Jesco EASYPOOL SMART 02 User manual

EASYPOOL SMART 02

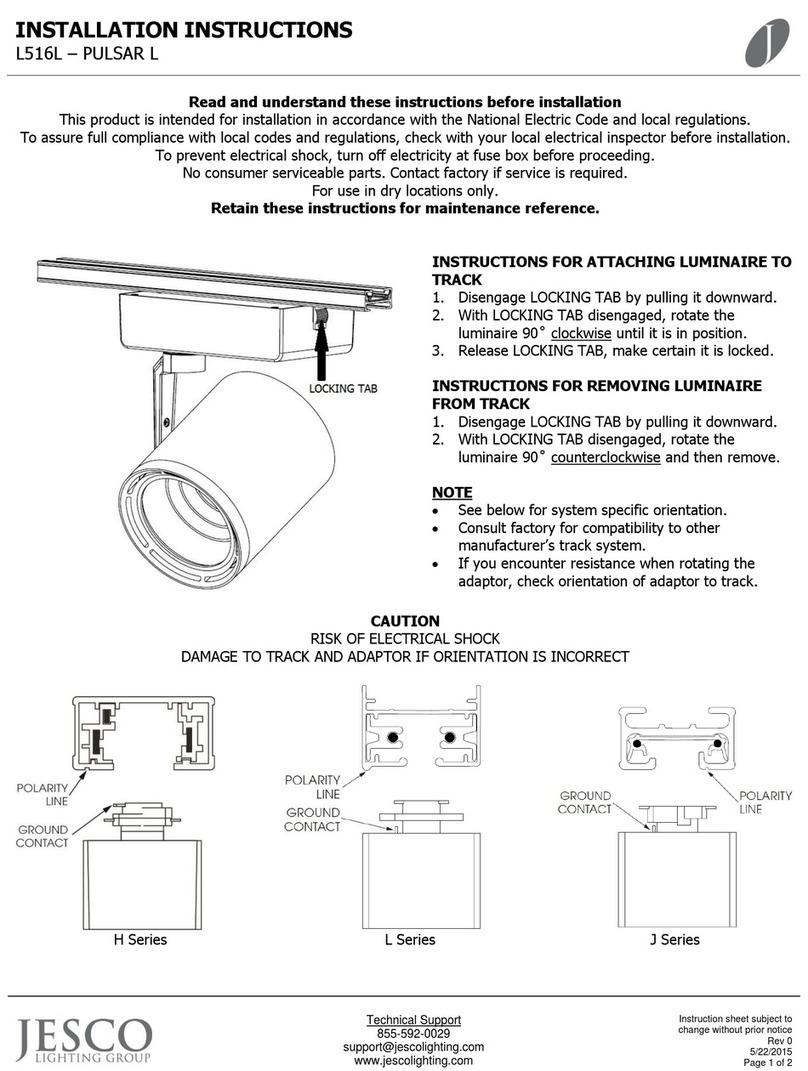

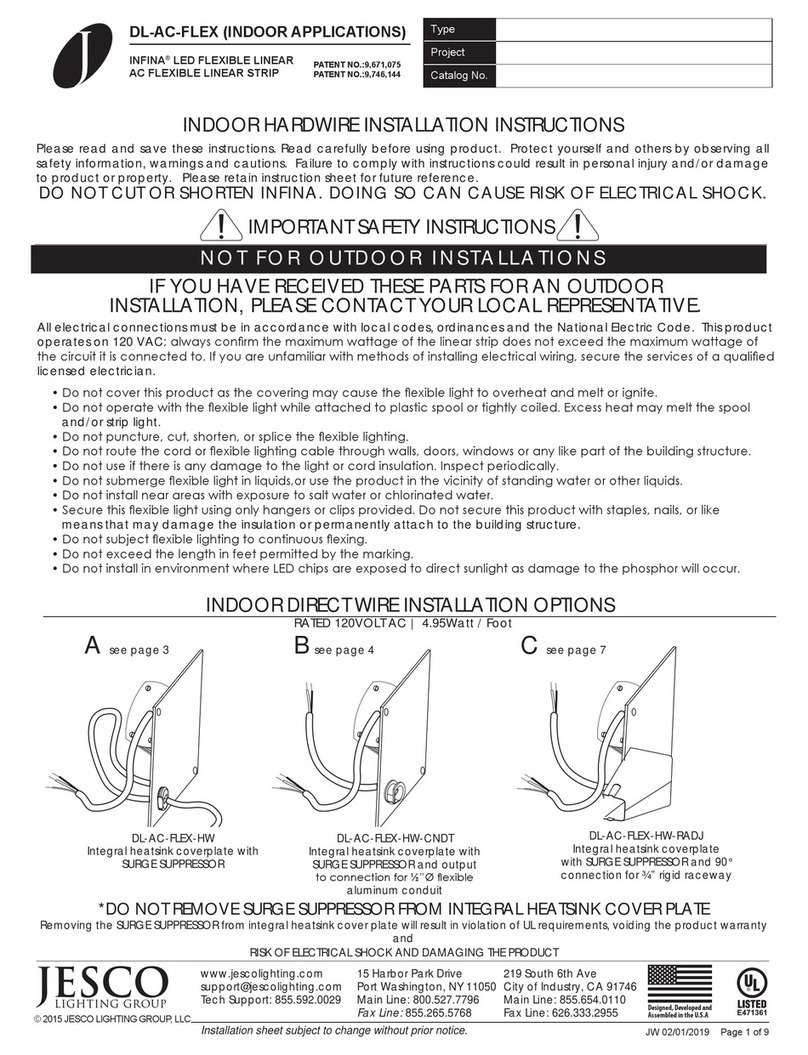

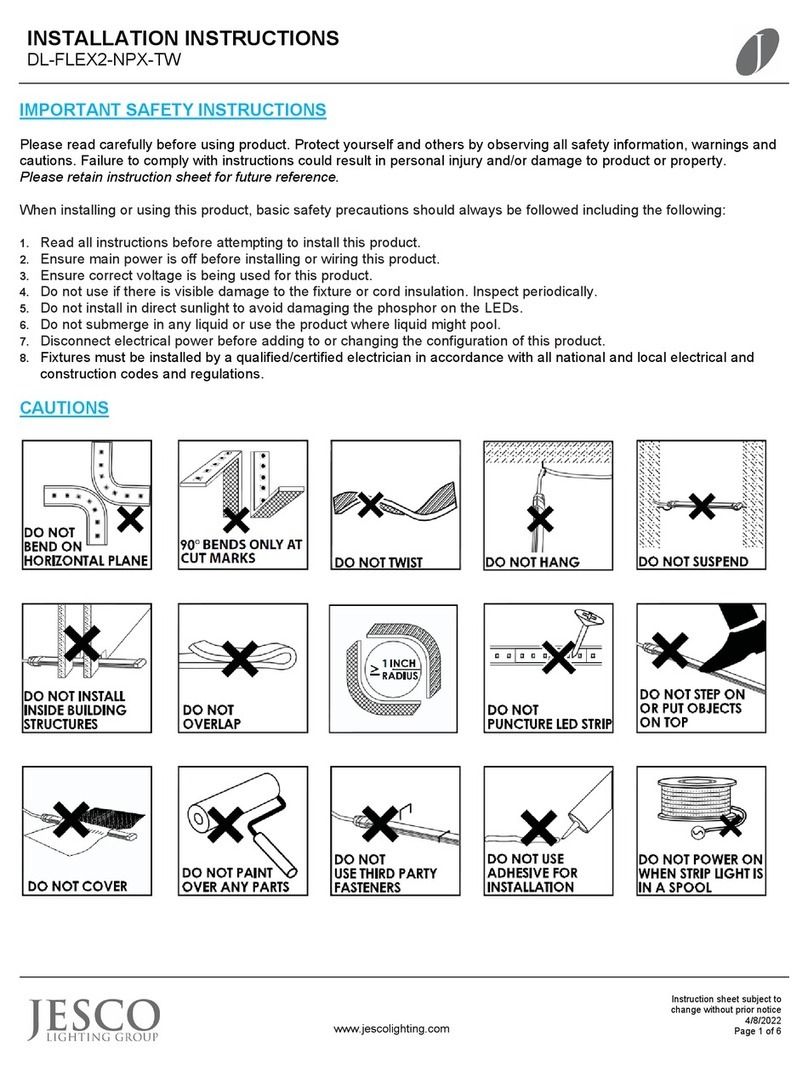

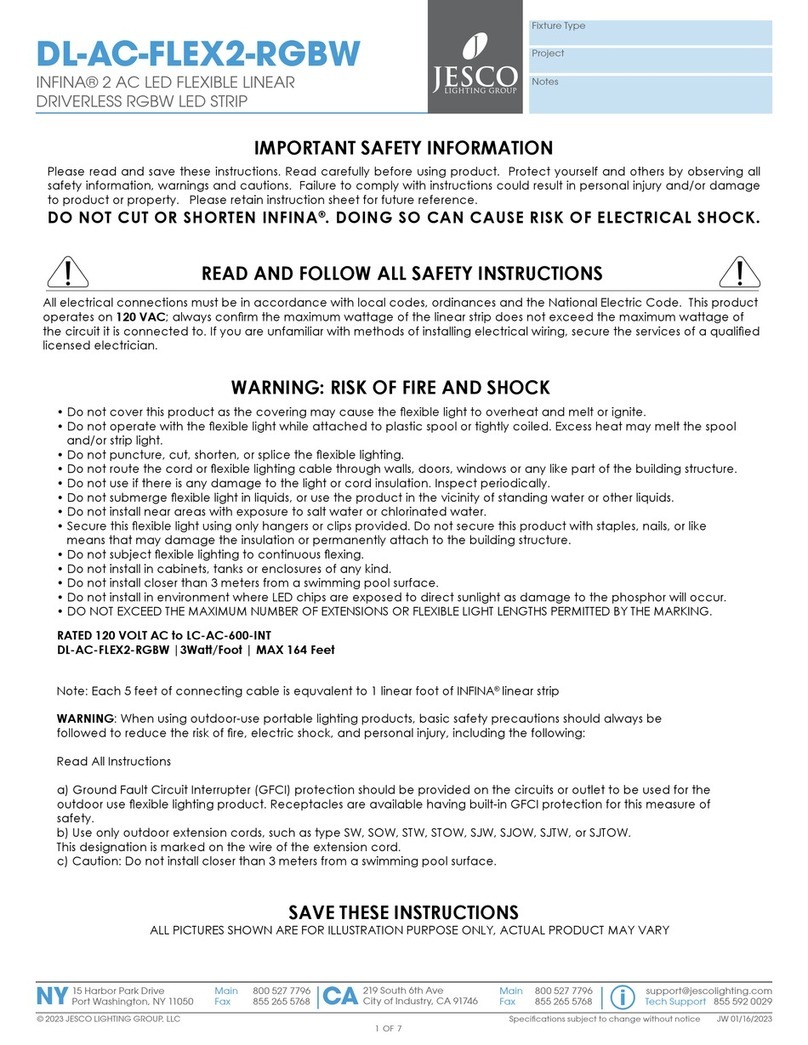

Water sampling station for private swimming pool applications

EN 01

Dosing

Conveying

Control

Liquids

Gases

Systems

Operating Manual

Read this operating manual before start-up!

To be retained for future reference.

2 | EASYPOOL SMART 02 Operating Manual

Table of Contents

Table of Contents

1. Safety Instructions .............................................................................. 3

1.1 General ................................................................................................ 3

1.2 Identification of safety instructions in this operating manual..................... 3

1.3 Operators qualification and training........................................................ 3

1.4 Electrical safety tips .............................................................................. 3

1.5 Hazards due to failure to follow safety instructions .................................. 3

1.6 Safety-conscious working...................................................................... 3

1.7 Safety instructions for the operator......................................................... 3

1.8 Safety instructions for installation, maintenance and inspection................ 4

1.9 Self-made modifications and spares procurement................................... 4

2. Before start-up .................................................................................... 4

2.1 Use for intended purpose....................................................................... 4

2.2 Scope of delivery .................................................................................. 4

2.3 Steps to start-up................................................................................... 4

3. Water sampling station ....................................................................... 5

3.1 Swimming pool water system ................................................................ 5

3.2 Versions ............................................................................................... 6

3.3 Dimensioned drawing............................................................................ 7

3.4 Water sampling station components....................................................... 7

3.5 Water sampling station technical data .................................................... 7

4. Controller ............................................................................................. 8

4.1 Technical data....................................................................................... 8

4.2 Product design...................................................................................... 9

4.3 Terminal diagrams for the main board and technical assemblies ............ 10

4.4 Operation and menu structure ............................................................. 17

4.5 Measurement value inputs................................................................... 18

4.6 Explanation of digital inputs ................................................................. 21

4.7 Control outputs ................................................................................... 22

4.8 Controllers.......................................................................................... 22

4.9 Alarms ............................................................................................... 24

4.10 Analogue power outputs 0/4 … 20 mA for remote displays................. 25

4.11 Controlling the flocculant pump.......................................................... 25

4.12 Service menu ................................................................................... 25

4.13 Memory card .................................................................................... 27

4.14 Connecting to the PC ........................................................................ 27

5. Installation and Commissioning ....................................................... 29

5.1 Tools required ..................................................................................... 29

5.2 Wall mount ......................................................................................... 29

5.3 Electrical connection ........................................................................... 29

5.4 Connection to the pool water circuit ..................................................... 29

5.5 Fitting and calibrating sensors ............................................................. 31

5.6 Starting automatic mode ..................................................................... 32

6. Shutdown, Recommissioning and Disposal ..................................... 33

7. Maintenance and Care....................................................................... 34

7.1 Regular inspection .............................................................................. 34

7.2 Annual maintenance............................................................................ 34

7.3 Adjusting the flow monitor (insufficient sample water)............................ 34

7.4 Peristaltic pump maintenance.............................................................. 34

8. Spare parts, Consumables and Accessories .................................... 35

9. Troubleshooting ................................................................................. 36

9.1 Troubleshooting and diagnostics .......................................................... 36

9.2 Fault resolution ................................................................................... 37

Device revision ...................................................................................... 37

Index ...................................................................................................... 38

CE declaration of conformity................................................................ 41

Declaration of no objection................................................................... 42

Warranty claim....................................................................................... 43

Dear Sir or Madam,

We are delighted you have chosen your EASYPOOL SMART 02

water sampling station. For over 50 years the name Jesco has

stood for innovative products in dosing technology, measurement

and control and water analysis. EASYPOOL SMART 02 continues

a successful product line of high quality water sampling sta-

tions.

Lutz-Jesco GmbH

Please note:

The water sampling station must be set up by someone with spe-

cialist knowledge of swimming pool technology and the bathing

water must be disinfected. Contact the engineer responsible for

installing your swimming pool if necessary.

To ensure full, unrestricted use of the product it must be han-

dled professionally during set-up, operation and servicing. You

should therefore read this operating manual before working on

the equipment.

EASYPOOL SMART 02 Operating Manual | 3

Safety Instructions

1. Safety Instructions

1.1 General

This manual contains very important information for assembly,

start-up, use and maintenance of the meter. The manual must

be read by all staff and any person in charge of the unit before

starting work on the equipment. Store the manual safely in a

place where mechanics, installers and other technical staff as

well as operators can rapidly access it in case of emergency. Pay

special warning and provide compliance with all safety notices

in this manual!

1.2 Identification of safety instructions in this operating

manual

This Operation & Maintenance Manual contains vital information

which may endanger people and the unit if they are disregarded.

These statements are identified by the following symbols:

WARNING!

Refers to a potentially hazardous situation. Failure to

follow this instruction may lead to death or extremely

serious injuries.

CAUTION!

Refers to a potentially hazardous situation. Failure to

follow this instruction may lead to minor injuries or

damage to property.

IMPORTANT! or NOTICE!

Failure to follow these safety instructions may en-

danger the machine and its functions.

IMPORTANT!

This indicates additional information that makes work

easier and ensures trouble-free operation. Notes

attached directly to the unit, e.g. cable references,

directly must be observed and kept in a fully legible

condition for future reference.

1.3 Operators qualification and training

Your assembly, operation, maintenance and inspection staff must

be trained and have the appropriate qualification for use and op-

eration of the unit. Area of responsibility, tasks and supervision

of the personnel must be provided at all times by the customer.

Unskilled operators must be duly trained and instructed. If neces-

sary, this can also be undertaken by the manufacturer or certi-

fied supplier on behalf of the owner. Operators who are to work

with the meter must read and understand the manual in all of

its parts.

1.4 Electrical safety tips

Basic safety precautions should always be followed when install-

ing and using this electrical equipment. These precautions in-

clude the following:

WARNING!

1.) Read and follow all instructions.

2.) To reduce the risk of injury, do not permit children

to use this product unless they are closely super-

vised at all times.

3.) Risk of electric shock. Ensure that the device is

secured with an earth-leakage circuit breaker (GFCI).

Contact a qualified electrician if you cannot verify

that the receptacle is protected by a GFCI.

4.) Do not bury the cable. Locate cord to minimize

abuse from lawn mowers, hedge trimmers, and

other equipment.

5.) To reduce the risk of electric shock, replace the

cable immediately if damaged.

6.) To reduce the risk of electric shock, do not use an

extension cable to connect the device to the power

supply; use an appropriately located outlet socket.

7.) Keep this instruction at close for future refer-

ence.

ATTENTION!

The device is not suitable for installation in explosive

areas.

1.5 Hazards due to failure to follow safety instructions

Failure to comply with the safety instructions may endanger not

only people, but also the environment and the unit. Non com-

pliance with the safety information will immediately cancel your

rights of claiming for damages even during the warranty period.

The following hazards in particular may arise: - Failure of system

functions. - Danger to people due to electrical, mechanical and

chemical effects. - Danger to the environment due to leakage of

hazardous substances.

1.6 Safety-conscious working

The safety instructions contained in this operating manual must

be observed. The operating company is responsible for ensuring

compliance with local safety regulations. Disturbances suscepti-

ble of impairing safety are to be eliminated immediately!

1.7 Safety instructions for the operator

Statutory regulations must be observed. A safe and ecologically

beneficial disposal of process materials as well as replacement

parts must be ensured. Danger due to electric current must be

excluded (for further details, refer to the German VDE1) standards

as well as local rules and regulations as well as chapter 1.4).

1) Association of German Electrotechnical Engineers

4 | EASYPOOL SMART 02 Operating Manual

Before start-up

1.8 Safety instructions for installation, maintenance and

inspection

The operator has to ensure that all assembly, maintenance and

inspection works are done by authorized and qualified technical

operators.

WARNING!

Assembly and maintenance of the equipment are

to be strictly done after disconnecting the device

from the power supply. It must be secured against

reconnection during the works! Auxiliary assemblies

and tools should be dismounted prior to maintain-

ing. Cables are to be attached likewise only in this

condition.

Neglecting of these instructions can lead to severe damages of

device and loss of warranty.

All safety mechanisms and guards must be refitted and reacti-

vated as soon as the work is complete.

NOTICE!

Apart from an incorrect installation also wrong con-

troller settings (default settings, data of the param-

eter and configuration level, and internal changes of

the instrument) can impair or damage the process

normal functions.

There should always be a safety device that is independent of the

controller. Configurations may only be carried out by technical

personnel! If necessary use password protection! Always comply

with the safety regulations and accident prevention laws of the

country of use.

1.9 Self-made modifications and spares procurement

The device may be converted or changed only by qualified tech-

nical personnel.

If the device is incorrectly configured by assembly or service

personnel, faults and hazards can arise during operation. In this

case, the manufacturer declines any liability.

NOTICE!

Genuine spare parts and sensors authorized by the

manufacturer ensure greater safety. Otherwise the

guarantee expires.

NOTICE!

Local safety instructions and applicable regulations

must be observed. The operating manuals of prod-

ucts used in the system must be observed, in par-

ticular the operating manual of the peristaltic pump

which is included separately with the water sampling

station.

2. Before start-up

2.1 Use for intended purpose

The EASYPOOL SMART 02 water sampling station is solely de-

signed for sampling and control applications in the preparation of

swimming and bathing water in swimming pools and whirlpools

not operated in accordance with DIN 19643. The operational

safety of the delivered unit can only be guaranteed when it is

used in conformity with its intended use.

Use for any other purpose is not permitted and will invalidate any

liability under the warranty.

2.2 Scope of delivery

Carefully check the delivery prior to installation to ensure the de-

livery is complete and to check for any transport damage. Con-

tact the supplier and/or carrier regarding any questions concern-

ing the delivery and/or transport damage.

Do not operate defective devices.

Items fixed to the EASYPOOL SMART 02 include:

TOPAX DX SMART controller

Temperature gauge (depending on model)

1-2 peristaltic pumps (depending on model)

Chlorine measuring cell (depending on model)

Wall holder

0

9

3

66

1

5

:;

87

4

2

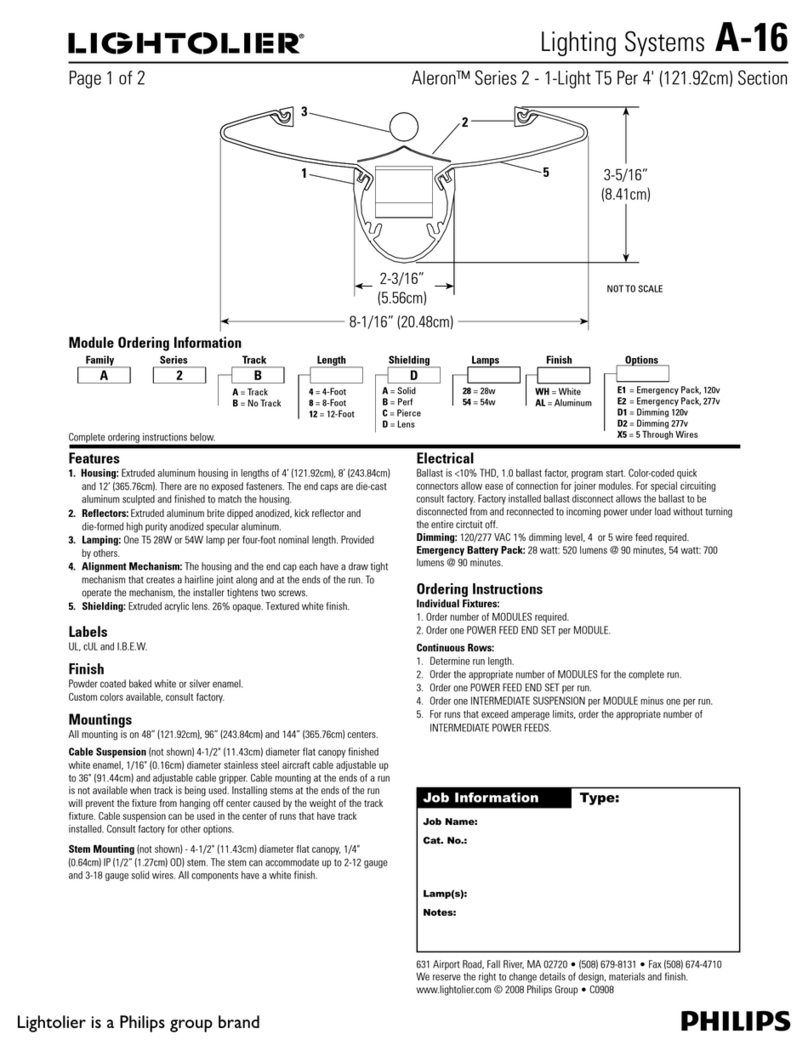

Fig. 2.1: Accessories supplied

Also included in the scope of delivery are:

a Mounting material

b 3 connections with ball valve

c 1-2 suction lines (depending on model)

d 1-2 Injection nozzles (depending on model)

e 1-2 x 5 m pressure line hose (depending on model)

f 10 m sample water line hose

g 2 sample water connections with G 1/4 male thread

h REDOX electrode (depending on model)

i pH electrode

j Buffer solutionsfor the pH- (6.8 and 9.27 pH) and REDOX

electrodes (465 mV)

k Set of decals for use on the water sampling station

l "Chlorine bleach..." warning decal (depending on model)

2.3 Steps to start-up

After reading the operating manual, assembly and start up the

equipment as detailed in chapter 5.

•

•

•

•

•

EASYPOOL SMART 02 Operating Manual | 5

Water sampling station

3. Water sampling station

The EASYPOOL SMART 02 water sampling station is a precise

tool for maintaining auxiliary bathing water hygiene parameters.

The EASYPOOL SMART 02 is highly compact and easy to use.

The base plate contains holes for guiding the water and housing

the sensors. As a result there is no need for external piping and

fittings and the water sampling station is highly compact.

The plate of the EASYPOOL SMART 02 water sampling station

contains all the components needed for controlled, optimum dis-

infection of the bathing water.

These include:

Several sensors for measuring the water values,

Valves, taps and connections

TOPAX DX SMART multi-channel controller (see chapter 4)

- to analyse the readings,

- to provide controlled supply of chemicals,

Pumps to deliver the chemicals.

0

12

4

3

5

Fig. 3.0: EASYPOOL SMART 02 water sampling station with TOPAX DX SMART

a, peristalitic pumps(s) b, Chlorine measuring cell c(depending

on model), needle valve d, temperature gauge e(depending on

model) and pH electrode f

The water sampling station is connected to the swimming pool

water system. All the items required for inclusion in the system

and for disinfection are either contained on the sampling station

or provided as accessories.

•

•

•

•

3.1 Swimming pool water system

In a typical installation a circulation pump delivers the bathing

water through a filter. When the disinfectant and the pH-adjust-

ing solution (normally a pH reducing agent) have been added, the

water returns to the pool via inlet nozzles. The water sampling

system is incorporated in this system.

IMPORTANT!

A continuous flow of water is required to achieve suc-

cessful sampling and control of the water quality. Any

deviations in the flow velocity and frequent interrup-

tions to the flow will have a negative effect on the

control system and hence the water quality.

The following functional diagram illustrates the instal-

lation.

a

g

e

d

c

b

f

h

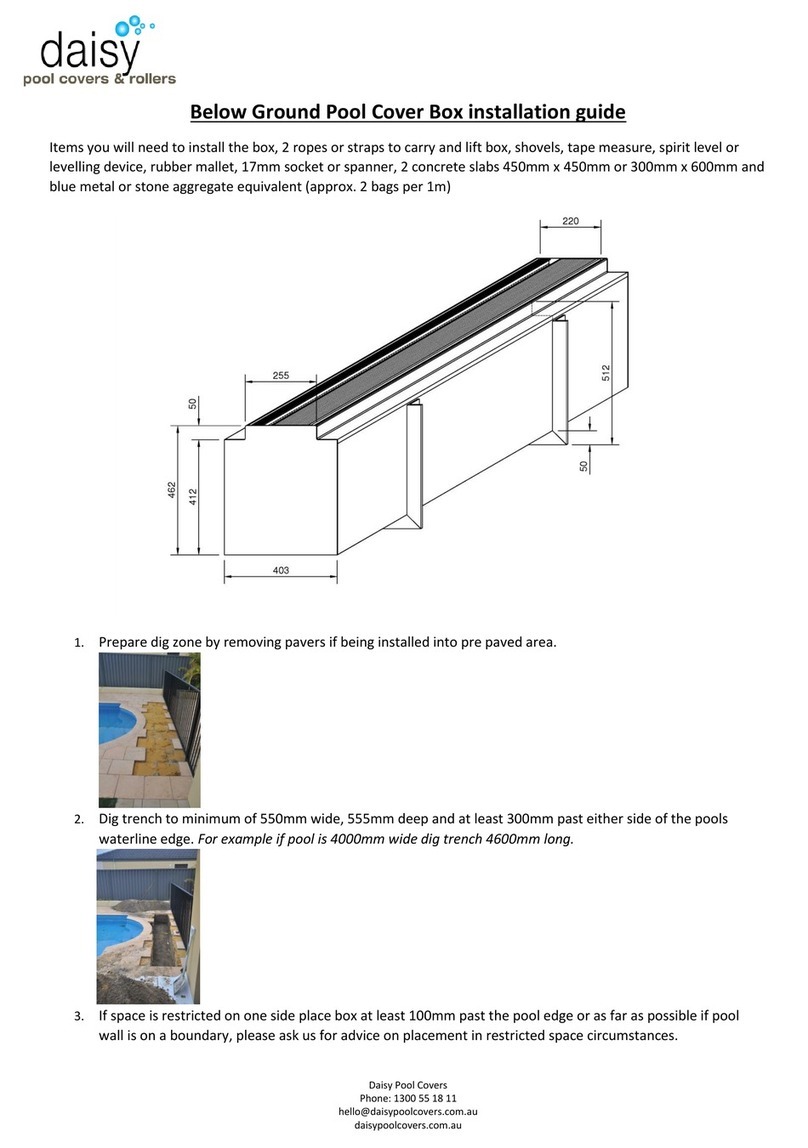

Fig. 3.1: Functional diagram of a swimming pool water system with an overflow

channel

aSwimming pool

bSplash water tank

cCirculation pump

dFilter

eSample water removal

fSample water return

g Injection nozzles for disinfectant and pH-adjusting solution

h Sample water filter

6 | EASYPOOL SMART 02 Operating Manual

Water sampling station

3.2 Versions

The EASYPOOL SMART 02 water sampling station comes in different versions.

The following overview shows the options:

Item no. Disinfectant Control

system

Sampling system

RS 485

Free chlorine REDOX

pH

Tem-

pera-

ture

Conductivity

Salt water Salt water

42401002

Chlorine bleach

Chlorine,

pH value

Yes - -

Yes

-

-

-

42401102 - Yes

42401005 Yes -

42401014 - Yes -

42401003

REDOX

pH value - Yes -

- -

42401004 Yes -

42401000 Active oxygen - -

42401010

Flow-through chlorine electrolysis,

0 … 20 mA

Chlorine,

pH value

- Yes -

Yes

- -

42401001 Chlorine,

pH value,

Conductivity

0 … 20 mS/cm

-

42401006 Yes

42401011 Flow-through chlorine electrolysis,

ON/OFF

Chlorine,

pH value - - -

42401007

Flow-through chlorine electrolysis,

0 … 20 mA

REDOX,

pH value

- - Yes

- - Yes

42401009

REDOX,

pH value,

Conductivity

- 0 … 20 mS/cm -

42401008

Flow-through chlorine electrolysis,

ON/OFF

REDOX,

pH value - - -

42401012

REDOX,

pH value,

Conductivity

- 0 … 20 mS/cm -

42401016 REDOX,

pH value Yes - Yes

Table 3.2: EASYPOOL SMART 02 versions

EASYPOOL SMART 02 Operating Manual | 7

Water sampling station

3.3 Dimensioned drawing

465

504

385

454

167

454

504

167

465

385

1

234

⑮

6

8

⑬;

9

5

:

0

7

⑭

⑯

⑰

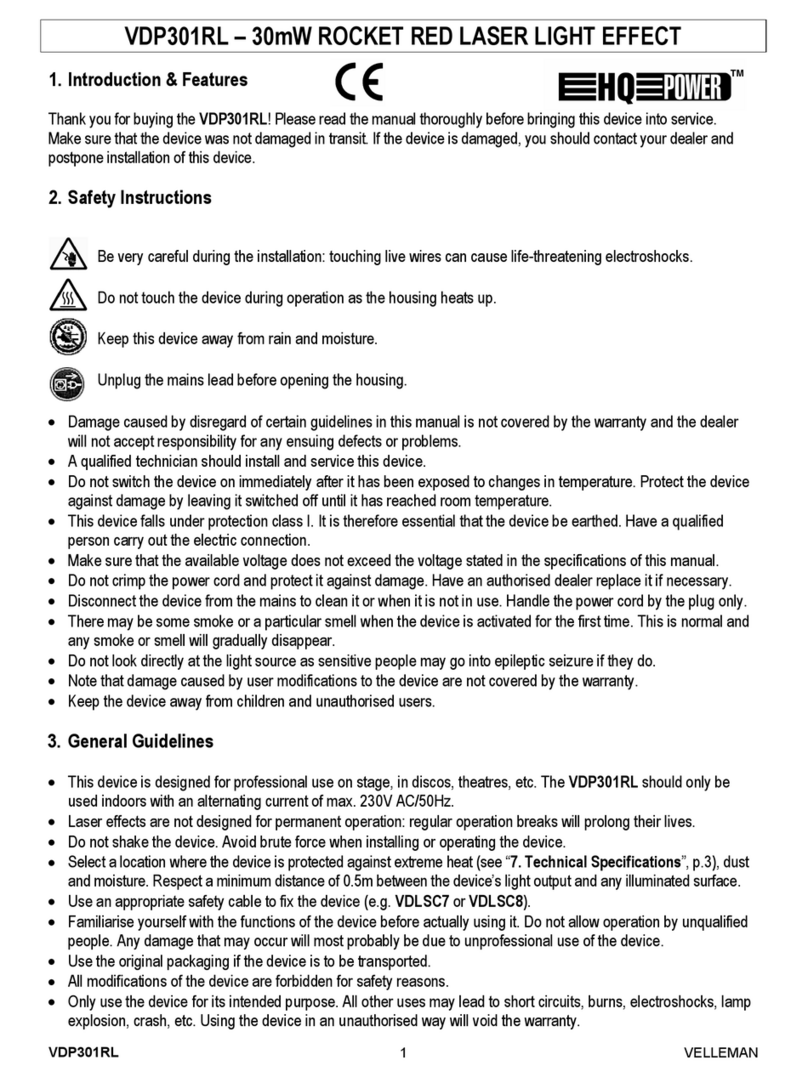

Figs. 3.3.1 and 3.3.2: EASYPOOL SMART 02 with 2 peristaltic pumps (left) and EASYPOOL SMART 02 with conductivity transmitter and one peristaltic pump (right)

3.5 Water sampling station technical data

Water sampling station

Free chlorine sensor 2-electrode measuring cell with

automatic electrode cleaning

Platinum/copper electrodes

(platinum/silver for salt bathing

water)

0 … 10 mg/l

REDOX potential sensor Single rod measuring cell

Platinum electrode (gold for salt

bathing water)

0 … 1000 mV

pH value sensor Single rod measuring cell

Glass membrane electrode

2 … 12 pH

Temperature sensor Resistance thermometer

Pt100 electrode

0 … +80 °C

Conductivity sensor Conductive measuring cell

Stainless steel / PP electrode

Output signal 4 … 20 mA

0 … 20 or

0 … 60 mS/cm

Operating pressure 0.2 . . . 3 bar

Operating temperature 5...40 °C

Water requirement approx. 45 l/h

Weight approx. 11 kg

Hydraulic connections Clamped connection for 6/8 mm PE tubing

Conductivity transmitter

Power supply 230 V AC, 50 … 60 Hz

Output signal 4 … 20 mA

Working resistance load max. 800 Ω

Protection class IP 65

Ambient temperature max. 55 °C

Housing PP

Peristaltic pump

Power supply 230 V AC, 50 Hz

See also attached peristaltic pump operating manual.

3.4 Water sampling station components

aWater sampling station

bTOPAX DX SMART controller

cConductivity sensor (depending on model)

dpH sensor

eREDOX sensor (depending on model)

fTemperature sensor (depending on model)

gFree chlorine sensor (depending on model)

hFlow monitors

iSampling water inlet with stop valve

jSampling water outlet with stop valve

kWater sample tap connection

lDisinfectant peristaltic pump

⑬pH-adjustment solution peristaltic pump

⑭Wall holder

⑮Needle valve for flow control

⑯Hinges

⑰Anti-oscillation retaining screw

rConductivity transmitter

r

8 | EASYPOOL SMART 02 Operating Manual

Controller

4. Controller

The EASYPOOL SMART 02 water sampling station is equipped with the TOPAX DZ SMART multi-channel controller. This device uses the

TOPAX DX technology designed for public swimming pools and has been specially configured for use in non-DIN 19643 operated swim-

ming pools. It features a graphic colour display, an intuitive user interface with support for the installation and maintenance of the water

sampling station.

4.1 Technical data

Power supply 90 … 264 V AC, 47 … 63 Hz

Power consumption approx. 24 W

Housing dimensions 302 x 231 x 108 mm (W x H x D) wall mounted unit

Display Graphic colour display 5.7 inch, 320 x 240 pixels (RGB), with background lighting

Keyboard Keypad

Measuring inputs

(potential-free)

• Free chlorine

• pH value

• REDOX potential

• Temperature

• 4 … 20 mA for conductivity (passive)

Regulating characteristic for 3 inputs

(free chlorine, pH value, conductivity)

P, PI, PD or PID performance

Disinfection output also with timer control system

Control parameters Xp: 1 … 500%, Tn: 1 … 200 minutes, Tv: 1 … 1200 seconds

Measuring input Free chlorine Open amperometric measuring cell with mechanical cleaning (excess chlorine detector with 2 electrodes, CS120)

Measuring range adjustable between 0 … 1, 0 … 2, 0 … 5 or 0 … 10 mg/l. Connected via series terminals*

pH value 0 … 14 pH, input resistance 109Ω connection via line-up terminals*

REDOX potential 0 … 1000 mV, input resistance 109Ω

Temperature -10 … +150 °C

Conductivity conductiv or inductive

with separate measuring amplifier

20 mA type, measuring range depending on type of measuring amplifier

Digital inputs • Early warning level input for disinfectant

• Warning level input for disinfectant

• Early warning level input for pH adjustment solution

• Warning level input for pH adjustment solution

• Filter cleaning: disconnection of the controller function without alarm

• Insufficient sample water: disconnection of the controller function with alarm

2-3 control outputs Digital output (optocoupler) 48 V DC, 250 mA (pulse frequency 10 … 200 pulses/min)

Relay output • ON/OFF

• Pulse frequency 10 … 100 pulses/min

• Pulse length 10 … 120 seconds

Continuous analog output 0/4 … 20 mA, max. working resistance 500 Ω

Alarm output Relay output as common alarm for all readings

Measuring value alarm min. and max. alarm freely adjustable, adjustable time delay: max. 200 min

Safety shut off To prevent overdosing (Y alarm), time delay adjustable: max. 200 min

Current outputs to remote transmission of

measuring values

• Free chlorine

• pH value

• REDOX potential

• Temperature and conductivity

0/4 … 20 mA possible spreading; max. working resistance 500 Ω potential free

average spreading >50 % with measuring input free chlorine and 0/4 ... 20 mA

>10 % with measuring input pH value and REDOX potential

Computer interface (optional) RS 485

Support battery VARTA CR 1/2 AA 2 V lithium (soldered in), useful life approx. 5 … 10 years

Load capacity of the relay 230 V AC, 3 A

Protection class IP 65 with locked screw connections

Ambient temperature -5 … +45 °C

Atmospheric moisture 95 % non-condensing

*) max. 0.5 mm² with cable ends protection sleeve and max. 1.0 mm² without cable end sleeve.

EASYPOOL SMART 02 Operating Manual | 9

Controller

4.2 Product design

The front housing aand the rear housing bof the controller

are fitted together with two pivots (cand d) (see Fig. 4.2).

The unit is designed so that the controller can be opened from

either side.

db

c

a

e

f

Fig. 4.2: Housing structure

aFront housing

bRear housing

cHinge pivot (fitted)

dHinge pivot (disassembled)

ePivot head (screw-on)

fPivot disassembly tool

Opening the casing

To open the housing it is preferable to remove the right pivot. To

do this, unscrew head eof the pivot.

NOTICE!

In order to open the housing remove only one hinge

pivot from the equipment. If both bolts are removed

at the same time, the upper part and the lower part

of the box will fall loose.

NOTICE!

The equipment is to be opened only when plugged

off the power supply.

reare housing

The rear housing contains the main board with slots for the func-

tional assemblies. Depending upon the model, two input blocks

are available together with an output block. For create a network

connected to a PC, an interface assembly (RS 485) can also be

installed. All blocks are connected by plug connectors to the main

board and fastened with several nuts.

front housing

On the front housing there are the display plate and the key-

board. A colour display is available for displaying measurements

and adjustments. The display board contains the memory card

slot.

10 | EASYPOOL SMART 02 Operating Manual

Controller

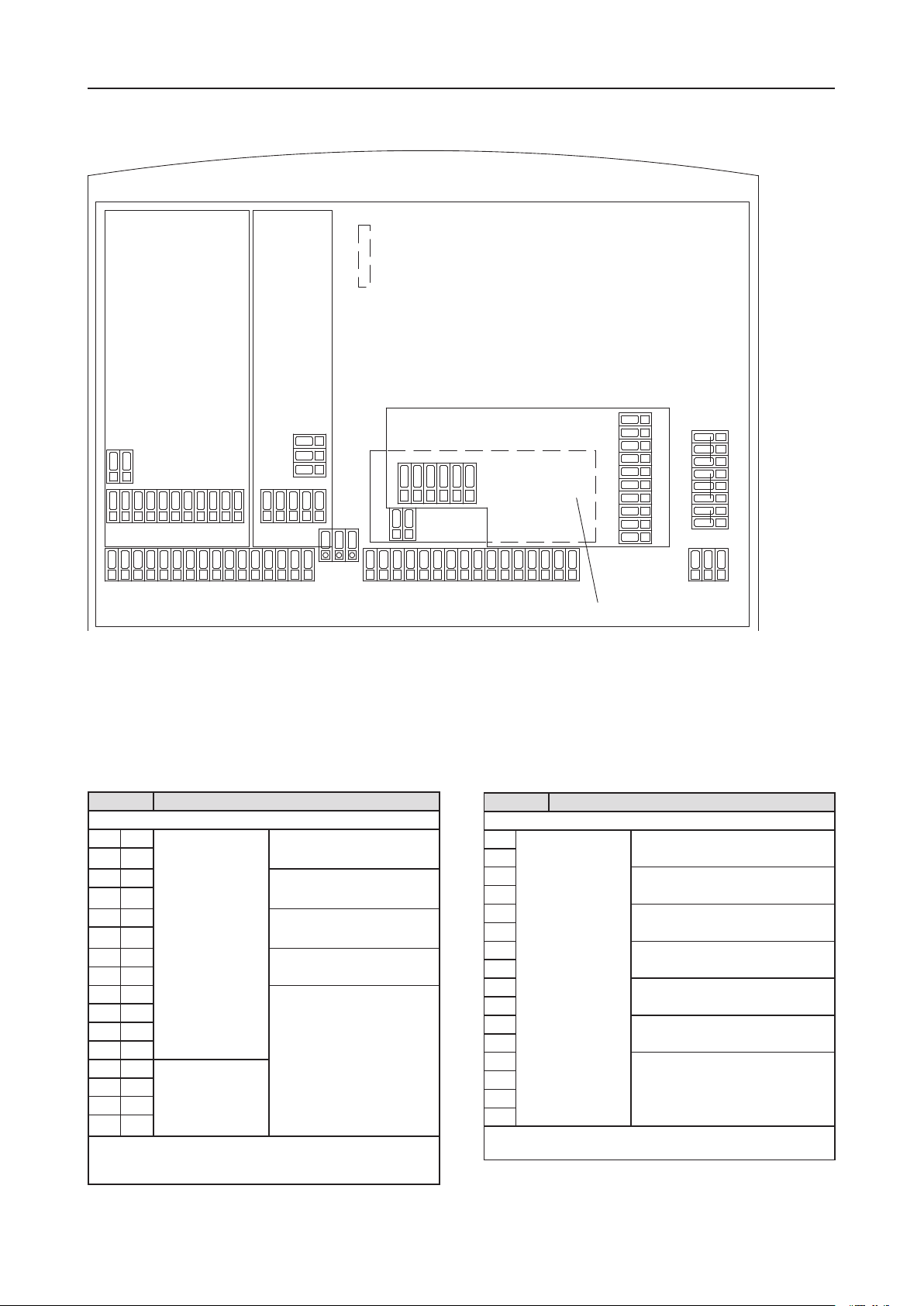

4.3 Terminal diagrams for the main board and technical assemblies

DO4 DO3 DO2 DO1

78404

78403

78402

DO7 DO6 DO5

DO0

78399

78406

+-

+-

+-+-+-+-+-+-

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

36

37

38

PE

N

L

33

34

92

93

94

87

88

89

90

91

86

-+

81

82

83

84

85

- -+ +

56

57

58

59

60

-+

51A

52A

53

54

55

61

51B

52B

- -+ +

-

+

71

72

73

74

75

76

77

78

39

40

41

43

44

45

46

42

35

95

96

B

A

Fig. 4.14: Rear housing with the "78402" main board, input module "78403" (5x), input module "78404" (3x), output module "78399" and the partially hidden PC

interface "78406".

Main board (order no. 78402)

Terminal Function

Analogue power outputs 0/4 … 20 mA (see also chapter 4.10)

1 + Measurement value

output

0/4...20 mA

Disinfection

2 -

3 + pH value

4 -

5 + Temperature

6 -

7 + Salt content

8 -

9 + Programmed as controller output***

10 -

11 +

12 -

13 + Continuous controller

output

0/4...20 mA

14 -

15 +

16 -

***) The routing of the configurable outputs is displayed according to the

configuration and can be selected at any time in the Service >> HW-Status

menu

Terminal Function

Digital inputs

17 Potential free input Insufficient sample water *)

18

19 Filter cleaning *)

20

21 Level input pre-alarm

Disinfectant **)

22

23 Level input alarm

Disinfectant **)

24

25 Level input pre-alarm

pH adjusting solution **)

26

27 Level input alarm

pH adjusting solution **)

28

29 not used

30

31

32

*) normally ON or normally OFF

**) normally ON or normally OFF or not active

EASYPOOL SMART 02 Operating Manual | 11

Controller

Terminal Function

33 A Internal

PC interface

Interface for software-update

34 B

35

36 Alarm relay as com-

mon alarm

Normally Closed (N.C.)

37 Middle contact

38 Normally Open (N.O.)

39 PE Protection conductor 90 … 264 V AC

40

41 N Neutral conductor

42

43

44 L Phase

45

46

5-fold Input block (part no. 78403):

Terminal Function Cable colour

51A + Free chlorine

Chlorine measuring cell CS120

Electrode mating copper/platinum or

silver/platinum

CS120 (Cu/Pt)

Cu : blue (-)

Pt : red (+)

CS120 (Ag/Pt)

Ag : purple(-)

Pt : red (+)

52A -

51B + not used

52B -

53 + pH value

54 -

55 + REDOX

56 -

57 Temperature

(Polarity at wish)

58

59 not used

60

61

Input module (3x) (part no. 78404) optional:

Terminal Function

71 not used

72

73

74 + 20 mA passively (without supply to the sensor)

Conductivity measurement

75 -

76 not used

77

78

outputs board (order no. 78399)

Termi-

nal

Output

81 + Digital output

(optocoupler)

DO7 programmable ***)

82 -

83 + DO6

84 -

85 + DO5

86 -

87 Relay output DO4

88

89 DO3

90

91 DO2

92

93 DO1

94

95 DO0

96

***) The routing of the configurable outputs is displayed according to the

configuration and can be selected at any time in the Service >> HW-Status

menu

IMPORTANT!

To prevent the output relays from bonding in the case

of a short in the load circuit, it must be separatly

protected with the maximum relay switching cur-

rent. For inductive loads, apply a protective circuit to

the contacts of the relays (spark suppression). The

manufacturer recommends the use of the interfer-

ence suppression module / spark suppression device

(part no. 78614).

12 | EASYPOOL SMART 02 Operating Manual

Controller

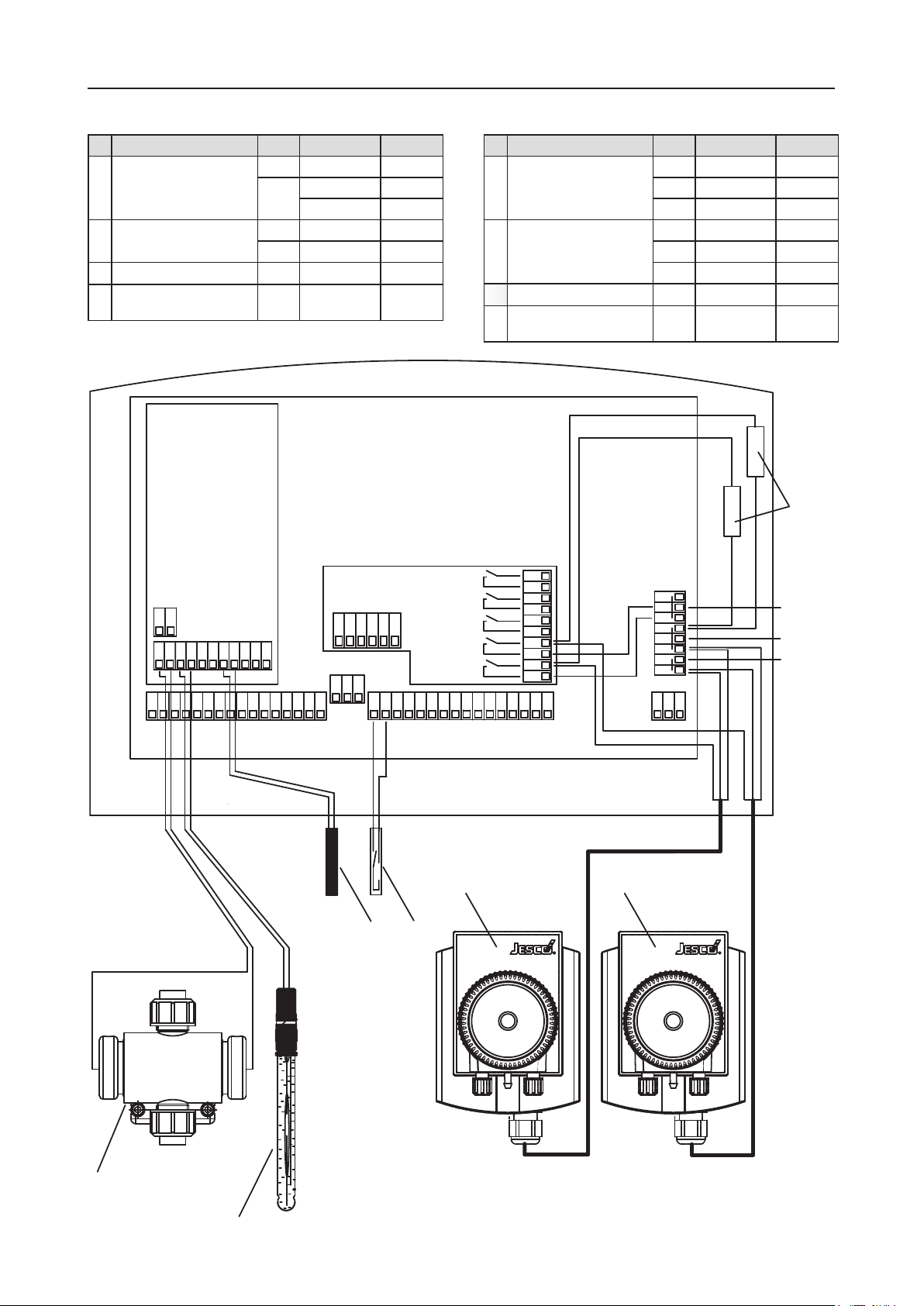

4.3.1 Terminal connection 1: control of two peristaltic pumps (disinfection and pH), free chlorine and pH measurement

78403

78399

+-

+-+-+-+-+-+-+-

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

36

37

38

PE

N

L

33

34

92

93

94

87

88

89

90

91

86

-+

81

82

83

84

85

- -+ +

56

57

58

59

60

-+

51A

52A

53

54

55

61

51B

52B

- -+ + 39

40

41

43

44

45

46

42

35

95

96

230 V / 50 Hz

Description Term. Cable Remarks

aChlorine measuring cell CS120 51 A + red (RD) platinum (Pt)

52 A - Blue (BU) Copper (Cu)

purple (VT) Silver (Ag)

bpH single-rod measuring cell 53 + white (WH) Internal lead

54 - black (BK) Screen

dTemperature sensor Pt 100 57/58

eInsufficient sample water

contact

17/18

Description Term. Cable Remarks

fDisinfection peristaltic pump 88 Brown (BN) Relay

41 Blue (BU) N

39 Yellow/green (YE/GN) PE

gPeristaltic pump pH 90 Brown (BN) Relay

41 Blue (BU) N

39 Yellow/green (YE/GN) PE

hpH relay suppression module 90/43 black (BK) Relay / N

iDisinfection relay suppression

module

88/43 black (BK) Relay / N

a

b

d e

f g

h i

EASYPOOL SMART 02 Operating Manual | 13

Controller

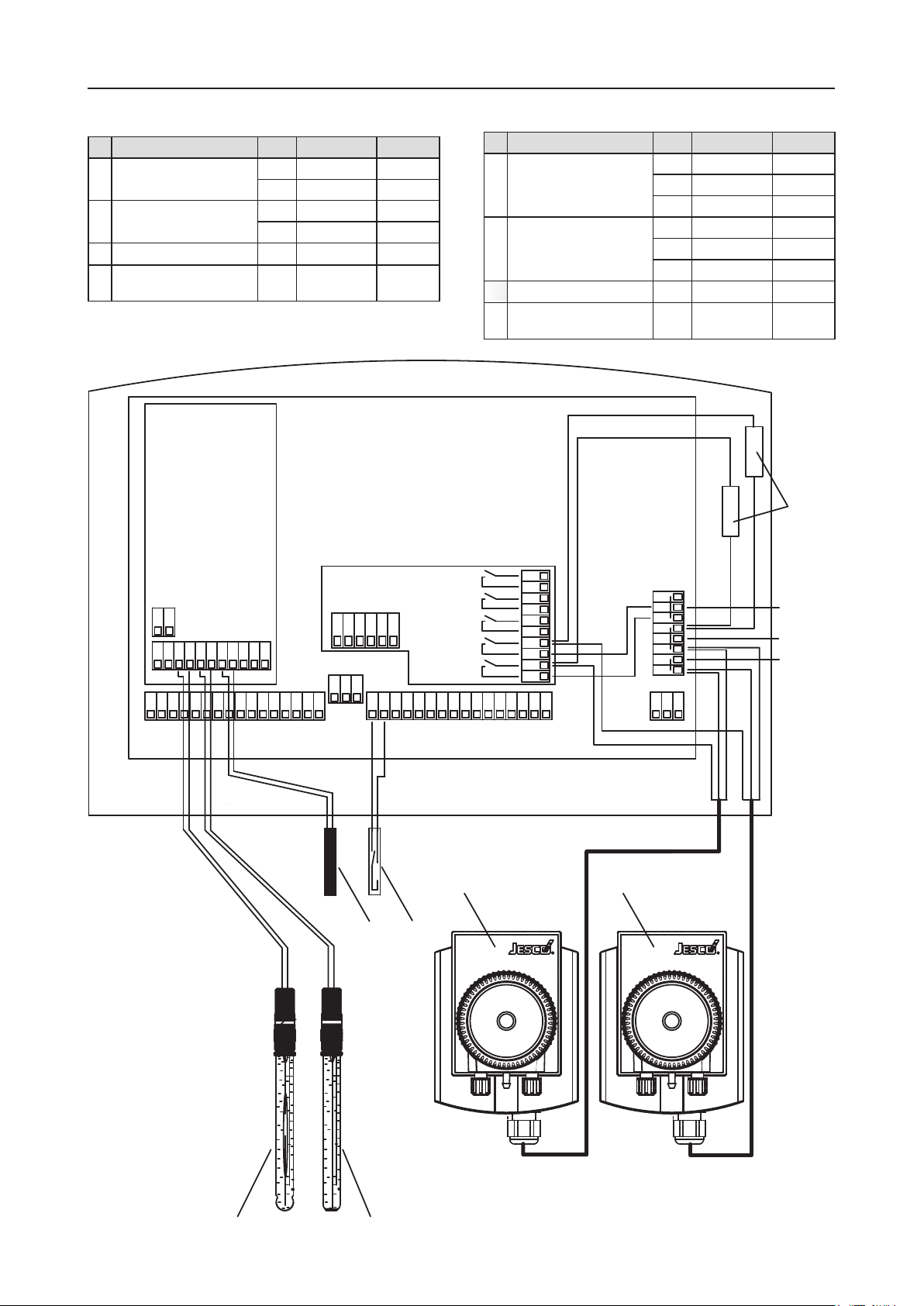

4.3.2 Terminal connection 2: control of two peristaltic pumps (disinfection and pH), REDOX and pH measurement

Description Term. Cable Remarks

bpH single-rod measuring cell 53 + white (WH) Internal lead

54 - black (BK) Screen

cREDOX single-rod measur-

ing cell

55 + white (WH) Internal lead

56 - black (BK) Screen

dTemperature sensor Pt 100 57/58

eInsufficient sample water

contact

17/18

Description Term. Cable Remarks

fDisinfection peristaltic pump 88 Brown (BN) Relay

41 Blue (BU) N

39 Yellow/green(YE/GN) PE

gPeristaltic pump pH 90 Brown (BN) Relay

41 Blue (BU) N

39 Yellow/green(YE/GN) PE

hpH relay suppression module 90/43 black (BK) Relay / N

iDisinfection relay suppression

module

88/43 black (BK) Relay / N

78403

78399

+-

+-+-+-+-+-+-+-

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

36

37

38

PE

N

L

33

34

92

93

94

87

88

89

90

91

86

-+

81

82

83

84

85

- -+ +

56

57

58

59

60

-+

51A

52A

53

54

55

61

51B

52B

- -+ + 39

40

41

43

44

45

46

42

35

95

96

230 V / 50 Hz

c

b

d e

f g

h i

14 | EASYPOOL SMART 02 Operating Manual

Controller

4.3.3 T.C. 3: control of flow-through chlorine electrolysis and peristaltic pump (pH), free chlorine and pH measurement

Description Term. Cable Remarks

aChlorine measuring cell CS120 51 A + red (RD) platinum (Pt)

52 A - Blue (BU) Copper (Cu)

purple (VT) Silver (Ag)

bpH single-rod measuring cell 53 + white (WH) Internal lead

54 - black (BK) Screen

dTemperature sensor Pt 100 57/58

eInsufficient sample water

contact

17/18

Description Term. Cable Remarks

jTechnoline SC 11 / 14

Flow-through chlorine elec-

trolyses

1: power supply unit

2: control unit

3: cable (A/N 91190000)

4: electrolytic cell

87/88 yellow (YE) Relay

gPeristaltic pump pH 90 Brown (BN) Relay

41 Blue (BU) N

39 Yellow/green (YE/GN) PE

ipH relay suppression module 88/43 black (BK) Relay / N

78403

78399

+-

+-+-+-+-+-+-+-

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

36

37

38

PE

N

L

33

34

92

93

94

87

88

89

90

91

86

-+

81

82

83

84

85

- -+ +

56

57

58

59

60

-+

51A

52A

53

54

55

61

51B

52B

- -+ + 39

40

41

43

44

45

46

42

35

95

96

230 V / 50 Hz

a

b

d e

j

g

i

1 2

3

4

EASYPOOL SMART 02 Operating Manual | 15

Controller

4.3.4 T.C. 4: control of flow-through chlorine electrolysis and peristaltic pump (pH), REDOX and pH measurement

Description Term. Cable Remarks

bpH single-rod measuring cell 53 + white (WH) Internal lead

54 - black (BK) Screen

cREDOX single-rod measur-

ing cell

55 + white (WH) Internal lead

56 - black (BK) Screen

dTemperature sensor Pt 100 57/58

eInsufficient sample water

contact

17/18

Description Term. Cable Remarks

jTechnoline SC 11 / 14

Flow-through chlorine elec-

trolyses

1: power supply unit

2: control unit

3: cable (A/N 91190000)

4: electrolytic cell

87/88 yellow (YE) Relay

gPeristaltic pump pH 90 Brown (BN) Relay

41 Blue (BU) N

39 Yellow/green(YE/GN) PE

ipH relay suppression module 88/43 black (BK) Relay / N

78403

78399

+-

+-+-+-+-+-+-+-

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

36

37

38

PE

N

L

33

34

92

93

94

87

88

89

90

91

86

-+

81

82

83

84

85

- -+ +

56

57

58

59

60

-+

51A

52A

53

54

55

61

51B

52B

- -+ + 39

40

41

43

44

45

46

42

35

95

96

230 V / 50 Hz

c

b

d e

g

i

j

1 2

3

4

16 | EASYPOOL SMART 02 Operating Manual

Controller

4.3.5 Terminal connection 5: Conductivity measurement (option)

Description Terminal Remarks

k4 … 20 mA input

Conductivity measurement

74 +

75 -

lRelay output

Conductivity control (e.g. brine dosing)

90 Relay

42 N

Description Terminal Remarks

⑬Power supply

Conductivity transmitter

45 L

41 N

39 PE

⑬Conductivity measuring cell

78403

78399

+-

+-+-+-+-+-+-+-

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

36

37

38

PE

N

L

33

34

92

93

94

87

88

89

90

91

86

-+

81

82

83

84

85

- -+ +

56

57

58

59

60

-+

51A

52A

53

54

55

61

51B

52B

- -+ + 39

40

41

43

44

45

46

42

35

95

96

230 V / 50 Hz

4 ... 20 mA

78404

71

72

73

74

75

+-

k

⑬

⑭

l

EASYPOOL SMART 02 Operating Manual | 17

Controller

4.4 Operation and menu structure

4.4.1 Operation

0

1

2

3

4

5

Fig. 4.15: View of TOPAX DX SMART housing with with operating panel.

Keys Functions

Crossed arrow keys

• Menu change-over in the menu "service";

• Change-over between the individual numbers

• Numerical values change, parameter adjust

Press the key to change from one menu item to

the other. Numeric values are entered and modi-

fied continuously.

Key "OK" between

the arrow keys

Input information are received and saved.

Successful saving is notified by a longer beep

Key a: „ESC“ Exit the menu, one level up

Terminate input without storage

Key a: „ESC“

(hold 5 seconds)

Return to the main menu

Keys b- fThe functions of the keys vary according to the

menu and are displayed respectively.

TOPAX DX SMART key layout

If no key is operated, the controller returns automatically to the

measuring mode after approx. 5 minutes. Changed parameters,

which were not confirmed with the “OK” key, are not stored.

Exception: During the calibration and with the configuration no

“time out” takes place.

NOTICE!

If no values are to be changed, "ESC" can be pressed

and the selected menus left at any time. The control-

ler continues working with the old settings. Changed

values are confirmed with the “OK” button. The

"clock" and "timer" functions are exceptions. Their

modification does not require any confirmation.

General rules for entries:

The values can only be changed within the admissible value

range.

The function of the key is signalled with a tone.

Some functions can be password-protected against unau-

thorised access (see chapter 4.12, menu 5.9 "Password").

NOTICE!

An auxiliary function is available for many menu items.

In this case, the "Help" key is shown.

4.4.2 Menu structure

The menus are as a result shown on the display with its col-

oured presentation and high resolution in clear text and clearly

arranged. As a result only the structure is described, not every

detail. (for details of the service menu see chapter 4.12)

Standard display

If there is no entry made within 5 minutes, the device changes to

the standard display (see Fig. 4.4.2.1).

7.040.39

26.3

mg/l

ºC

temperature

free Chlorine pH value

eff. cl 0.30 mg/l

Topax DX SMART

14:28 31.03.2008

YY

Fig. 4.4.2.1: Standard display

The bars below the digits of the measurements indicate the

strength of the respective output signal. The display colour

changes, depending on the signal power, from green (0 ... 85%)

to orange (85 ... 95%) and red (95 ... 100%). Blue stands for

manual operation or basic load dosing.

By pressing a random key you go to the main menu (menu 1).

IMPORTANT!

All menus are given a number in the bottom left cor-

ner (see menu 1). See tab. 4.4.2.2.

•

•

•

18 | EASYPOOL SMART 02 Operating Manual

Controller

Menu 1 and 2: Main menu and sub-main menu

mg/l pH ºC

039 702 22.3

1

0 1 2

menu 2

trend

calibration

setpoint

ESC

status

main-menu

Menu 1: The main menu and starting point for reaching all further sub-menus

and their functions: With the displays for afree chlorine, bpH value and c

temperature (°C).

Menu 2 serves as a sub-main menu (see menu 2)

mg/l pH

039 702 22.3

ºC

2

alarms

controller

ESC

menu 2

recorder

service

Menu 2: Extension of the main menu

You can access all other sub-menus through the main menu

(menu1) and the sub-main menu (menu 2).

Menu Key Comment on sub-menu

1 Main menu

ESC Return to the standard display

1.1 Target values Set the default values of the configured controller

1.2 Calibrate Calibrate all sensors connected to the system

1.3 Trend Show measurements as line diagram and zoom

at wish

1.4.1 Status Displays all important parameters for information

2 Menu 2 Change to other menus

2 Menu 2

ESC Return to the main menu

2.1 Controller Sets the characteristics of all configured controllers

(this menu can be password-protected).

2.2 Alarms Assigning the alarms to the related measurement

signals

2.3 Recorder Sets the zooming function for the analog outputs

0/4 … 20 mA

5 Service Further adjustment options

(this menu can be password-protected)

Table 4.4.2.2: Overview of the TOPAX DX SMART sub-menus.

4.5 Measurement value inputs

This chapter exemplifies the chemical and physical correlation,

which is necessary to understand the behaviour of the input

measuring values.

The input measuring values are examined for:

Free chlorine

pH value

REDOX potential

Temperature

Conductivity

In doing so an important element is the calibration of the sen-

sors.

NOTICE!

When set up the unit for the first time, care should be

taken to perform individual calibration of each output

immediately after connecting the sensors in the sys-

tem. The controller monitors all calibration processes

based on reasonable parameters (zero point and

transconductance). The measured data is recorded.

Non calibrated and „Roughly calibrated” value inputs

are marked out in clear text. „Roughly calibrated”

values are shown on the main display in red.

NOTICE!

Please note that time delays are possible due to the

initial running times of the sensors.

The limits of „Roughly calibrated” are:

measurement value limits

Transconductance pH value < 53 or > 61 mV/pH

zero point pH < -40 or > 40 mV

REDOX transconductance < 0.85 or > 1.2 mV / mV

Chlorine transconductance for amperom.

measuring cell

< 3 or > 100 µA / mg/l

The remark „roughly calibrated” sheds light on the calibration

quality and the conditions of the electrochemical electrodes. If

necessary you can look for calibration faults and replace the sen-

sors at the appropriate time. You can use the sensors unchanged

until replacement. The controller will continue to work normally.

NOTICE!

Correct calibration is a pre-requisite for the safe op-

eration of the water sampling station. The calibration

must be checked at regular intervals.

4.5.1 Free chlorine measurements input

The free chlorine reading depends on the pH value of the water

sample. This is based on the reaction of the chloride ions at dif-

ferent pH values. This relationship determines the chlorine dis-

sociation curve (see Fig. 4.5.1).

•

•

•

•

•

EASYPOOL SMART 02 Operating Manual | 19

Controller

Fig. 4.5.1: Chlorine dissociation curve as a function of the pH value

For photometric measurements the pH value of the sample is

buffered to approx. pH 6.5. As a result the measurement has a

higher effective chlorine content than is actually in the bathing

water. In the presence of high pH-values significant differences

will occur between expected and actual disinfection if assessed

by photometric analysis. The main display will show therefore

2 free chlorine values: the photometry value and the the effec-

tive chlorine content ("eff. chlor") to kill germs at the current pH

value.

NOTICE!

For saline bathing water use a platinum/silver chlorine

measurement cell instead of platinum/copper.

Calibration

Before starting the calibration, the upper value of the measuring

range of the sensor must be specified (Main menu >> Menu 2

>>Service >> Inputs). In non-DIN 19643 operated swimming

pools it is preferable to use the 0 … 2 mg/l measuring range.

The input can then be calibrated using a two-point calibration

(Main menu >> Calibrate >> Free Chlorine >> 2 point):

The physical value (µA) measured at the sensor is shown on the

display during calibration.

Calibration method 1: Zero-point calibration

The sample water flow is therefore stopped. (ball valve on water

sampling station inlet). The value of the physical quantity shown

on the display (approx 5 … 10 μA) can be saved with "OK" as

soon as it stops changing. The device automatically changes to

the next menu section.

Calibration method 2: DPD

The sensor is operated with sample water. If the physical value

on the display does not change any more, the chlorine content in

the sample water is determined via a photometer (DTP method).

To avoid signal deviations during DTP determination as reading

errors, the sample water must be taken from the measuring cell

and the current signal at the time of removal of the sample water

must be saved. The content of chlorine in water is measured by

means of the DPD method. The value must be set in the control-

ler and saved by pressing OK.

After storage the transconductance value of the chlorine sensor

is shown. The typical transconductance reading is 25 µA … 35

µA (depending on water sample) per mg/l of free chlorine. The

accuracy of resistivity measurements is monitored throughout

the process.

1-point calibration is often sufficient (reference value 2 only) to

check the chlorine content after optimization.

4.5.2 Measuring input pH value

The voltage signal transmitted by the combination electrode is

proportional to the pH value. This voltage is defined by the Nernst

voltage. The Nernst voltage ist he change in voltage per pH unit.

It depends on the temperature of the medium to be measured

(see corresponding technical literature or German Standard DIN

19261).

The Nernst voltage is measured between the pH glass electrode

and a reference electrode. Mechanically these two electrodes are

integrated in a pH combination electrode.

Calibration

Calibration of the electrode may be performed by ways of "2-

point calibration" with 2 buffer solutions or by "1-point calibra-

tion" with final input of the resistivity value. "Single point calibra-

tion" requires the transconductance of the single-rod measuring

cell to be measured in a laboratory beforehand.

The actual voltage of the single-rod measuring cell and the

theoretical value (ideal value) of the buffer solution setting are

displayed during calibration. This allows the rating of the single-

rod measuring cell to be determined during calibration, assuming

fresh buffer solutions.

The reaction time for any brand new electrode is just a few sec-

onds and the electrode is considered as fully adjusted when the

physical reading becomes stable. In the case of older combina-

tion electrodes the reaction time may be longer.

2-point calibration

Main menu >> Calibrate >> pH value >> 2 point

Buffer 1: Zero-point calibration

Submerge the pH combination electrode in a buffer solution

which is equivalent or close to the zero point of the electrode.

The ideal zero point (O mV) of the combination electrode is pH

7.00, the actual zero point, however, deviates slightly from this

value. For zero-point calibration a buffer solution of pH 6.80 is

available from the manufacturer. When immersing the pH single-

rod measuring cell in this solution, a voltage of 12 mV can be

displayed theoretically. The physical value actually measured is,

however, always different from the theroretical one.

When the physical value on the display becomes stable, you may

save the calibrated value by pressing „OK“.

IMPORTANT!

Should the actual measured voltage strongly differ

from the design zero-point of the electrode, it means

there is a zero-point drift of the electrode. Zero-point

drift should not exceed the specifications of the DIN

Standards 19265. In the event of zero-point drift

exceeding ± 40 mV, TOPAX DX gives a poor probe

calibration warning.

20 | EASYPOOL SMART 02 Operating Manual

Controller

Buffer 2: Transconductance calibration

Accurately clean the electrode with deionised or distilled water

before calibration of the resistivity.

NOTICE!

Avoid rubbing off glass electrodes as this will pro-

duce a static charge on the electrode. This would

result in faulty readings.

For slope calibration a buffer solution must be used which differs

at least 2 pH units from the zero point. For zero-point calibration

a buffer solution of pH 9.27 is available from the manufacturer.

If you are using a different buffer solution for transconductance

calibration, the value for this buffer solution must be set on the

controller. When immersing the single-rod measuring cell in the

buffer solution (Ph = 9.27), a theoretical voltage of -134 mV

should be displayed. The physical value actually measured is,

however, always different from the theroretical one. Confirm pre-

setting by pressing the “OK“ key.

Then the slope value of the combination electrode is displayed.

In accordance with the DIN Standards 19265 the resistivity if an

electrode should range between 52 and 59 mV per pH-value.

The zero-point stability and reasonableness of the transconduct-

ance are monitored.

IMPORTANT!

If the transconductance reading differs considerably

from these values, check the single-rod measuring

cell or the connecting cable and the plug connectors.

Should zero-point and resistivity values of the com-

bination electrode exceed the admissible tolerances,

the system notifies the operator with a warning mes-

sage. In this case provide for immediate replacement

of the electrode.

IMPORTANT!

Store buffer solutions in a cool and dark place! Con-

sider its durability. Make sure that the buffer solution

is not contaminated. That is why you should not put

single-rod measuring cells directly from one buffer

solution into another solution.

1-point calibration

Main menu >> Calibrate >> pH value >> 1 point

Single-point calibration may also be used for pH calibration with

a single-rod measuring cell (see section 6, menu 1.2).

Submerge the pH combination electrode in a buffer solution

which is equivalent or close to the zero point of the electrode.

The ideal zero point (O mV) of the combination electrode is pH

7.00, the actual zero point, however, deviates slightly from this

value. The manufacturer provides a buffer solution with pH value

of 6.80 for zero-point calibration. When immersing the pH single-

rod measuring cell in this solution, a voltage of 12 mV can be

displayed theoretically. The physical value actually measured is,

however, always different from the theroretical one.

When the physical value on the display becomes stable, you may

save the calibrated value by pressing „OK“.

Now enter the resistivity of the electrode.

IMPORTANT!

Should the actual measured voltage strongly differ

from the design zero-point of the electrode, it means

there is a zero-point drift of the electrode. Zero-point

drift should not exceed the specifications of the DIN

Standards 19265 (±40 mV).

Offset compensation

In accordance with DIN 19643, the control of the pH value is to

be made with an electrical metric pH value measurement.

By external influences it can be possible that the pH value of

the electrical metric measurement, measured by hand with the

photometer, deviates by a constant value. The "Offset compensa-

tion" menu allows you to compensate for this difference (setting

range +/- 0.30 pH).

NOTICE!

The offset value is set to „0“ after every new calibra-

tion.

4.5.3 REDOX potential measurement input

The REDOX potential is measured using the REDOX single-rod

measuring cell. It measures the voltage which exists in the water

due to oxidizing and reducing ions.

NOTICE!

For saline bathing water use a RESOX single-rod

measuring cell with a gold electrode instead of a

platinum electrode.

Calibration

Main menu >> Calibrate >> REDOX

Calibrate the combination electrode during startup. To calibrate

the REDOX single-rod measuring cell only one reference value

must be set. The physical value (mV) measured at the sensor is

shown on the display during calibration.

To calibrate you need a buffer solution in order to measure a

defined voltage in conjunction with the REDOX single-rod meas-

uring cell (default value: 468 mV). This value can be changed

when using other buffer solutions and/or combination electrodes

with other electrolytes. To change, use the buttons on the control

panel. The voltage actually measured is shown on the display

during calibration. This value has a small deviation from the given

value of the buffer solution. The deviation should not be bigger

than approx. 10%.

The accuracy of resistivity measurements is monitored through-

out the process.

After a reaction time (approx. 1 minute) the physical value does

not change anymore.

The reference value can be now entered and saved by pressing

the “OK” button.

IMPORTANT!

With old combination electrodes the response time

can become larger and vary. Furthermore the meas-

ured value can be largely different from that of the

buffer solution. This signifies that the combination

electrode must be checked and possibly replaced.

Table of contents

Other Jesco Lighting Equipment manuals

Popular Lighting Equipment manuals by other brands

Briloner

Briloner MAL 2267-150P Mounting instructions

Grizzly

Grizzly T33679 instructions

Steren

Steren LAM-225 instruction manual

MULTIQUIP

MULTIQUIP GloBug GB113BC Operation and parts manual

PR Lighting

PR Lighting AQUA 580 BWS manual

Foxfury Lighting Solutions

Foxfury Lighting Solutions Nomad Transformer product manual