– 7 –

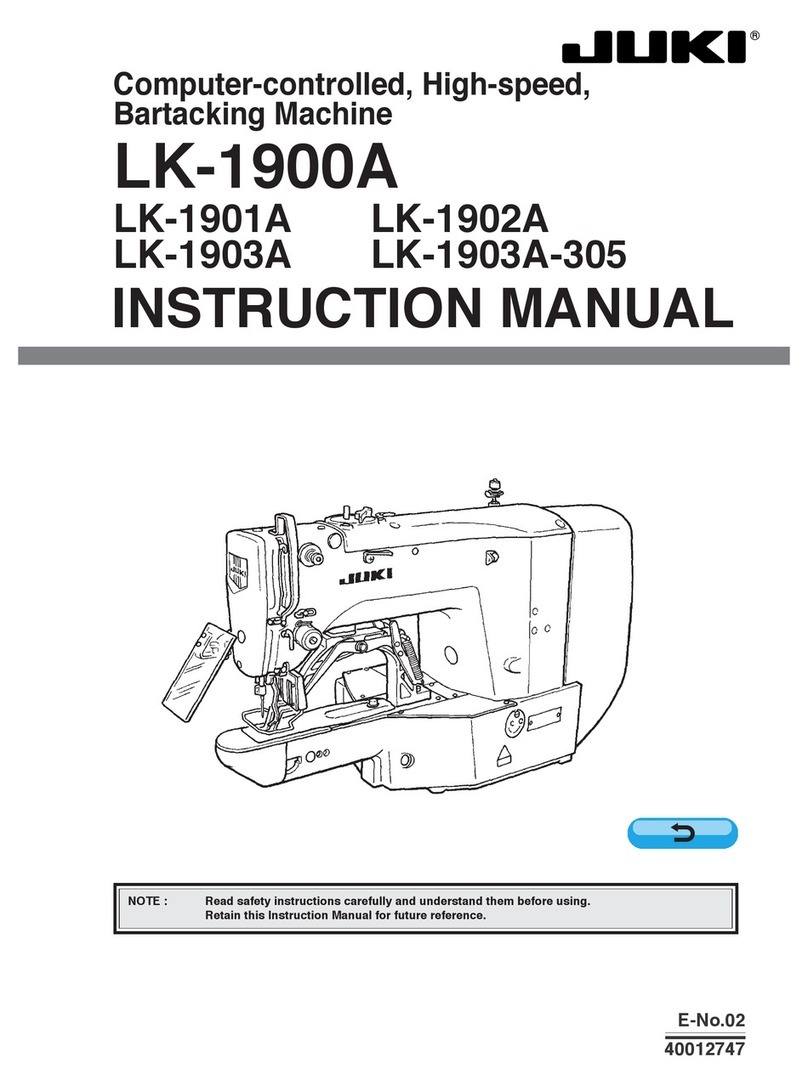

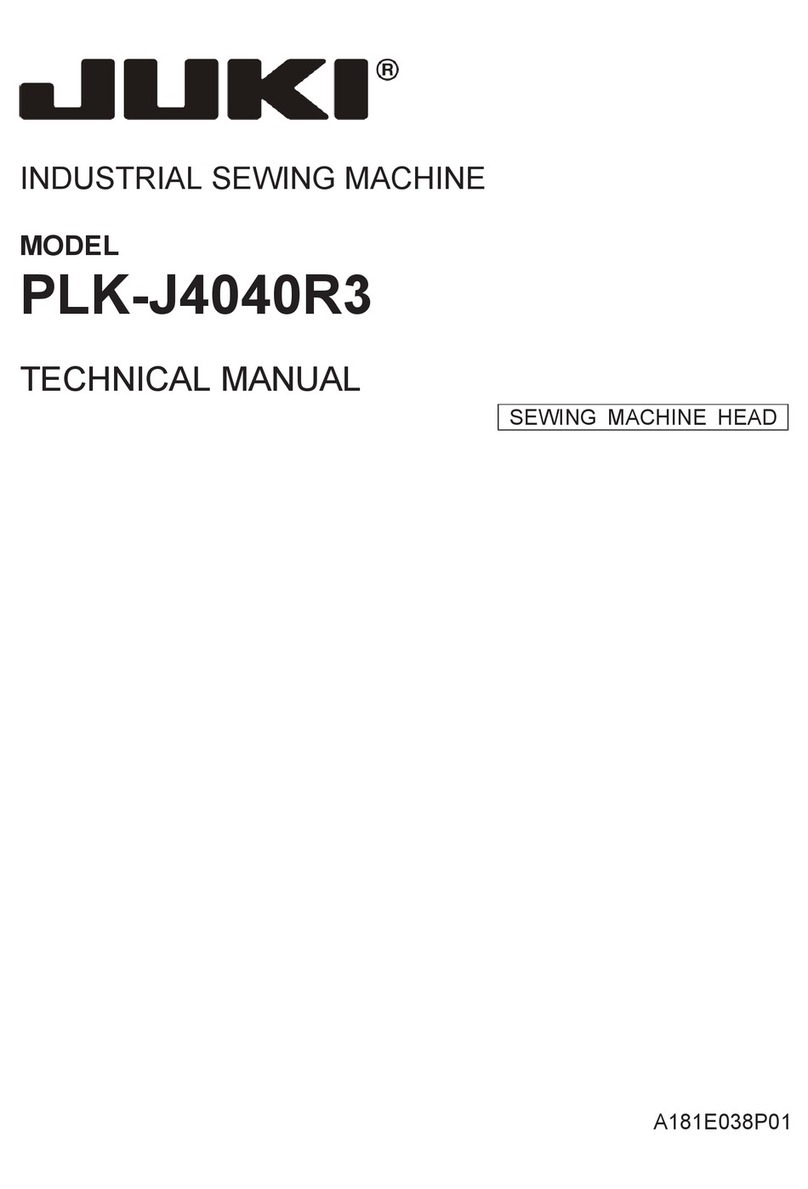

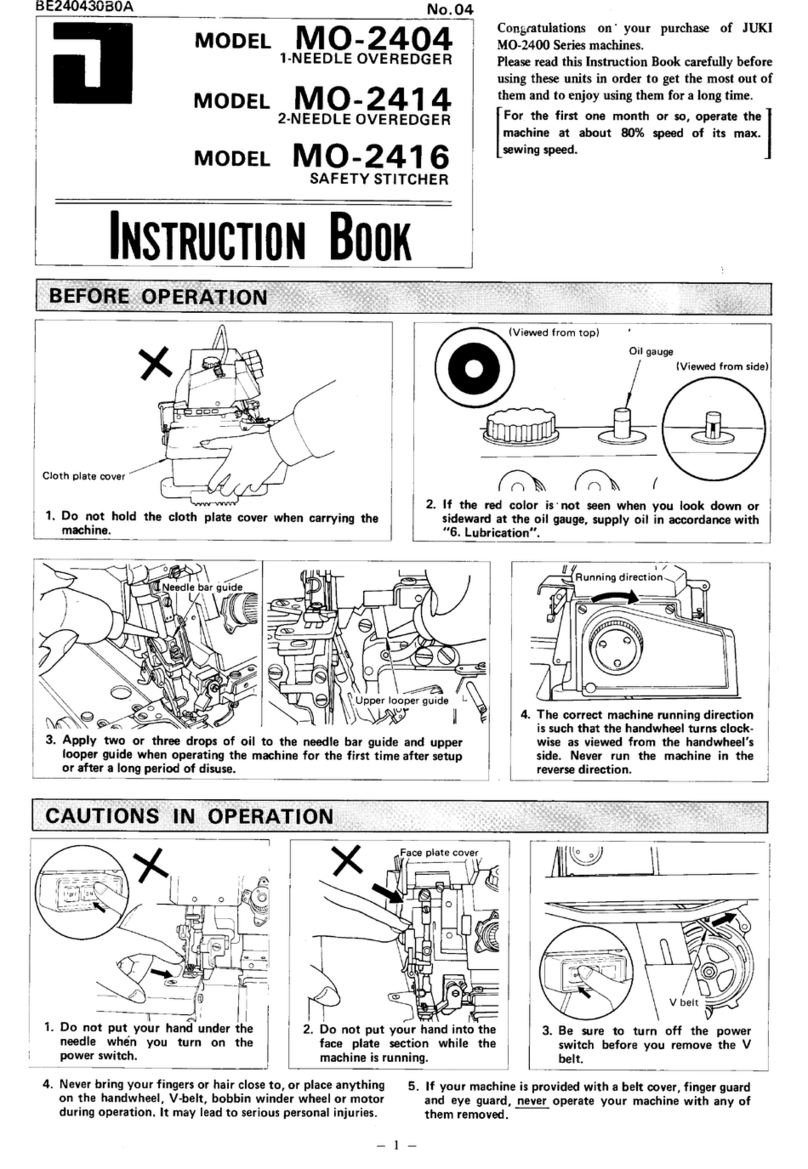

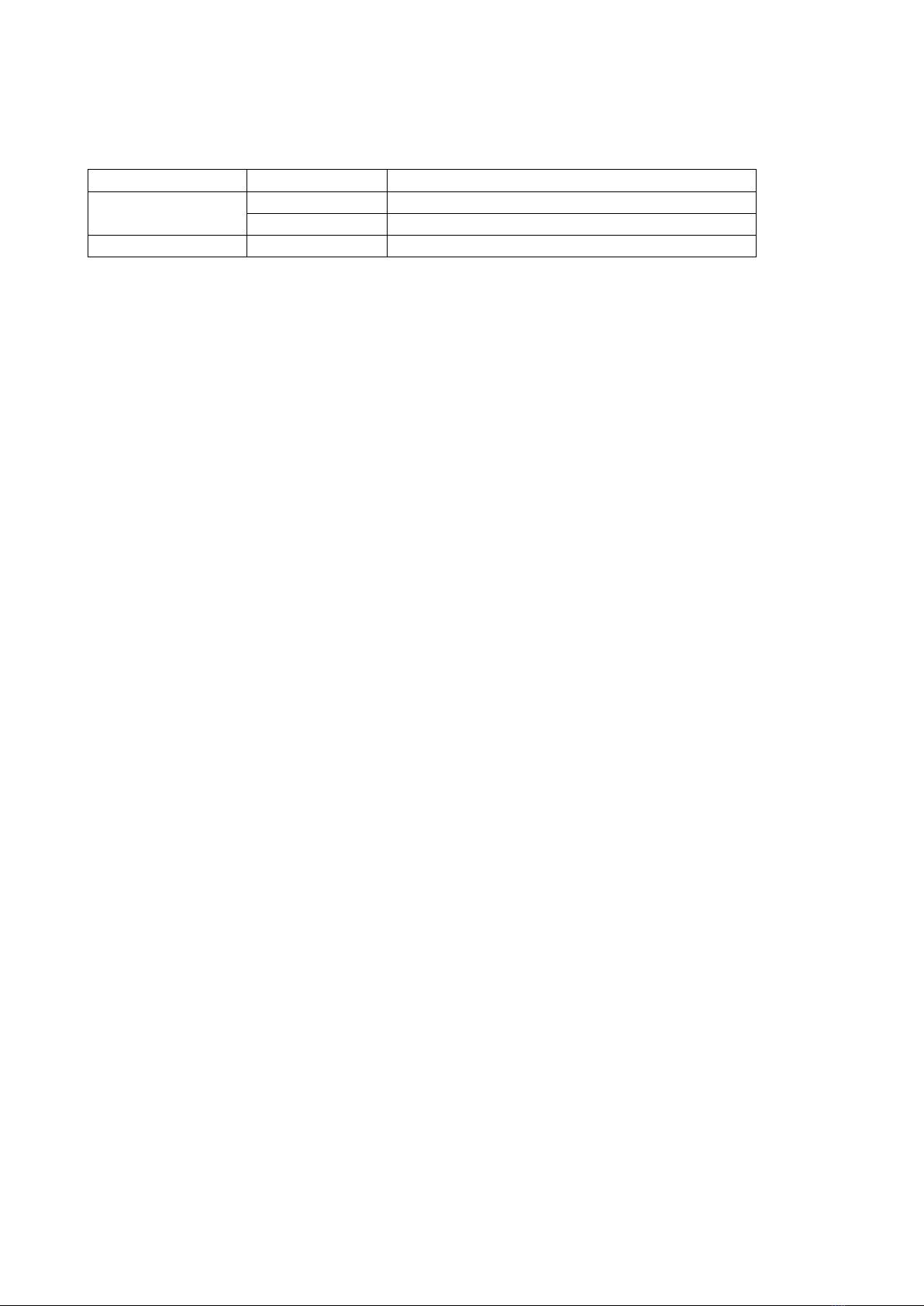

4) Adjusting the synchronizer

1. Loosen screw and remove cover .

2. Turn disk on this side by hand, and adjust the adjusting

mark "B" of disk in the rear to edge of disk .

3. Temporarily tighten the synchronizer to the lower main

shaft handwheel with screw .

4. When the power is turned ON, the sewing machine turns

approximately by one half and stops.

5. Turn OFF the power, and loosen screw .

6. Holding section of the synchronizer so as not to move,

turn the upper main shaft handwheel, adjust mark of the

handwheel to the position where mark on the machine

head side aligns with it, and temporarily tighten screw .

7. Again, turn ON the power, and conrm that the sewing ma-

chine stops at the position where mark of the handwheel

aligns with mark on the machine head side. Then tighten

screw .

8. After the adjustment, be sure to attach cover and tighten

screw .

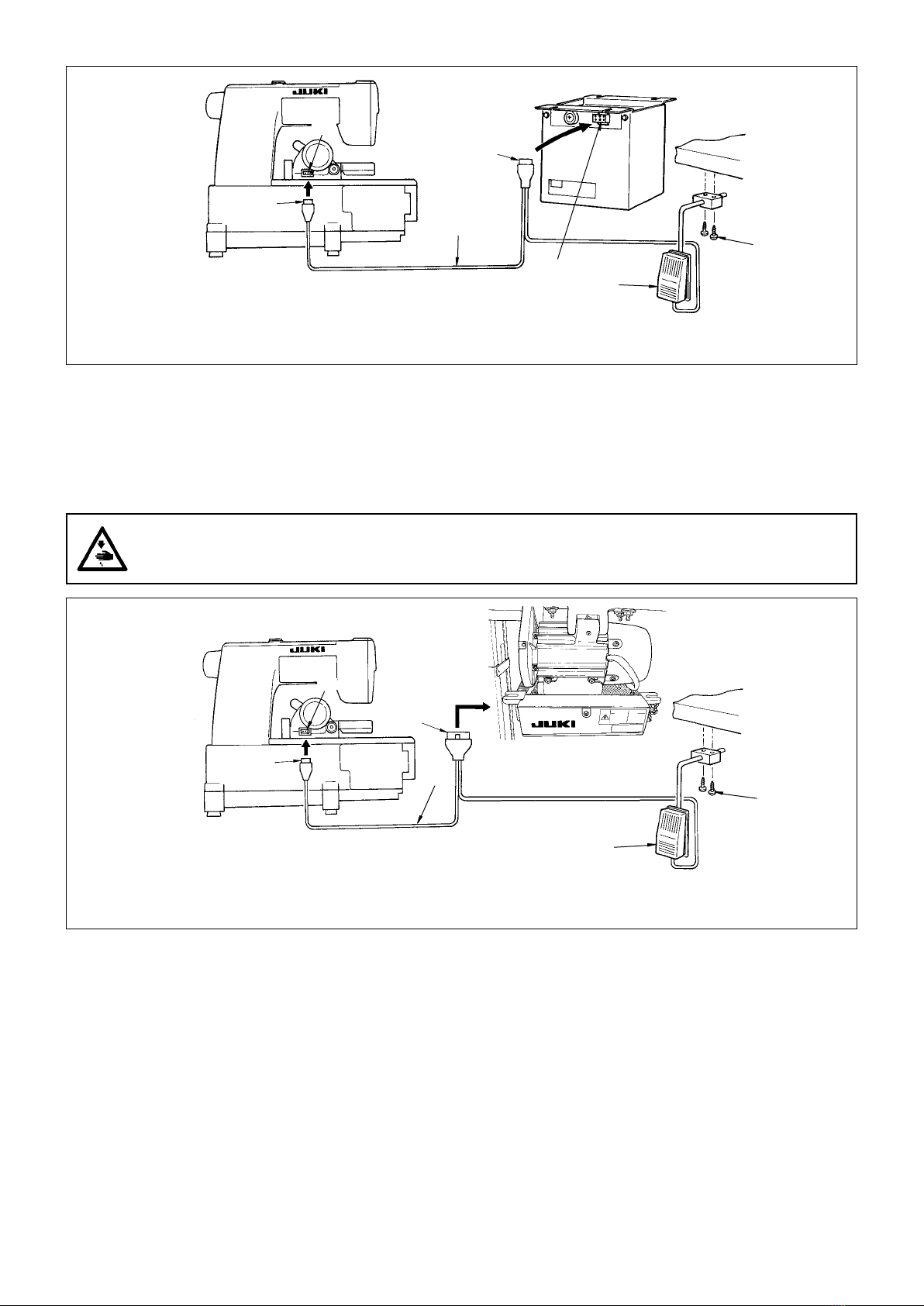

9. After the adjustment above has been performed, when the

sewing machine stops at the DOWN position, top end of

the looper is located at the position where it has scooped

loop of left needle thread as shown in the gure 1.

When using the synchronizer as UP/DOWN

stop position type without using the thread

trimmer device, change the setting of

the function setting No. 74 to "1 (thread

trimming) / 0 (UP/DOWN position)". Thread

trimmer safety device error occurs unless

the setting is changed, and it is impossible

to operate the sewing machine. So, be

careful.

Fig. 1

WARNING :

To protect against possible injury to hands or

ngers due to abrupt start of the machine during

performing adjustment, perform the adjustment of

the stop position under the function setting mode.