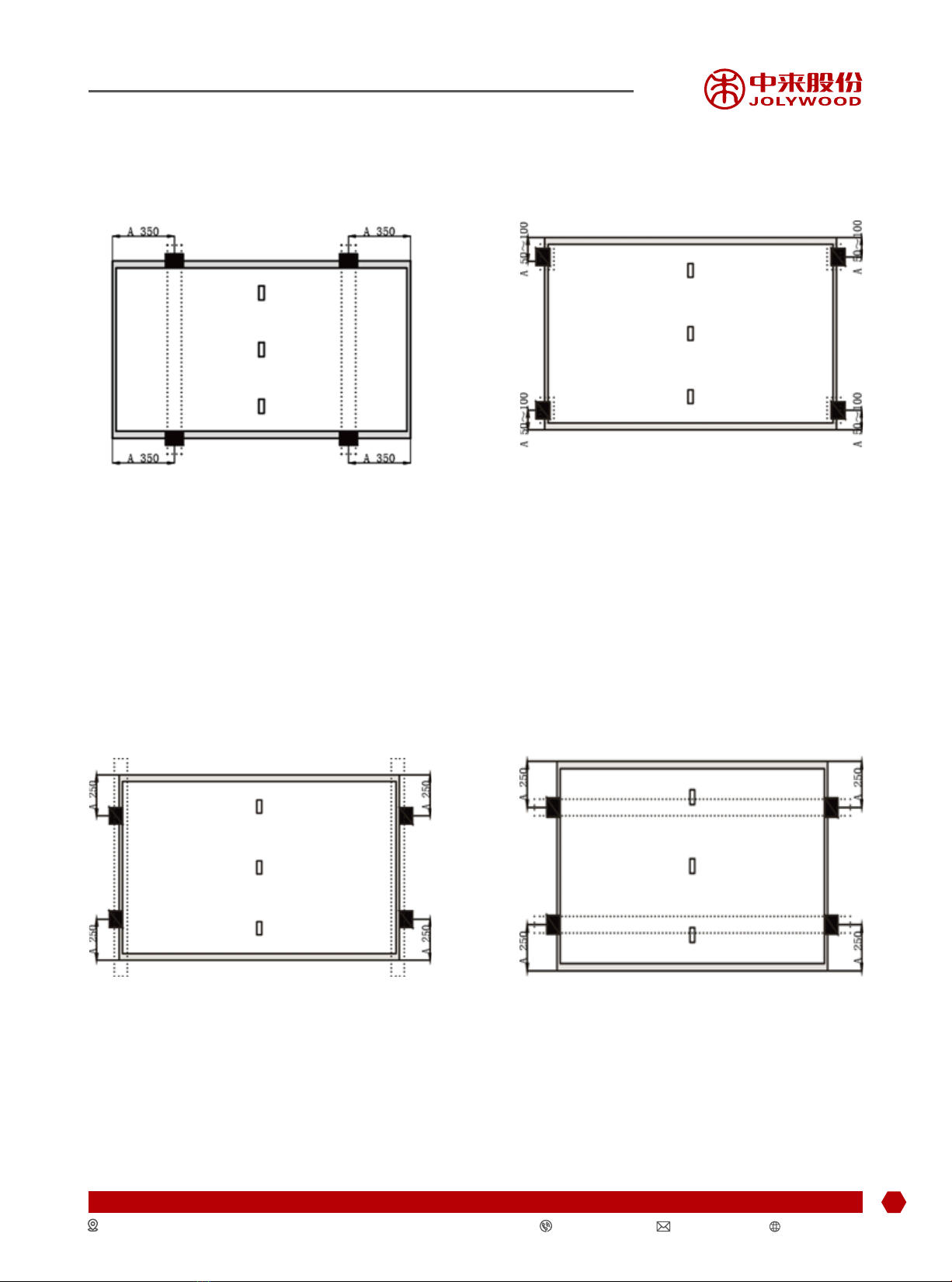

4.1.2

4.2 Unpacking steps

4.2.1

7

Jolywood (Taizhou) Solar Technology Co.,Ltd.

Kai

yang Rd., Jiangyan EconomicDevelopment zone, Taizhou City, Jiangsu Province, P. R. Chinawww.jolywood.cn[email protected] +86-523-8061 2361

Installation Manual - Jolywood N-type Mono-crystalline Double Glass Module

4.0 Unpacking instruction

4.1 Unpacking safety instruction

4.1.1

For long-term storage of modules, it is

recommended to store them in a standard

warehouse for regular patrol inspection. In case of

abnormal inclination, please reinforce them in

time under the condition of ensuring personal

safety.

The shelves in the warehouse shall have sufficient

bearing capacity and storage space, and regular

patrol inspection shall be conducted to ensure the

safe storage of goods. If the modules need to be

stored in the project site, it is forbidden to select

the soft and collapsible ground. Instead, the hard

ground or the ground with high terrain should be

selected and leveled to ensure that the modules

will not collapse or tilt during long-term storage.

When modules unpacked outdoors, it is forbidden

to work under rain, as carton would become soft

and be broken. Modules inside of it would come

out, damage or bruises may be caused to module.

During windy days, special attention should be

paid for safety, it is recommended not to transport

modules, and the unpacked modules should be

properly fixed.

The ground needs to be flat enough to ensure

package could be placed horizontally and stably.

Supportive tool should be used when

disassembling the carton to prevent the modules

from falling down.

4.1.3

Wear protective gloves during unpacking to avoid

injury and fingerprints on the glass surface.

4.1.4

Module information could be queried from outer

package, please read it carefully before

unpacking.

4.1.5

Each module should be lifted by two man. Do not

lift module by grasping the module terminal box

or lead wires. Use both hands to carry module, do

not stack modules during lifting.

4.1.6

The unpacked modules must all be installed,

should not be stored at the project site. It is

forbidden to stack in the project site for a long

time, and the number of temporarily stacked

modules shall not exceed 16.

Before unpacking, please check the product name

and serial number on an A4 paper on the surface

of the package, unpacking method should not be

randomly changed.

In rainy weather, please use a rain cloth to

completely cover the modules and pallets, and

take rain and moisture-proof measures for the

pallets and cartons. In case of sunshine or wind,

remove the rain cloth to dry the outer packaging

as soon as possible, so as to avoid collapse due to

moisture deformation.It is forbidden to soak the

tray in the rain to cause mildew and decay. The

ground drainage measures should be taken first to

prevent the ground from being soft and sinking

due to a large amount of water on the ground

after the rain. Unauthorized access to the module

storage area is prohibited.