i

CONTENTS

1. SPECIFICATION .............................................................................................................. 1

1-1. Specications of the sewing machine head ..................................................................................1

1-2. Specications of the control box .................................................................................................... 1

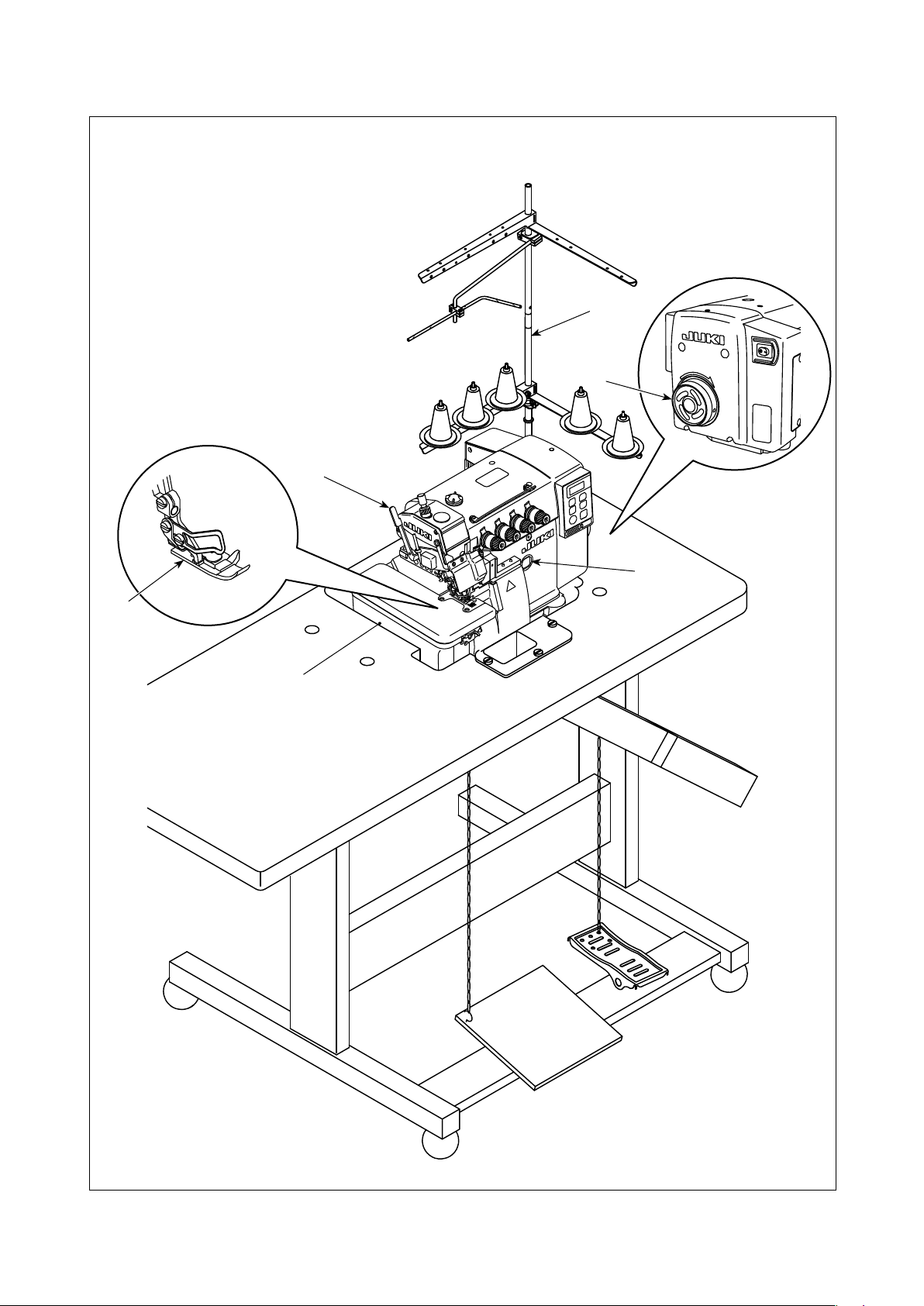

2. NAMES OF MAJOR PARTS............................................................................................ 2

3. INSTALLATION................................................................................................................ 3

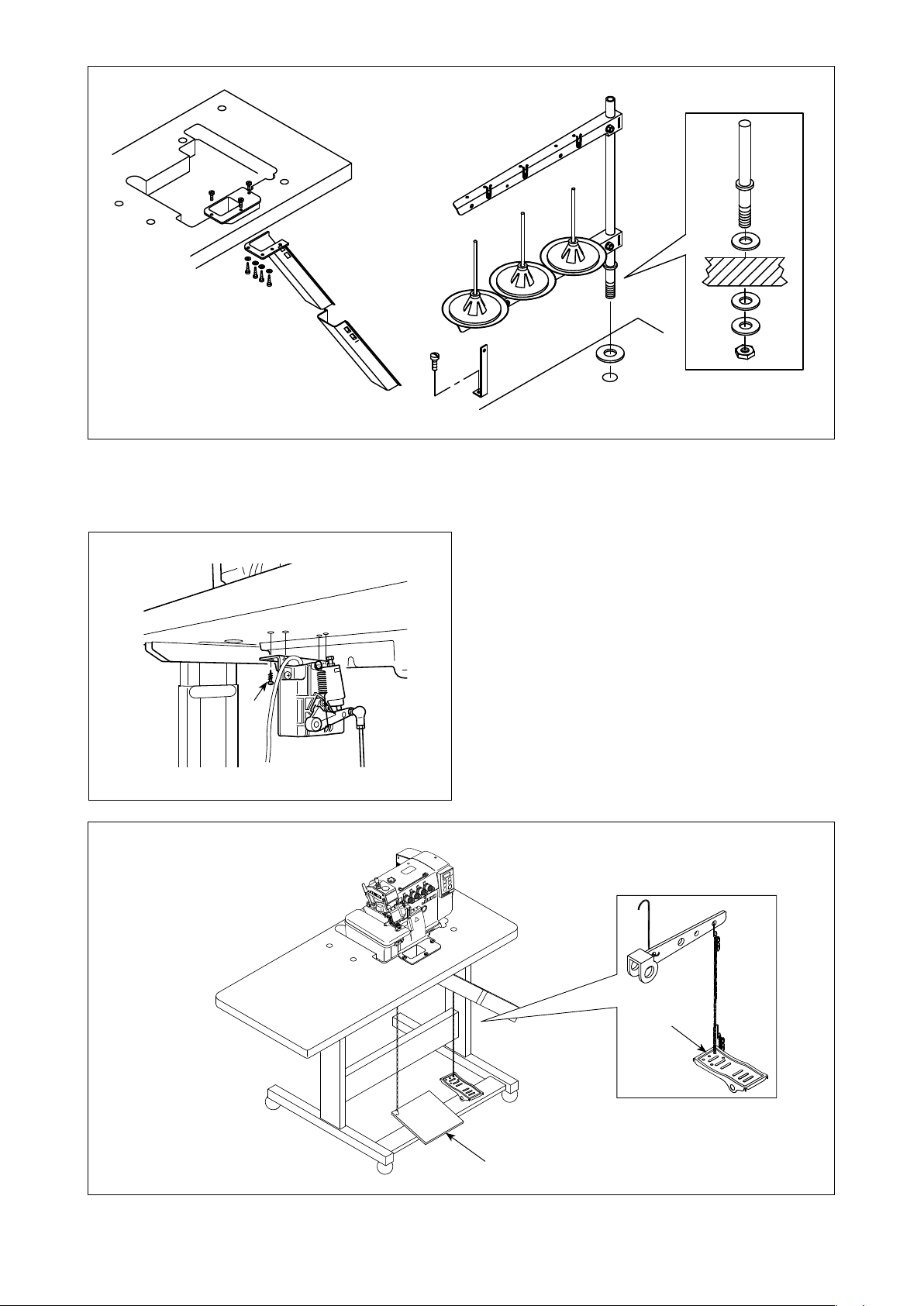

3-1. Installing the table and the table stand ..........................................................................................3

3-2. Installing the pedal sensor ..............................................................................................................4

3-3. Attaching the connecting rod..........................................................................................................5

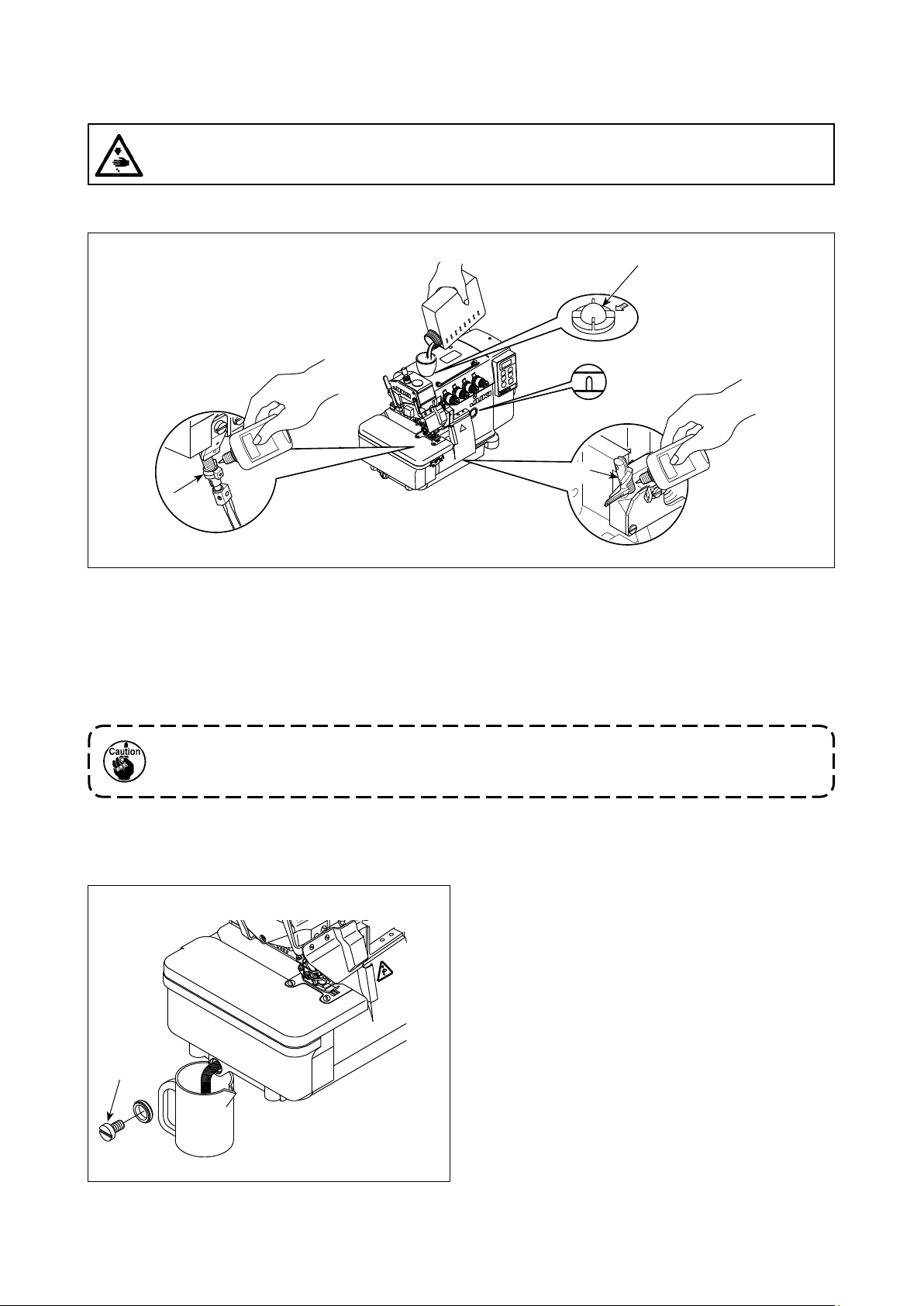

3-4. Connecting the connector ...............................................................................................................6

3-5. How to install the power plug.......................................................................................................... 7

3-6. Power switch..................................................................................................................................... 7

4. LUBRICATION AND DRAINAGE .................................................................................... 8

4-1. Lubrication oil ...................................................................................................................................8

4-2. Drainage and rell the oil................................................................................................................. 8

4-3. Exclusive grease replenishment (only for the MO-6800S).......................................................... 10

5. PREPARATION BEFORE SEWING .............................................................................. 11

5-1. Threading ........................................................................................................................................ 11

5-2. Adjusting the thread tension .........................................................................................................14

5-3. Replace the needle .........................................................................................................................15

5-4. Adjusting the stitch length.............................................................................................................16

5-5. Adjusting the dierential feed ratio ..............................................................................................16

5-6. Replace the knives .........................................................................................................................17

5-7. Adjusting the overedge width........................................................................................................18

5-8. Adjusting the needle height...........................................................................................................18

5-9. Adjusting the presser foot .............................................................................................................19

5-10. Adjusting the feed dog.................................................................................................................21

5-11. The relationship between the needle and the looper ................................................................22

5-12. Adjusting the amount of travel of the double chainstitch looper ............................................ 24

6. OPERATION PROCEDURE .......................................................................................... 25

6-1. Operation panel ..............................................................................................................................25

6-2. Font comparison table ...................................................................................................................26

6-3. Function setting.............................................................................................................................. 27

6-4. Function setting table ....................................................................................................................28

6-5. Details of setting of the main functions .......................................................................................32

6-6. Initialization of the function setting data...................................................................................... 34

6-7. Hand LED light ................................................................................................................................35

6-8. About the USB.................................................................................................................................36

7. MAINTENANCE............................................................................................................. 37

8. ADJUSTMENT DIMENSION VALUES .......................................................................... 38

8-1. Dimensions use to adjusting the looper and the needle guard .................................................38

8-2. Dimensions related to the position of the thread take-up and the looper thread cam

(standard adjustment)..................................................................................................................39

9. ERROR CODE LIST ...................................................................................................... 41

10. TABLE DRAWING ....................................................................................................... 42