3-12-2. How to conrm the amount of oil (oil splashes)................................................................. 24

3-12-3. Sample showing the appropriate amount of oil.................................................................. 24

3-13. Adjusting the thread take-up spring and the thread take-up stroke............................. 25

3-14. Micro-lifting mechanism of the presser foot................................................................... 26

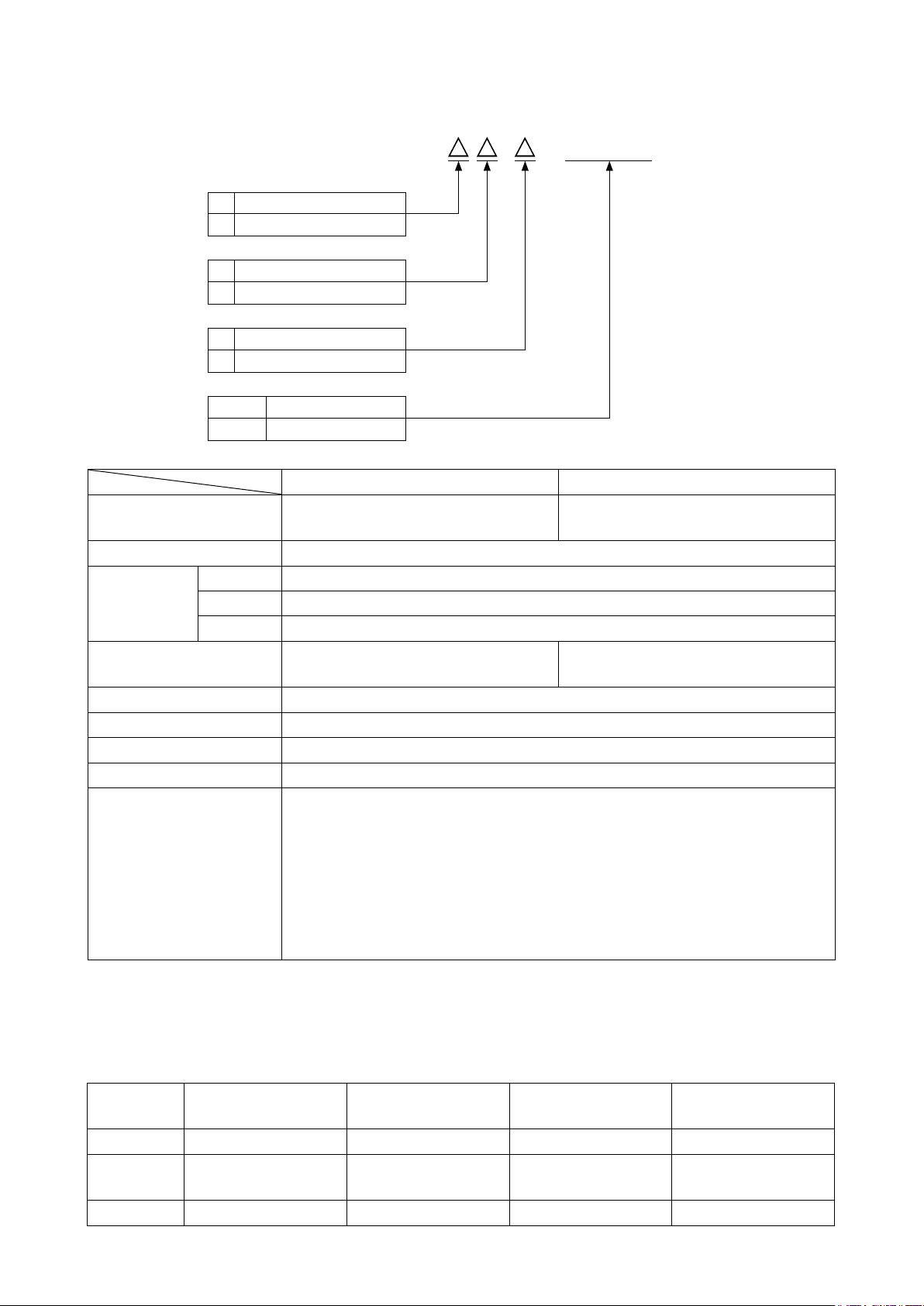

4. HOW TO USE THE OPERATION PANEL ..................................................................... 27

4-1. Explanation of the sewing screen (when selecting a sewing pattern) ......................... 27

4-2. Sewing patterns................................................................................................................. 30

4-2-1. Sewing pattern conguration .................................................................................................30

4-2-2. Reverse feed stitching (at start) pattern ................................................................................31

4-2-3. Editing the sewing patterns ....................................................................................................33

4-2-4. List of pattern functions.......................................................................................................... 35

4-2-5. Reverse feed stitching (at end) pattern .................................................................................37

4-2-6. Teaching function ....................................................................................................................38

4-2-7. One-touch type changeover button .......................................................................................40

4-2-8. Registration of a new sewing pattern ....................................................................................41

4-2-9. Copying a pattern ....................................................................................................................42

4-3. Counter function................................................................................................................ 43

4-3-1. Displaying the sewing screen under the counter display mode .........................................43

4-3-2. Types of the counter................................................................................................................ 43

4-3-3. How to set the counter ............................................................................................................44

4-3-4. How to reset the count-completion state ..............................................................................46

4-4. Simplied chart of panel displays ................................................................................... 47

4-5. List of memory switch data .............................................................................................. 48

4-6. List of errors ...................................................................................................................... 52

4-7. Memory switch data .......................................................................................................... 55

4-7-1. Setting up the memory switch data .......................................................................................55

5. MAIN NEW FUNCTIONS............................................................................................... 57

5-1. Shorter-thread remaining thread trimming ..................................................................... 57

5-2. Adjusting the feed dog height.......................................................................................... 60

5-3. Operating timing of the feed............................................................................................. 61

5-4. Changing the feed locus................................................................................................... 62

6. CARE ............................................................................................................................. 63

6-1. Maintenance mode ............................................................................................................ 63

6-2. Conrmation of the amount of oil in the hook oil tank .................................................. 63

6-3. Cleaning ............................................................................................................................. 64

6-4. Applying grease................................................................................................................. 64

6-5. Applying grease to the needle bar lower bushing and the presser bar bushing ........ 65

6-6. Replacing the fuse............................................................................................................. 65

7. ADJUSTMENT OF THE MACHINE HEAD (APPLICATION) ........................................ 66

7-1. Needle-to-hook relationship ............................................................................................. 66

7-2. Adjusting the needle thread presser device ................................................................... 67

7-3. Adjusting the thread trimmer ........................................................................................... 70

7-3-1. For checking of the thread trimming cam timing .................................................................70

7-3-2. Adjustment of the thread trimming cam timing ....................................................................70

7-3-3. Checking of the knife unit .......................................................................................................71

7-3-4. Adjustment of the knife unit ..................................................................................... 72

7-3-5. Adjustment of thread trimming speed ...................................................................................73

7-4. Adjustment of the picker................................................................................................... 74

ii