(such as a 2x4") slightly longer than the depth of the tank or drum, into the

bottom of the tank. Center the piece of wood in the tank. Rap the top end of

the wood with a hammer. Inspect the mounted magnet for gaps. Repeat if

necessary.

WARNING: Do not try and mount the magnet on the tank by pounding on the

magnet. This will likely damage the magnet or split the tank.

To use a magnet-equipped tank or drum on a JOBO Lift equipped processor or Autolab, simply

add a Cog (#1505) to the lid. Do not remove the magnet when using the tank or drum on the

JOBO Lift or Autolab.

If you are purchasing a tank or drum, note its four-digit part number. If the part number ends in '1'

(such as 2521 or 2551, etc.), it already has a magnet attached. All other tanks and drums do not

come equipped with a magnet. Tanks that have the last number of '3', have cog type lids. These

lids would have to be replaced to use them with a magnet drive processor. Replacement lids

(without cap, funnel, or beaker) are available as parts from JOBO. The 1500 series requires

#91034, and both the 2500 and the 2800 series require a #91036 lid. (There is no non-cog lid

available for the 3000 series drums.) The #03046 membrane cap is needed by all three series lids.

Back to Top

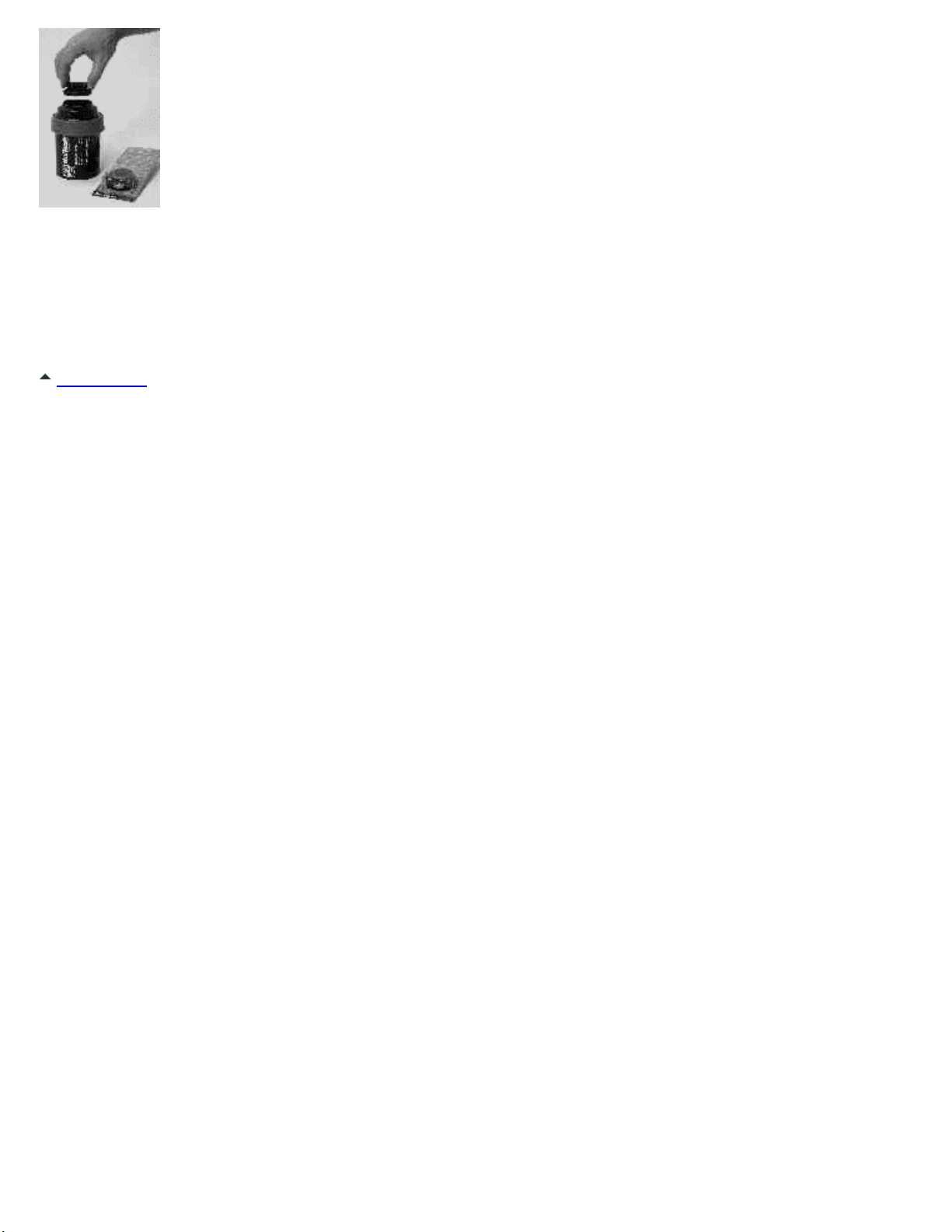

Mounting a Cog On a Lid

You must have a cog installed on a tank or drum lid to allow coupling with the JOBO Lift or

Autolab. Some tanks come with the cog already installed. If you are purchasing a tank, check the

JOBO part number of the tank. If the first or last digit of the four digit code is a '3' (3010, 2523,

etc.), then there is already a cog installed in the lid. If the first or last digit is not a '3', then you will

need to purchase a Cog (#1505) for the tank or drum.

One cog for each tank or drum is required, as they are permanently mounted into

the lid, and cannot be removed. If you wish to keep the lid for hand or magnet

processing, get a replacement cog lid. The JOBO part number for the

replacement cog lid in the 1500 series is #1503. Both the 2500 series and the

2800 series use the same replacement lid, #2503. This replacement lid comes

with a funnel and a stopper. (The stopper is placed in the funnel only when

replacing the beaker. The stoppered funnel is used exclusively for print

processing with a lift.) The 3000 series of drums cannot be used with the magnet drive. 3000

series lids are always supplied with a cog.

You may use the lift with a tank or drum having a magnet attached on the bottom. The daylight

loading tank #2400, or the discontinued series 1000, 2000, and 4000 tanks or drums cannot be

equipped with a cog.

The procedure for mounting a cog is the same for all tank or drum lids.

1. Remove the lid from the tank or drum. Remove the red membrane cap and funnel or

beaker.

2. Place the lid, red ring down, on a hard and smooth surface.

3. Place the cog, wide side down, into the opening for the cap, at a slight angle.

4. Press the cog down with your hands. (You may find it helpful to lean towards the lid to apply

a firm pressure.)

5. Examine the seam between the cog and the lid for gaps. When seated correctly, there will

be no gap between the cog and lid. (If you can place a fingernail between them, the cog is

not seated fully.)