2 Intended use

2.1 General

Locks R 403 FR and R 403 FL are not independently functioning

units. They are intended for mounting on a semi-trailer for trans-

porting ISO containers.

They must not be brought onto the market until it has been

established that the semi-trailer fitted with the locks satisfies the

domestic road traffic regulations.

The locks may only be brought into operation together with the

instructions in the owner’s manual of the tractor unit and trailer,

and the instructions for the locks themselves.

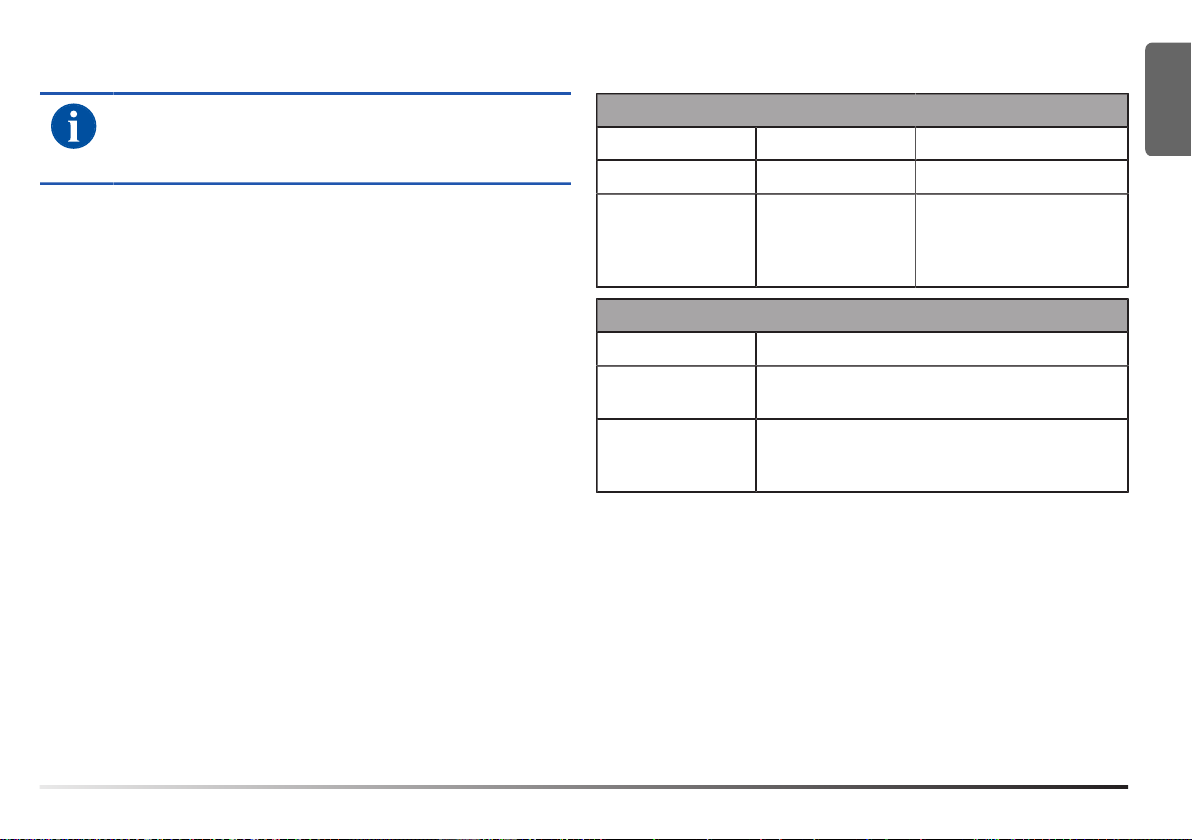

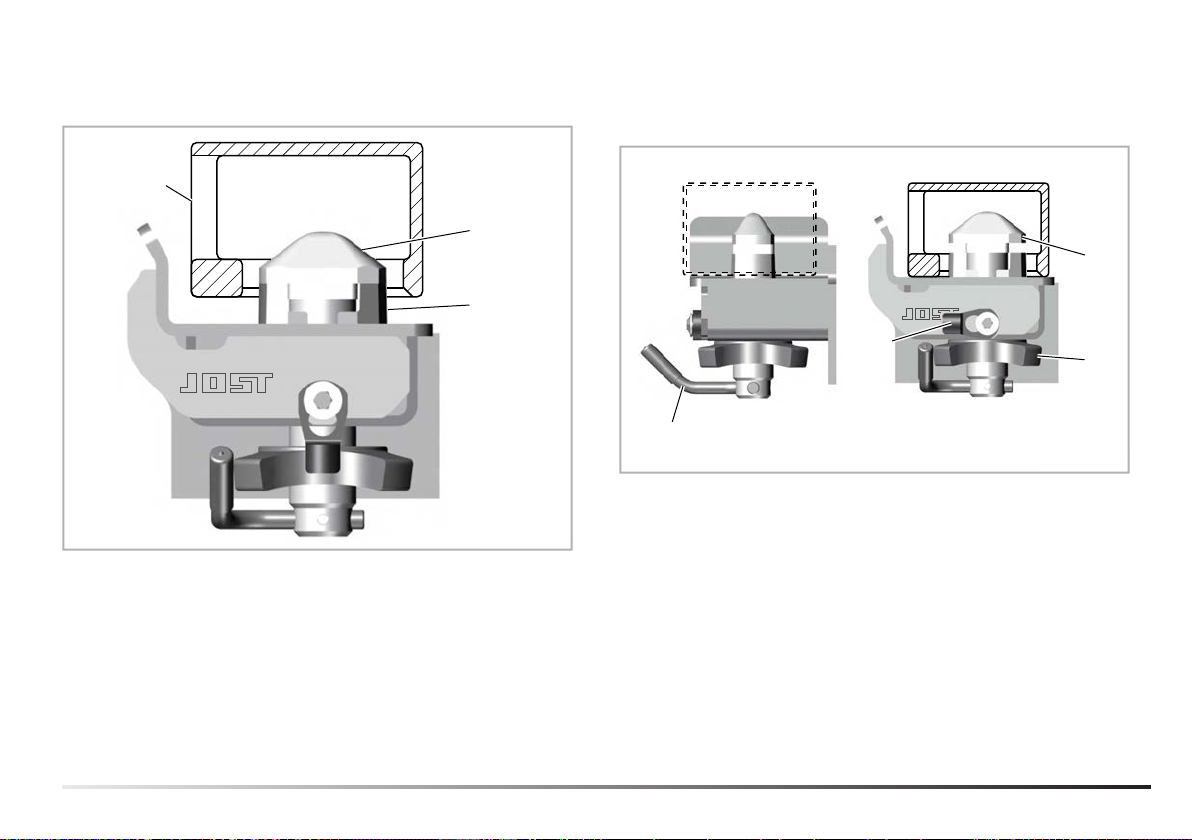

Locks R 403 FL and R 403 FR are used on the rear of a tipping con-

tainer chassis, for securing ISO containers. The R 403 FL is installed

on the left in the direction of travel, the R 403 FR on the right.

The lock components are reinforced, so that they can absorb the

loads acting on the tipping chassis during tipping.

The admissible loads can be found in the technical data, see

Chapter 2.2, "Technical data and spare parts".

We recommend fitting additional rear stabilisers, for use during

the tipping process.

2.2 Technical data and spare parts

ADVICE!

Test report 8109405693 from TÜV Nord Mobilität grants

approval based on ADR 2011 for a container weight of

34t.

WARNING!

The tipping angle must not exceed 55°. The maximum

admissible container weight when using this lock is 34t.

ADVICE!

Other combinations of container weight and tipping

angle may be approved following consultation with

JOST-Werke GmbH.

For spare parts numbers, please refer to the parts lists

of the latest product catalogue.

EN

Twist Locks R 403 Fx MUB 013 005 M30 (REV-B) 07-2020 5