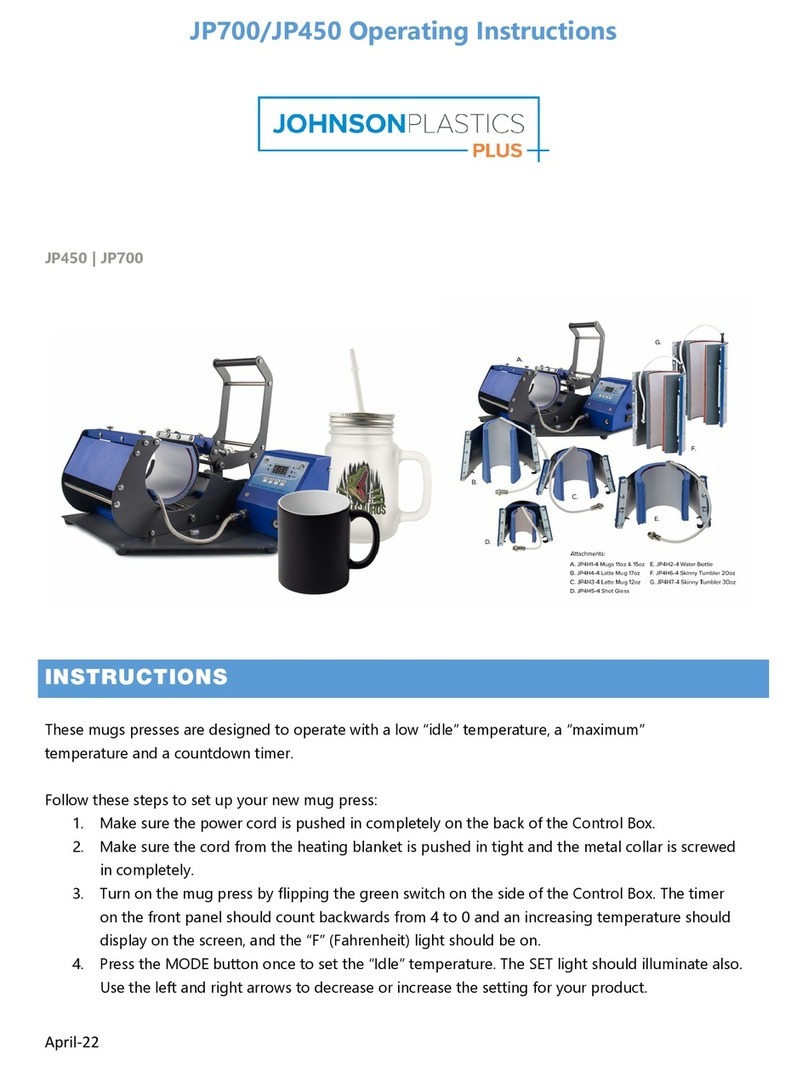

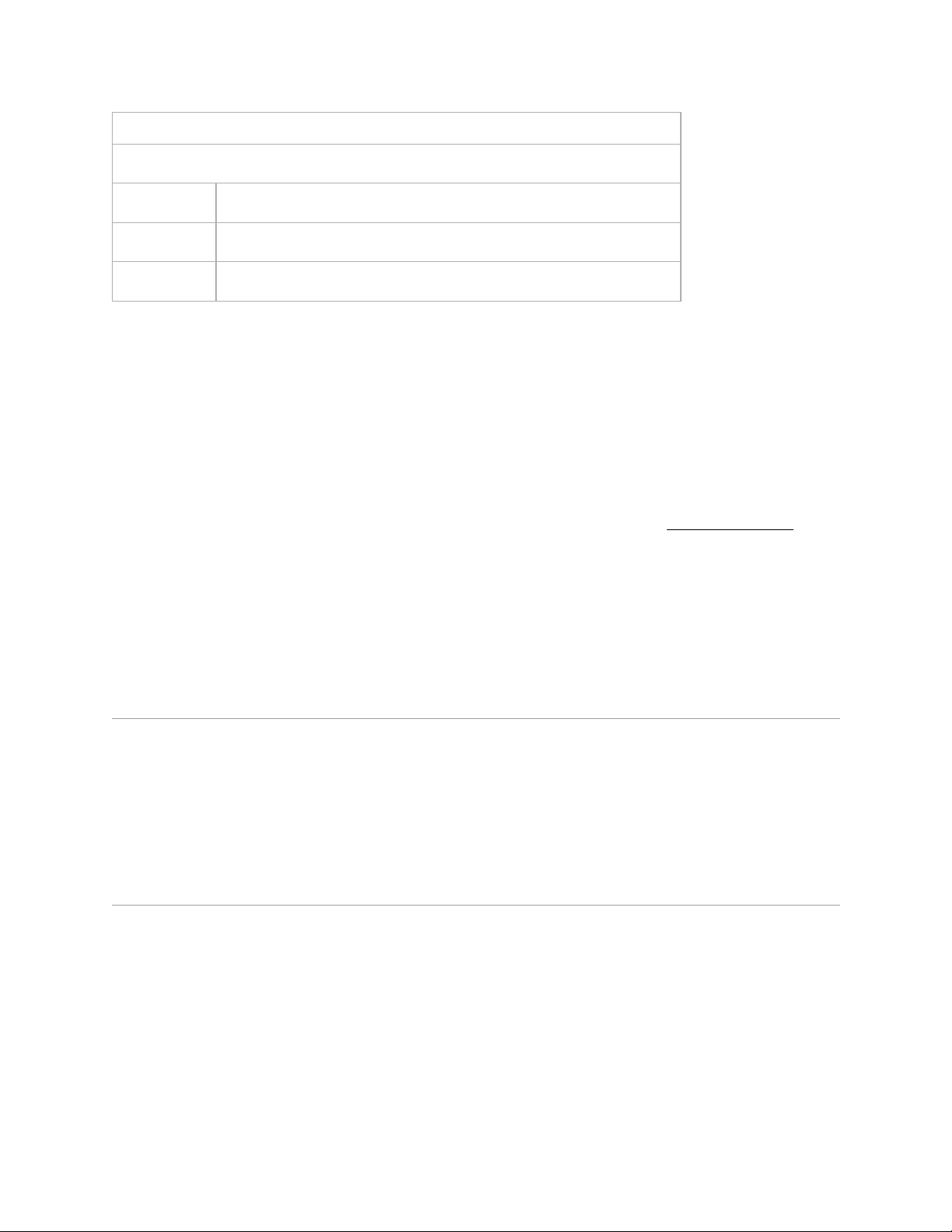

Recommended Settings - Constant Temperature Mug Press

Refer to the Heat Transfer Paper Instructions for best results.

General Heat Transfer Instructions - Constant Temperature Mug Press

•Follow the Heat Transfer Paper Instructions for best results.

•Preheat the press to 300°F. Set the time to 50-60 sec., set pressure to medium/heavy.

•Wipe down the drinkware with soft cloth misted with isopropyl alcohol.

•Print and apply transfer to the drinkware using heat tape.

•Place the drinkware into the mug press. Close and press for recommended time.

•When finished, remove the product from press. Wait until the drinkware cools enough to be able to

touch without heat gloves, then peel the transfer paper off and discard.

oSubmerging the drinkware into water to speed up the cooling process is not recommended.

•To increase the durability of the heat transfer image on the drinkware, after peeling the transfer

paper, place the drinkware into a convection oven that is preheated to 350-360°F.

•Heat the drinkware in the oven for 20 minutes.

•When finished, remove the drinkware from the oven and set aside to cool.

oHeating the drinkware in the convection oven is highly recommended for stainless steel/metal,

glass, and ceramic drinkware.

Tips and Tricks

•For best image placement, utilize the product template found on the product page on JPPlus.com.

•If using an orange silicone heat pad, adjust temperature to 330°F.

•To prevent damage to the transferred image, hand wash drinkware only, using a soft cloth or sponge.

oAvoid cleaning with abrasive sponges or pads.

Troubleshooting

•The image did not completely transfer to the product.

oSlightly increase the press pressure.

oThe product may still be too warm when peeled. Wait a little more time before peeling the

transfer paper.

•Ensure that the Hard Surface paper used is compatible with the product material, as there are several

types of Hard Surface papers available for different types of hard surface goods.