3170 Wasson Road • Cincinnati, OH 45209 USA

Phone 513-533-5600 • Fax 513-871-0105

I & M Mark 508UBS

Installation & Maintenance Instructions for

Mark 508UBS Back Pressure Regulators

Warning: Thorough maintenance operations and overhauls are important for the safe and reliable operation of all

valves. The service procedures recommended by Jordan and described in this manual are for carrying out main-

tainance operations. Please note that this service manual contains various warning and caution notices which

should be read carefully in order to minimize the risk of injury to people or the possibility of using incorrect work

methods which may damage the valves or make them unsafe. It is important to realise, however, that these warn-

ings cannot be exhaustive. Jordan is unable to know, assess and inform customers or users of all the conceivable

methods of performing maintainance operations and all the risks deriving from the use of such methods. Therefore,

whoever uses a service method or piece of equipment which is not recommended by Jordan must make sure that

neither his own or other people’s safety, nor valve safety and performance are jeopardized by the chosen method.

Testing, installing or removing the valves or accessories may cause you to come into contact with fluids at very high

pressures or temperatures and/or corrosive or erosive. Therefore, take all safety precautions while testing, install-

ing or removing the product; these include, wearing ear plugs, goggles and safety clothing, such as gloves, both in

or near the work area. Users of Jordan products are responsible for training the staff that will use the product. It is

most important for these people to acquire a thorough knowledge of the instructions of the product, especially the

ones contained in this manual.

Please read these instructions carefully!

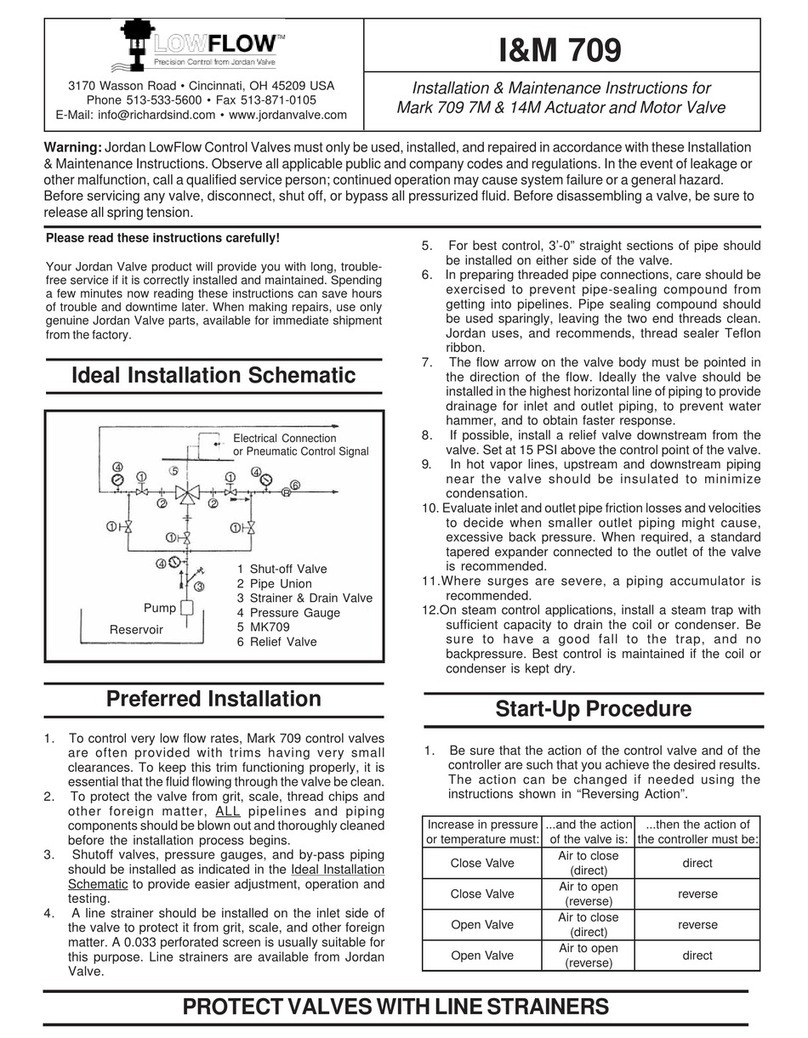

Ideal Installation

Safety Precautions

Always observe the current plant safety regulations to-

gether with the following indication:

• Wear safety clothing. Hot water can scald you and

overheated steam is invisible.

• When removing a valve, wear safety clothing to pre-

vent being sprayed by any process fluid that may

have accumulated inside. Remember that this fluid

may generate a potentially explosive mixture. Make

sure the valve is isolated from any pressure source

in the system before staring to remove it.

• Inspect/ service the valves at least once a year.

The outer surfaces of the valves reach the same tem-

perature as that of the fluid flowing inside them. For

this reason, when installing a valve in a potentially

explosive atmosphere, make sure that the flashover

temperature of the mixture surrounding the valve is

safely above that of the fluid flowing inside the valve

and do not allow flammable powders to deposit on

the outer surface of the valve.

• The system must be at zero static potential at the

connection between the valve and the piping in or-

der to prevent the accumulation of static electricity

on the outer surfaces of the system that can act as

an efficient flashover trigger in a potentially explosive

atmosphere.

Transport, Storage & Handling

Transport

Depending on their size, valves can be transported

loose, packed in cardboard boxes or in wooden crates.

All of the valve ends are fitted with covers to prevent

dirt from entering. Packs can be places on pallets if

required. Follow all and any indications written on the

packaging.

Storage

Valves must be kept in a dry place to protect them from

atmospheric conditions. They may only be removed

from their crates or packing immediately prior to instal-

lation. The end protections and covers must be kept on

until the last moment. Valves, whether packed or not,

must not be subject to violent knocks. Valves, whether