Chapter 1 Overview

Thank you for purchasing and using our products. Before you use this instrument, please confirm

it according to the "Setting and Warranty" section at the end of the manual. If there is any

discrepancy, please contact our company as soon as possible to protect your rights.

1.1 Instrument Introduction

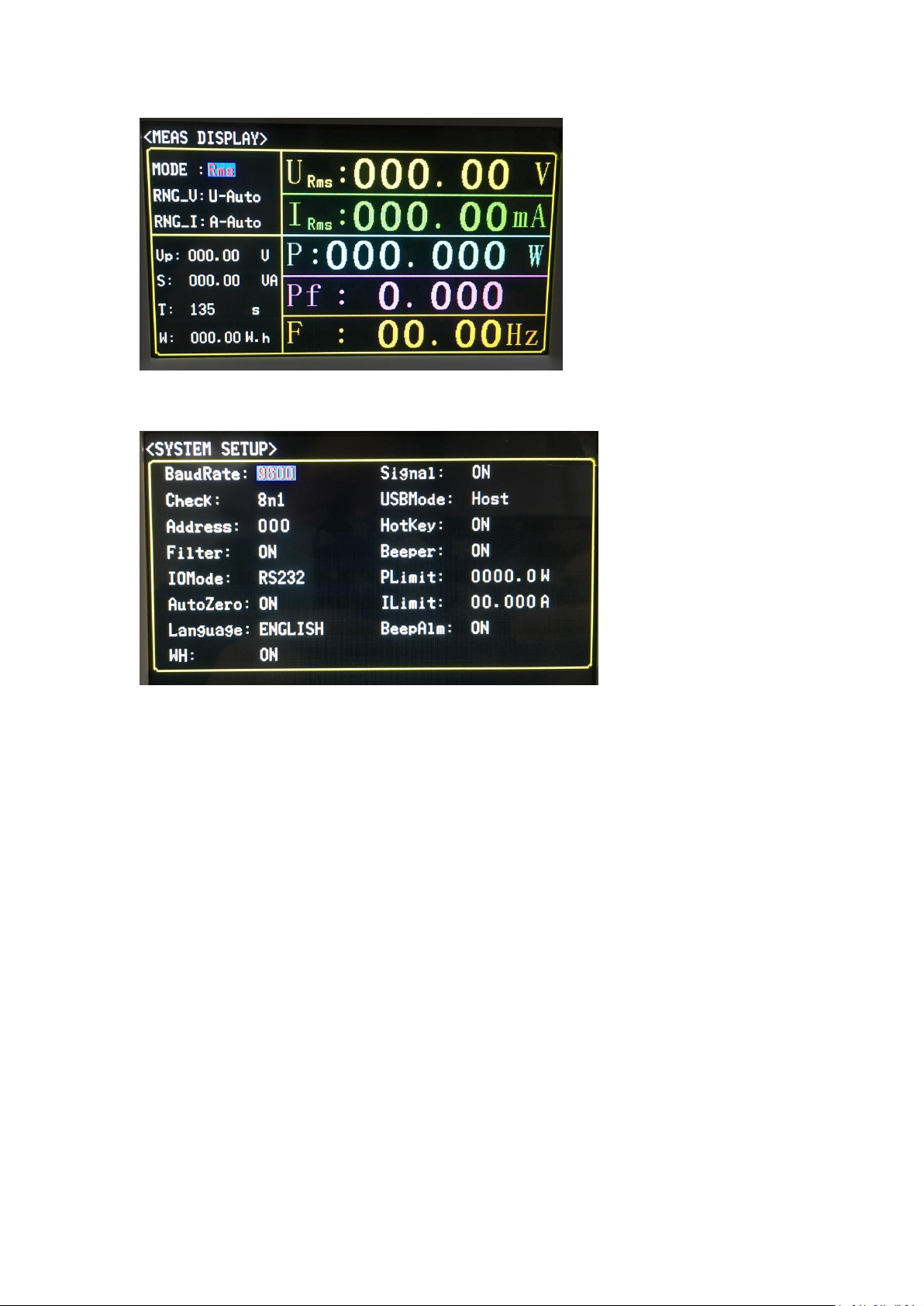

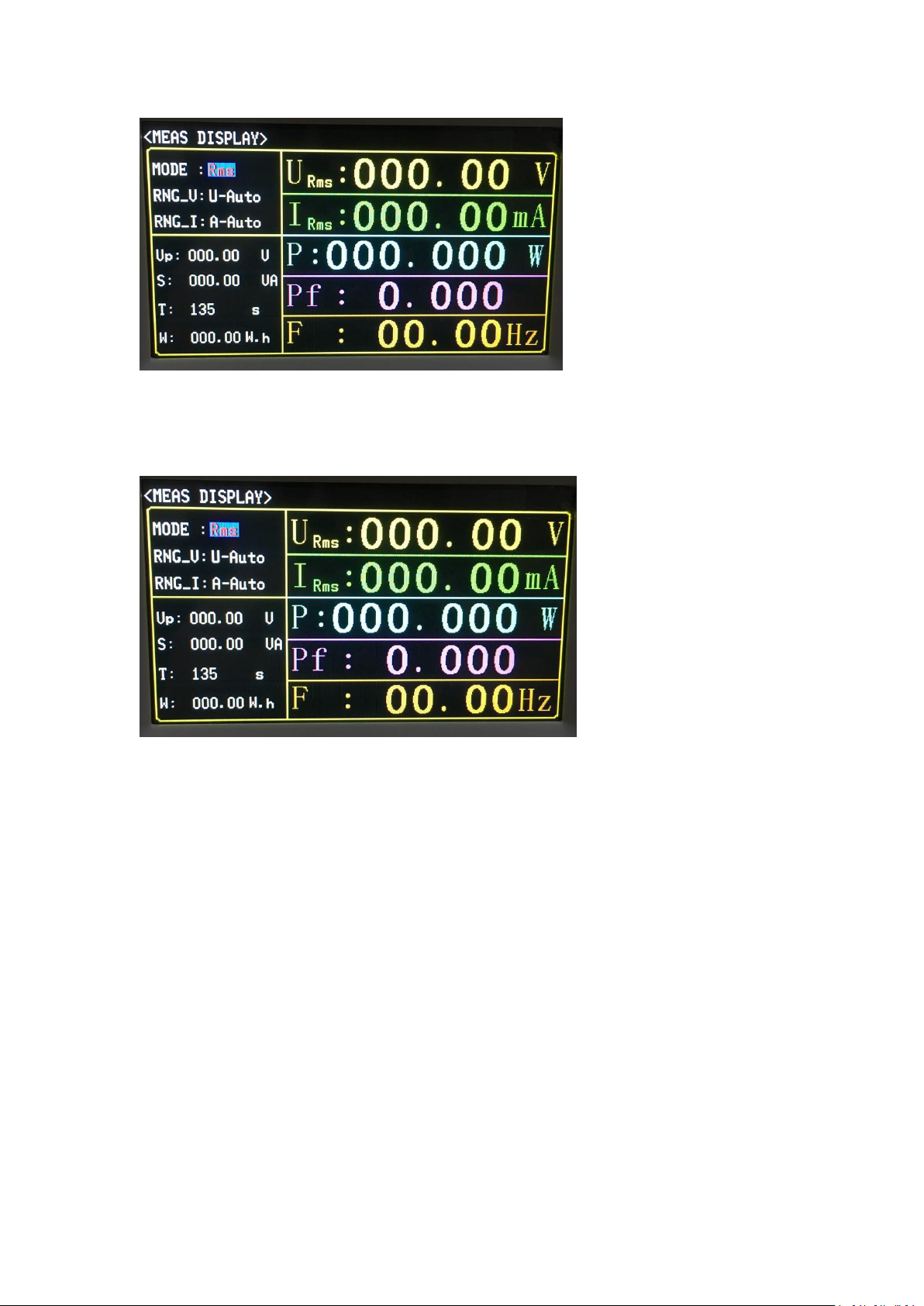

JK9306 series single-phase digital power analyzer (digital power meter) uses a high-speed

32-bit processor and a professional DSP digital signal processor. It has fast speed, frequency

bandwidth, full-featured, compact structure, stable testing, simple operation and good

performance. The human-machine interface is a new generation of digital power analyzer. The

main parameters that can be measured are: RMS value of voltage and current, AC component of

voltage and current, DC component of voltage and current, active power, reactive power,

apparent power, electrical energy timing, power factor, frequency, peak factor of voltage and

current, peak value of voltage and current etc. electric parameters, depending on the model of

the instrument, some instruments do not have a harmonic analysis function.

This manual covers the JK9306 single-phase power analyzer. It covers most of the power

supplies on the market with the advantages of a large input bandwidth (45 ~ 400Hz). In addition

to the basic electrical parameter measurement, the four instruments also provide intuitive

comparison functions. Input waveform display, meanwhile, the HANDLER interface, RS232C /

RS485 interface and USBTMC, USBCDC interface provided by the instrument provide conditions

for the instrument to be used in automatic sorting system and computer remote operation; the

difference between different models is mainly the current measurement range and Whether it

has the function of harmonic analysis, the maximum test current is 40A, and the measurement

accuracy is stable. The specific differences can be found in the following instrument model

comparison table.

The main features of the instrument:

4.3 inch LCD liquid crystal display;

Soft power switch;

Chinese and English optional operation interface;

Input frequency range (45 ~ 400Hz);

The range can be controlled automatically / manually;

The maximum test current is 40A (depending on the model), and the minimum current

can be 1uA (depending on the model);

Controllable synchronization trigger source;

Provide 5kHz line filter switch;

Flexible energy integration control;

Parameter comparison and Handle controllable output function;

Parameter file selection function;

Harmonic analysis function (related to specific models);

Waveform display function;

Support U disk file storage, instrument programs can be upgraded through U disk;

Serial interface: RS-232C provides great convenience for serial communication between the

instrument and peripherals. Peripherals can set various functions and parameters of the