1001281353 JLG Industries (Australia) Pty Ltd Page 1-7

Oshkosh Corporation 28JUL22

JLG LT3

OshkoshCorporationClassification‐Restricted

1.2 SAFETY PRECAUTIONS

This section outlines the safety

precautions applicable to the general use

of this lighting tower.

Throughout the Operation and Safety

section of this manual, cautions and

warnings are shown in BOLD TYPE.

These outline where special care is

required when undertaking the various

procedures outlined.

Safety precautions applicable to machine

service and maintenance are in the

SAFETY PRECAUTIONS section of the

Service and Maintenance Manual.

The user of this machine should read and

study this manual thoroughly to ensure

that all operating procedures are clearly

understood prior to accepting

responsibility.

1. Modifications or alterations to the

lighting tower are not permitted without

the prior written permission of the

manufacturer.

2. Failure to comply with the safety

precautions listed here and elsewhere

in the manual may result in injury or

death.

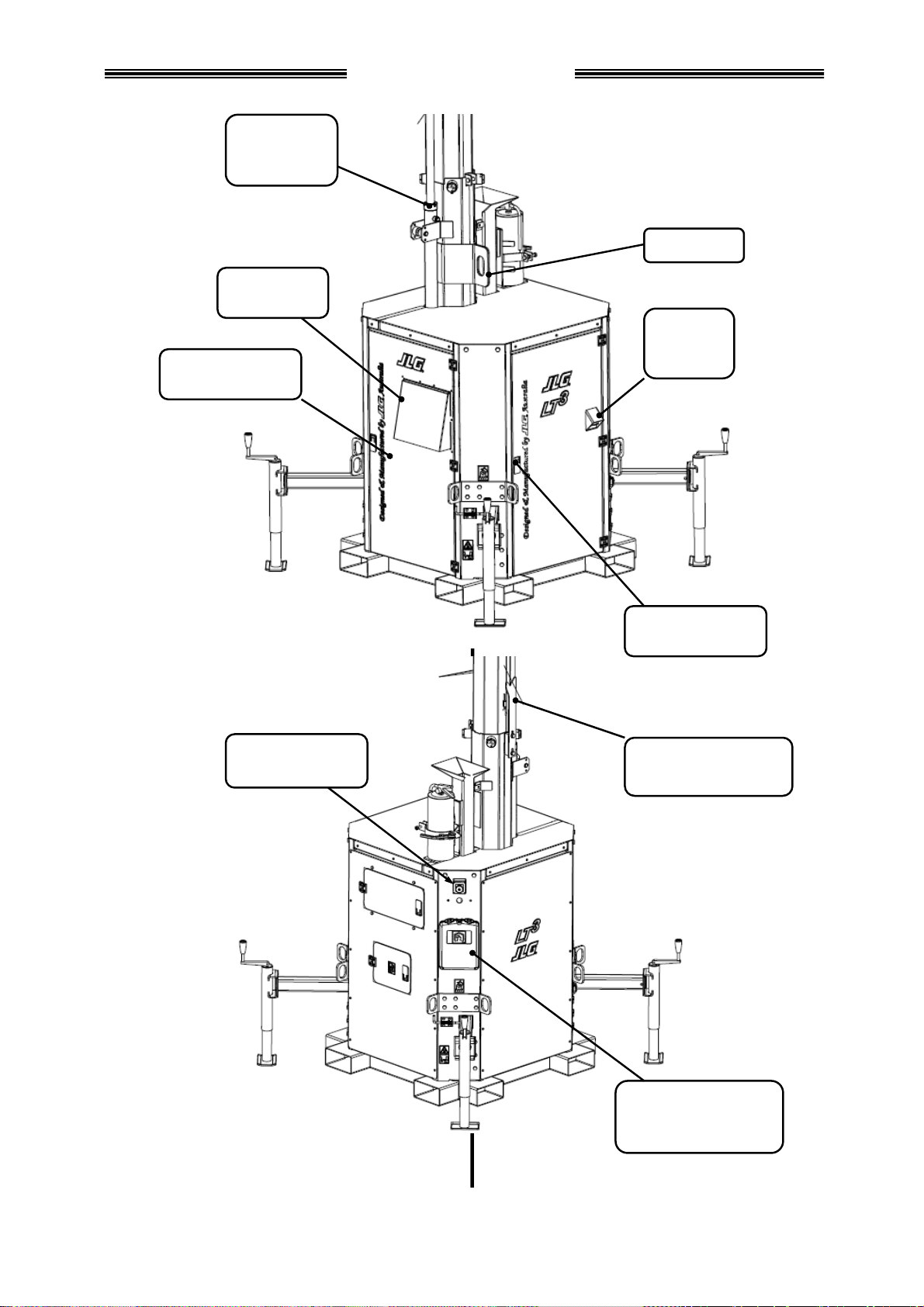

3. When moving the lighting tower by

forklift use the forklift tyne pockets

running through the LT3’s base. Ensure

that the forklift is rated to handle the

lighting tower prior to attempting the lift.

4. When lifting the lighting tower by

craning use the rated lifting point

provided on the lighting tower mast.

Ensure that the crane is rated to lift the

lighting tower prior to attempting the lift.

Refer to the diagrams and illustrations

shown elsewhere in this manual for

correct handling procedures using a

crane and forklift.

DO NOT POSITION THE LIGHTING

TOWER INSIDE THE PROHIBITED

(M.A.D.) ZONE. ASSUME ALL

ELECTRICAL PARTS AND WIRING

ARE ENERGISED UNLESS KNOWN

OTHEREWISE.

5. Maintain distance from electrical lines,

apparatus, or any energized (exposed or

insulated) parts according to the

Minimum Approach Distance (MAD) as

shown in Table 1-1.

6. Maintain a clearance of at least 3 m

(10.0 ft) between any part of the lighting

tower from any electrical line or

apparatus carrying up to 50 000 volts.

An additional clearance of 0.3 m (1.0 ft)

is required for each additional 30 000

volts or less of line voltage.

7. The minimum approach distance may

be reduced if insulating barriers are

installed to prevent contact, and the

barriers are rated for the voltage line

being guarded. These barriers shall not

be part of (or attached to) the machine.

The minimum approach distance shall

be reduced to a distance within the

designed working dimensions of the

insulating barrier.

8. A reduced minimum approach distance

shall be determined by a qualified

person in accordance with the

employer, local, or government

requirements for safe work practices

near energised equipment.

Voltage Range

(phase-to-phase)

Minimum Approach

Distance

metres (feet)

0 to 50 kV 3 (10)

over 50 kV to 200 kV 5 (15)

ove

200 kV to 350 kV 6 (20)

ove

350 kV to 500 kV 8 (25)

over 500 kV to 750 kV 11 (35)

over 750 kV to 1000 kV 14 (45)

Note: This requirement shall apply except where

employer, local or government regulations are

more stringent.

Table 1-1. Minimum Approach Distances (M.A.D.)

!

1.2 SAFETY PRECAUTIONS