Johnson Controls CVWSEK-240BK/DP Owner's manual

Other Johnson Controls Air Conditioner manuals

Johnson Controls

Johnson Controls D Series User manual

Johnson Controls

Johnson Controls DSH024C Series User manual

Johnson Controls

Johnson Controls York YDEC028 User manual

Johnson Controls

Johnson Controls MagnaDRY DK-15 User manual

Johnson Controls

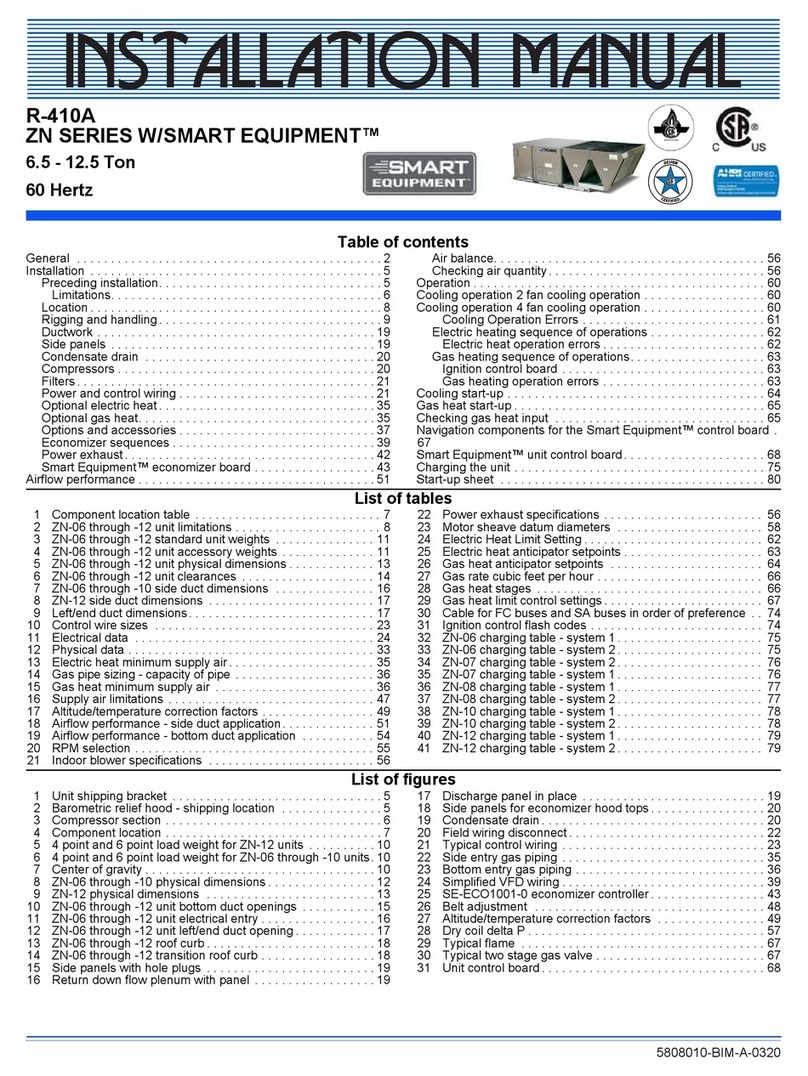

Johnson Controls York ZN-06 User manual

Johnson Controls

Johnson Controls J ZB Series User manual

Johnson Controls

Johnson Controls DHW18CMB21S User manual

Johnson Controls

Johnson Controls YORK YH9FXH18BAH--FX User manual

Johnson Controls

Johnson Controls YXV SERIES User manual

Johnson Controls

Johnson Controls HIC2018B21S User manual

Johnson Controls

Johnson Controls York Predator ZT Series User manual

Johnson Controls

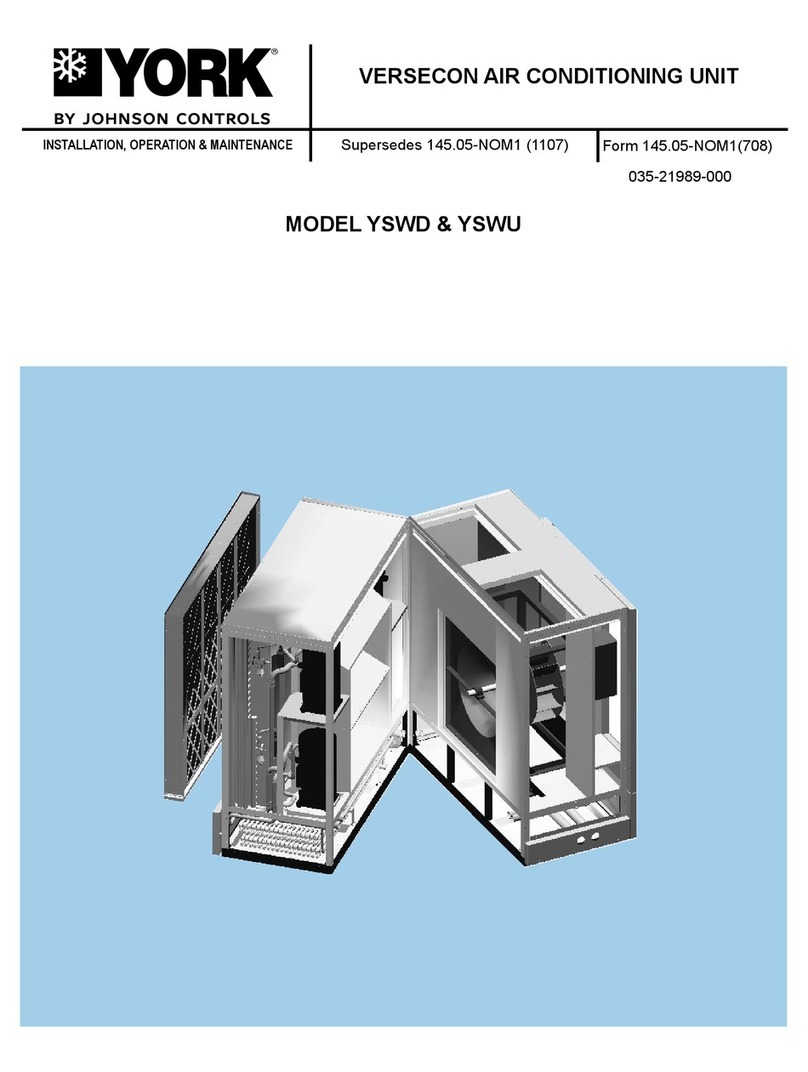

Johnson Controls York VERSECON YSWD Series Owner's manual

Johnson Controls

Johnson Controls DU-15 User manual

Johnson Controls

Johnson Controls R Series Manual

Johnson Controls

Johnson Controls HVAHP0721CW Series User manual

Johnson Controls

Johnson Controls YORK EOKC-09 FS User manual

Johnson Controls

Johnson Controls ZY Series User manual

Johnson Controls

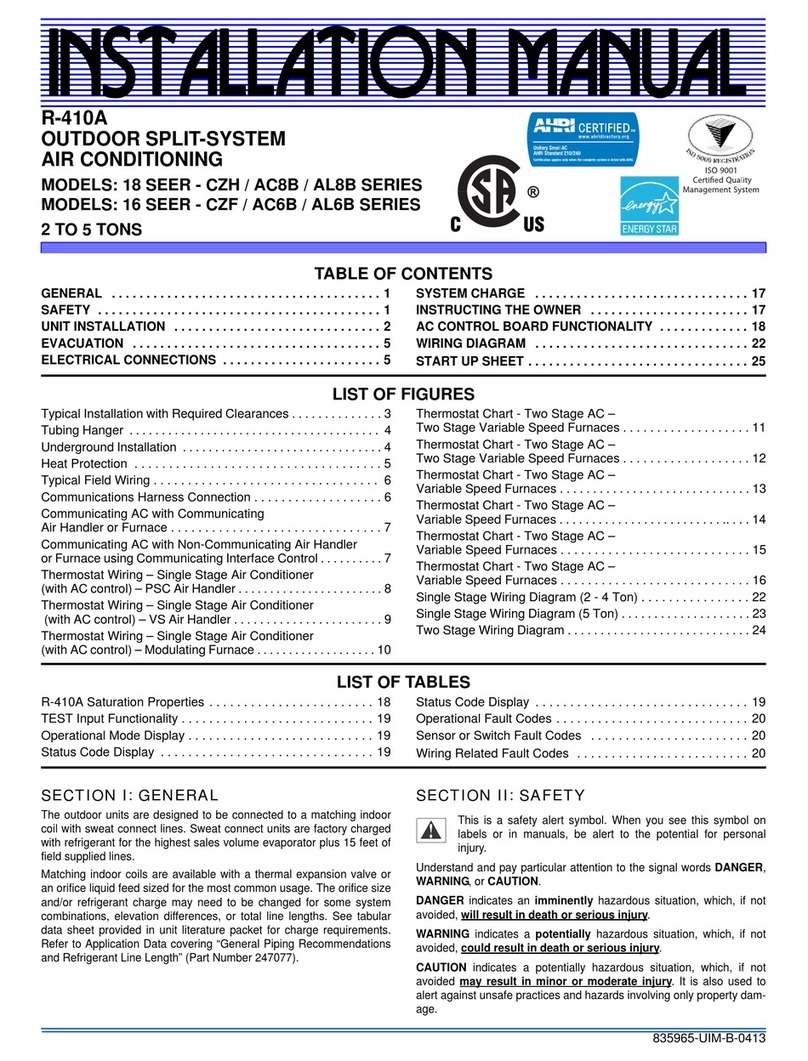

Johnson Controls 18 Seer-CZH Series User manual

Johnson Controls

Johnson Controls YORK YH9FXC18BAH-FX User manual

Johnson Controls

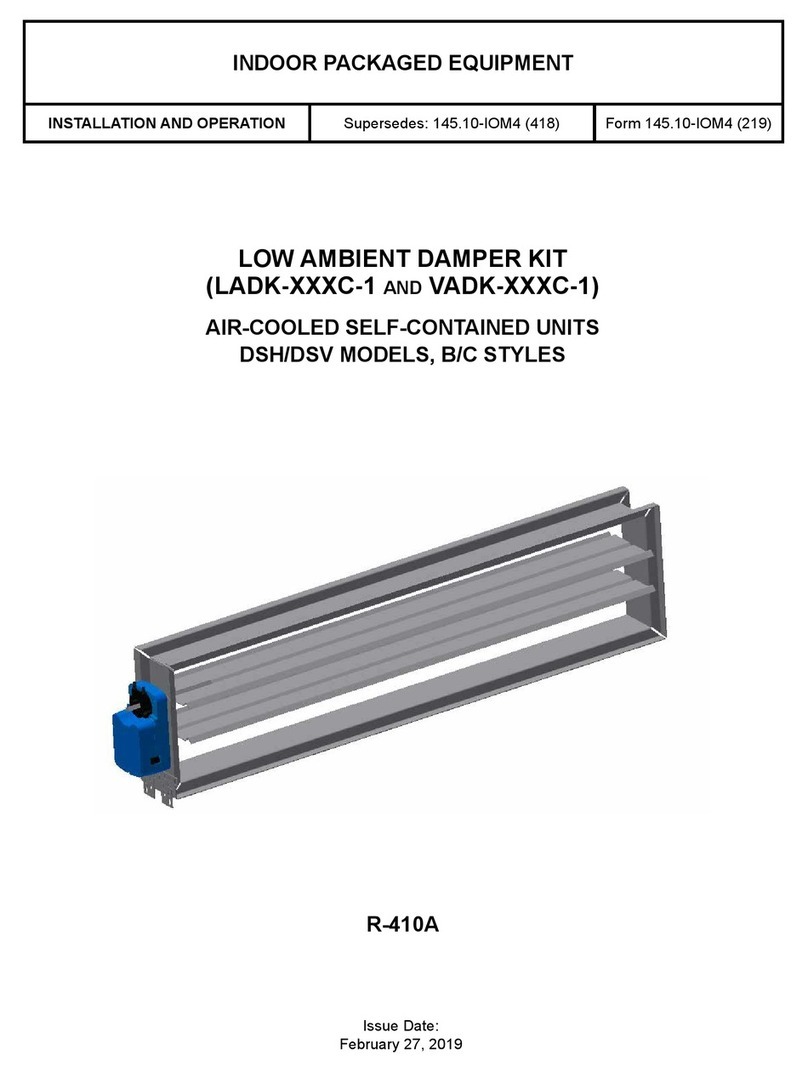

Johnson Controls Duct R-410A Owner's manual

Popular Air Conditioner manuals by other brands

CIAT

CIAT Magister 2 Series Installation, Operation, Commissioning, Maintenance

Bestron

Bestron AAC6000 instruction manual

Frigidaire

Frigidaire FFRE0533S1E0 Use & care guide

Samsung

Samsung AS09HM3N user manual

Frigidaire

Frigidaire CRA073PU11 use & care

Soleus Air

Soleus Air GB-PAC-08E4 operating instructions

McQuay

McQuay MCK020A Technical manual

Webasto

Webasto Frigo Top 25 DS Instructions for use

Frigidaire

Frigidaire FAZ12ES2A installation instructions

Mitsubishi Electric

Mitsubishi Electric MSC-GE20VB operating instructions

Mitsubishi Electric

Mitsubishi Electric PLA-M100EA installation manual

Daikin

Daikin Split Sensira R32 Service manual