We

thank

you

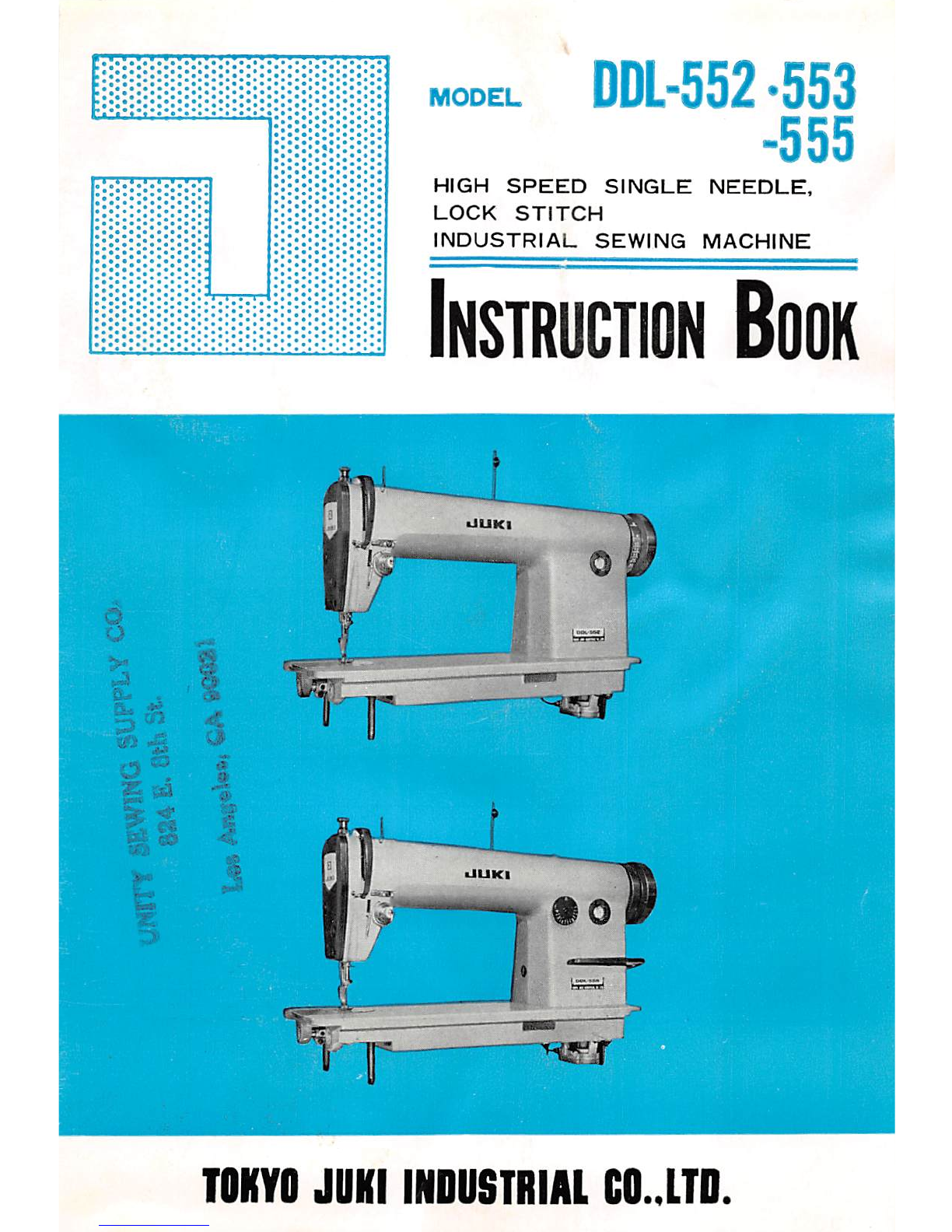

for purchasing JUKI Model DDL-552-553-555, high speed, single needle,

lockstitch

industrial

sewing machines.

DDL-SS2 is best suited for sewing general fabric; DDL-S53 is designed and constructed

for sewing heavy weight materials and DDL-555 is equipped with reverse feed mechanism

for a wide area of usage such as sewing men's shirts, blouses

and

other

general garments.

The thread take-up, sewing

hook,

feed mechanism, etc. are all specially designed

and

constructed for high speed sewing. Therefore, at high speed sewing, the running sound is

nominal

and

the

stitching

condition

is superb.

Before operating these machines, please read this INSTRUCTION BOOK carefully

and thoroughly digest the functions of these efficient machines and enjoy everlasting

pleasure

of

using these machines.

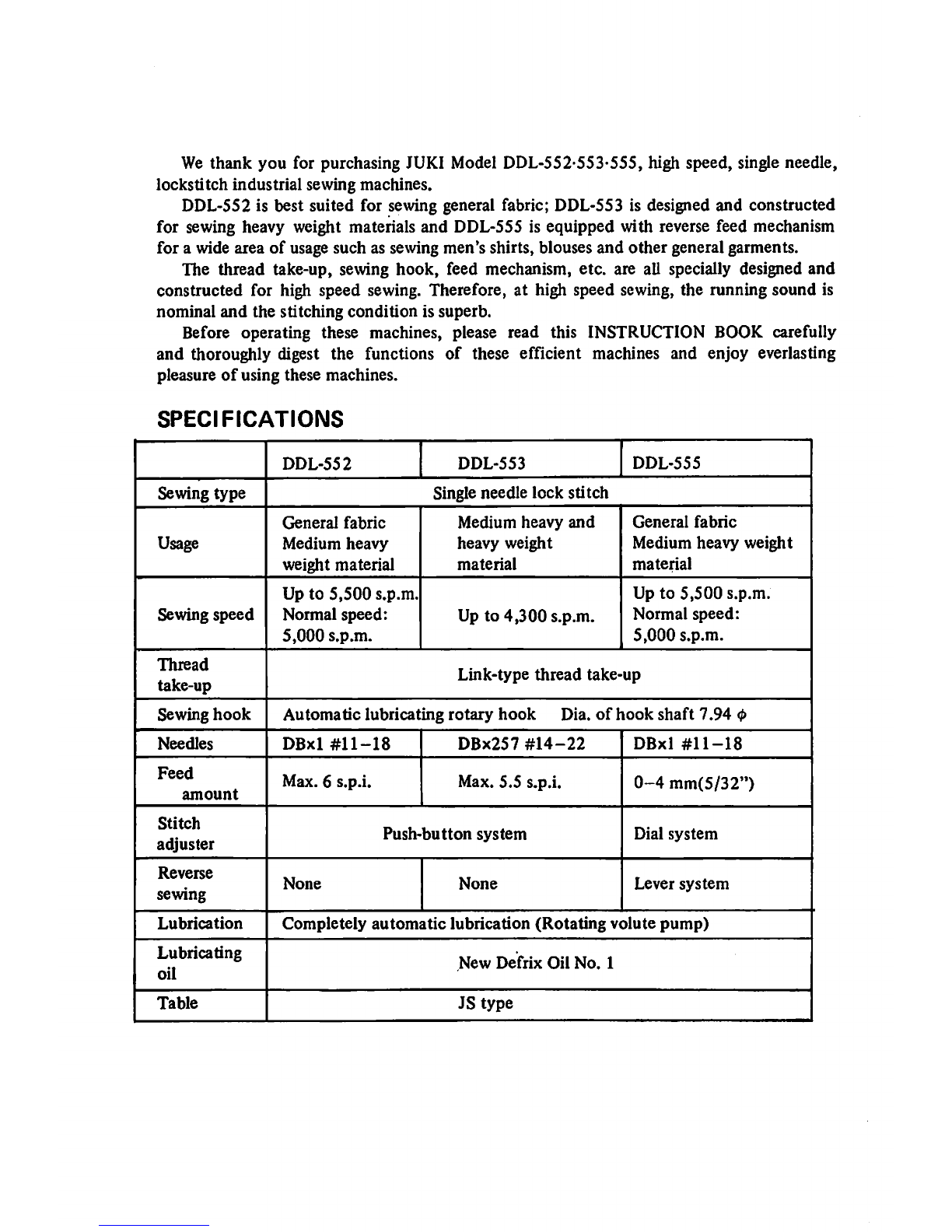

SPECIFICATIONS

DDL-552

DDL-553

DDL-555

Sewing

type

Single needle

lock

stitch

Usage

General

fabric

Medium

heavy

weight

material

Medium

heavy

and

heavy

weight

material

General

fabric

Medium heavy weight

material

Sewing

speed

Up to

5,500

s.p.m.

Normal speed:

5,000

s.p.m.

Up to

4,300

s.p.m. Up to

5,500

s.p.m.

Normal

speed:

5,000

s.p.m.

Thread

take-up

Link-type

thread

take-up

Sewing

hook

Automatic

lubricating

rotary

hook

Dia.

of

hook

shaft

7.94

<l>

Needles

DBxl

#11-18

DBx257

#14-22

DBxl

#11-18

Feed

amount

Max. 6 s.p.i. Max. 5.5 s.p.i.

0-4

mm(5/32")

Stitch

adjuster

Push-button

system

Dial

system

Reverse

sewing

None

None

Lever

system

Lubrication

Completely

automatic

lubrication

(Rotating

volute

pump)

Lubricating

oil

New

Defrix

Oil

No.

1

Table

JS

type