iii

2-25. LCD section when the cycle sewing is selected...................................................... 73

(1) Cycle sewing data entry screen..................................................................................................73

(2) Sewing screen of the cycle sewing.............................................................................................75

2-26. How to carry out cycle sewing .................................................................................. 77

(1) Selection of the cycle-sewing data .............................................................................................77

(2) Method to create the cycle-sewing data .....................................................................................78

(3) Method to insert the cycle-sewing data ......................................................................................79

(4) Method for deleting the cycle sewing data.................................................................................. 80

(5) Method for deleting a step of the cycle sewing data...................................................................80

2-27. How to edit the sewing data....................................................................................... 81

(1) Method for changing the sewing data.........................................................................................81

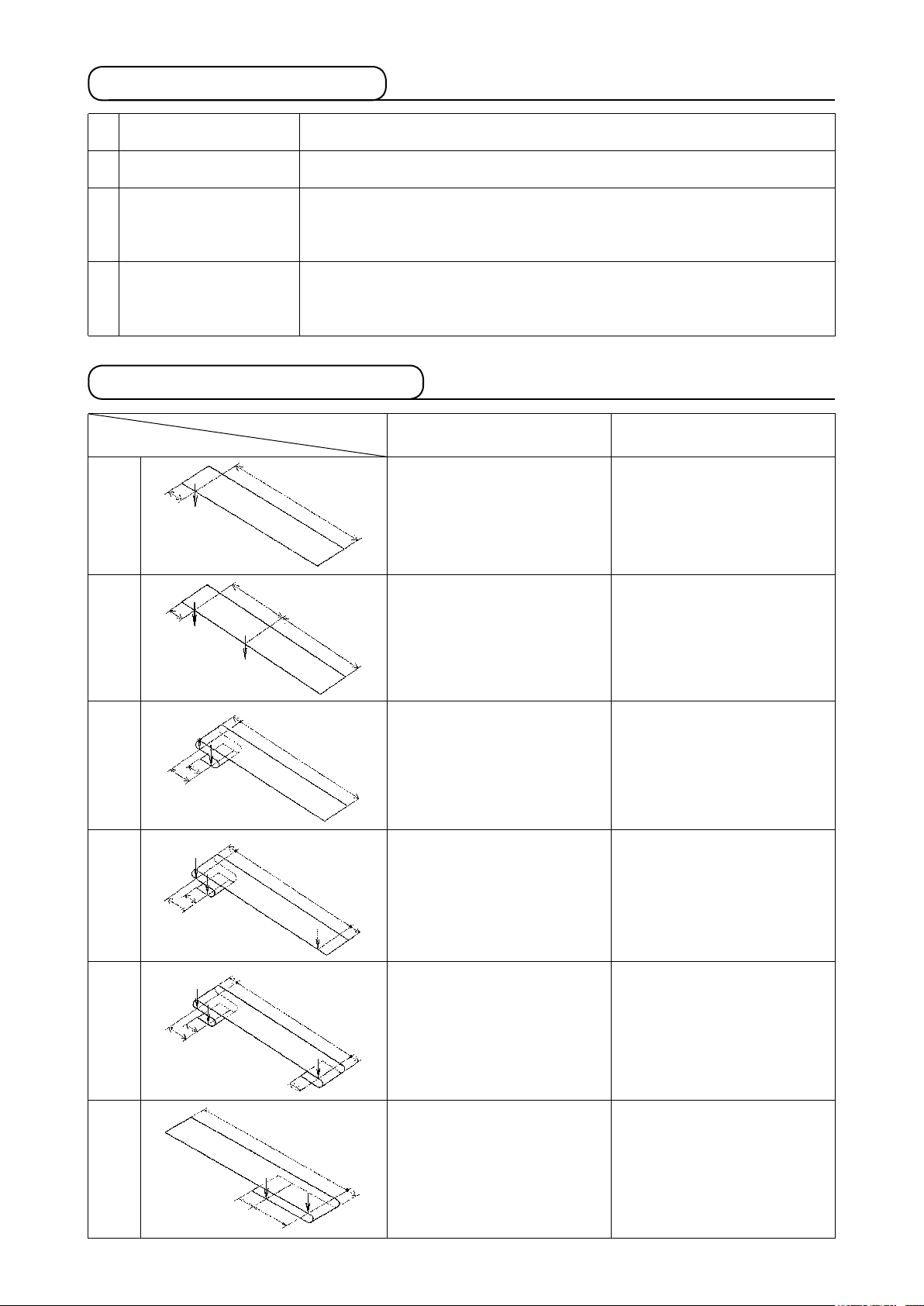

(2) Sewing data list...........................................................................................................................82

2-28. How to change the memory switch data .................................................................. 93

(1) Method for changing the memory switch data ............................................................................ 93

(2) Memory switch data list ..............................................................................................................94

2-29. How to set the device ................................................................................................. 98

(1) Device setting changing procedure ............................................................................................98

(2) Listing of the device settings....................................................................................................... 99

2-30. How to adjust the origin of work clamp foot .......................................................... 101

2-31. Using communication function ............................................................................... 102

(1) Handling possible data .............................................................................................................102

(2) Performing communication by using the media........................................................................102

(3) Performing communication by using USB ................................................................................ 102

(4) Take-in of the data ....................................................................................................................103

(5) Taking in plural data together....................................................................................................104

2-32. Performing formatting of the media........................................................................ 106

2-33. Trial stitching function ............................................................................................. 107

2-34. How to use information ............................................................................................ 109

(1) How to visually check maintenance/inspection information......................................................109

(2) How to reset the warning ...........................................................................................................111

(3) How to set the time ....................................................................................................................111

2-35. How to re-start sewing from the position where the machine has stopped by the

detection of thread breakage ....................................................................................... 112

3. ERROR CODE LIST .......................................................................................... 113

4. Massage list ...................................................................................................... 126

#. Maintenance ....................................................................130

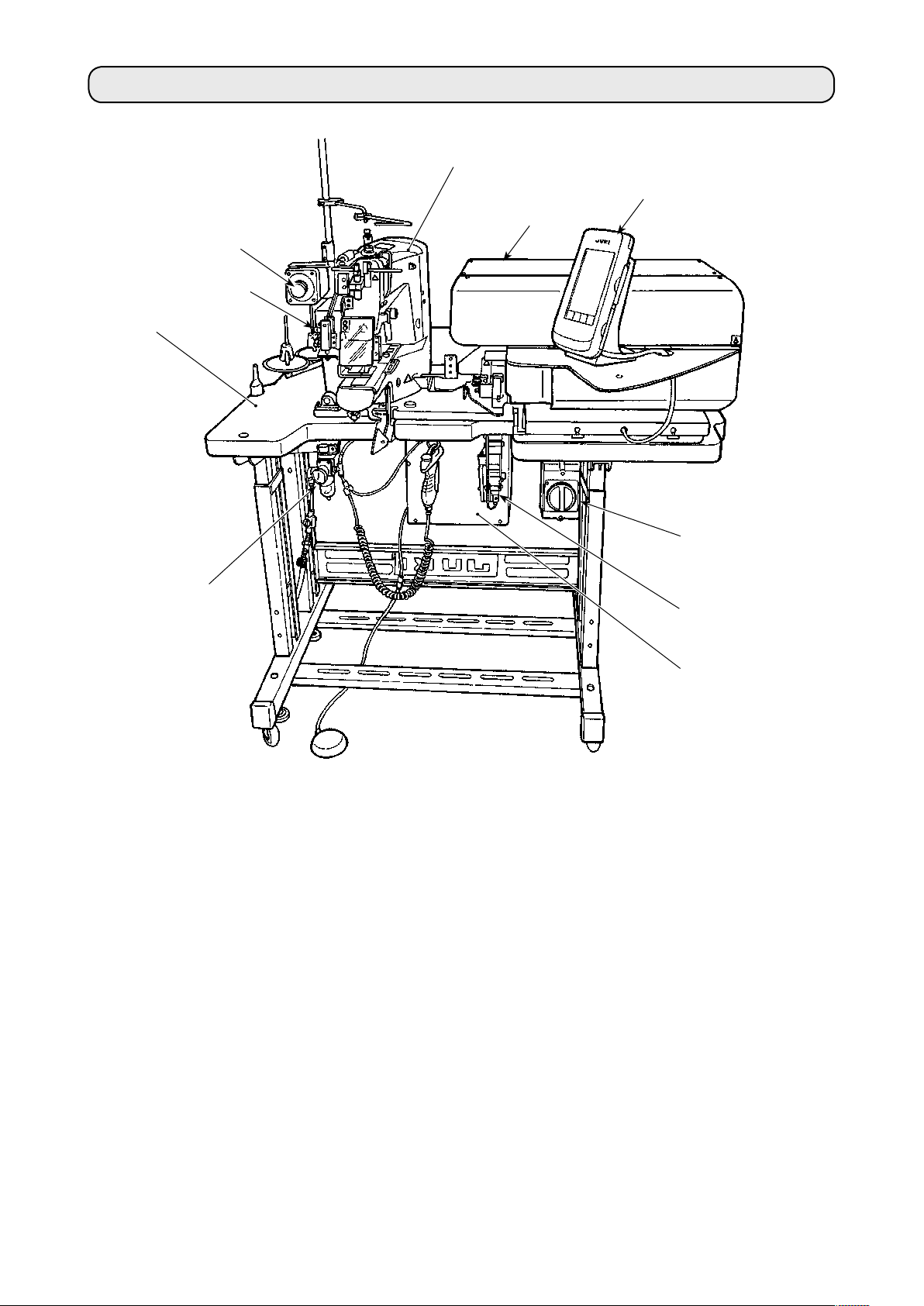

1. Maintenance...................................................................................................... 130

1-1. Discharging drainage water....................................................................................... 130

1-2. Adjusting the height of the needle bar...................................................................... 130

1-3. Adjusting the needle-to-shuttle relation ................................................................... 131

1-4. Adjusting the lift of the work clamp foot .................................................................. 132

1-5. The moving knife and counter knife ......................................................................... 132

1-6. Needle thread clamp device....................................................................................... 133

1-7. Adjustment of the wiper ............................................................................................. 133

1-8. Thread breakage detector plate ................................................................................ 134

1-9. Draining waste oil ....................................................................................................... 134