.01 or 10.01) by using the Up

or Down arrow keys. Refer to your calibration solutions/capsules temperature

coefcients before any alterations are carried out.

13

‘FAIL’ will be shown if 7.00 pH buffer isn’t used as the rst calibration point.

If the electrode and buffer solution’s combined error is greater than 0.5 pH

or 30mV then ‘Error I/P’ will be displayed and the calibration aborted. If the

electrode and buffer solution’s combined error is greater than 30mV then ‘FAIL’

will be displayed and the calibration aborted. If the electrode and buffer solution’s

combined slope error (4.01 or 10.01) is greater than 0.5pH or 15% ‘Slope error’

will be displayed. If the slope error is greater than 15% the ‘FAIL’ will be displayed.

If an error is displayed during a correctly performed pH calibration this can be

investigated using the mV reading from the pH electrode to determine if the

electrode needs to be replaced. With the instrument in mV mode place the

clean/conditioned electrode and temperature probe into buffer pH 7.00 at a

temperature of 25°C and leave for 30 seconds to stabilise. Record the mV reading

(Asymmetry Potential). Rinse the electrode and temperature probe in distilled or

deionised water, blot and repeat the process in buffer pH 4.01. Record the mV

reading and calculate the difference between the two to obtain the span.

Example:

Reading at 7.00 pH: 4 mV

Reading at 4.01 pH: 178 mV

Span = 178 – 4 = 174mV

In order to calculate the slope percentage (Condition), divide the calculated span

by the theoretical span and times it by 100. The theoretical span between 7.00

pH and 4.01 pH is 176.9 mV.

Slope % = 174/176.9 x 100 = 98%

If your results are below 85% or your mV reading exceeds ±30mV at 7pH, then

you will need to replace the electrode.

Once the instrument is calibrated the sample can be measured. Place the pH

electrode and temperature probe into the sample and allow to stabilise.

If ‘Over Range pH Err’ is displayed the readings are higher than 16pH or 1000mV.

If ‘Under Range pH Err’ is displayed the readings are below -2pH or -1000mV.

If ‘No Probe Err’ is displayed the pH electrode is not connected.

14

SECTION 5 - Care and Maintenance

Over time the electrode sensor will degrade, but regular calibrating, cleaning and

the correct storage will prolong its life. The epoxy bodied combination electrode

supplied with this instrument is suitable for the majority of tests carried out in

aqueous solutions. For other applications, such as low ionic strength, Tris buffers,

high temperatures and strongly acidic solutions a more suitable pH/reference

electrode pair may be required. Details or advice are supplied on request

(cptechsupport@coleparmer.com).

If the electrode readings are slow or erratic, place the electrode into cleaning

solution or 7.00 pH solution for at least half an hour to one hour before testing

again. The temperature probe and pH electrodes are not waterproof and cannot

be fully immersed in water. It is recommended that the instrument is calibrated

daily to achieve consistent and accurate results.

The following general guidelines indicate the care and maintenance required:

Always rinse the pH electrode with cleaning solution or deionised water before

next use.

Electrodes should be stored:

● away from direct sunlight

● in a vertical position

● within their specied temperature range

Always ensure the electrode is used within its specied temperature range. Ageing

of electrodes used above their specied temperature is rapid and irreversible.

DO NOT touch the sensitive glass pH membrane or reference junction. Excess

droplets of solution may be removed by gently blotting with lter paper or tissue.

DO NOT rub the electrode as this may induce an electrostatic charge.

During use ensure the electrode is rinsed between each measurement to eliminate

the contamination of solutions.

15

5.1 BATTERY REPLACEMENT

Replace the battery when the battery icon is low.

This meter will continue to measure accurately but after further usage the meter

will display ‘FLAt bAT’ and shutdown.

Unscrew the screws on the back of the meter and replace with three AAA

batteries ensuring that the polarities are correct.

16

SECTION 6 - Accessories and Spare Parts

6.1 OPTIONAL ACCESSORIES

Part Code Description

025 037 pH 4 buffer (red, 500ml)

025 038 pH 7 buffer (yellow, 500ml)

025 039 pH 10 buffer (blue, 500ml)

025 179 pH 4 buffer sachets (pack of 10)

025 180 pH 7 buffer sachets (pack of 10)

025 181 pH 10 buffer sachets (pack of 10)

025 192 pH electrode storage solution (250ml)

025 161 pH electrode cleaning solution (500ml)

570 401 White silicon case for 570 pH meter

570 402 Blue silicon case for 570 pH meter

6.2 SPARES

Part Code Description of Spare Part

924 001 Epoxy bodied electrode

170 101 Temperature probe

033 275 Carry Case

17

SECTION 7 – Service and Support

7.1 SERVICE

Our dedicated service staff are on hand to help in the unlikely event that your

Jenway equipment develops a fault. Please contact them by one of the following

means with a clear description of the problem:

E-mail: cpservice@coleparmer.com

Tel: +44 (0) 1785 810475

On occasion it may be necessary for your equipment to be sent back to our

Service Department for repair. In this case please contact the Service Department

for a reference number which you should include with your faulty equipment.

Please also ensure you include a clear description of the fault and a completed

copy of our Decontamination Certicate. Please clearly mark the package for the

attention of the Service Department and post to the following address:

Cole-Parmer Ltd.

Beacon Road,

Stone,

Staffordshire,

ST15 0SA,

United Kingdom

All replacement parts are guaranteed for 6 months and where ever possible,

returned equipment is turned around in 5 working days.

7.2 TECHNICAL SUPPORT

Jenway have a dedicated Technical Support team made up of experienced

scientists who are on hand to help with any applications advice and questions you

may have about our products and how to use them. If you require any technical

or application assistance please contact the team at:

E-mail: cptechsupport@coleparmer.com Phone: +44 (0)1785 810433

18

SECTION 8 – Declaration of Conformity

and so we cannot guarantee that interference will not

occur in practice. Where there is a possibility that injury,

damage or loss might occur if equipment malfunctions

due to radio frequency interference, or for general

advice before use, contact the manufacturer.

This product meets the applicable EC

harmonised standards for radio frequency

interference and may be expected not to

interfere with, or be affected by, other equipment with

similar qualifications. We cannot be sure that other

equipment used in its vicinity will meet these standards

Plastic materials and articles intended to come into contact

with food.

Materials and articles intended to come into contact with

food.

Registration, Evaluation, Authorisation and Restriction of

Chemicals (REACH).

EU Regulation 10/2011

EC Regulation 1935/2004

EC Regulation 1907/2006

EU Declaration of Conformity

This declaration of conformity is issued under the sole responsibility of the manufacturer

Signed for and on behalf of the above manufacturer

Product Laboratory Equipment

Manufacturer Cole-Parmer Ltd

Beacon Road

Stone, Staffordshire

ST15 0SA

United Kingdom

File Number P225

Authorised Cole-Parmer

Representative Beacon Road

Stone, Staffordshire

ST15 0SA

United Kingdom

Object of Declaration Portable pH Meters

(reference the attached list of catalogue numbers)

The object of the declaration described above is in conformity with the relevant Union Harmonisation Legislation:

Additional Information

Place of Issue

Date of Issue

Authorised Representative

Title

Signature

Year of CE Marking: 2016

Stone, Staffordshire, UK

02 March 2016

Steve Marriott

Technical Director

References to the relevant harmonised standards used or references to the other technical specications in relation

to which conformity is declared:

IEC/EN 61010-1:2010

Safety requirements for electrical equipment for

measurement, control and laboratory use.

Part 1: General requirements.

Electrical equipment for measurement, control and

laboratory use. EMC requirements.

Part 1: General requirements (Class A).

IEC/EN 61326-1:2013

Low Voltage Directive

EMC Directive

RoHS Directive

2014/35/EU

2014/30/EU

2011/65/EC

Declaration of Conformity is also available to view online at www.jenway.com

Cole-Parmer Ltd.

Beacon Road,

Stone,

Staffordshire,

ST15 0SA,

United Kingdom

Tel: +44 (0)1785 812121

Email: cpinfo@coleparmer.com

Web: www.jenway.com

Table of contents

Other jenway Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Shot-Scope

Shot-Scope PRO L1 user manual

WATANABE ELECTRIC INDUSTRY

WATANABE ELECTRIC INDUSTRY AL-512 Series instruction manual

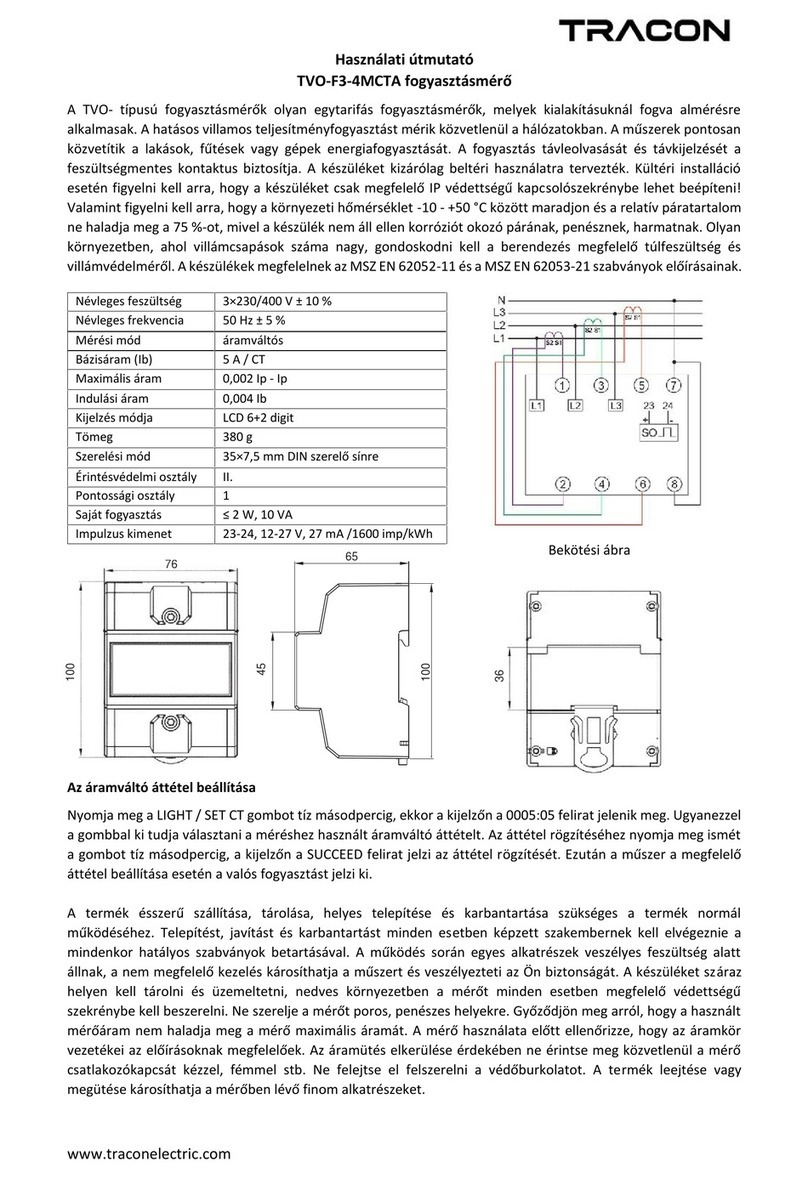

Tracon

Tracon TVO-F3-4MCTA user manual

YOKOGAWA

YOKOGAWA FLXA202 technical information

Yealink

Yealink BLT60 Direction for Installation and Use

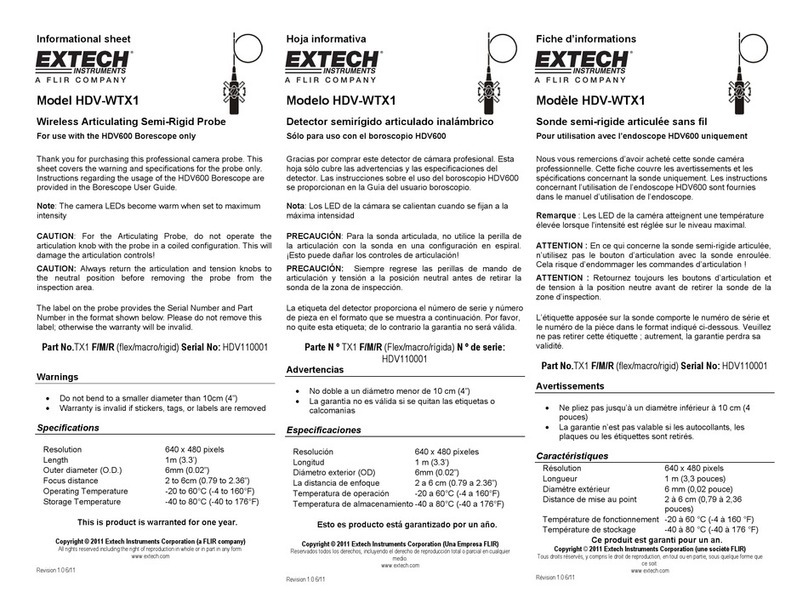

FLIR

FLIR EXTECH HDV-WTX1 Informational sheet

Fluidwell

Fluidwell F Series Operation manual

EUTECH INSTRUMENTS

EUTECH INSTRUMENTS STANDARD PHSCAN 2 PH TESTER Caractéristiques

Hanna

Hanna HALO2 instruction manual

HODAKA

HODAKA HT-1200N operating manual

PCB Piezotronics

PCB Piezotronics 3501B1260KG Installation and operating manual

Secure

Secure APEX 100 user manual