-4- Model T33679 (Mfd. Since 3/23)

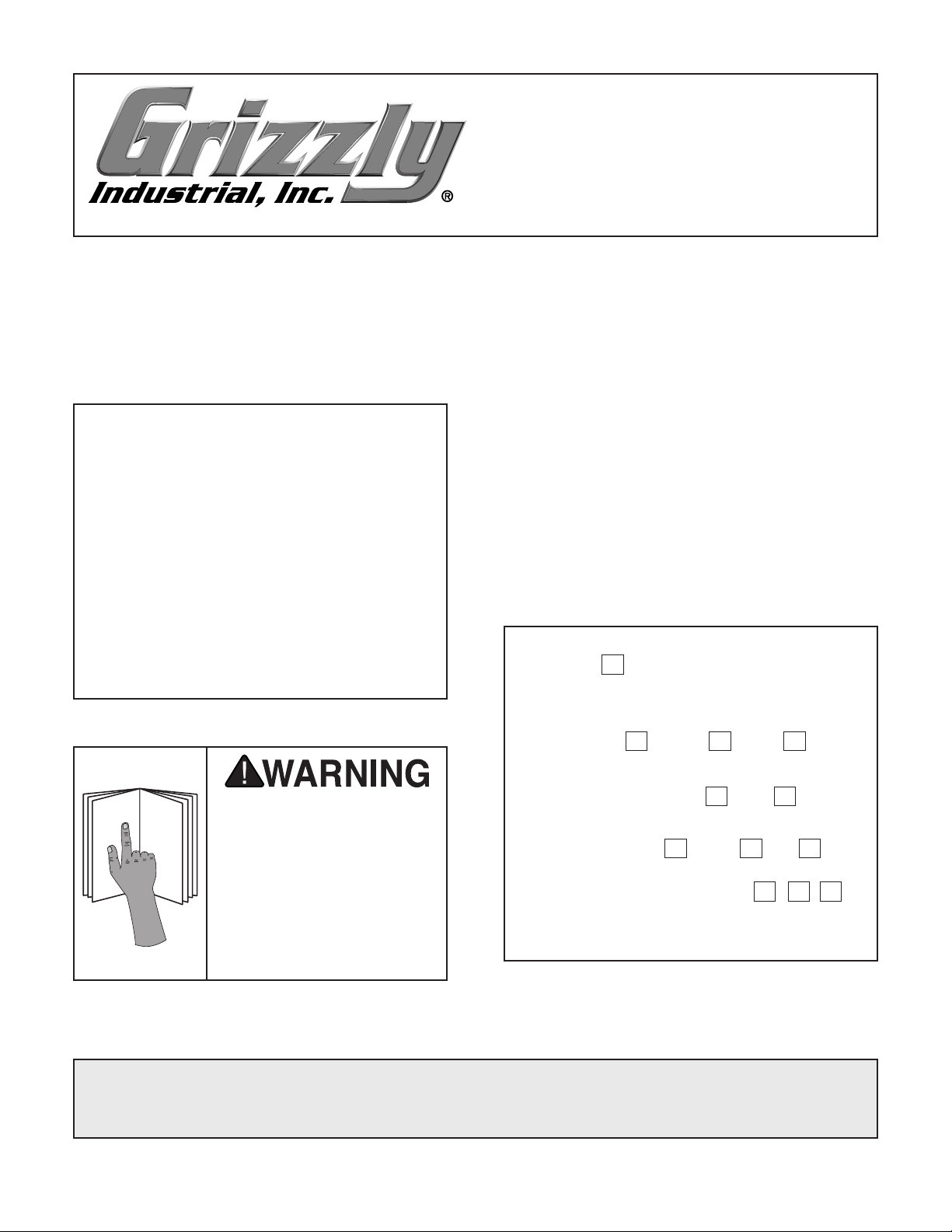

Figure 10. Typical 5-15 plug and receptacle.

Grounding Pin

Neutral Hot

5-15 PLUG

GROUNDED

5-15 RECEPTACLE

SHOCK HAZARD!

Two-prong outlets do not meet the grounding

requirements for this tool. Do not modify or

use an adapter on the plug provided—if

it will not fit the outlet, have a qualified

electrician install the proper outlet with a

verified ground.

This tool is equipped with a power cord that has

an equipment-grounding wire and a grounding

plug. Only insert plug into a matching receptacle

(outlet) that is properly installed and grounded in

accordance with all local codes and ordinances.

DO NOT modify the provided plug!

Apply light pressure at each of the articulating

joints to manuever the light to the desired position.

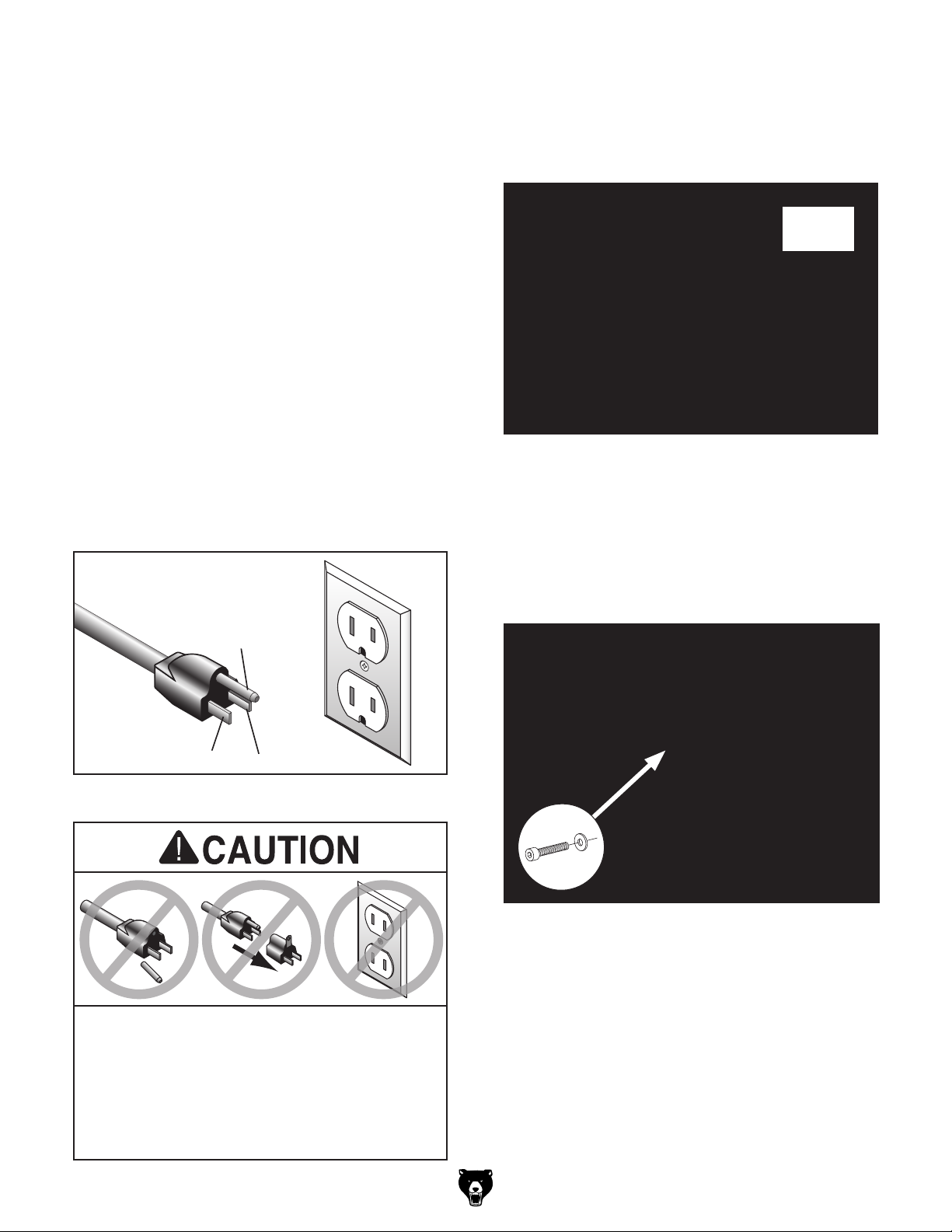

To rotate the light from side to side, loosen the

cap screws shown in Figure 12, rotate the light

to the desired position, then tighten the screws to

secure.

Figure 12. Location of cap screws in base.

x 2

Operation

Press the ON/OFF button shown in Figure 11

once to turn the LED light ON; press the button

again to turn the light OFF.

Figure 11. Location of ON/OFF button.

ON/OFF

Button

Grounding & Plug Requirements

120V Circuit Requirements

Nominal Voltage .................... 110V, 115V, 120V

Cycle ..........................................................60 Hz

Phase ........................................... Single-Phase

Power Supply Circuit ......................... 15 Amps

Plug/Receptacle ............................. NEMA 5-15

This tool is prewired to operate on a power supply

circuit that has a verified ground and meets the

following requirements:

This tool MUST be grounded. In the event of

certain malfunctions or breakdowns, grounding

reduces the risk of electric shock by providing a

path of least resistance for electric current.