- 4 –

wwww.johnnyvac.com

Precautions

The following safety warning signs are used with title “For the sake of safety” throughout this manual,

which have several functions as below:

------Both warning signs and nameplates provide important information of safe operation.

------Except information in operation manual, all other rules about universal safety information and

accident prevention regulated by laws shall be obeyed as well.

Warning: used for warning that serious personal injury, death or unsafe operation

maybe caused.

For the sake of safety: point out the items must be obeyed for safe operation.

The following safe prevention symbol point out situations that may lead to potential danger to

operator or machine. All operators must read, understand and implement following safety precautions:

Warning: fire disaster or blast

----Flammable liquid is not allowed to be used; Do not operate machine in the site near or in the place

of flammable liquid, gas or dust.

Flame-proof motor is not equipped with this machine. During the start and operation of machine,

spark will be caused by electronic motor, which may result in flash fire or blast if the machine is

operated in the place with flammable gas, liquid or dust.

-----Do not sweep flammable material or active metal.

Warning: Electrical shock.

------Disconnect the wire of battery and plug of charger before the maintenance of machine.

------Do not use damaged wire to charge battery or refit plug.

The wire of charger must be changed by manufacturer, maintenance agency or other person with

similar qualification if it is damaged or broken, in order to avoid the occurrence of danger.

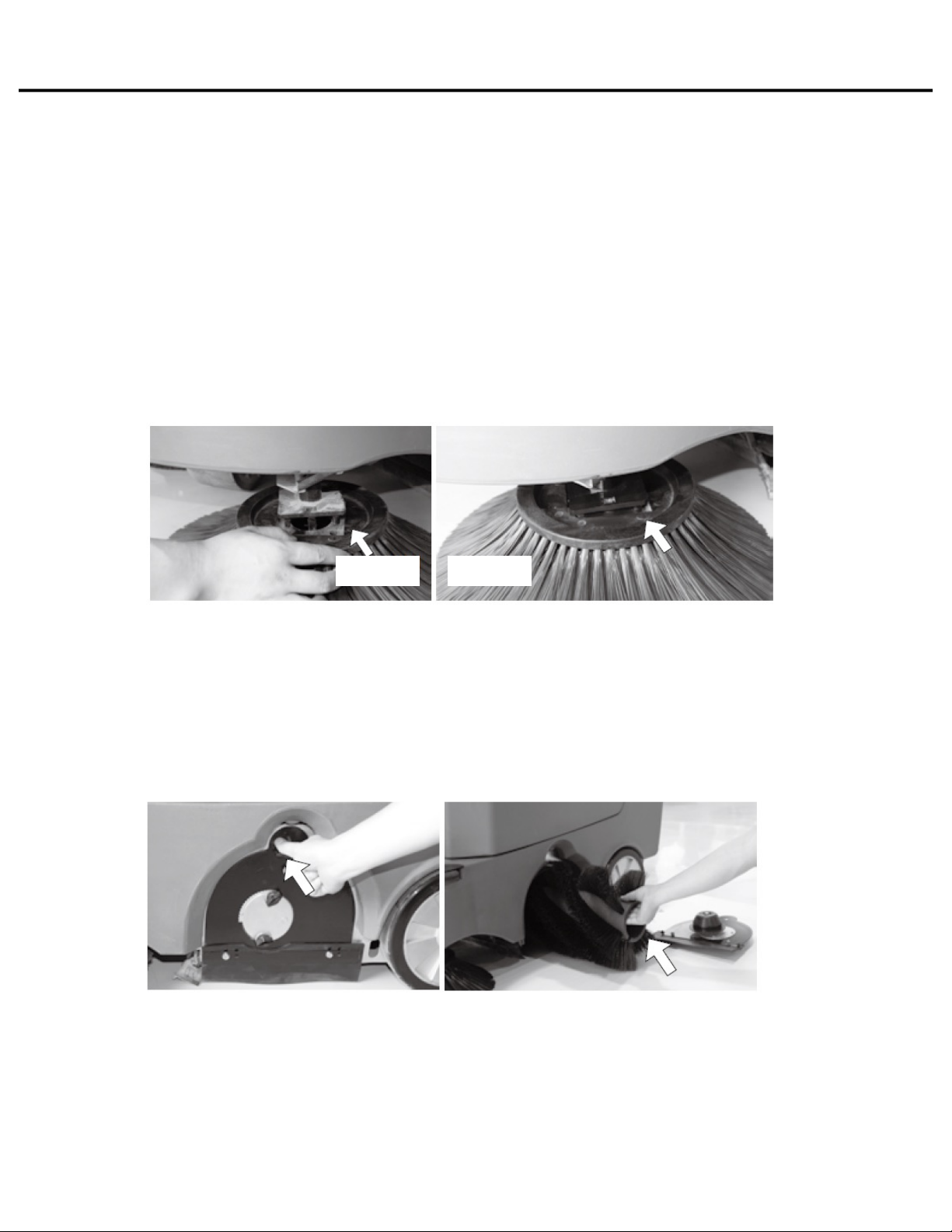

Warning: The rotary brush is running. Do not close it by hands. Please switch off the

power before maintenance of machine.

Warning: used for warning that serious personal injury, death or unsafe operation may be

caused.