R-410A

ZR SERIES

3 - 5 Ton

60 Hertz

403134-YIM-E-0311

TABLE OF CONTENTS

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation Safety Information. . . . . . . . . . . . . . . . . . . . . . . 5

Limitations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Rigging And Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Ductwork. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Condensate Drain. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Compressors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Power And Control Wiring. . . . . . . . . . . . . . . . . . . . . . . . . 13

Optional Electric Heat . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Options/Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Economizer And Power Exhaust Set Point

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Checking Supply Air CFM. . . . . . . . . . . . . . . . . . . . . . . . . 40

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Sequence Of Operations Overview. . . . . . . . . . . . . . . . . . 41

Cooling Sequence Of Operation. . . . . . . . . . . . . . . . . . . . 41

Reheat Mode Sequence Of Operation . . . . . . . . . . . . . . . 41

Cooling Operation Errors . . . . . . . . . . . . . . . . . . . . . . . . 42

Electric Heating Sequence Of Operations . . . . . . . . . . . . 43

Electric Heat Operation Errors . . . . . . . . . . . . . . . . . . . . 43

Gas Heating Sequence Of Operations . . . . . . . . . . . . . . . 44

Gas Heat Operation Errors . . . . . . . . . . . . . . . . . . . . . . . . 45

Flash Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Resets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Heat Anticipator Setpoints. . . . . . . . . . . . . . . . . . . . . . . . . 46

Start-up (Cooling) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Start-up (Gas Heat). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Checking Gas Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Charging The Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Fan On And Off Delays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

LIST OF TABLES

1 ZR036-060 Unit Limitations. . . . . . . . . . . . . . . . . . . . . . . . 6

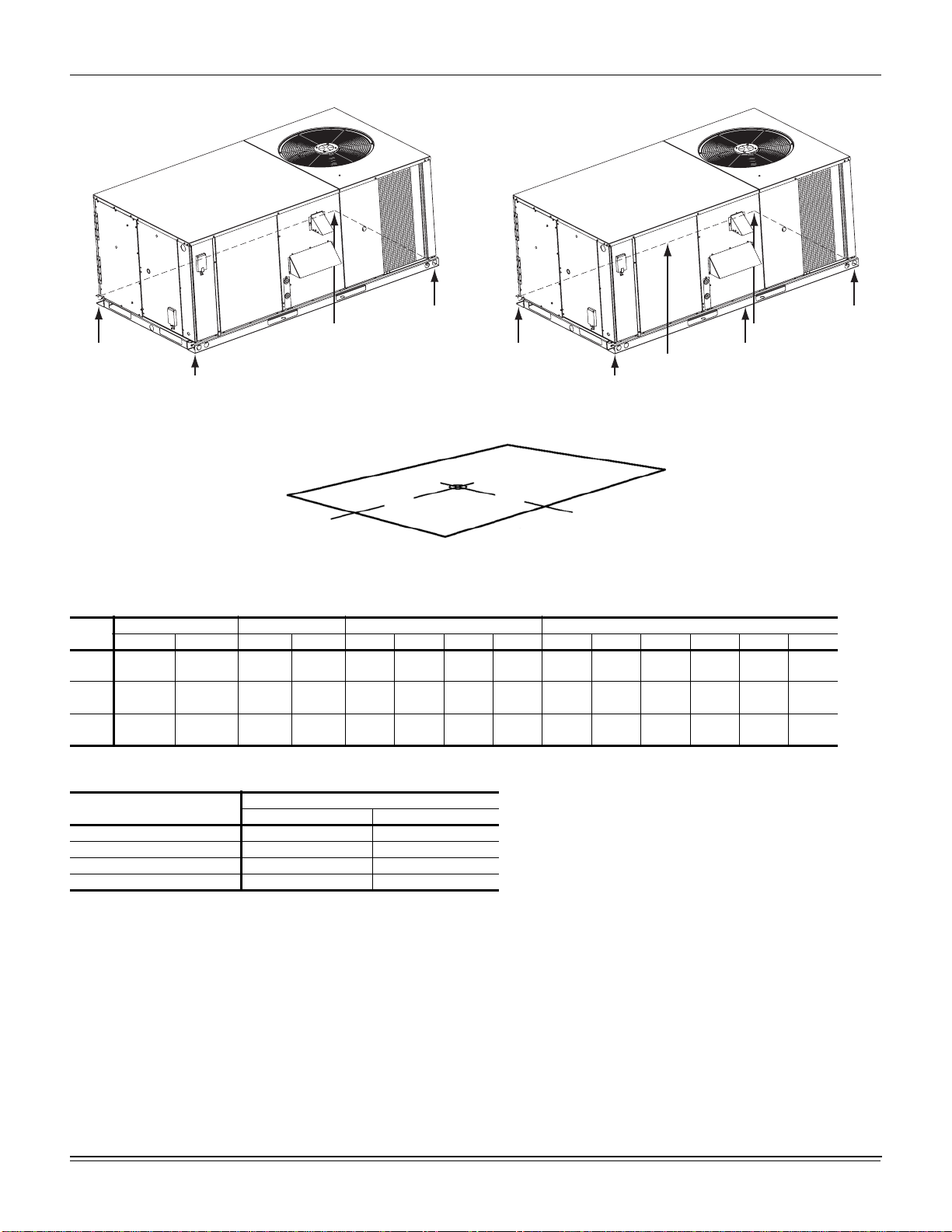

2 Weights and Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 ZR036-060 Unit Accessory Weights. . . . . . . . . . . . . . . . . 8

4 ZR036-060 Unit Clearances . . . . . . . . . . . . . . . . . . . . . . 10

5 ZR036-060 Utilities Entry . . . . . . . . . . . . . . . . . . . . . . . . 11

6 Control Wire Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7 Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8 ZR036-060 Physical Data . . . . . . . . . . . . . . . . . . . . . . . . 28

9 Electric Heat Minimum Supply Air. . . . . . . . . . . . . . . . . . 30

10 Gas Heat Application Data . . . . . . . . . . . . . . . . . . . . . . . 30

11 Gas Pipe Sizing - CapacIty of Pipe. . . . . . . . . . . . . . . . . 31

12 Altitude/Temperature Correction Factors . . . . . . . . . . . . 35

13 ZR Blower Performance Side Duct . . . . . . . . . . . . . . . . . 37

14 ZR Blower Performance Bottom Duct. . . . . . . . . . . . . . . 38

15 Belt Drive RPM Selection . . . . . . . . . . . . . . . . . . . . . . . . 39

16 Indoor Blower Specifications (Belt Drive) . . . . . . . . . . . . 39

17 Power Exhaust Specifications . . . . . . . . . . . . . . . . . . . . 40

18 Additional Static Resistance . . . . . . . . . . . . . . . . . . . . . . 41

19 Electric Heat Limit Setting. . . . . . . . . . . . . . . . . . . . . . . . 44

20 Electric Heat Anticipator Setpoints . . . . . . . . . . . . . . . . . 44

21 Single Stage Gas Heat Limit Control Setting . . . . . . . . . 46

22 2 Stage Gas Heat Limit Control Setting . . . . . . . . . . . . . 46

23 Gas Heat Anticipator Setpoints. . . . . . . . . . . . . . . . . . . . 46

24 Gas Rate-Cubit Feet per Hour . . . . . . . . . . . . . . . . . . . . 49

25 Unit Control Board Flash Codes . . . . . . . . . . . . . . . . . . . 57

26 Ignition Control Board Flash Codes . . . . . . . . . . . . . . . . 57

LIST OF FIGURES

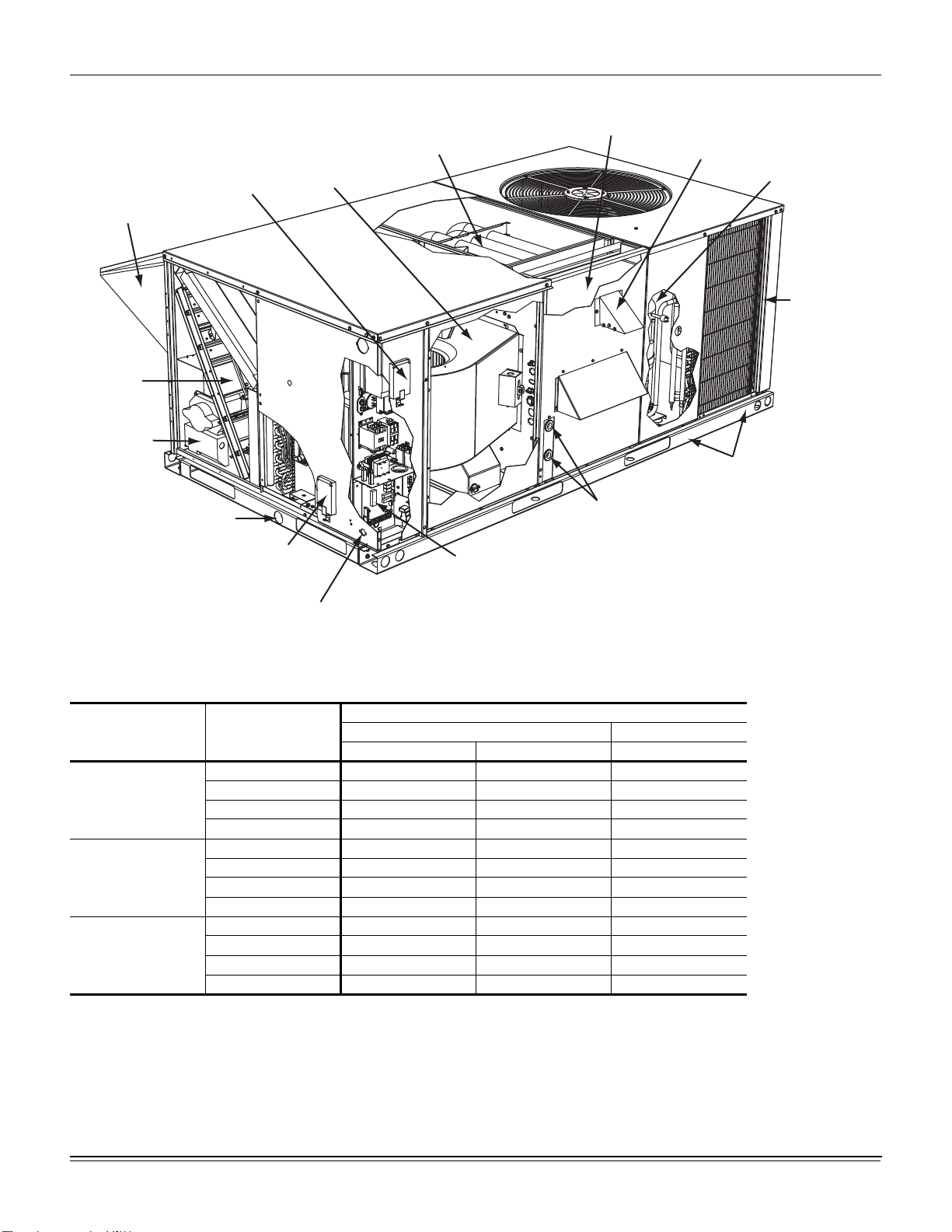

1 ZR036-060 Component Location. . . . . . . . . . . . . . . . . . . 6

2 Unit 4 Point Load Weight . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Unit 6 Point Load Weight . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Center of Gravity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5 ZR036-060 Cooling Only/Electric Heat Front View

Physical Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6 ZR036-060 Cooling Only/Gas Heat Front View Physical

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

7 ZR036-060 Fixed Outdoor Air Motorized Damper Rain

Hood Physical Dimensions . . . . . . . . . . . . . . . . . . . . . . 10

8 ZR036-060 Disconnect Location . . . . . . . . . . . . . . . . . . 10

9 ZR036-060 Unit Side Duct Openings. . . . . . . . . . . . . . . 11

10 ZR036-060 Roof Curb . . . . . . . . . . . . . . . . . . . . . . . . . . 11

11 Condensate Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

12 Compressor Restraining Bracket . . . . . . . . . . . . . . . . . . 13

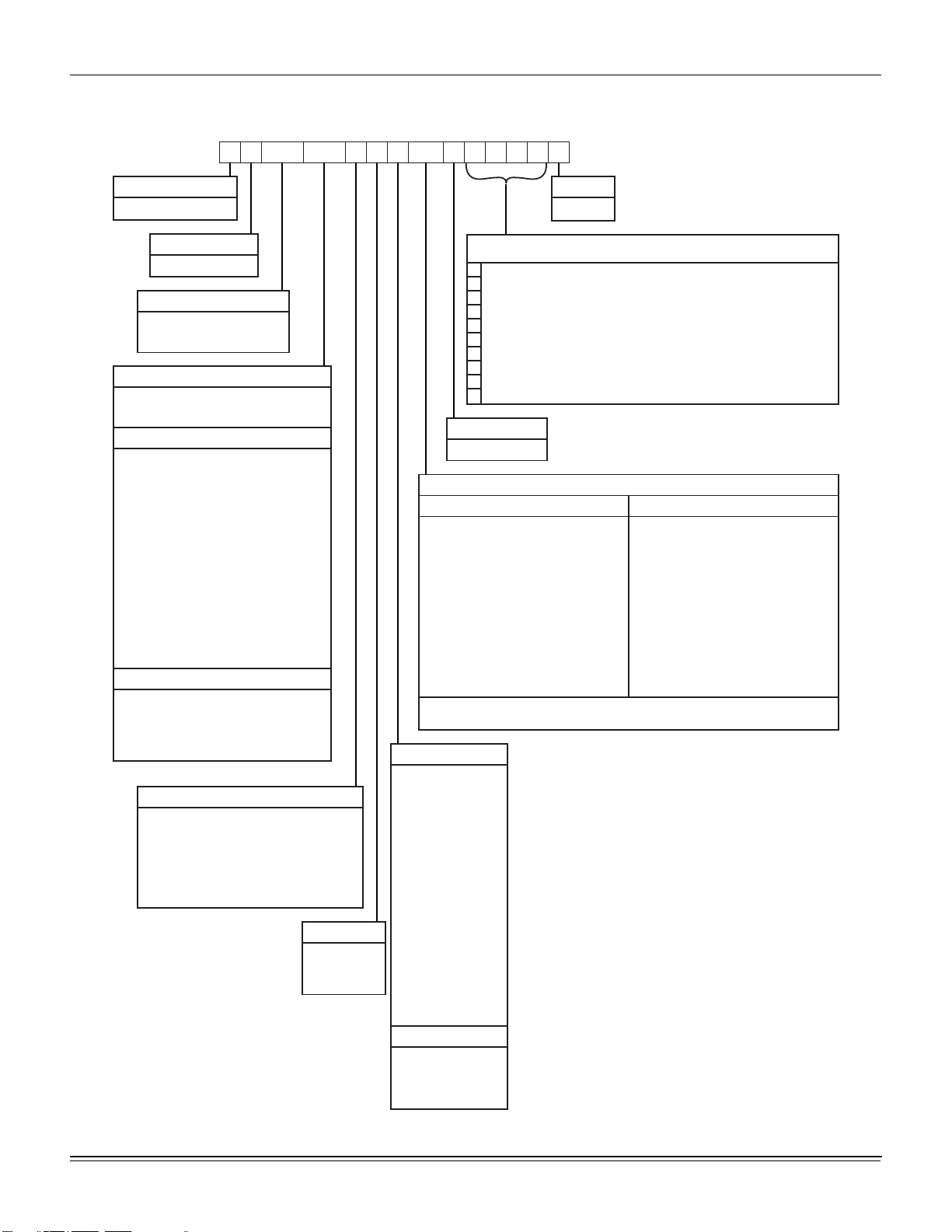

13 Typical Field Power and Control Wiring. . . . . . . . . . . . . 15

14 Side Entry Gas Piping . . . . . . . . . . . . . . . . . . . . . . . . . . 31

15 Bottom Entry Gas Piping . . . . . . . . . . . . . . . . . . . . . . . . 31

16 Vent And Combustion Air Hood . . . . . . . . . . . . . . . . . . . 33

17 Enthalpy Set Point Chart . . . . . . . . . . . . . . . . . . . . . . . . 34

18 Honeywell Economizer Control W7212 . . . . . . . . . . . . . 34

19 Belt Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

20 Altitude/Temperature Correction Factors. . . . . . . . . . . . 35

21 Pressure Drop Across Coil. . . . . . . . . . . . . . . . . . . . . . . 40

22 Gas Valve Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

23 Typical Single Stage Gas Valves. . . . . . . . . . . . . . . . . . 47

24 Typical 2 Stage Gas Valves. . . . . . . . . . . . . . . . . . . . . . 47

25 Proper Flame Adjustment . . . . . . . . . . . . . . . . . . . . . . . 48

26 Typical Flame Appearance . . . . . . . . . . . . . . . . . . . . . . 48

27 ZR036 (3.0 Ton) Operating Pressures. . . . . . . . . . . . . . 51

28 ZR048 (4.0 Ton) Operating Pressures. . . . . . . . . . . . . . 52

29 ZR060 (5.0 Ton) Operating Pressures. . . . . . . . . . . . . . 52

30 Unit Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57