Table of contents

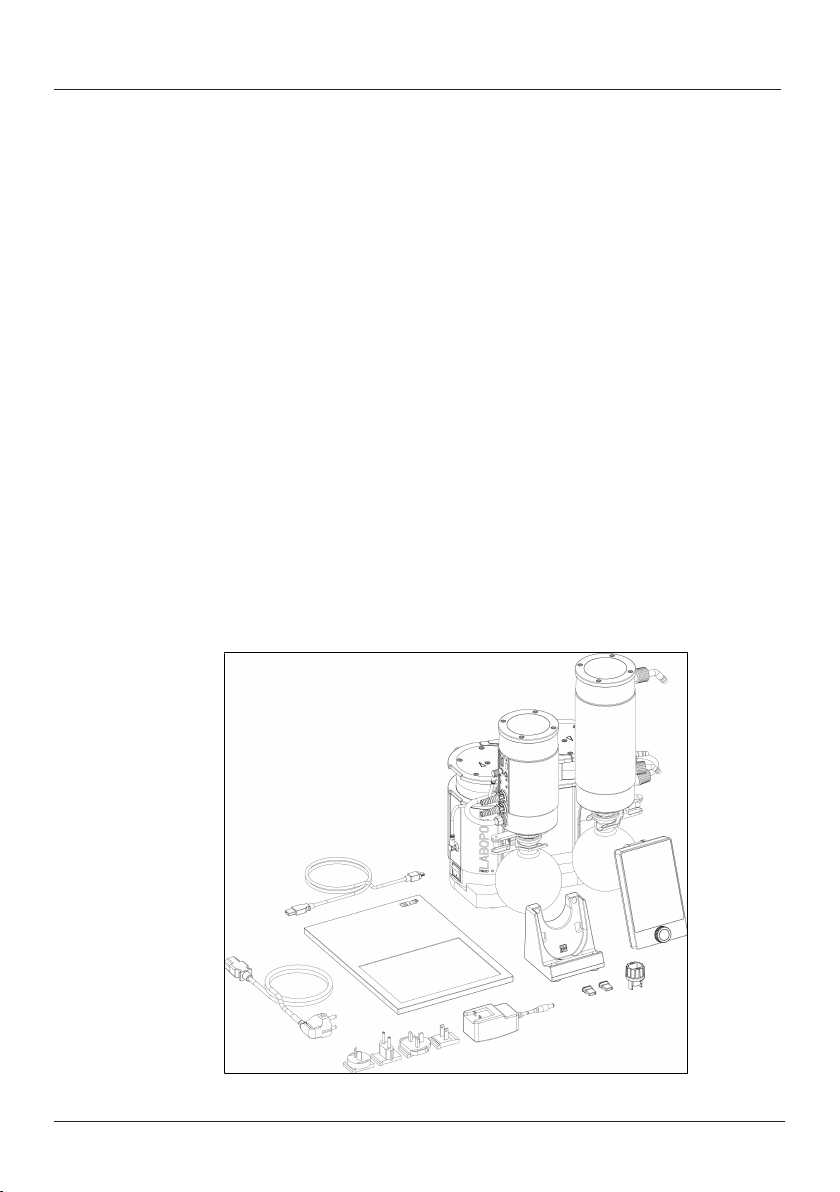

1 Scope of delivery................................................................................... 4

2 About this document ............................................................................. 6

2.1 Using the operating instructions.................................................... 6

2.2 Exclusion of liability....................................................................... 6

2.3 Applicable documents................................................................... 7

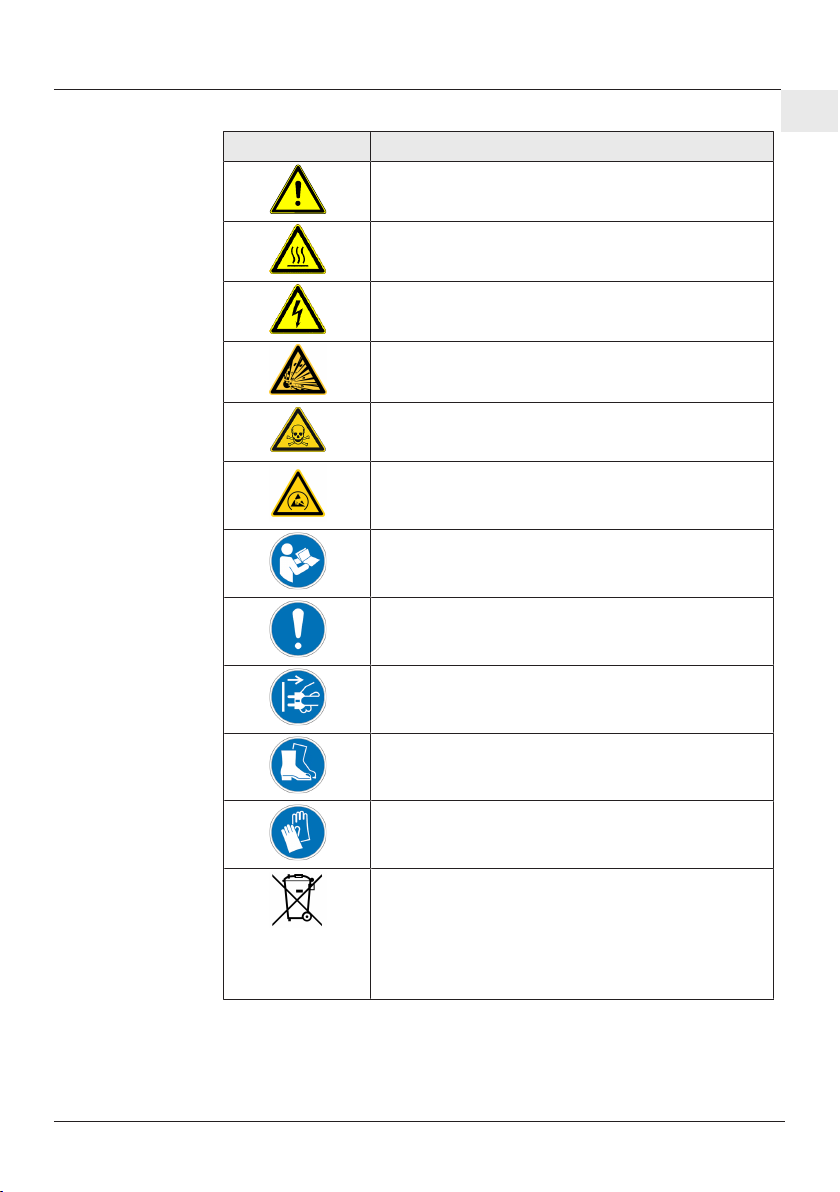

2.4 Symbols and markings.................................................................. 7

2.5 List of abbreviations .................................................................... 10

3 Safety .................................................................................................. 11

3.1 Personnel and target group ........................................................ 11

3.2 Responsibility of the operator ..................................................... 12

3.3 Working in a safety conscious manner ....................................... 12

3.4 Operating conditions ................................................................... 13

3.5 Media .......................................................................................... 13

3.6 Use.............................................................................................. 14

3.7 Directives and standards ............................................................ 15

3.8 Customer service and repair....................................................... 16

3.9 Disposal ...................................................................................... 16

4 Explosion protection............................................................................ 18

4.1 Using for transferring explosive atmospheres............................. 18

4.2 Information on the Ex-designation .............................................. 19

4.3 Explanations of the explosion protection designation ................. 20

5 Technical data..................................................................................... 26

6 Product description and function......................................................... 32

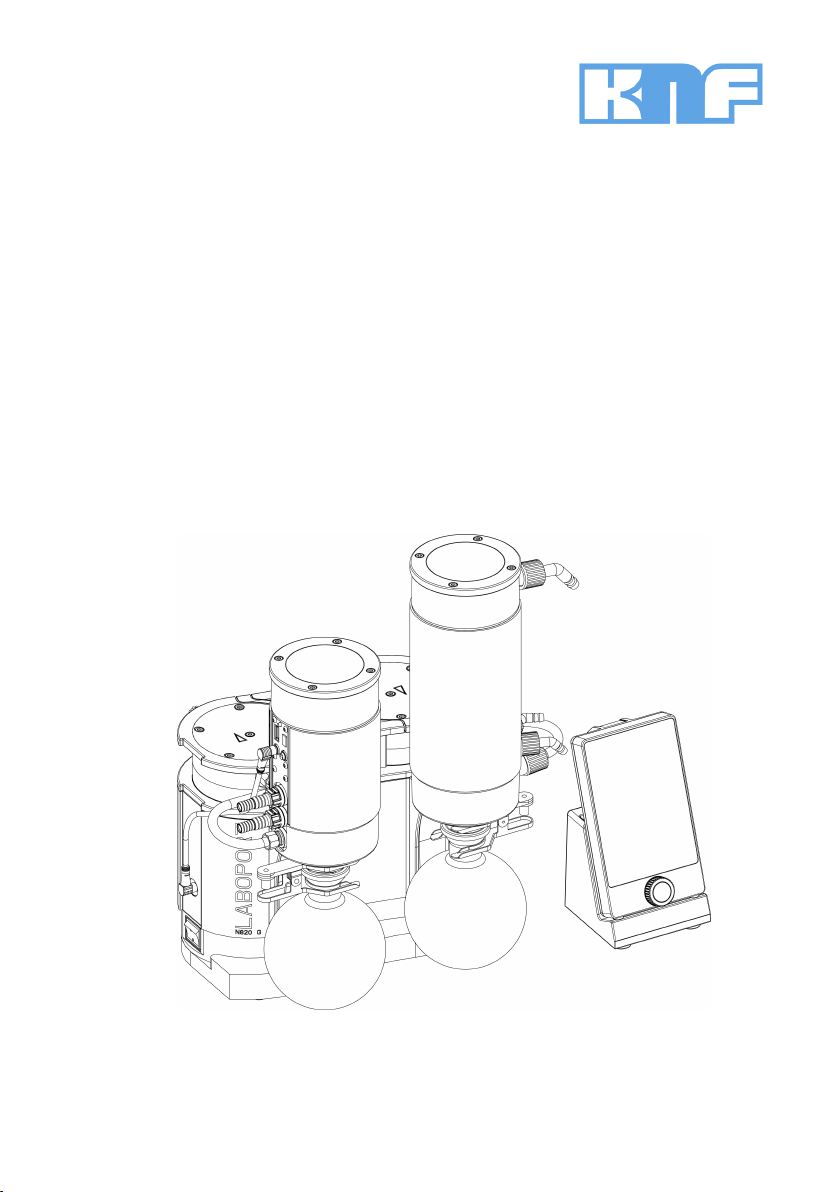

6.1 SC820G, SC840G ...................................................................... 32

6.2 Vacuum controller ....................................................................... 34

6.3 Pump........................................................................................... 36

6.4 Gas ballast .................................................................................. 37

7 Transport............................................................................................. 38

8 Commissioning.................................................................................... 40

8.1 Preparing for commissioning ...................................................... 42

8.2 Perform commissioning .............................................................. 43

8.3 Switching the vacuum controller on and off ................................ 48

8.4 Connecting the vacuum controller to the vacuum system .......... 50

9 Operation ............................................................................................ 51

10 Operating the vacuum system ............................................................ 55

10.1 Vacuum controller ....................................................................... 55