- 3 -

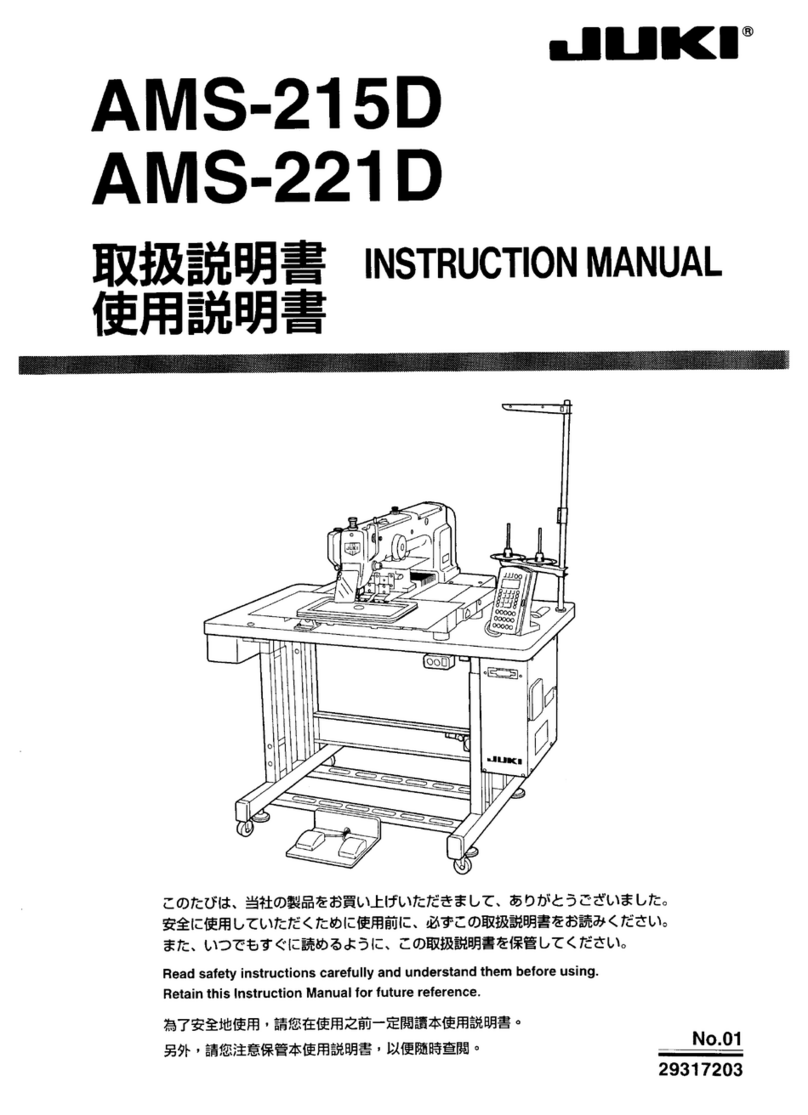

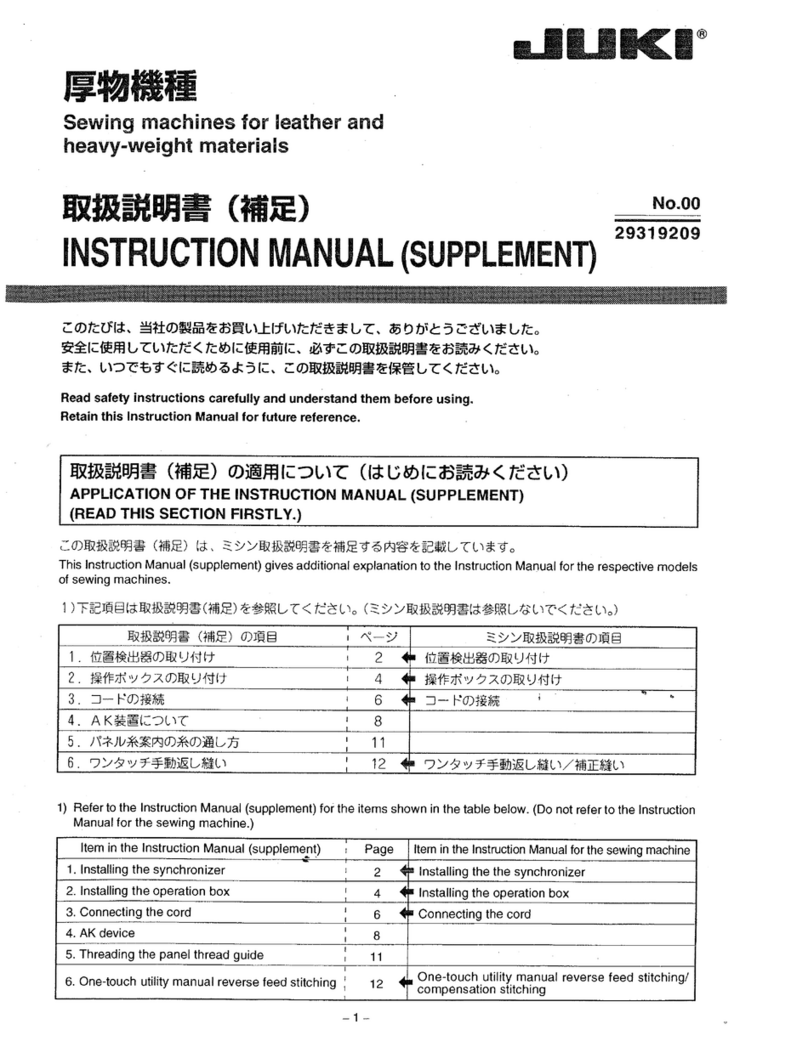

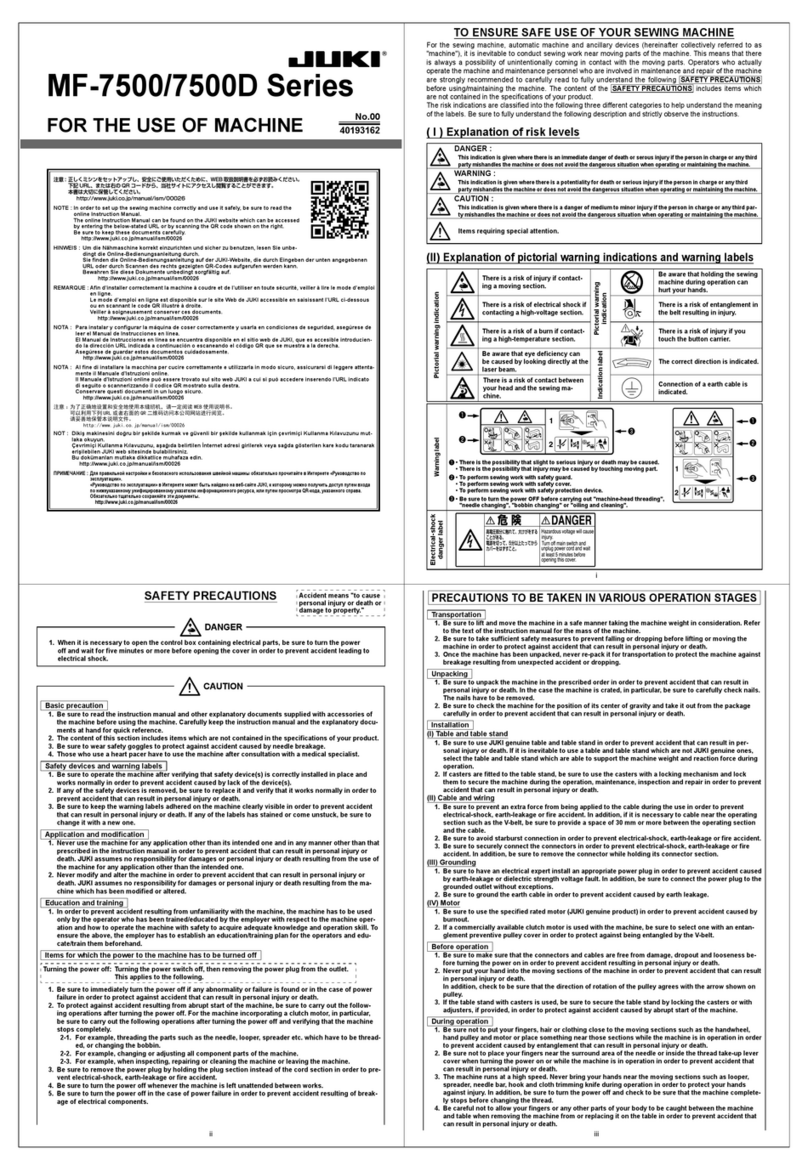

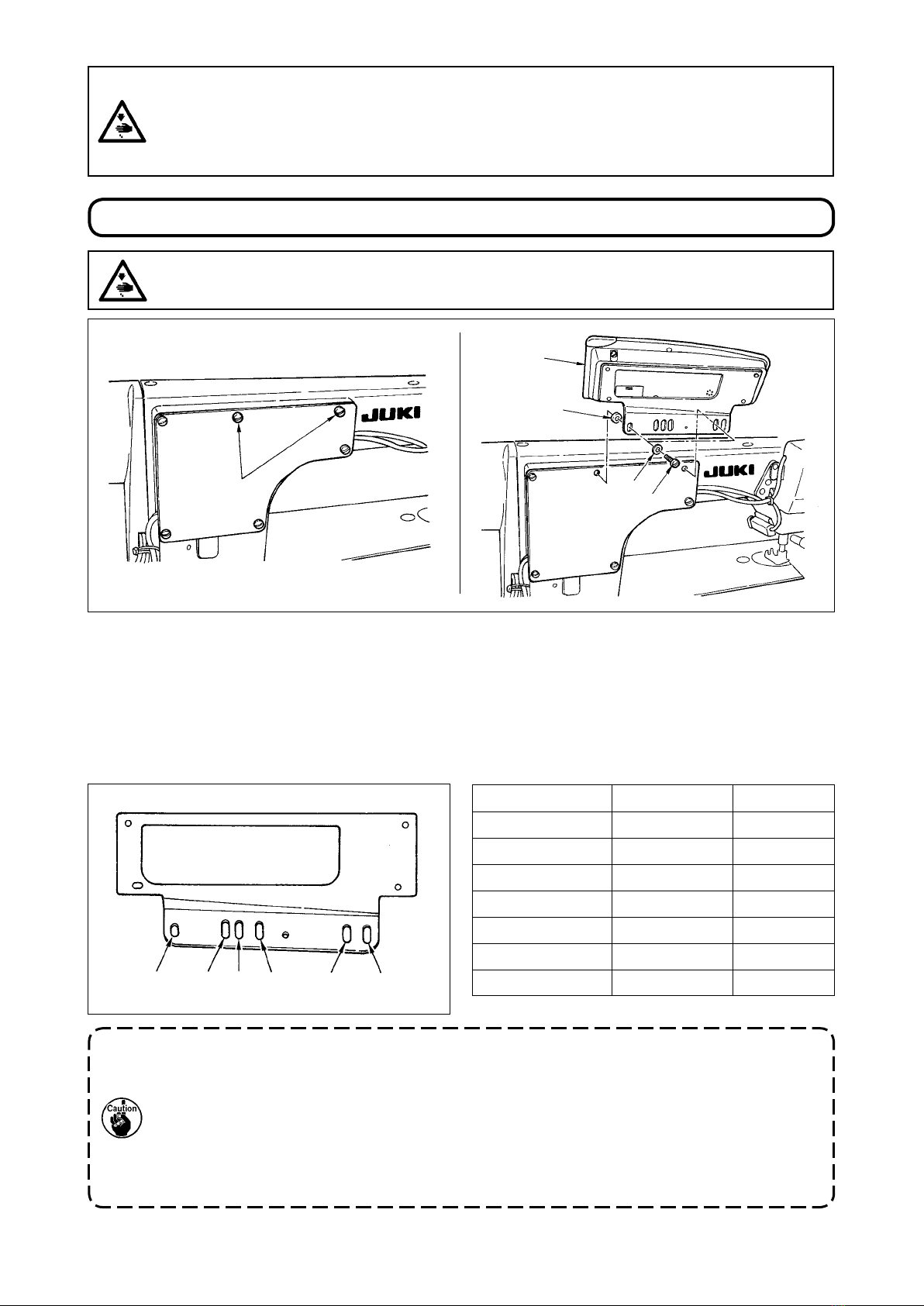

4. EXPLANATION OF THE CONTROL PANREL

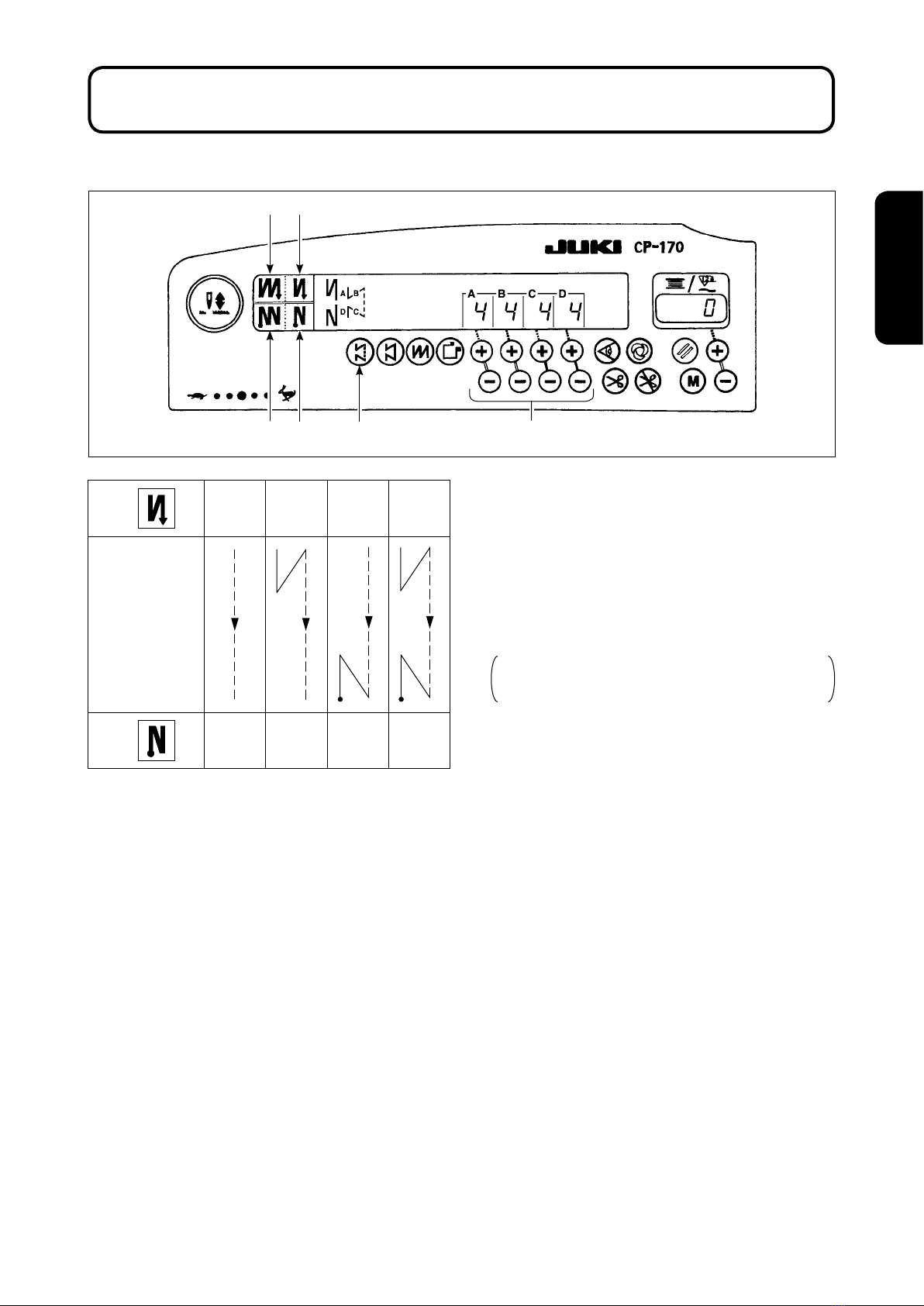

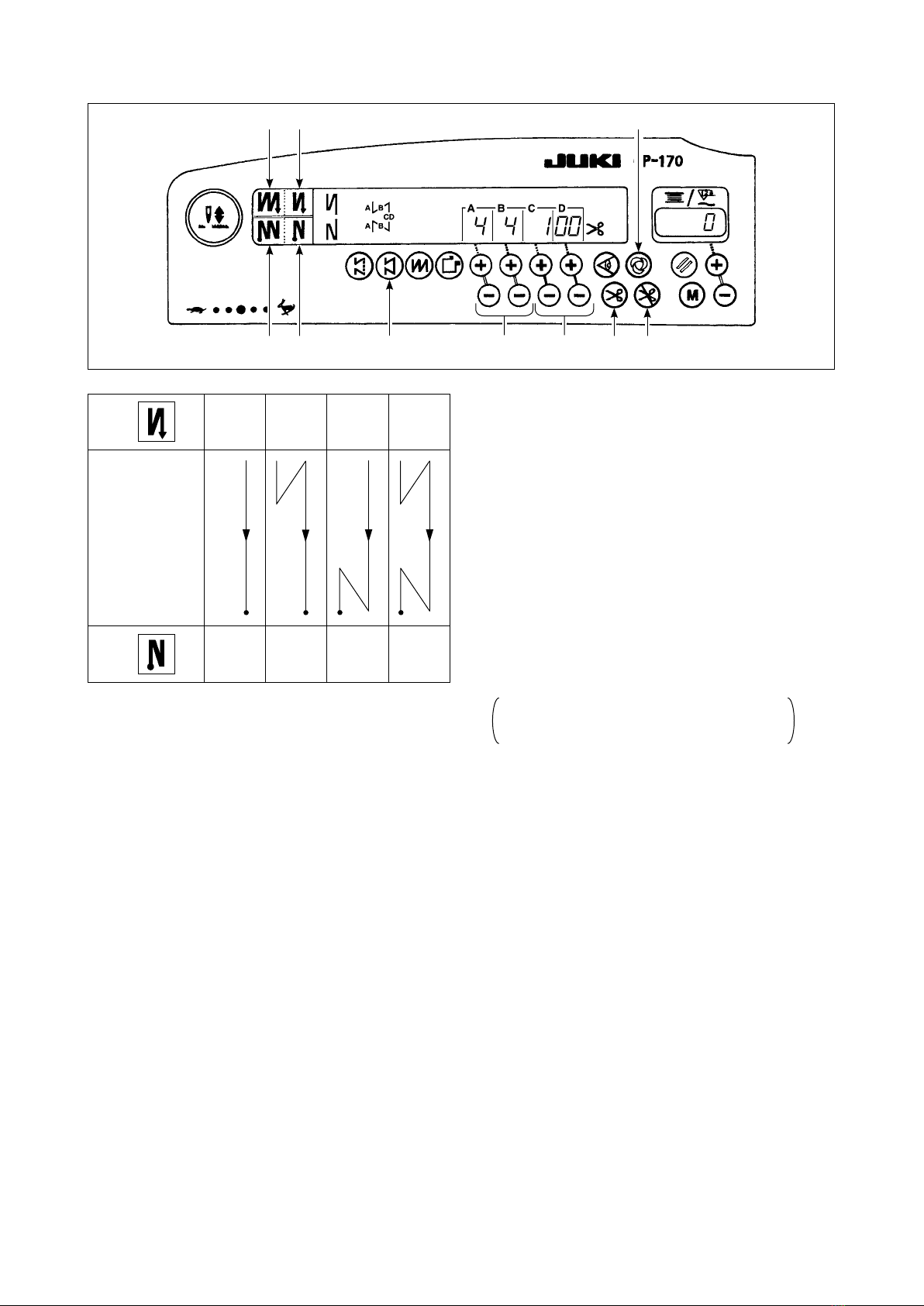

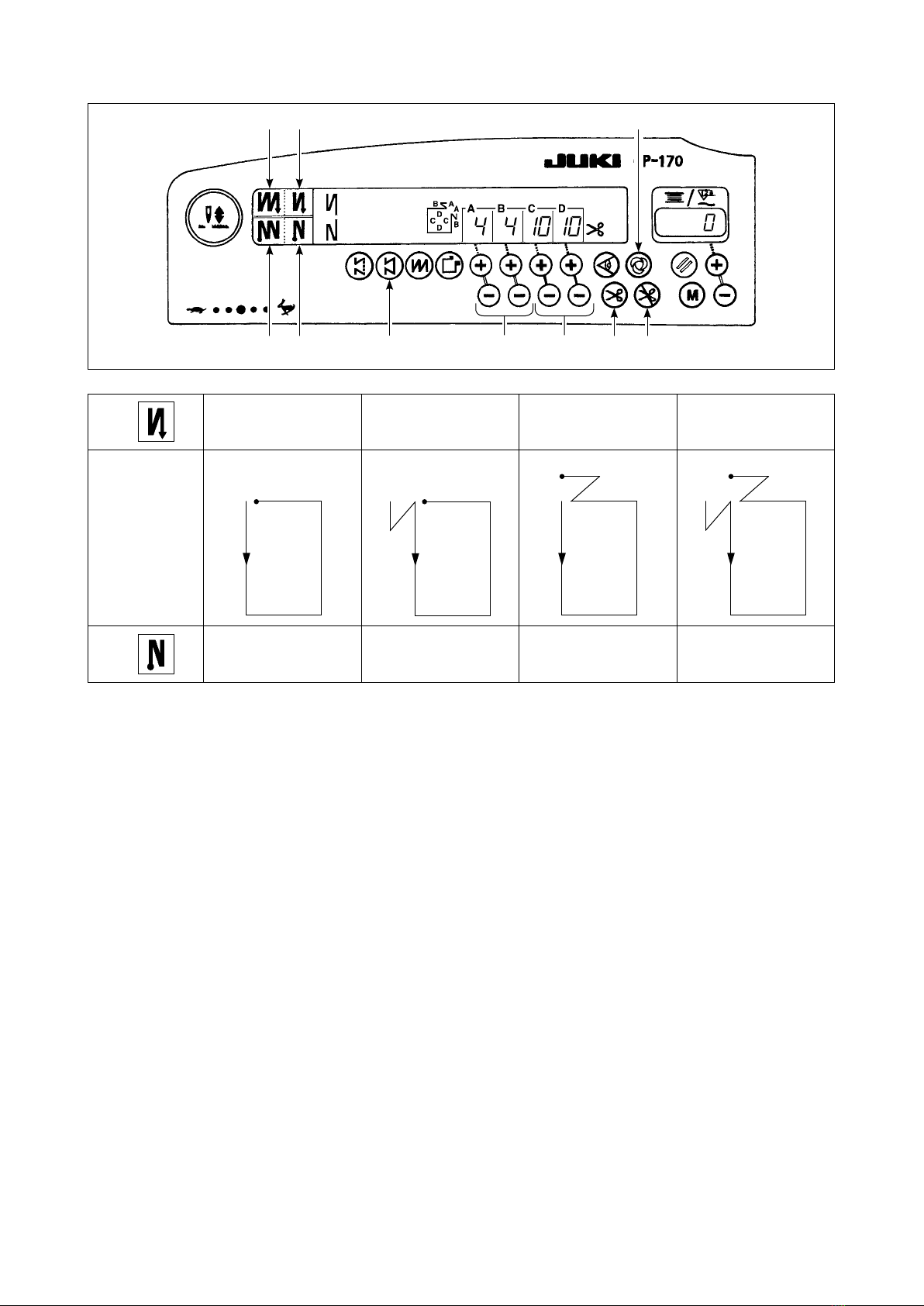

1Pattern selector switch

• Used for selecting a pattern from among the

four different patterns.

2Double reverse stitching (for start) switch

• Used for turning ON/OFF the double reverse

stitching for start.

3Double reverse stitching (for end) switch

• Used for turning ON/OFF the double reverse

stitching for end.

4Automatic reverse stitching (for start) switch

• Used for turning ON/OFF the automatic

reverse stitching for start.

5Automatic reverse stitching (for end) switch

• Used for turning ON/OFF the automatic

reverse stitching for end.

6Switches for setting the number of stitches

• Used for setting the number of stitches to be

sewn in processes A through D.

7Material edge sensor ON/OFF switch

• Rendered effective when the material edge

sensor is installed on the machine.

• Used for setting whether or not the material

edge sensor is used during sewing.

8One-shot automatic stitching switch

• Rendered effective when the material edge

sensor is installed on the machine or when

the sewing machine is operated under the

constant-dimension stitching mode.

• Start the sewing machine with this switch, and

the sewing machine will run automatically until

the material edge is detected or the end of a

constant-dimension stitching is reached.

9Automatic thread trimming switch

• Rendered effective when the material edge

sensor is installed on the machine or when

the sewing machine is operated under the

constant-dimension stitching mode.

• Even keep depressing the front part of the

pedal, the sensor can detect the material

edge, or after the completion of the constant-

dimension stitching mode, the machine will

automatically perform thread trimming.

!0 Thread trimming prohibition switch

•

Used for prohibiting thread trimming at any occasion.

!1

Bobbin thread counter/thread trimming counter

• Bobbin thread counter/thread trimming counter

can be changed over by the function of the control

box main body.

Bobbin thread counter :

• Indicates the amount of bobbin thread while

counting it by subtracting from the set value.

• When the bobbin thread remaining amount

detecting device is installed on the machine, the

counter indicates the number of times of detecting.

Thread trimming counter :

• Every time thread trimming is performed, the

counter value is added.

!2 Bobbin counter reset switch

• Used for returning the value shown on the

bobbin thread counter to the initial value.

!3 Bobbin thread amount setting switch

• Used for setting the amount of bobbin thread.

• When the thread trimming counter is selected,

it is reset to [0].

!4

No. of pcs. counter

•

The indication shown on the counter increase while

coupling up the number of niched pieces of gament

every time the machine performs thread trimming.

[Changeover selection of needle bar stop position

when the pedal is in its neutral position]

• Pressing the needle up/down compensation

switch, turn ON the power to the machine, and

the needle bar stop position when the pedal is

in its neutral position is changed over to down

position/up position.

• Conrmation of the stop position can be

performed at the front cover of the control box.

When up position stop is specied : " nP UP "

When down stop position is specied : " nP Lo "

!5 Function setting switch

• Pressing the function setting switch, turn ON

the power to the machine, and it is possible

to change the various function setting values.

The case is the same as the control panel of

the front of the control box.

The respective functions may not be used in accordance with the combined control box.

!4 2 4 8 !1

3 5 9 1 !5

61

!3

7!2