___________________________________________________________________________________

1

ENGLISH

Safety information......................................................................................................................4

Disclaimer...................................................................................................................................5

List of abbreviations .................................................................................................................. 6

1.0 Introduction ..........................................................................................................................7

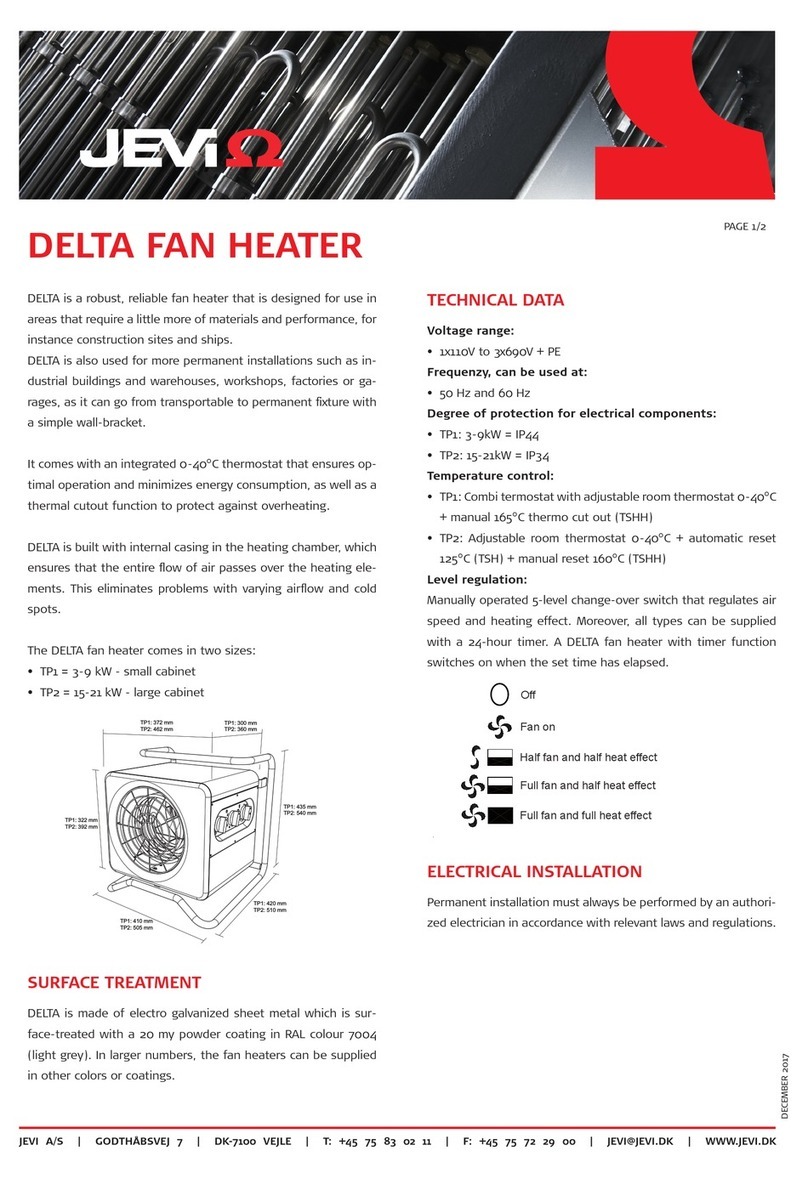

2.0 Description of product.........................................................................................................7

3.0 Packing .................................................................................................................................9

3.1 Choice of the Packing Type.....................................................................................9

3.2 Wood treatment

.....................................................................................................9

3.3 Pallets

.....................................................................................................................9

3.4 Handling

.................................................................................................................9

3.5 Centre of gravity

.....................................................................................................9

3.6 Labelling and tagging of equipment /

Identification

.............................................9

3.7 Shipping marks / labelling

....................................................................................10

4.0 Transportation....................................................................................................................11

4.1 HVAC .....................................................................................................................11

5.0 Storage and preservation ..................................................................................................12

5.1 Preservation during the transportation and pre-installation period .........................12

5.2 Preservation during the installation/construction period .........................................12

5.3 Suggestion for preservation specification & record: ...............................................14

6.0 Installation instructions .....................................................................................................16

6.1 General ..................................................................................................................16

6.2 Heater installation...................................................................................................16

6.3 Adjusting TSH thermal switch (if present) with auto reset ......................................17

6.4 Test procedure for TSH/TSHH thermal cut-off .......................................................17

7.0 Start up ............................................................................................................................... 18

7.1 Before energizing the heating elements: ................................................................18

7.2 Shutting down the heater:.......................................................................................18

8.0 Operating instructions .......................................................................................................19

9.0 Maintenance instructions ..................................................................................................20

9.1 Maintenance and service plan................................................................................21

10.0 Trouble shooting .............................................................................................................. 22

11.0 Disposal instructions ....................................................................................................... 23