3W/5W UV-AIO User manual

1

1 Product tour and technical parameter

1.1 Product overview

Compare with IR laser, the UV laser process is direct break the object chemical bond,

The process generate much less heat to minimize thermal effect, processed material turn

to Atom level,reduce contamination to the environment. The feature of UV laser is short in

wavelength, Small spot size, intense energy, high solution, it's good for precision marking,

narrow line width Requirement, high quality marking, less thermal effect, also with long term

stability. Widely used in micro machining, micro hole drilling, cutting, scribing, already apply

to many Material like metal, semiconductor material, ceramic, glass and polymer.

JPT made Seal-355-3/5 series UV laser are end pump solid state laser. Stable and compact

resonator design makes higher laser efficiency, good beam quality and high stability. Long

lifetime and maintenance free. The chamber inner LD design, reduced the fiber interference.

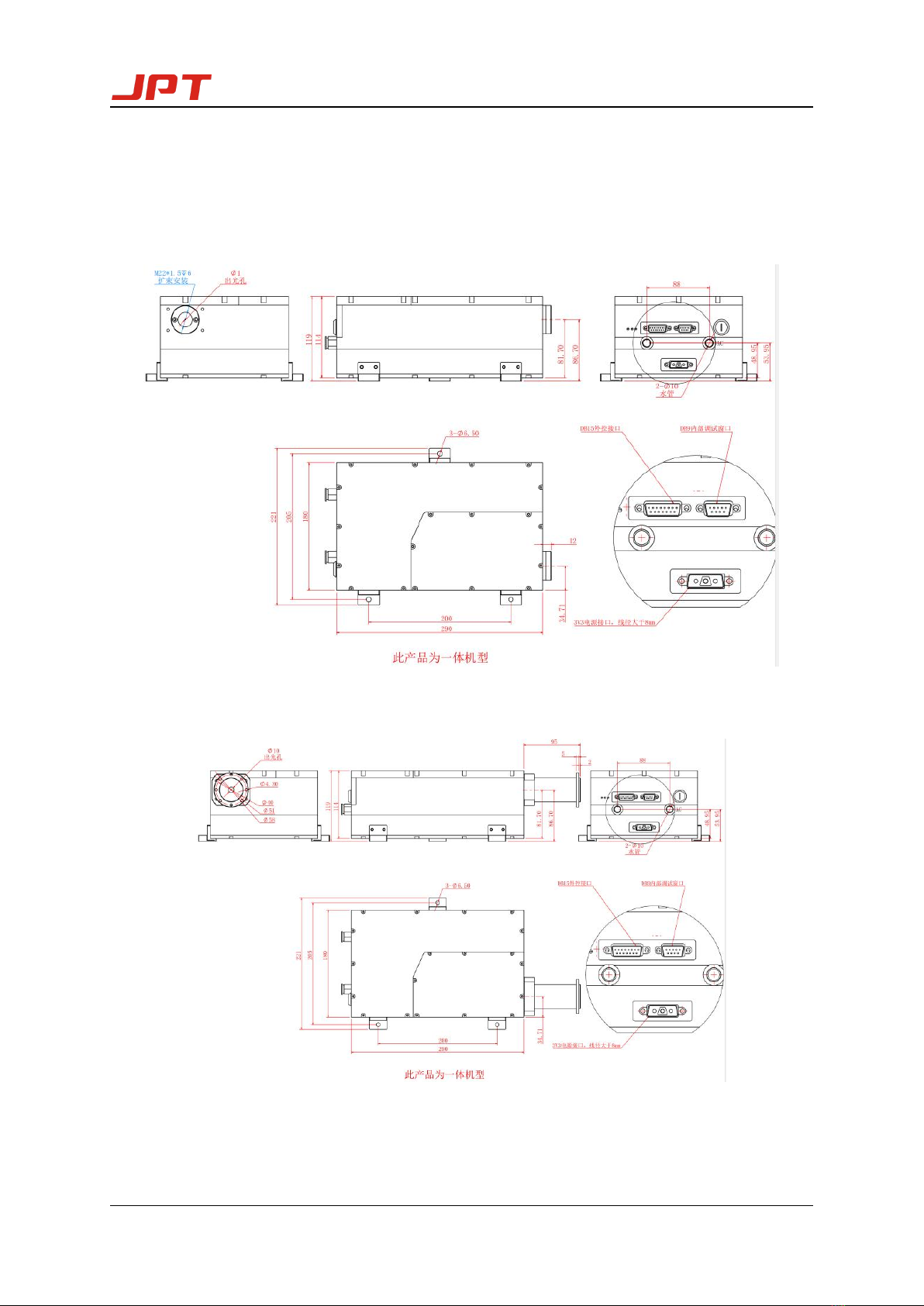

The new design of AIO, it’s space saving and has a stronger anti-interference capability.

Seal-355-3/5S is a member of Seal family. The laser of this series has excellent beam quality (M2

< 1.2) and perfect spot characteristics (circularity>90%). The whole machine adopts an

integrated structure design, which combines the optical and external driving circuit, making the

product series have strong anti-interference ability. Optimize and upgrade the fully sealed

structure to effectively prevent the entry of external dust. At the same time, the isolation of

external water molecules makes the whole machine have a strong anti-moisture characteristics,

making the Seal series can adapt more harsh industrial environments. In addition, the service

life can be greatly prolonged by introducing a self-cleaning system for intracavity As an

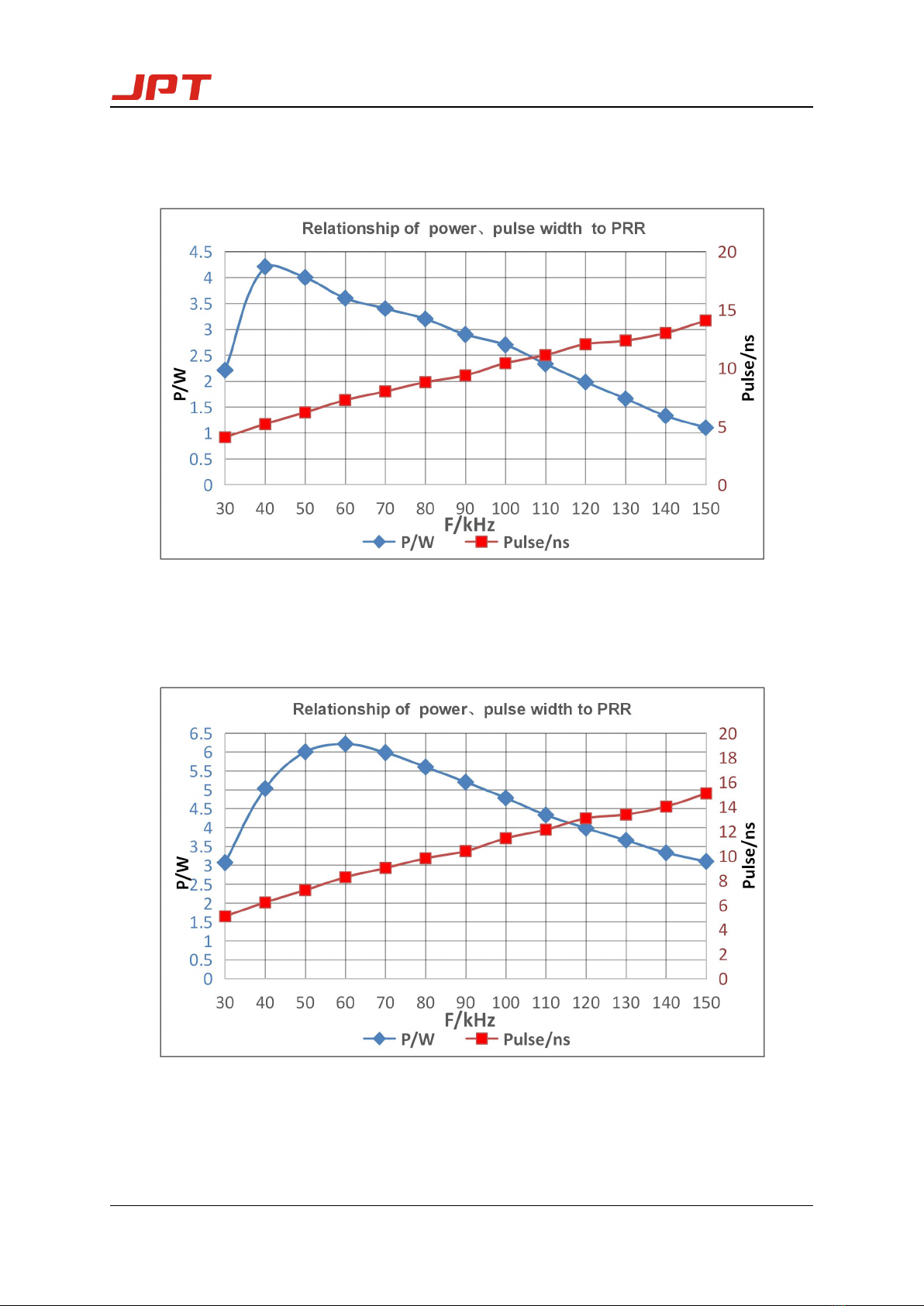

upgraded version of Seal-355-3/5, the output laser of Seal-355-3/5S series ultraviolet solid-state

lasers has very short pulse width (<10ns@60KHZ) and excellent pulse stability (<3%

RMS@60KHZ) at medium and high repetition frequencies.