3

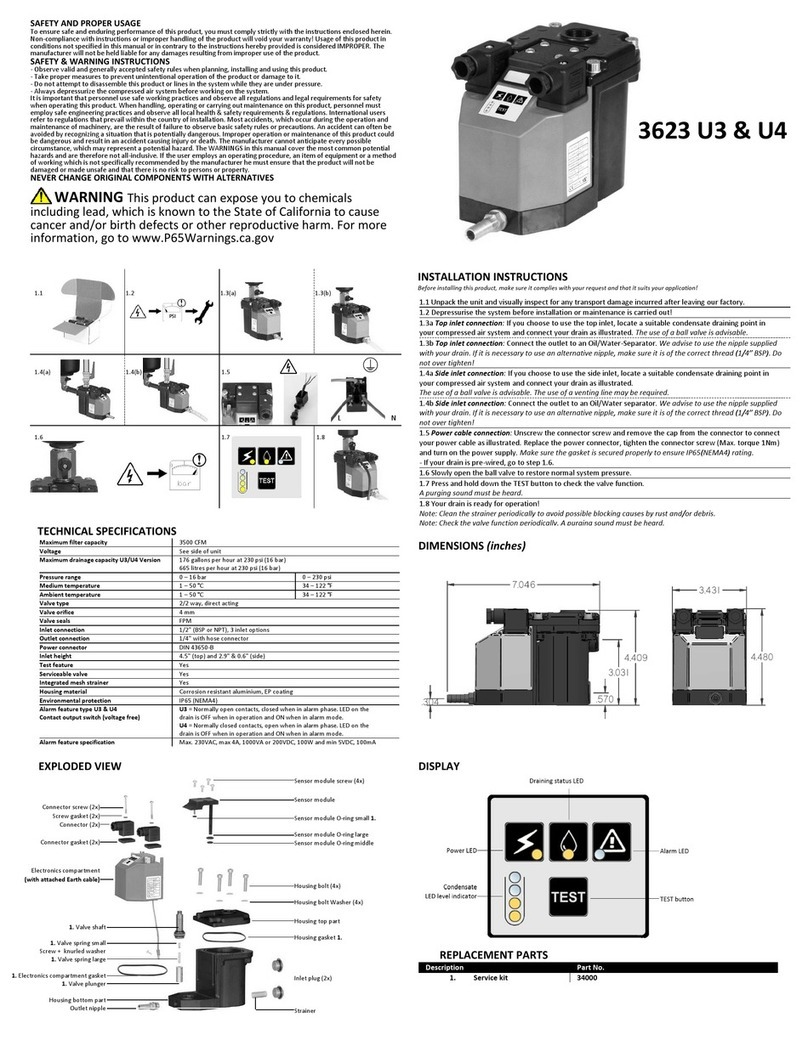

CONTROL PANNEL

1 Mode selector

switch 1

(operation mode)

2 Mode selector

switch 2 (setting

time, program)

3 LCD display

4 Override button

5 Setting the

minutes

6 Setting t he ho urs

7 RESET

8 Setting the days

9 Programming of

timer (saving

settings)

PROGRAMMING INSTRUCTIONS

Before you start programming the unit, move the mode selector switch (2) in to position and shortly press the RESET (7) button to clear

the existing program.

SETTING THE ACTUAL TIME AND DAY

1 After pressing the RESET (7) button, the display will look like this . All preprogrammed settings will be

deleted. The unit is now ready to be programmed.

2 You can set the actual time by pressing the [h] hours(6) and [m] minutes (5) , 24 hr display!

3 You can set the actual day by pressing the [1…7] button(8), (Mon=1, Tue=2, We=3…..).

1st Step

Move the mode selector switch (2) into position . The clock has 16 points: 8 x ON (OPEN the valve) and 8 x OFF (CLOSE the valve).

All odd (1,3,5 etc.) switch points open the valve, all even (2,4,6 etc.) switch points closes the valve. The switch points are numbered from 1

to 16. When programming the unit, the symbol will display when setting a valve open cycle.

When the following display appears yo u ca n e nter t he firs t va lve ope n c yc le.

2nd Step

Enter the time you would like the valve to open by means of pressing the (h)hours (6) and

(m)minute (5) buttons.

3rd Step

Set the day of the week when the valve should OPEN (by pressing [1…7]) (8).

- set the day (8) (Mon=1, Tue=2, We=3…..)

- Form time blocks Mon-Fri (1/2/3/4/5)

Mon-Sat (1/2/3/4/5/6)

Mon-Sun (1/2/3/4/5/6/7)

The day must be set otherwise the switching point will not be activated.

4th Step

By pressing the [ ] (9)key, you save the switching point data and go on to the next switching

point (CLOSE).

The display will show . You can now set the time and day for closing the valve.

By pressing the [ ] (9)key, you save the switching point data and go on to the next switching point

(OPEN).

5th Step

To set the next OPEN and CLOSE cycle, please refer to step 3, 4 and 5.

To go to the next day, you must complete the 16 switching points (leave the unused switching points at

the value 0:00 b y simply pressing the [ ] (9)key until the display shows (3)).

Then select the next day and continue programming as described under step 3, 4 and 5.

6th Step

After you have finished programming the unit, move the mode selector switch 2 in to position RUN

And move mode selector switch (1) in to position AUTO.

The unit will now operate fully automatically.

CHOOSING THE CORRECT WORKING MODE (Mode selector switch 1):

AUTO Unit will work by means of its program (also when using the remote switching feature)

I Unit will OPEN valve permanently (i.e. after hours work shift)

O Unit will CLOSE valve permanently (i.e. holiday facto ry shutdown)

PROGRAM OVERRIDE BUTTON [] (4)

By pressing the [ ] (4) button you will override the pro gram for this da y (meaning the valve will be c losed from the time you press the

[ ] (4) button , until 24:00 the same day. When in override mode the (4) symbol will be displayed, after which the symbol

will be displayed indicating the pro gram mod e per day.