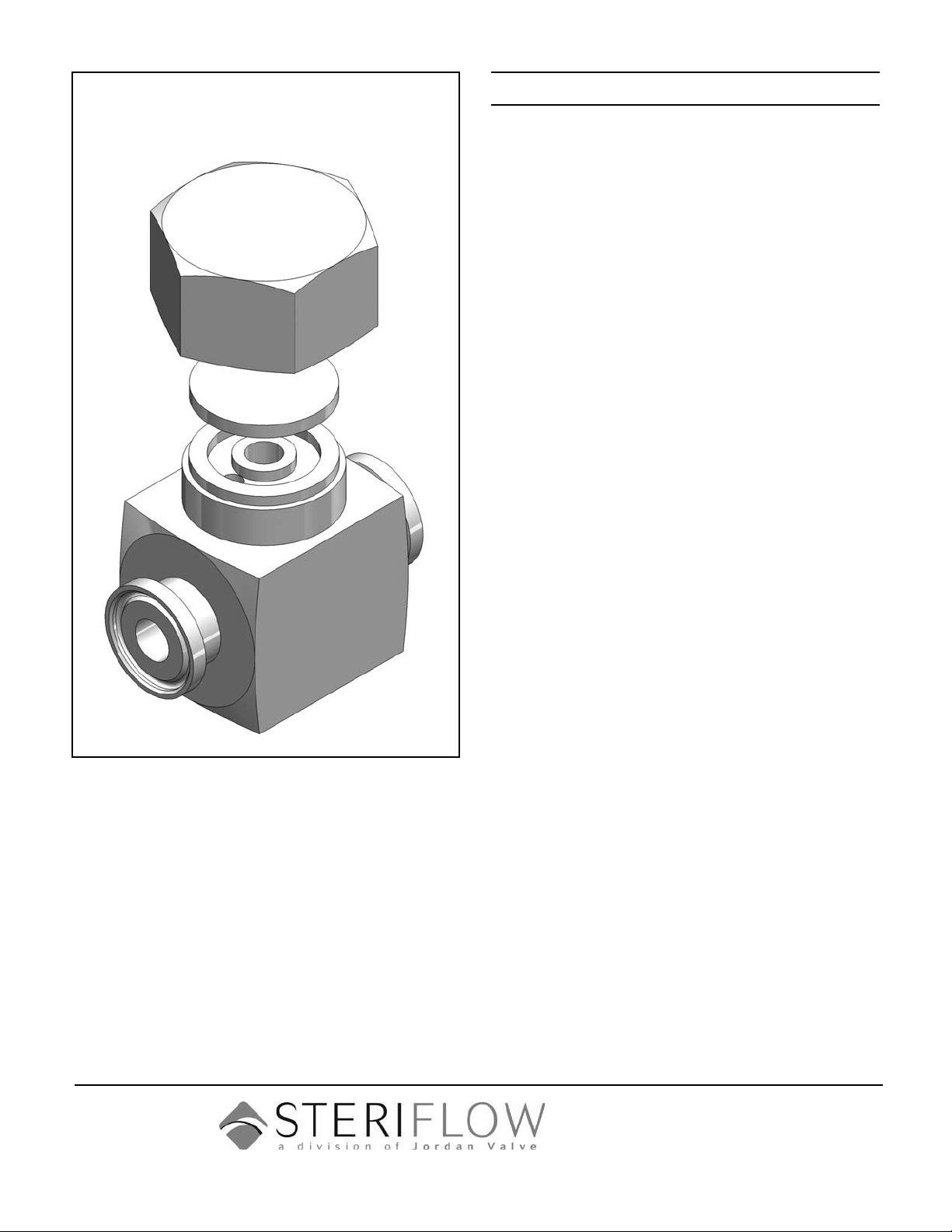

I & M CSDT Series

Installation & Maintenance Instructions for

CSDT Series Clean Steam Disc Traps

3170 Wasson Road • Cincinnati, OH 45209 USA

Phone 513-533-5600 • Fax 513-871-0105

Please read these instructions carefully!

Your Steriow product will provide you with long, trou-

ble-free service if it is correctly installed and maintained.

Spending a few minutes now reading these instructions

can save hours of trouble and downtime later. When

making repairs, use only genuine Steriow Valve parts,

available for immediate shipment from the factory.

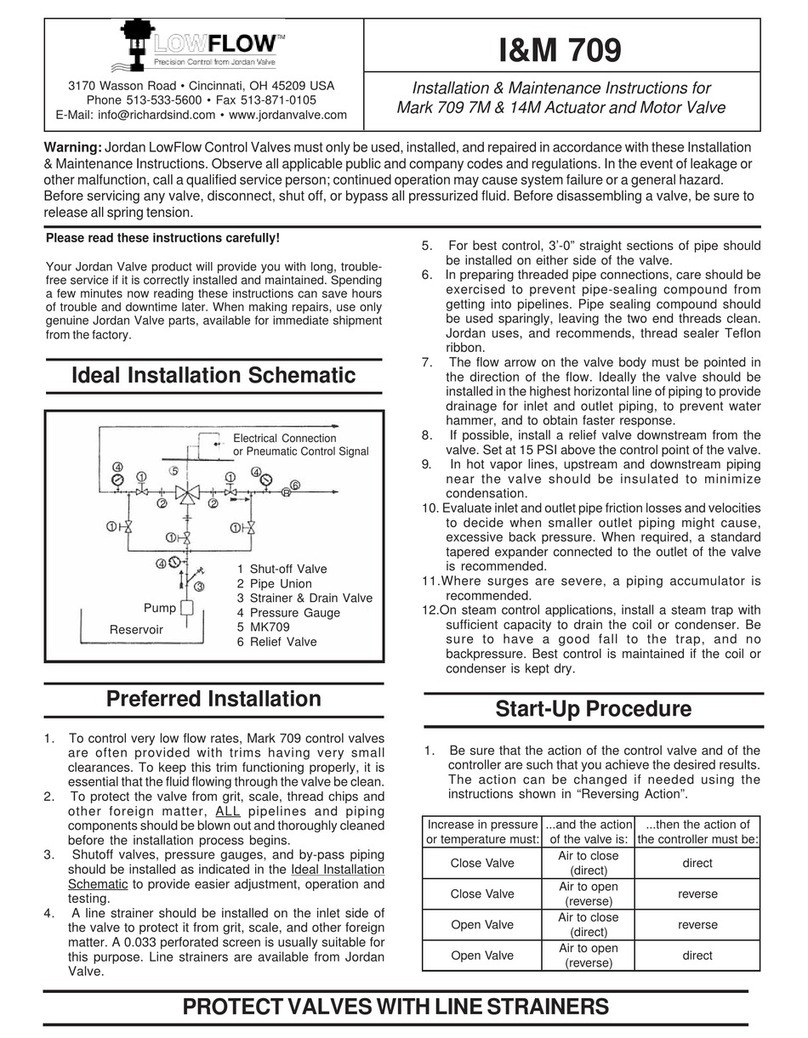

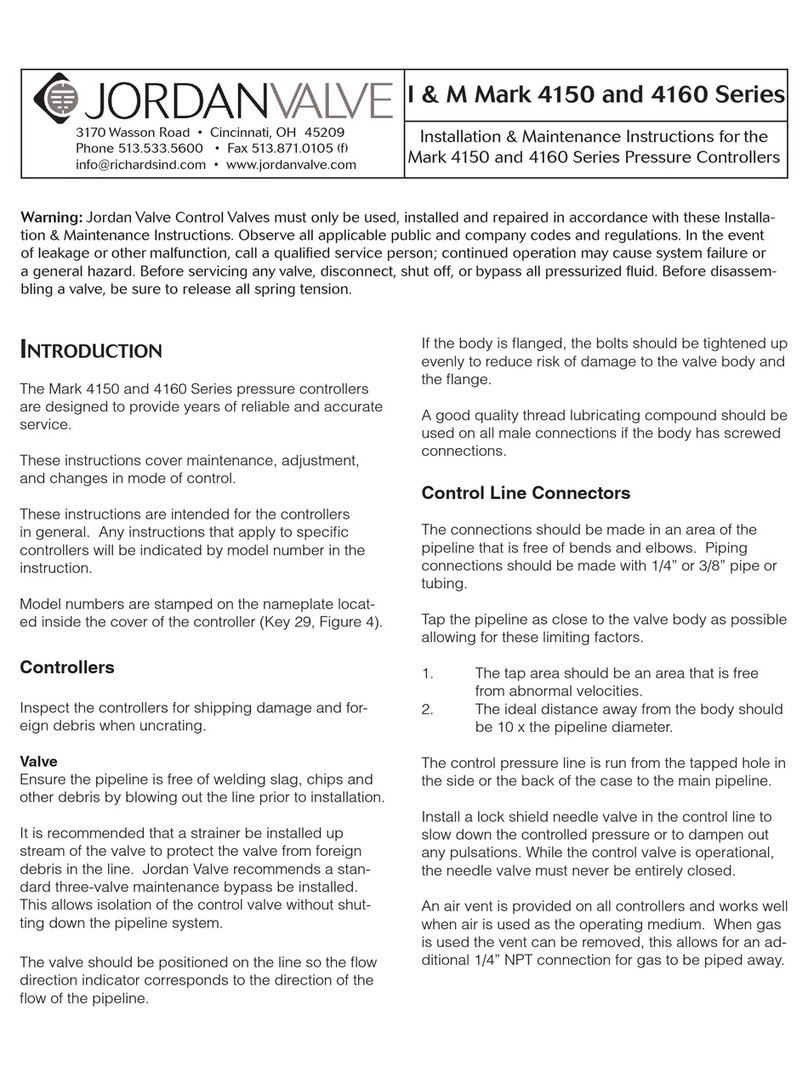

Ideal Installation Schematic

Installation

Check that steam supply is shut off. Ensure that 1.

all system pressures are off and trap is cool before

opening.

Remove steam trap from piping by disconnecting 2.

the inlet and outlet Tri-Clamp® and slipping the trap

from the line.

The trap may be installed horizontally or vertically 3.

with discharge downward. The preferred installation

is in the horizontal position as close as possible to

the equipment being drained. Whenever possible,

position the trap below the unit being drained.

Piping should be the same size as the trap connec-4.

tion. To avoid excessive backpressure, discharge

piping should not be smaller on short runs. For

longer lines, use one size larger.

A full-ported shut-off valve upstream is recommend-5.

ed to allow isolation for servicing. A shutoff valve

downstream will protect against back ow from the

return line during servicing.

A strainer should be installed with a blowdown valve 6.

immediately upstream of the trap to protect it from

grit, scale and other foreign matter.

A test valve outlet and pressure gauges should be 7.

provided to check trap operation where condensate

discharge is piped to a return line.

For freeze protection, the trap should be installed 8.

vertically with discharge downward, as shown

above. Discharge as close to drain connection

as practical and discharge to atmosphere directly

through a short pipe. A vacuum breaker upstream

may be require to provide complete drainage.

71

3

6 6

8

45

2

1

9

Shutoff Valve1.

Test Valve2.

Blowdown Valve3.

Strainer4.

Pipe Union5.

Pressure Gauge (with Snubber)6.

Pipe Eccentric Reducer (if required)7.

Steriow CSDT Series Disc Trap8.

Check Valve9.

6

3

1

4

8

56

2

9

Shutoff Valve1.

Test Valve2.

Blowdown Valve3.

Strainer4.

Pipe Union5.

Pressure Gauge6.

(with Snubber)

Steriow CSDT Series7.

Disc Trap

Check Valve8.