3

Contents

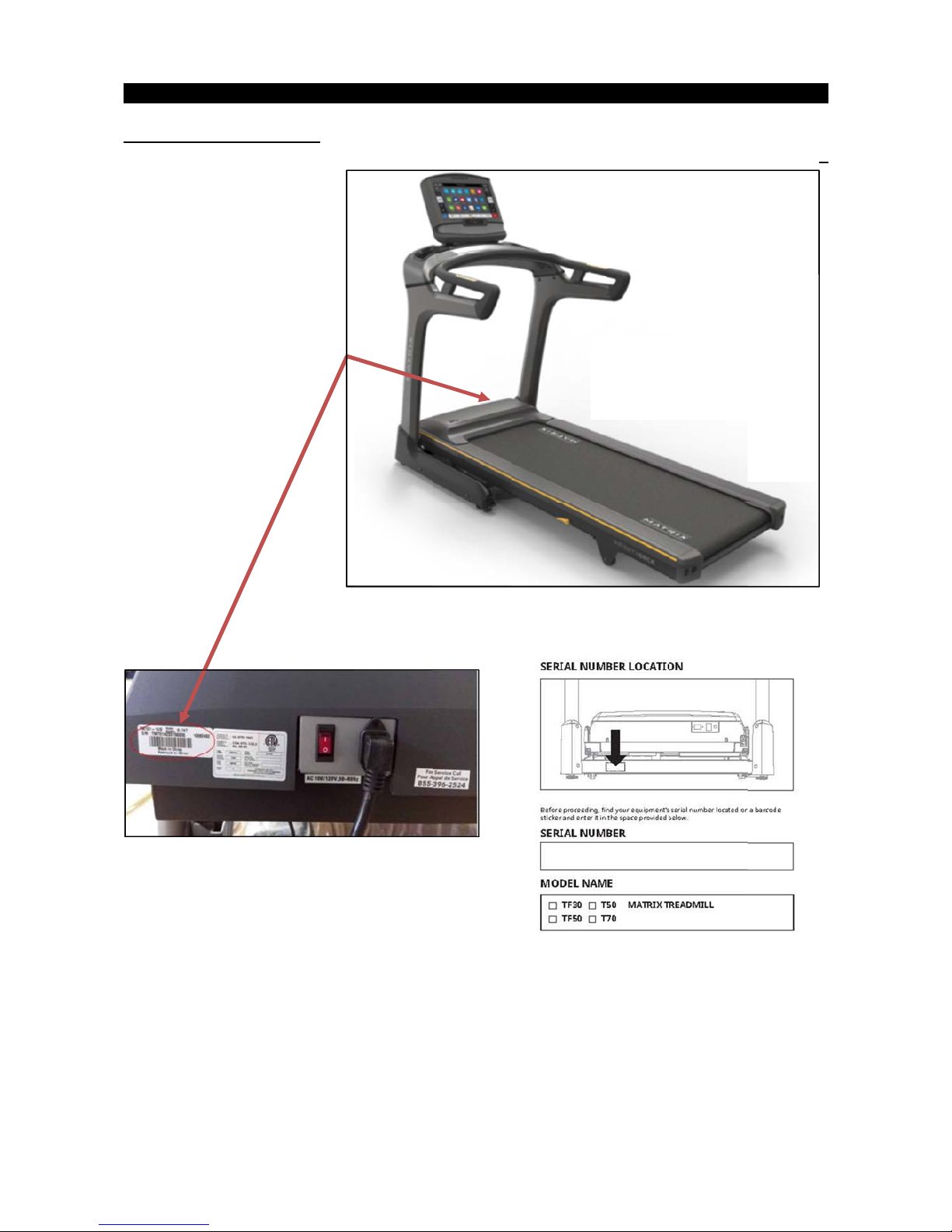

CHAPTER 1: SERIAL NUMBER LOCATION ................................................................................................... 4

CHAPTER 2: TROUBLESHOTING

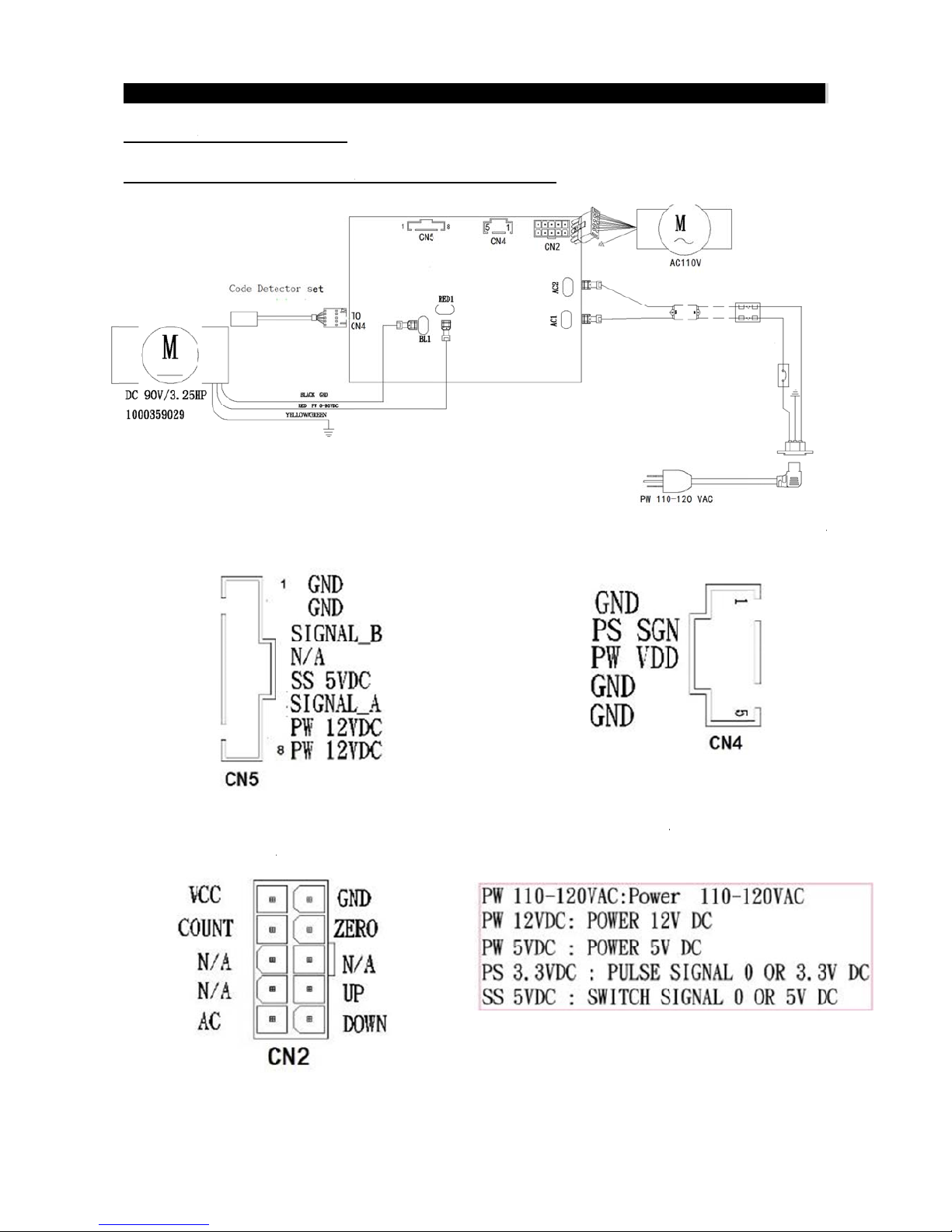

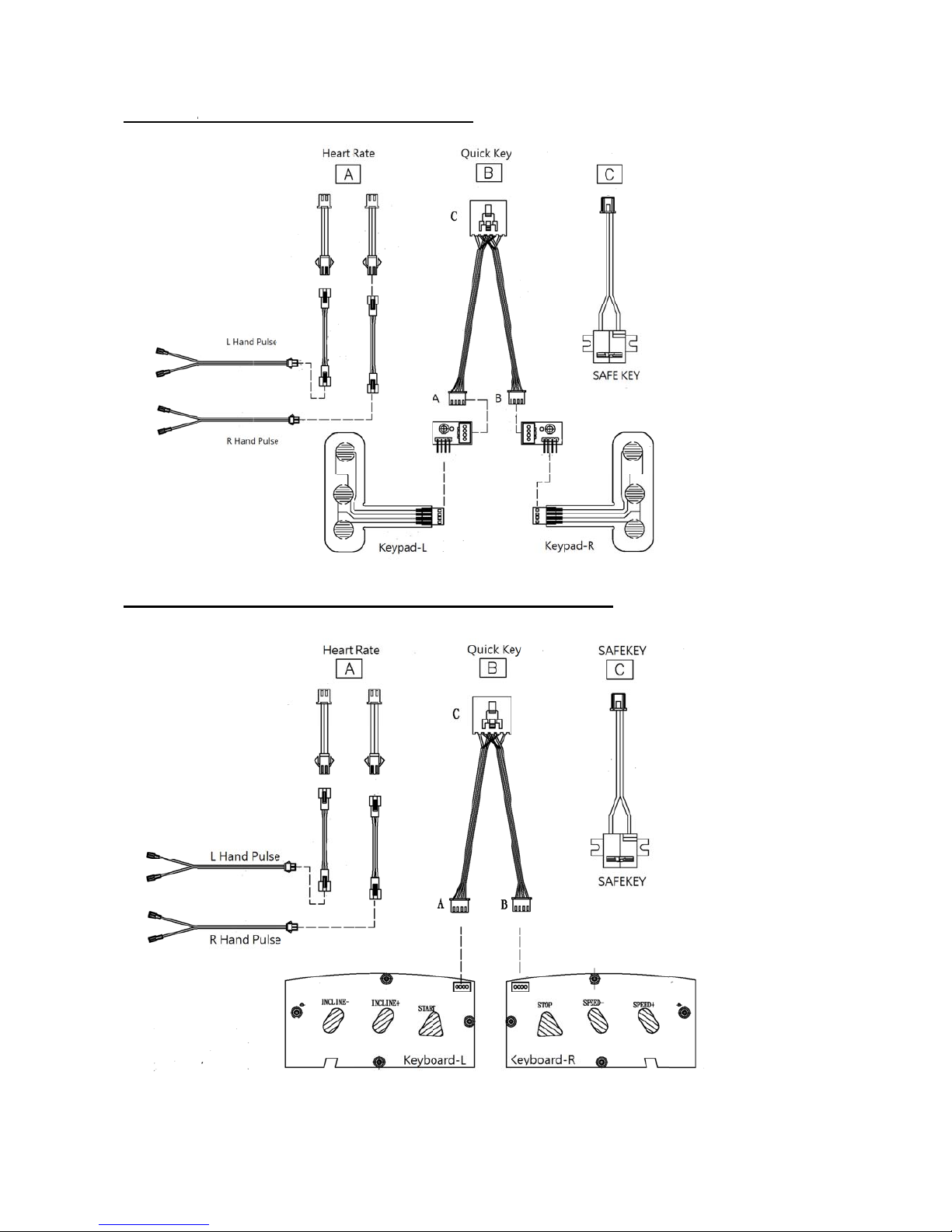

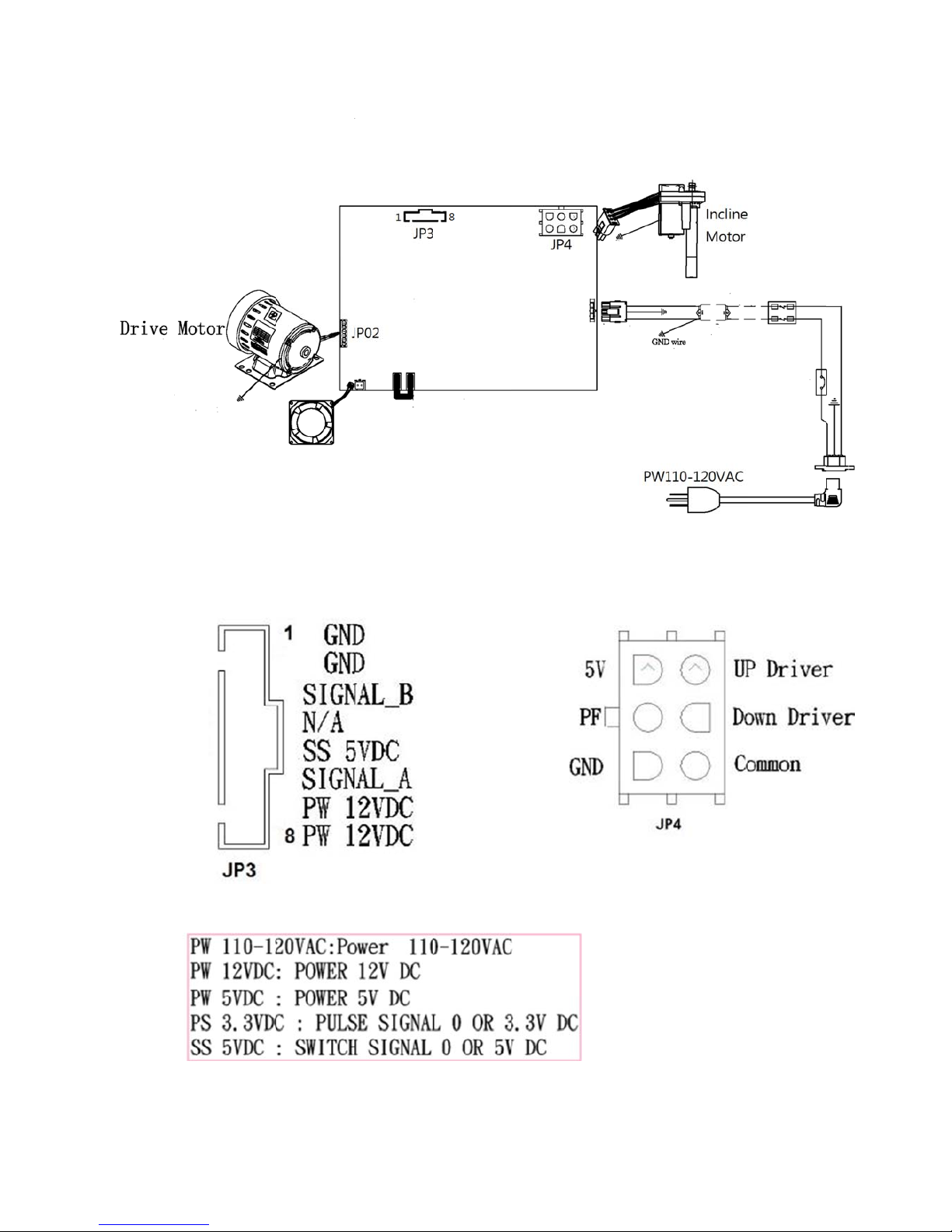

2.1 Electrical Diagram…………………………………………………………………………………………………5

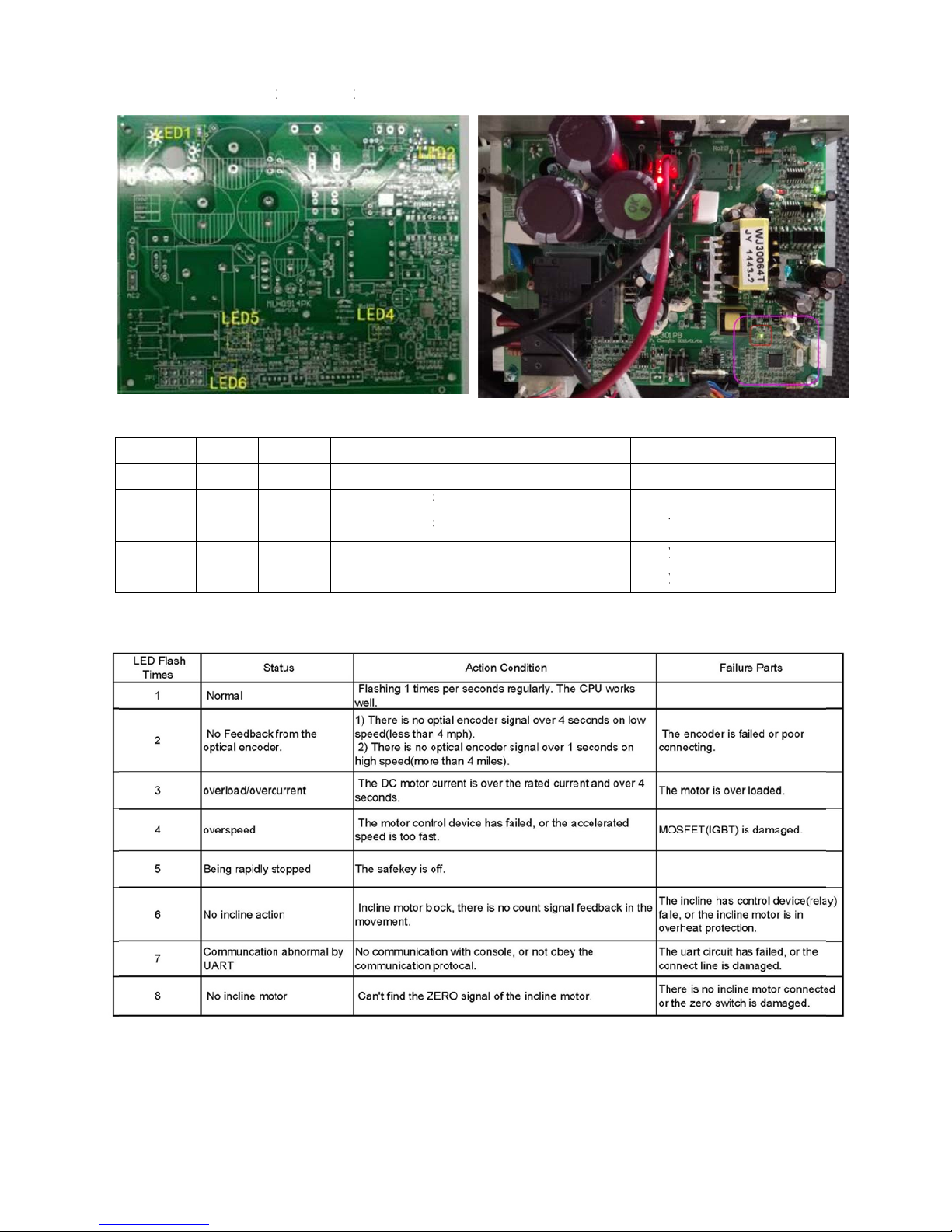

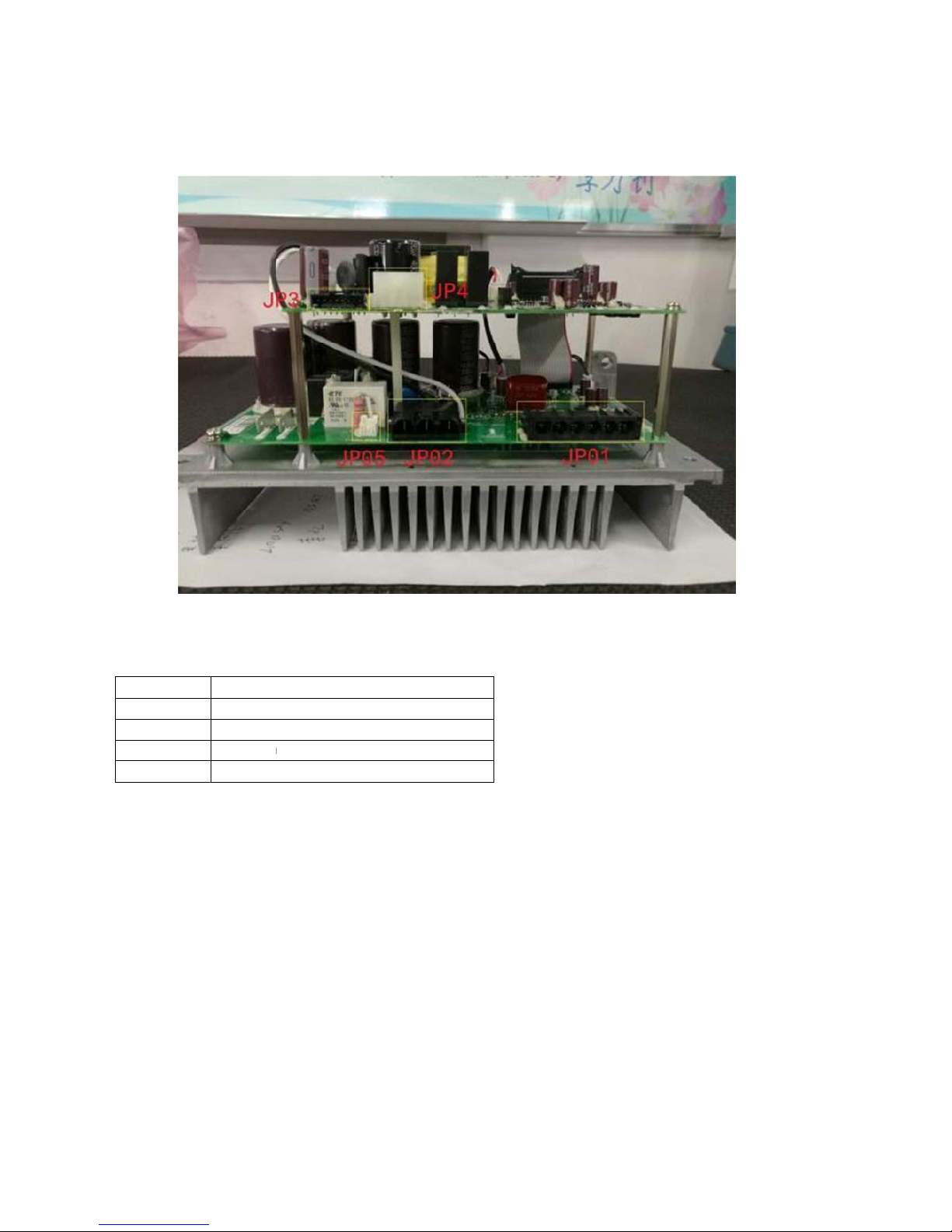

2.2 MCB instructions……………………………………….……………………………….…………………….......8

2.3.1 Troubleshooting - No Function For Safety Key ................................................................................... 12

2.3.2 Troubleshooting - No Response For Machine When Pressing Start……………………………………..13

2.3.3 Troubleshooting - Incline Motor Issues ................................................................................................. 14

2.3.4 Troubleshooting - Noise Issues ............................................................................................................ 15

2.3.5 Troubleshooting - Heart Rate Function Issues ..................................................................................... 16

CHAPTER 3: PART REPLACEMENT GUIDE

3.1 Motor Replacement .................................................................................................................................. 17

3.2 Side Rail Replacement ............................................................................................................................ 19

3.3 Rear Roller Replacement ......................................................................................................................... 20

3.4 Running Deck Replacement .................................................................................................................... 21

3.5 Front Roller Replacement ........................................................................................................................ 22

3.6 Running Belt Replacement ...................................................................................................................... 23

3.7 Motor Control Board (MCB) Replacement ............................................................................................... 24

3.8 Incline Motor Replacement ...................................................................................................................... 25

3.9 Console Replacement..............................................................................................................................26