Contents

1.Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 01

2.Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 02

3.Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 04

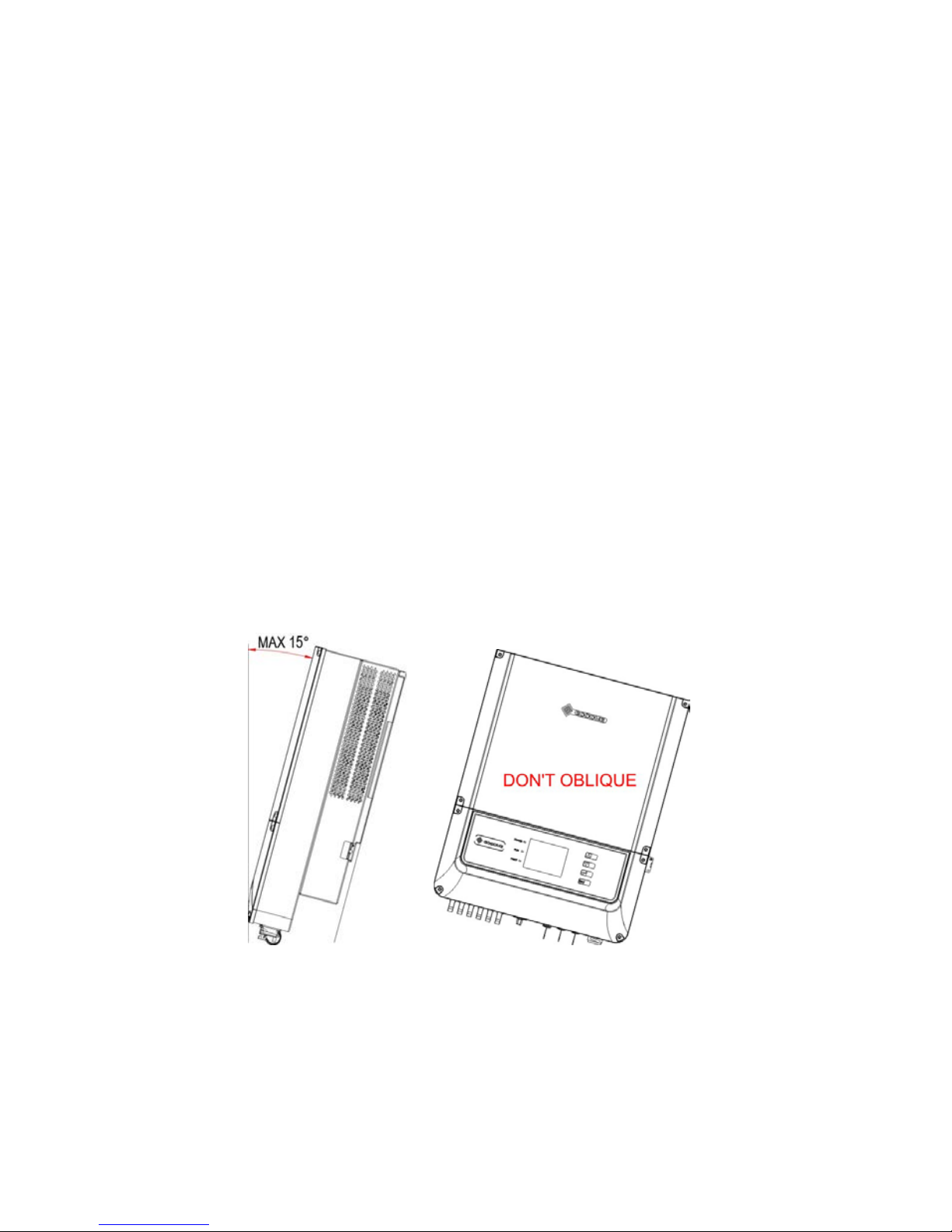

3.1 Mounting Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . 04

3.2 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 04

3.3 Equipment Installation.. . . . . . . . . . . . . . . . . . . . . . . . . 06

3.4 Electrical Connection.. . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.4.1 Connection to Grid (AC Side Connection) .. . . . . 12

3.4.2 DC Side Connection . . . . . . . . . . . . . . . . . . . . . . 15

3.4.3 RS485 Communication... . . . . . . . . . . . . . . . . . . 18

3.4.4 Wireless Communication. . . . . . . . . . . . . . . . . . 23

3.4.5 USB Communication. . . . . . . . . . . . . . . . . . . . ... 25

3.5 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . ... . 25

4.System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.1 Functions of Indicating Lights . . . . . . . . . . . . . . . . . . . 29

4.2 LCD Display Functions and Keys Operation . . . . . . . . 30

4.2.1 Top Area – Flow of Power Generated. . . . . . . . . 30

4.2.2 Middle Left – Status Information. . . . . . . . . . . . . 31

4.2.3 Right Middle Area—Histogram Display. . . . . . . . 36

4.2.4 Bottom Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.3 Key Operation and LCD Description . . . . . . . . . . . . . . 38

4.3.1 Key Description.. . . . . . . . . . . . . . . . . . . . . . . . . 38

4.3.2 Key Operation and LCD Description. . . . . . . . . . 39

4.4 Menu Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.5 Usual Start and Operation Display. . . . . . . . . . . . . . . . 40

4.6 Menu Display Description. . . . .. . . . . . . . . . . . . . . . . . 40

4.6.1 Error History Display. . . . . . . . . . . . . . . . . . . . . . 41

4.6.2 Time Setting. . ... . . . . . . . . . . . . . . . . . . . . . . . 41

4.6.3 Language Setting .... . . . . . . . . . . . ... . . . . . . 42

4.6.4 Set the Histogram Display in ‘Year Mode’ .. . . . . 43

4.6.5 Reset Wireless ID . . . . . . . . . . . . . . . ... . . . . . 44

4.7 Error Message. . .. .. . . ... . . . ... . . . ... . . . ... . . . 45

5.Technical Parameters. . . . . . . . . . . . . . . . . . . . . . . . . ... 47