SAFETY PRECAUTIONS

6308AN

SAFETY PRECAUTIONS

This section outlines the safety

precautions applicable to the general

use of this product.

Throughout the Operator and Safety

section of this manual, cautions and

warnings are shown in BOLD TYPE.

These outline where special care is

required when undertaking the various

procedures outlined.

NOTE: The safety precautions

applicable to the service and

maintenance of the machine are

covered in the SAFETY

PRECAUTIONS section of the Service

and Maintenance Manual.

The user of this machine should read

this manual thoroughly to ensure that

all operating procedures are clearly

understood prior to accepting

responsibility.

• Modifications or alterations to the

lighting tower are not permitted

without the prior written permission

of the manufacturer.

• Failure to comply with the safety

precautions listed here and

elsewhere in the manual may result

in injury or death.

• When handling the lighting tower

other than towing for the purposes

of lifting or manoeuvring, there are

forklift pockets provided at the rear

of the machine and 4 lifting points

provided on the main frame for

lifting by a crane. Ensure that the

forklift or crane is of suitable e lift.capacity prior to attempting th

Refer to the diagrams shown

elsewhere in this manual for correct

handling procedures using a crane

and forklift.

• Prior to erecting the mast the

operator should ensure that no

overhead obstructions are within a

6-metre radius of the base of the

machine.

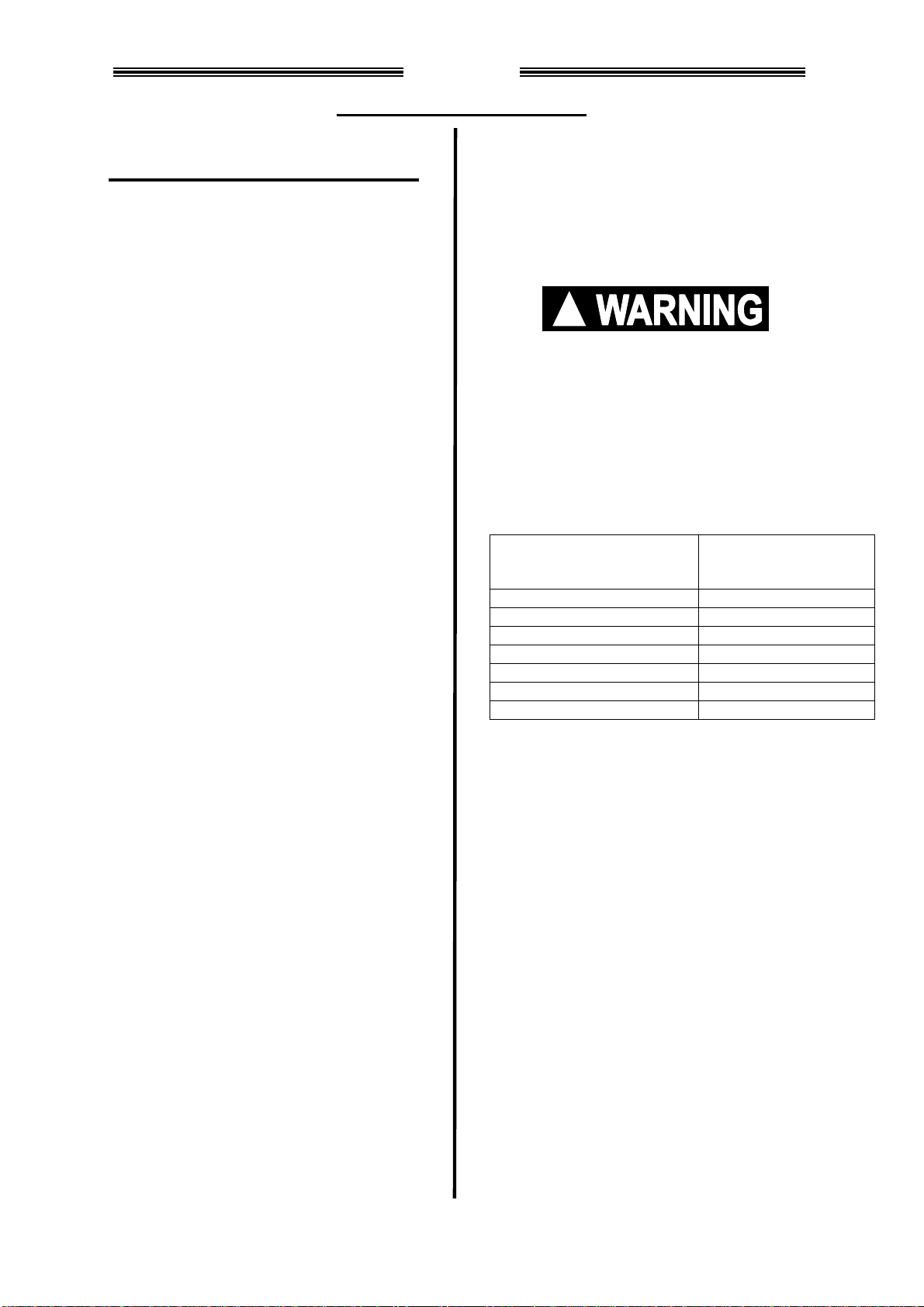

THERE IS ELECTROCUTION

HAZARD TO THE OPERATORS

IF THE MACHINE IS OPERATED

NEAR OVERHEAD

POWERLINES.

The following chart is a guide to the

applicable safe operating distances

from overhead power lines.

Voltage Range

(Phase to Phase) MINIMUM SAFE

DISTANCE

In Metres (Feet)

0-300V AVOID CONTACT

Over300-50 KV 3 (10)

Over 50 KV to 200 KV 5 (15)

Over 200 KV to 350 KV 6 (20)

Over 350 KV to 500 KV 8 (25)

Over 500 KV to 750 KV 11 (35)

Over 750 KV to 1000 KV 14 (45)

Be aware of the radius of the mast

when telescoped out and lowered.

Be aware of swaying power lines

and swaying tree branches in

strong winds.

• Be familiar with all controls on the

machine prior to operation. The

machine incorporates powerful

hydraulic mechanisms that can

cause serious mechanical damage

if the machine is allowed to strike

external structures such as

buildings etc.

• Ensure that the ground is suitable

to support the machine, particularly

under each of the outrigger pads. A

suitable packing material such as a

timber block may be required on

soft surfaces to ensure that the

outriggers do not sink under the

weight.

Page 1-3