i

CONTENTS

I. SPECIFICATIONS........................................................................................ 1

II. SET-UP........................................................................................................ 3

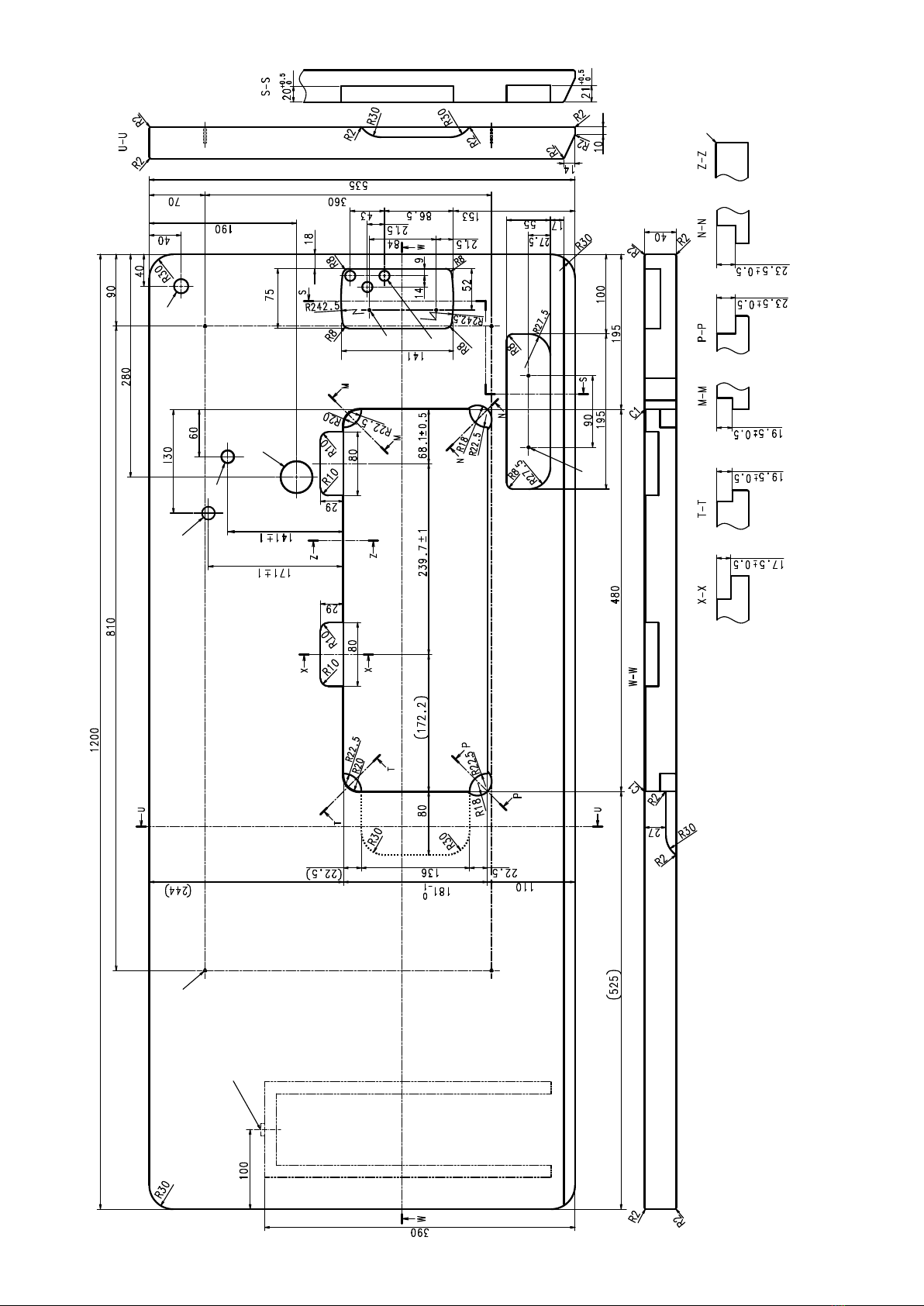

1. Installation .........................................................................................................................................3

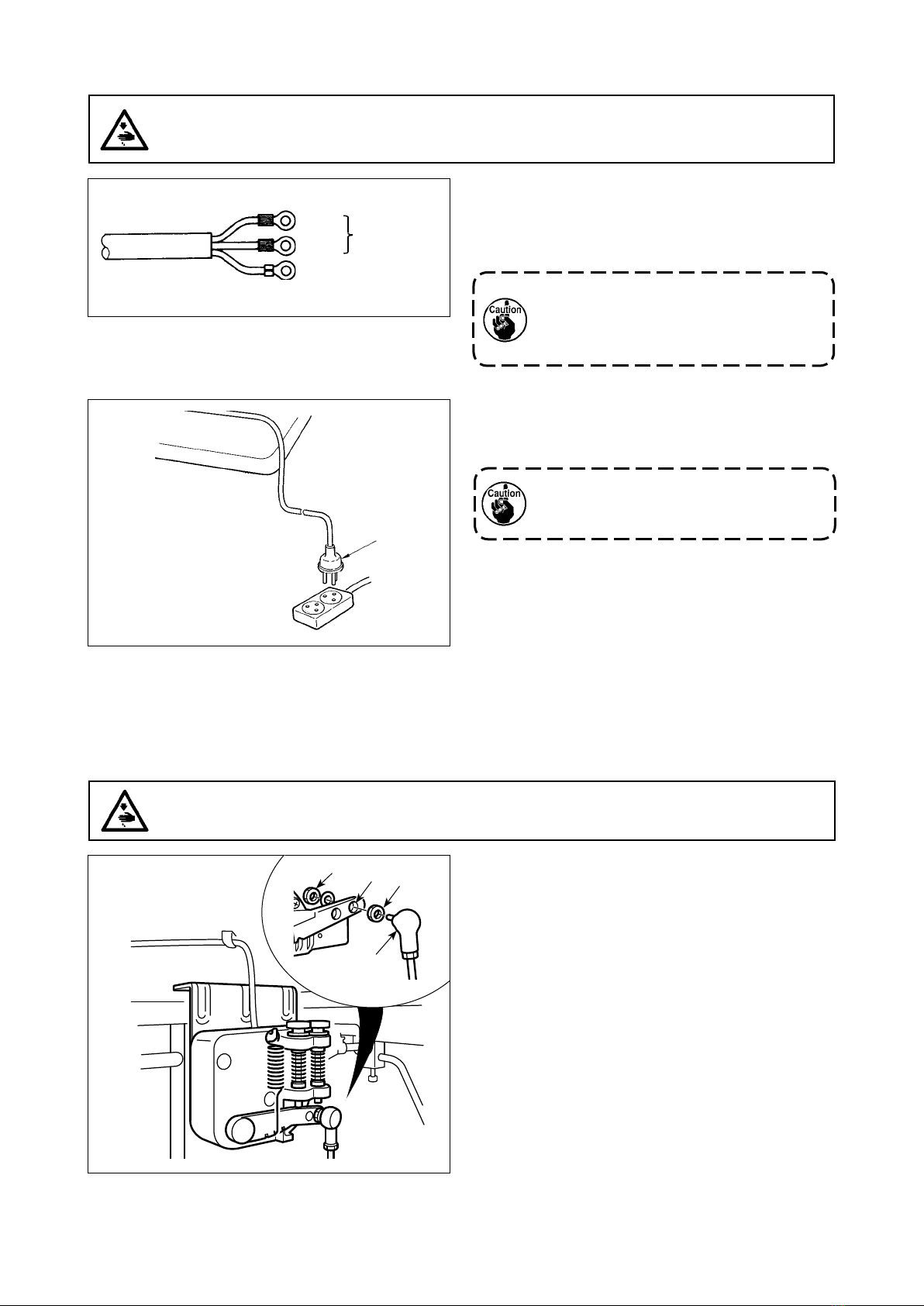

2. Installing the pedal sensor............................................................................................................... 4

3. Installing the power switch (for CE)................................................................................................ 4

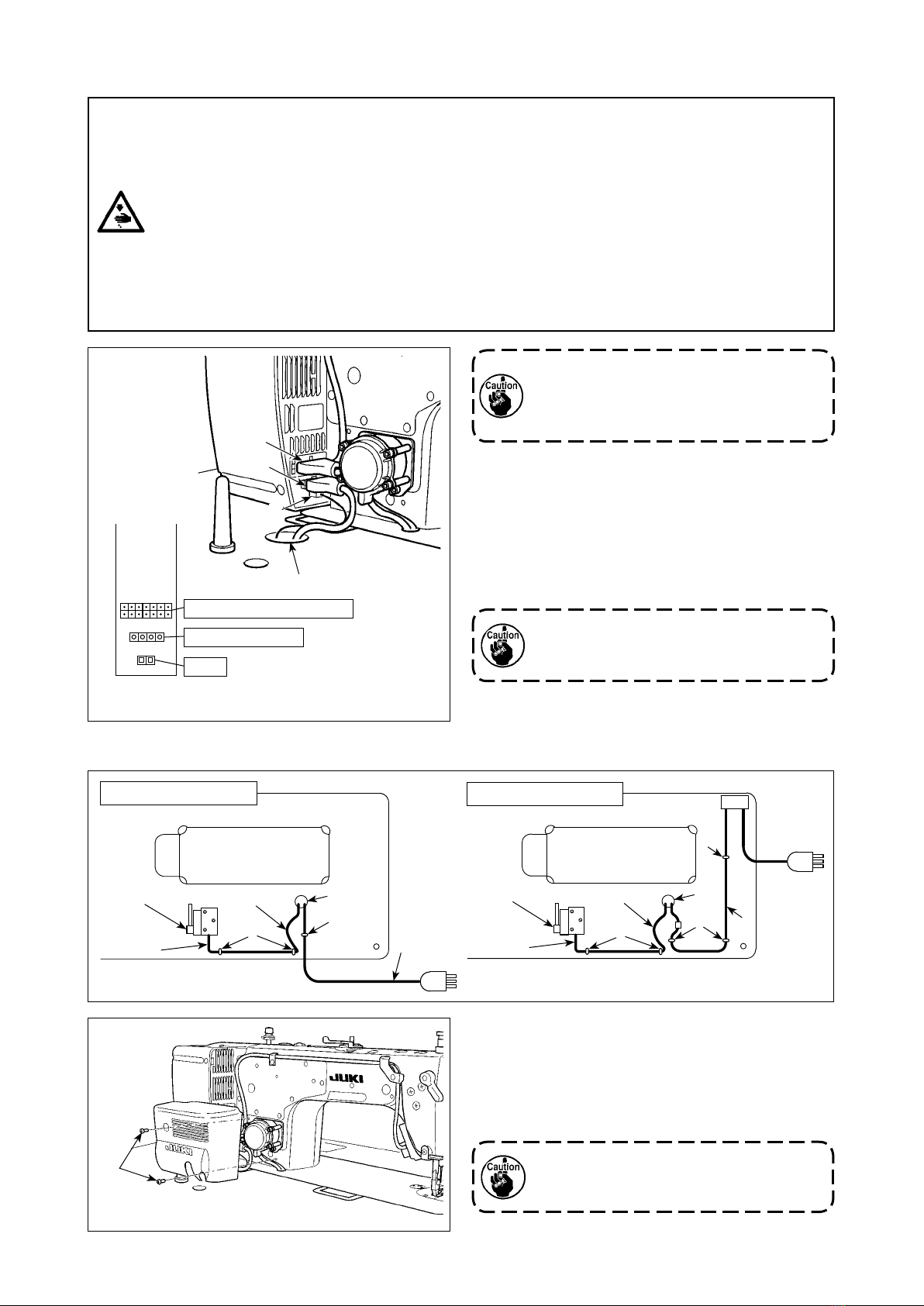

4. Connecting the connector ............................................................................................................... 5

5. How to install the power plug .......................................................................................................... 6

6. Attaching the connecting rod .......................................................................................................... 6

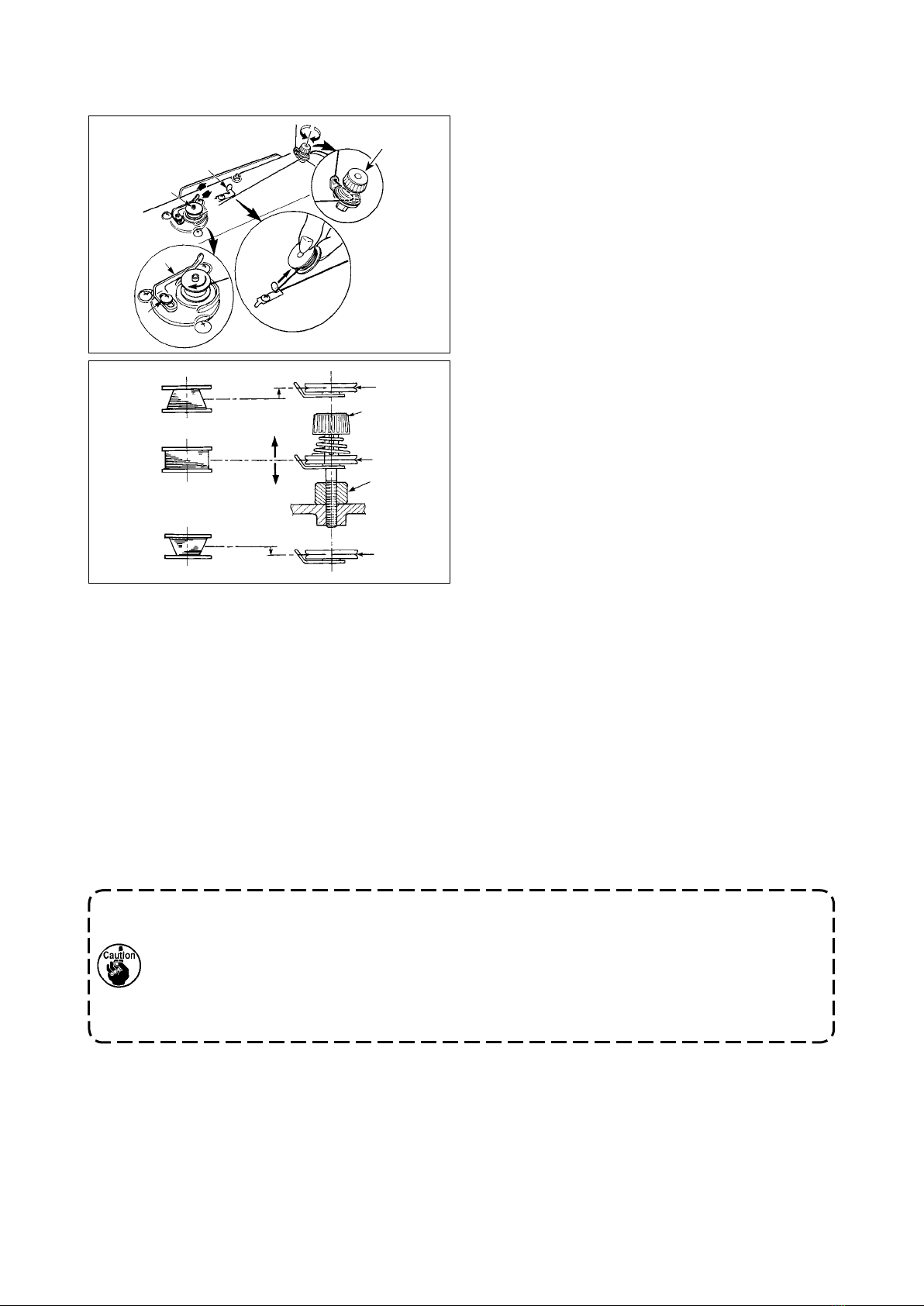

7. Winding the bobbin thread .............................................................................................................. 7

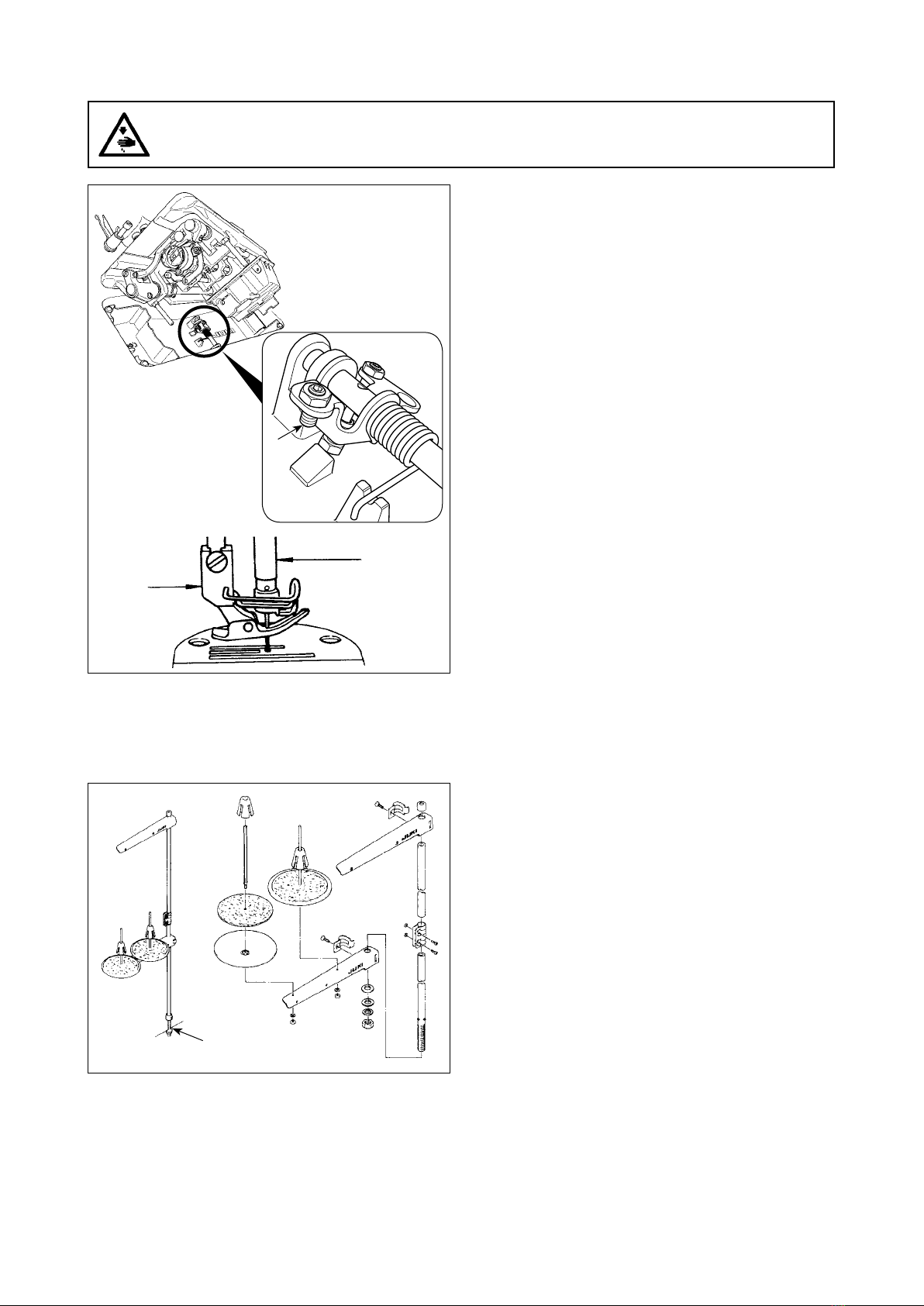

8. Adjusting the height of the knee lifter.............................................................................................8

9. Installing the thread stand ............................................................................................................... 8

10. Lubrication ........................................................................................................................................9

11. Adjusting the amount of oil (oil splashes)....................................................................................10

12. Attaching the needle....................................................................................................................... 12

13. Setting the bobbin into the bobbin case ......................................................................................13

14. Adjusting the stitch length............................................................................................................. 13

15. Presser foot pressure..................................................................................................................... 13

16. Hand lifter ........................................................................................................................................13

17. Adjusting the height of the presser bar........................................................................................14

18. Threading the machine head ......................................................................................................... 14

19. Thread tension ................................................................................................................................15

20. Thread take-up spring .................................................................................................................... 15

21. Adjusting the thread take-up stroke ............................................................................................. 15

22. Needle-to-hook relationship .......................................................................................................... 16

23. Height of the feed dog .................................................................................................................... 16

24. Tilt of the feed dog.......................................................................................................................... 17

25. Adjusting the feed timing............................................................................................................... 17

26. Counter knife...................................................................................................................................18

27. Pedal pressure and pedal stroke................................................................................................... 18

28. Adjustment of the pedal ................................................................................................................. 19

29. Marker dots on the handwheel ...................................................................................................... 19

III. FOR THE OPERATOR............................................................................. 20

1. Operating procedure of the sewing machine............................................................................... 20

2. Setting procedure of the machine head .......................................................................................21

3. Operation panel built in the machine head ..................................................................................22

4. Operating procedure of the sewing pattern ................................................................................. 23

5. One-touch setting ........................................................................................................................... 25

6. Setting of functions ........................................................................................................................ 26

7. Production support function ......................................................................................................... 27

8. Setting of thread clamp (NB type only).........................................................................................29

9. Function setting list........................................................................................................................ 31

10. Detailed explanation of selection of functions ............................................................................35

11. Automatic compensation of neutral point of the pedal sensor .................................................. 45

12. Selection of the pedal specications............................................................................................46

13. Setting of the auto lifter function .................................................................................................. 46

14. Selecting procedure of the key-lock function .............................................................................. 47

15. Initialization of the setting data ..................................................................................................... 47

16. LED hand light.................................................................................................................................48

17. Height adjustable one-touch type reverse stitching switch ....................................................... 48

IV. MAINTENANCE....................................................................................... 49

1. Adjusting the machine head .......................................................................................................... 49

2. Error codes...................................................................................................................................... 50