ASSEMBLY INSTRUCTIONS JK125

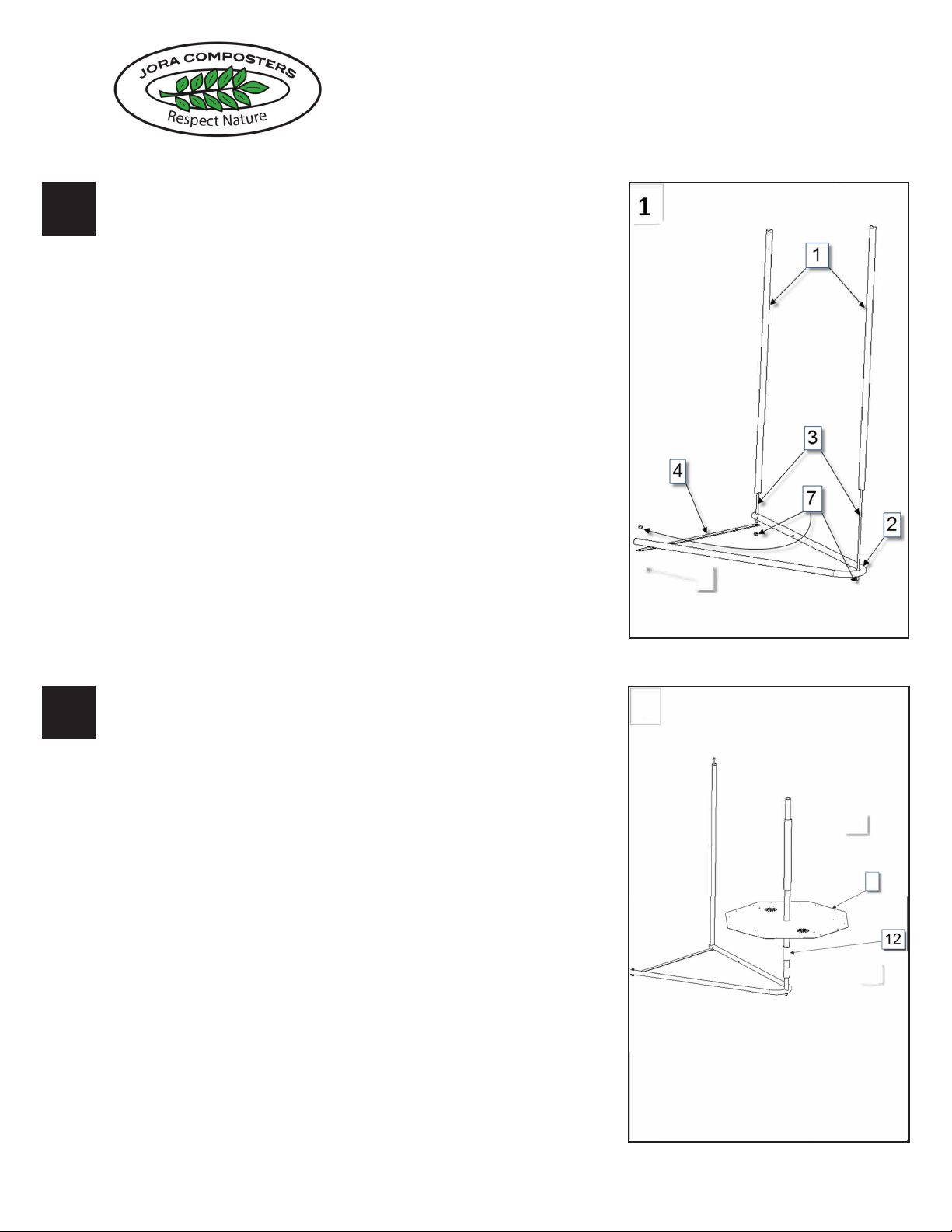

Slide the Octagonal foam insulation piece #9 (one of two with

ventilation holes) over the long and medium black tube until it

reaches the metal side piece. Line up ventilation holes.

Slide the square nylon piece #13 over the black tube until it

rests on the medium tube #11.

Slide on the octagonal insulator #14 (the one that does not

have ventilation holes)

Slide on 2nd square piece # 13 to rest on insulation and

sandwich the insulation.

Slide on 2nd medium plastic pipe #11

Slide on octagonal insulation piece #9 over the medium pipe.

Slide on 2nd metal side and line up ventilation holes.

Note: The diagram shows you can now insert the nylon bolts,

nuts and washers. I nd it easier to install these after Sketch

4 when the unit is standing up and after one panel has been

installed. It is up to you which you choose.

3

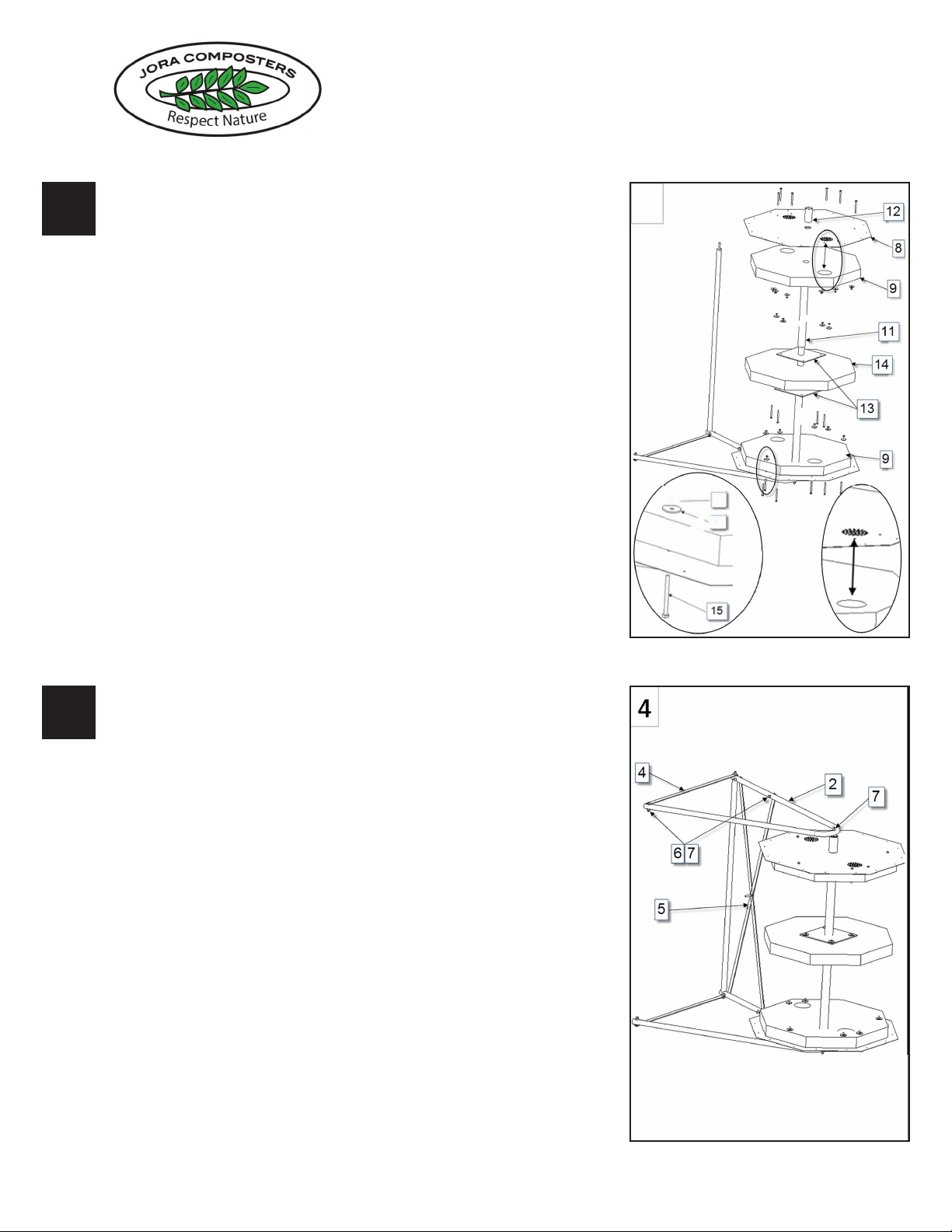

(Hand tighten only) Attach the cross brace #4 to the front hole

on the 2nd V shaped stand. Place 2nd side of the stand #2 on

the 2 metal threaded rods, and attach locknuts on the top and

bottom rods. Be sure the cross brace is on the threaded rod

and attached by the locknut.

Place and attach X brace #5 with bolts #6 and locknuts #7 to

rear of stand. Have 2 people stand up the composter. Tighten

all nuts and bolts.

Note: The ends of the hollow metal tubes are formed at

each end to conform to the sides to prevent spinning and

strengthens the composter. When tightening the locknuts you

may need the second person to lift the center slightly as well

as securing the nut to position this properly.

Line up the Octaganol insulation panels with the ventilation

holes and sides and insert plastic screws #15, through the

insulation, add washer#17 and bolt #16. (hand tighten) There

are no pre-drilled holes in the insulation, applying pressure to

the nut will force it through. Washers are only used on the end

panels. Repeat at other end.

For the middle section line up the sides and push the screws

through #15 and attach nut #16. (no washers are used for

these).

4

Tools needed:

2 pc adjustable wrenches

1 pc Phillips Screwdriver

1 pc Flathead Screwdriver

All Measurements Are In Metric Units*

Tools needed:

2 pc adjustable wrenches

1 pc Phillips Screwdriver

1 pc Flathead Screwdriver

All Measurements Are In Metric Units*