4

CONTENTS

1. DESCRIPTIONOFPDSERIESINVERTER......................................................................................................5

1.1GENERAL DESCRIPTION AND DESIGN PHILOSOPHY ................................................................................................5

1.2HARDWARE INPUT & OUTPUTCONFIGURATION ....................................................................................................5

2. INSTALLATION...................................................................................................................................................8

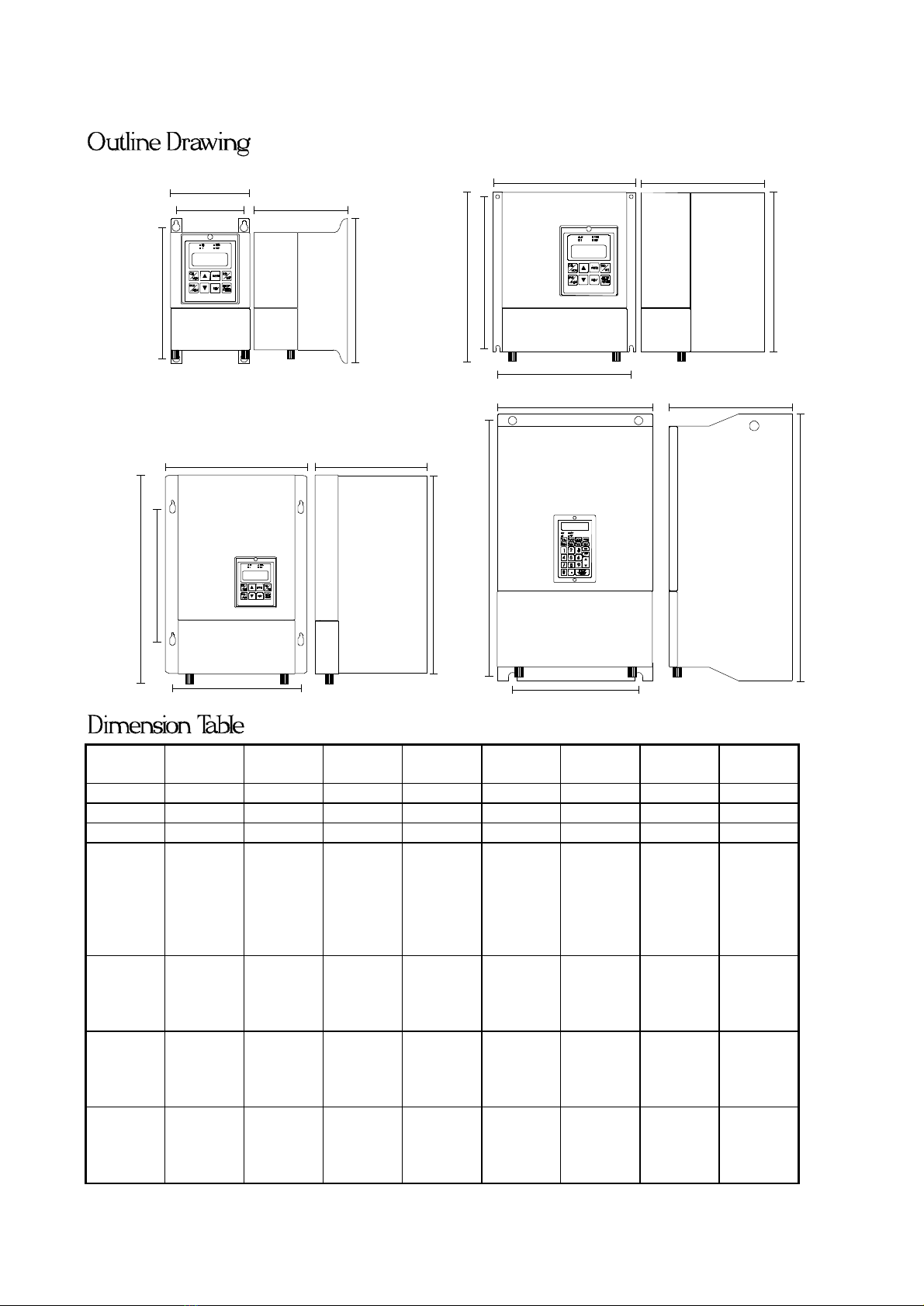

2.1OUTLINE DIMENSIONS.........................................................................................................................................9

2.2POWER TERMINAL.............................................................................................................................................10

2.3CONNECT POWER LINEINPUTTO INVERTER........................................................................................................11

2.4CONNECTINVERTER OUTPUTTO MOTOR ............................................................................................................11

2.5DC BUSOR BRAKE DISCHARGE TERMINAL ........................................................................................................11

2.6CONTROL TERMINAL CONNECTION.....................................................................................................................12

3. CONTROLPANEL.............................................................................................................................................13

3.1LOCALPANEL...............................................................................................................................................13

3.2REMOTEPANEL............................................................................................................................................14

4. SYSTEM START-UP...........................................................................................................................................16

4.1RESET &INITIALIZE THE INVERTER....................................................................................................................16

4.2SIMPLE START-UP &RUN BYKEY-PAD ..............................................................................................................16

4.3MONITOR THE INVERTER RUNNING STATUS ........................................................................................................16

4.4APPLY INVERTER TO YOUR SYSTEM....................................................................................................................16

5. PARAMETERS....................................................................................................................................................17

5.1PARAMETERSLIST......................................................................................................................................17

5.2PARAMETERPROTECTION.........................................................................................................................19

5.3PARAMETERSINITIALIZATION.................................................................................................................19

5.4DESCRIPTION OF ALLPARAMETERS ....................................................................................................................19

6. SELECTIONOFRUN/STOP/FWD/REV CONTROLCOMMAND.................................................................26

7. SELECTIONOFSET FREQUENCY INPUT SOURCE...................................................................................27

7.1SELECTION CHART......................................................................................................................................27

7.2SPEEDSOURCE DESCRIPTION...................................................................................................................28

8. SELECTIONOFDIGITALINPUT FUNCTION...............................................................................................36

9. SELECTIONOFDIGITALOUTPUTAND RELAYFUNCTION...................................................................42

10.SELECTION OFANALOGOUTPUT FUNCTION........................................................................................46

11.SPEED SEARCHAND BASEBLOCKFUNCTION........................................................................................47

12.AUTORUN FUNCTION...................................................................................................................................48

12.1AUTO MODESELECTION &RUNNING....................................................................................................48

12.2AUTO STEP EQUALOUTPUT.....................................................................................................................50

13.MONITORFUNCTION....................................................................................................................................51

13.1OPERATING STATUSCHECK....................................................................................................................51

13.2TERMINALSTATUSCHECK......................................................................................................................51

13.3A/DCONVERTERCHECK...........................................................................................................................51

14.MAINTENANCE&ERRORMESSAGE.........................................................................................................52

15.COMPUTER CONTROL..................................................................................................................................53

15.1PROTOCAL&FORMAT..............................................................................................................................53

15.2COMPUTERTO INVERTER.................................................................................................................................53

15.3INVERTER TO COMPUTER.................................................................................................................................54

15.4SAMPLEPROGRAM ..........................................................................................................................................55

16. BLOCKDIAGRAM OFPD-INVERTER.........................................................................................................58