Replace bulb with same type rated 15Watts.

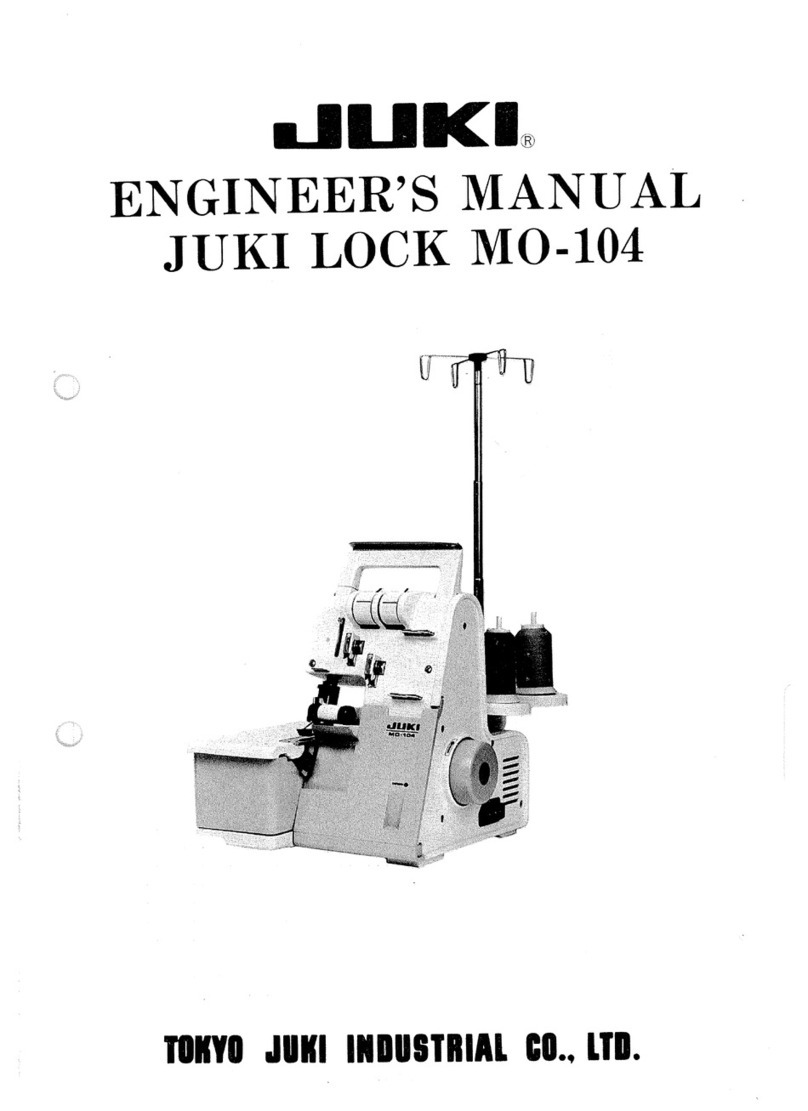

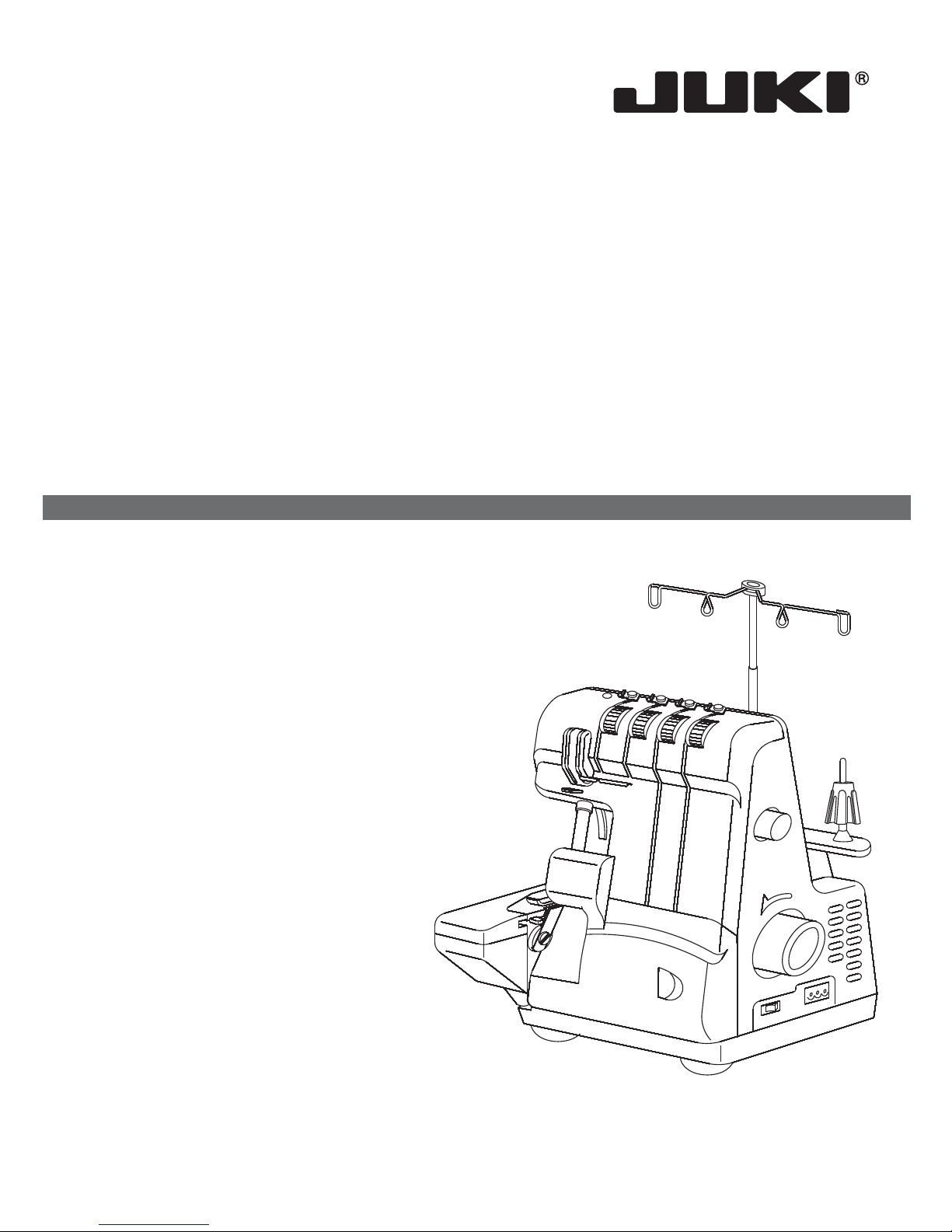

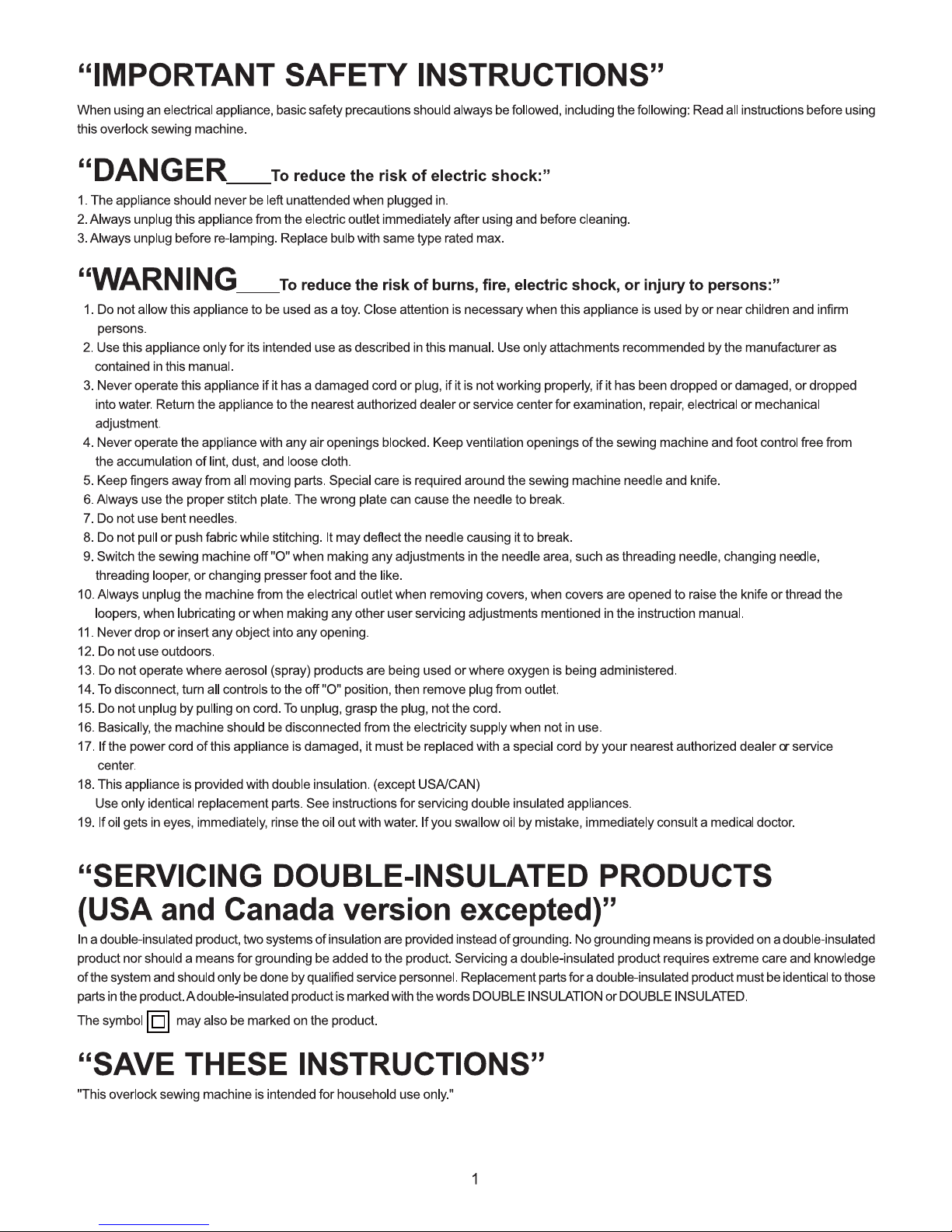

Use foot controller 7. - Details of the machine

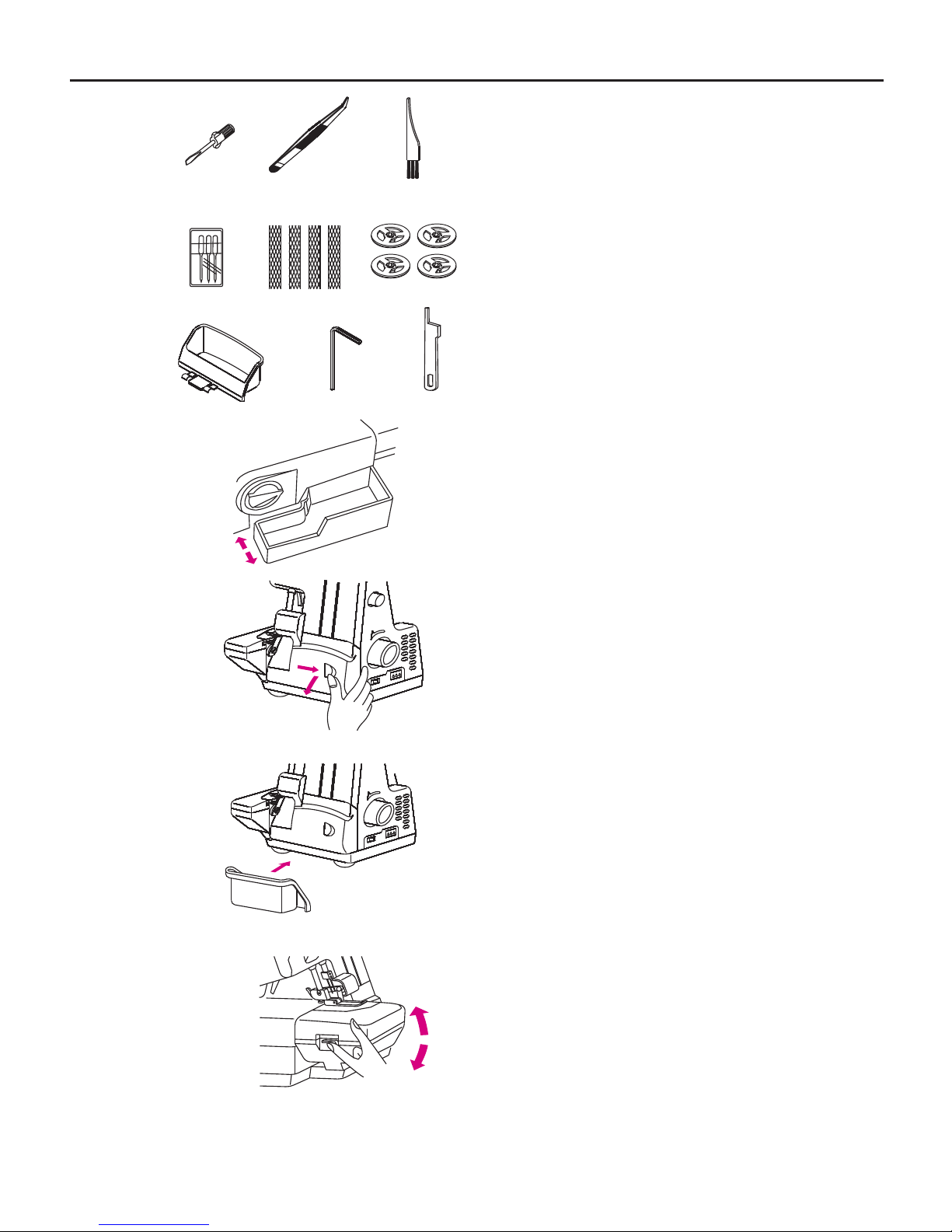

9. - Accessories

9. - Accessory Box

9. - Looper cover

9. - Waste collector

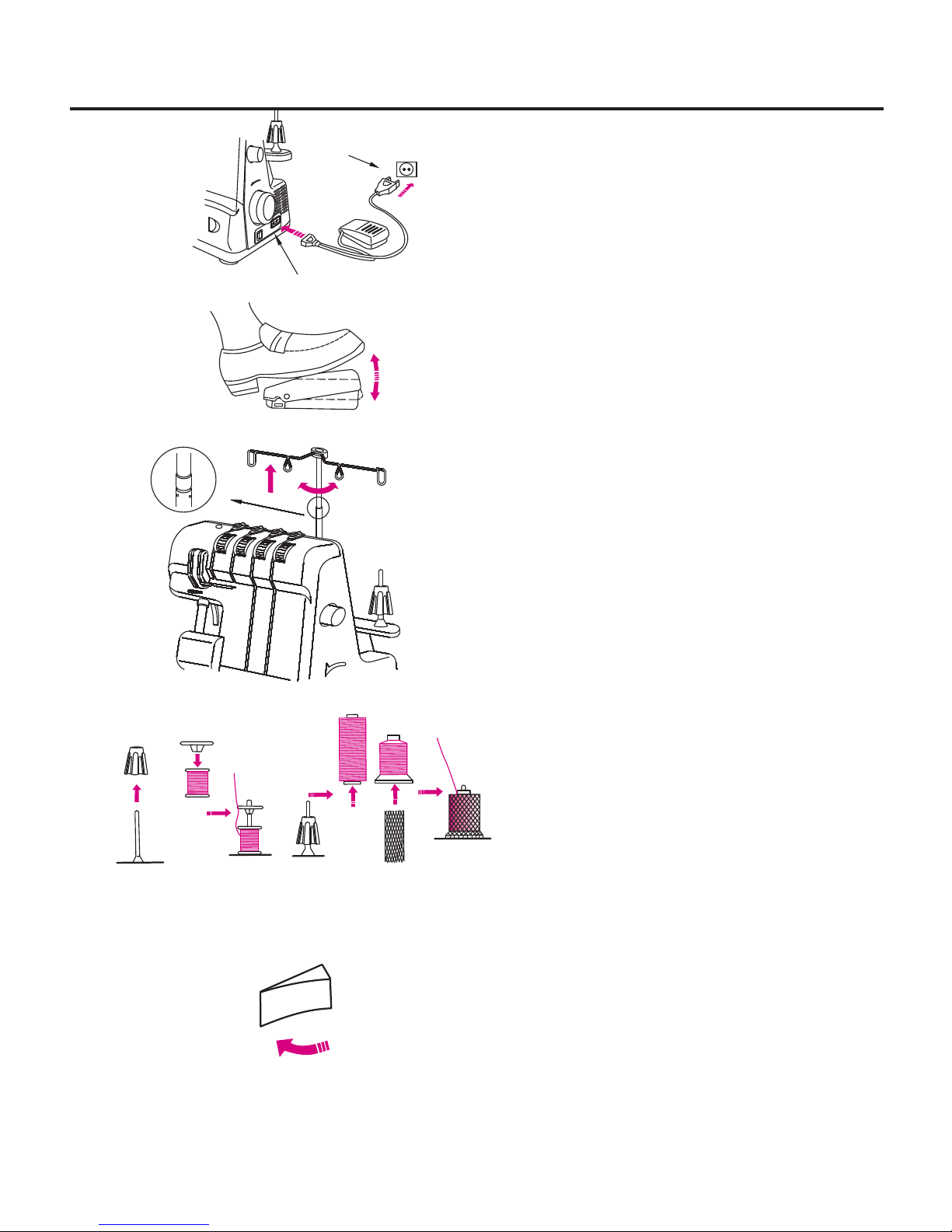

11. - Attaching the foot control

11. - Sewing speed

11. - Assembling the thread stand

11. - Thread cones

11. - Power/ light switch

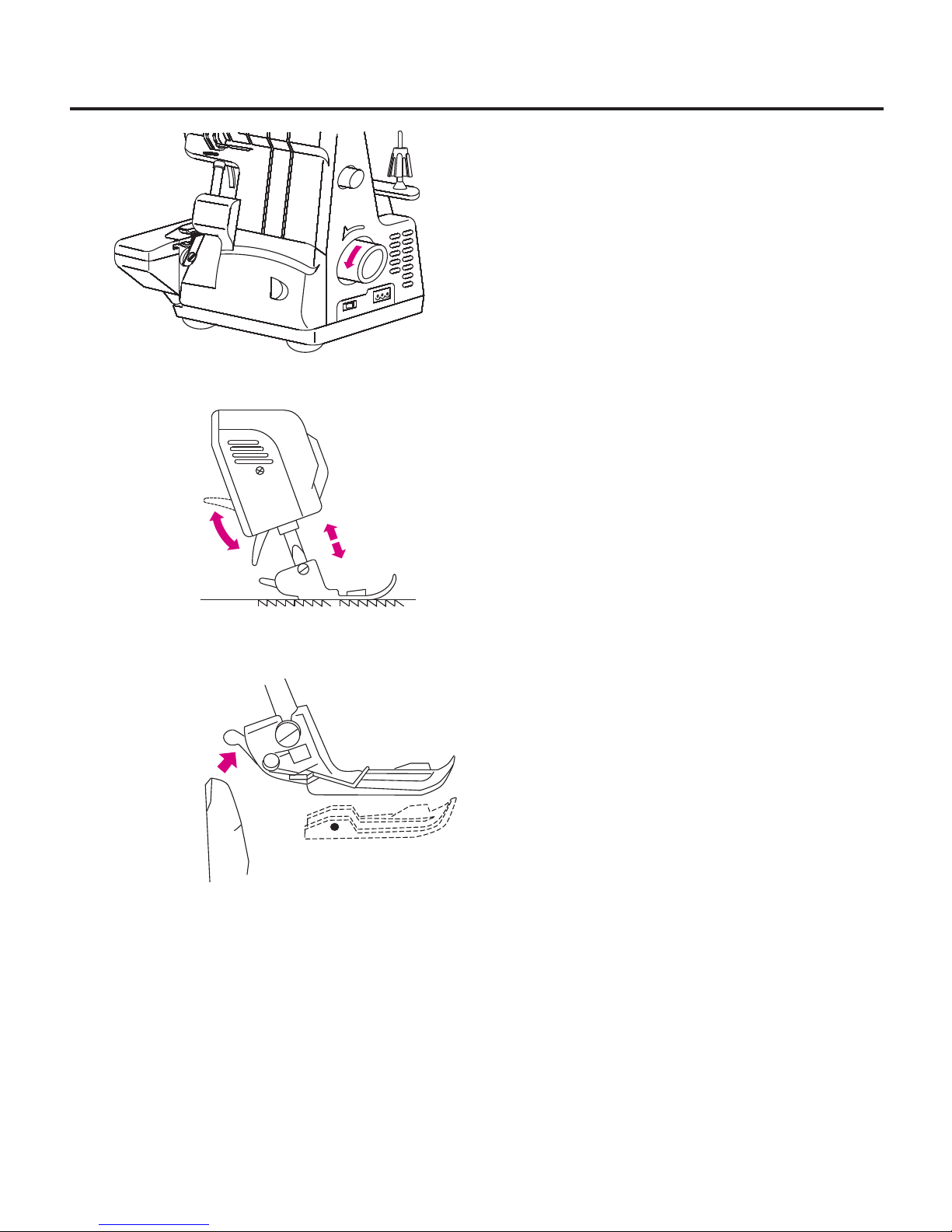

13. - Handwheel

13. - Presser foot lifter

13. - Changing the presser foot

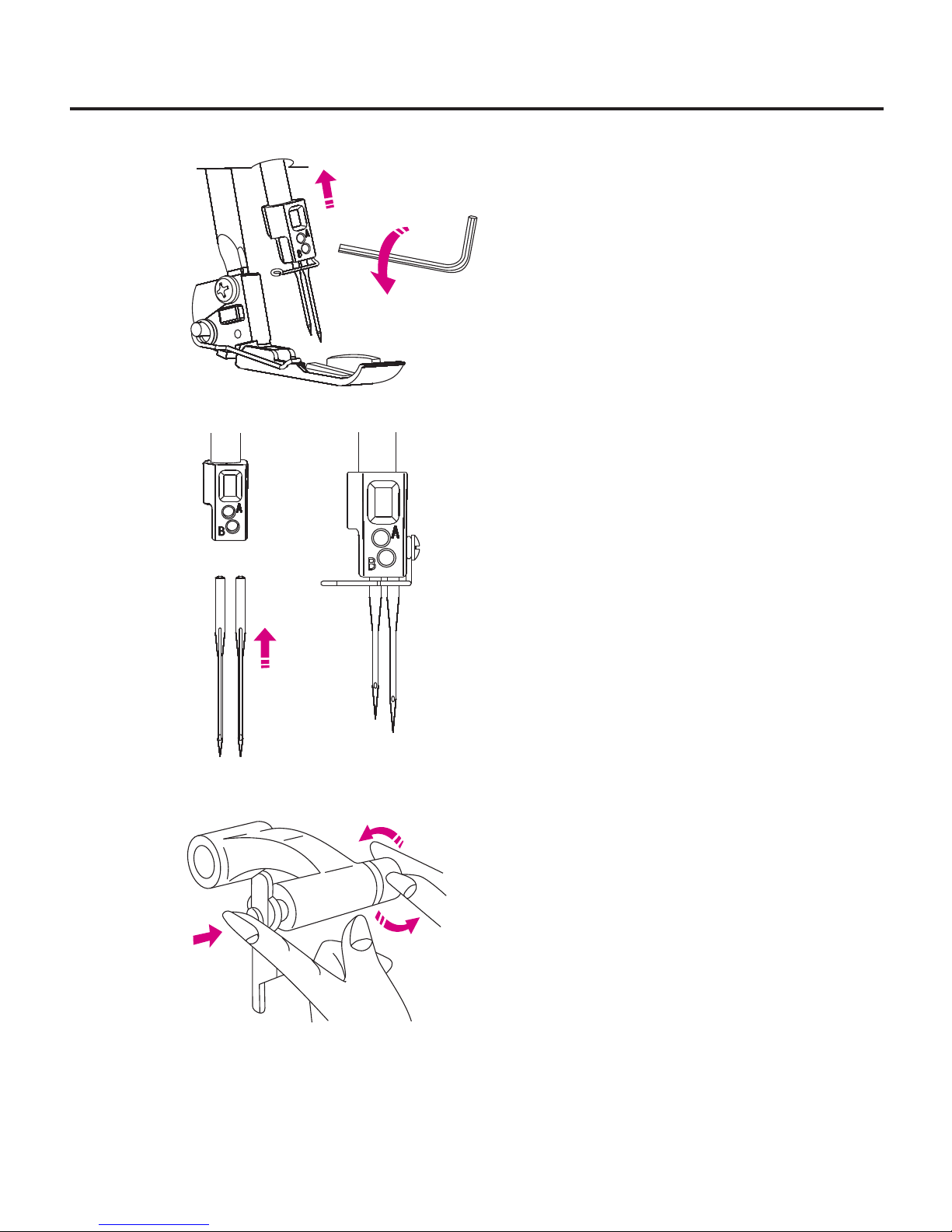

15. - Inserting needles

15. - To lower the upper knife

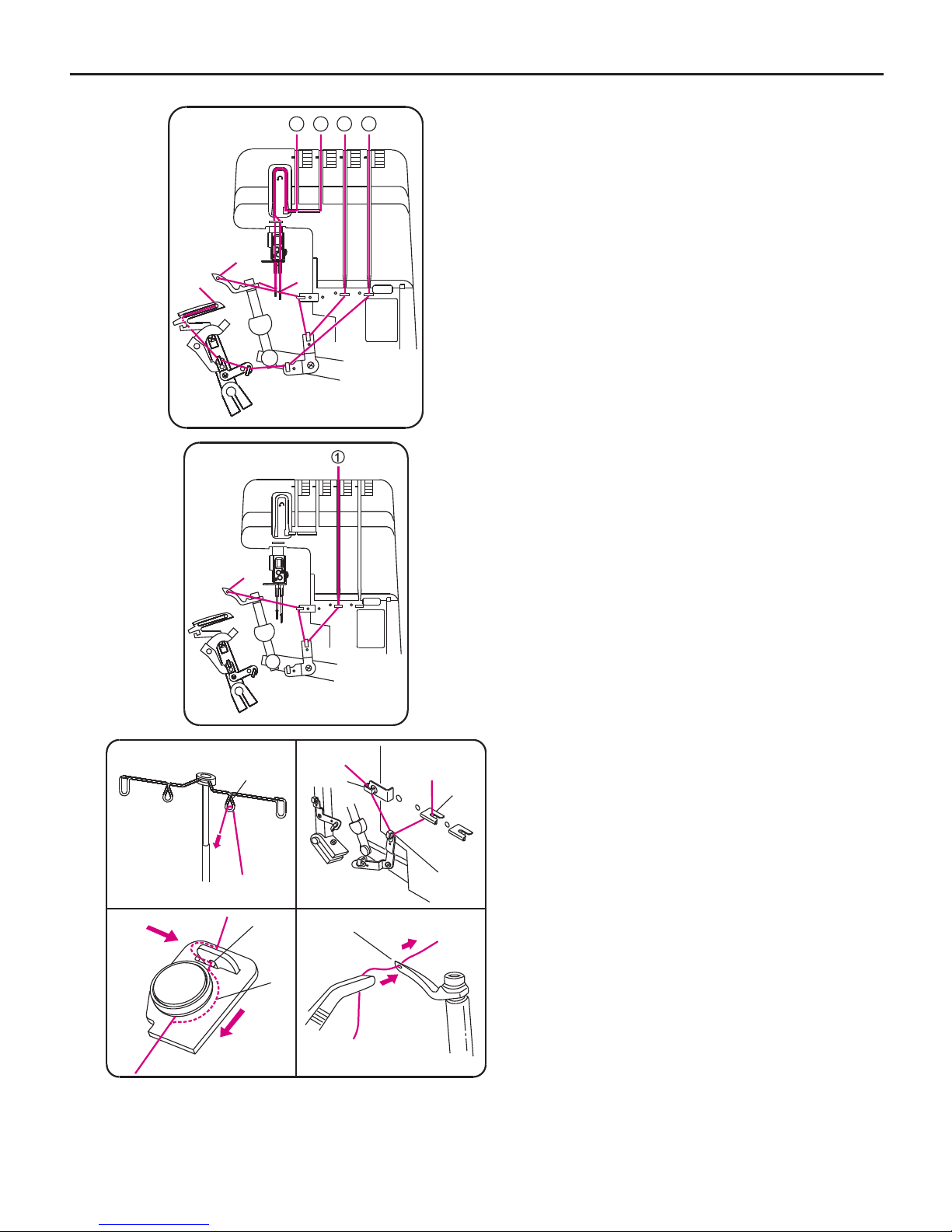

17. - Threading/ Preparation

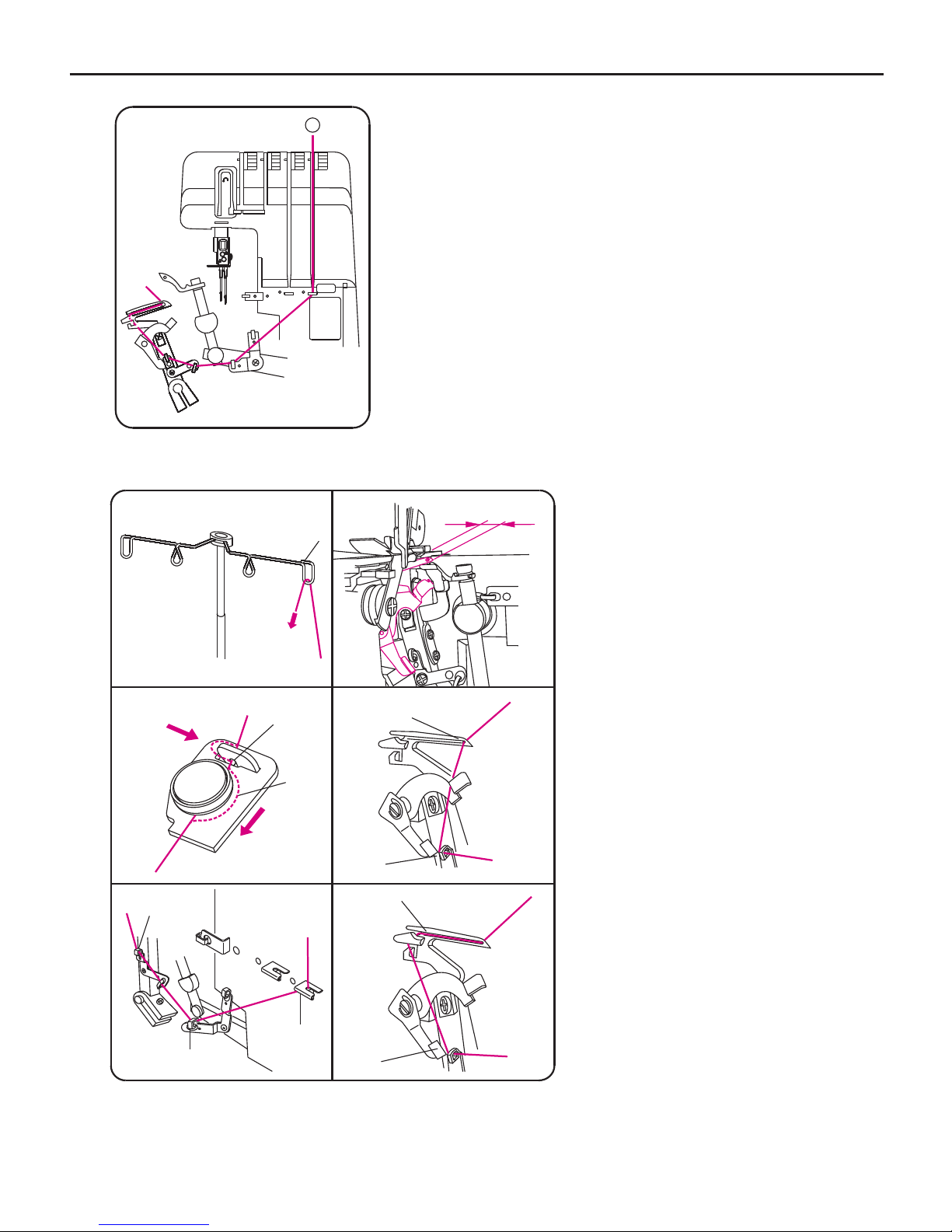

17. - Upper looper ( )Blue

19. - Lower looper (Red)

21. - Right needle (Green)

23. - Left needle (Yellow)

23. - After threading

25. - Sewing test

25. - Check your trial run

27. - Adjusting the thread tension

29. - Stitch length

29. - Cutting width

31. - Gathering*

- 3 thread overlock

- 3 thread rolled hem

- Unpicking seams

- Changing light bulb

- Cleaging and lubricating

31. - Differential feed*

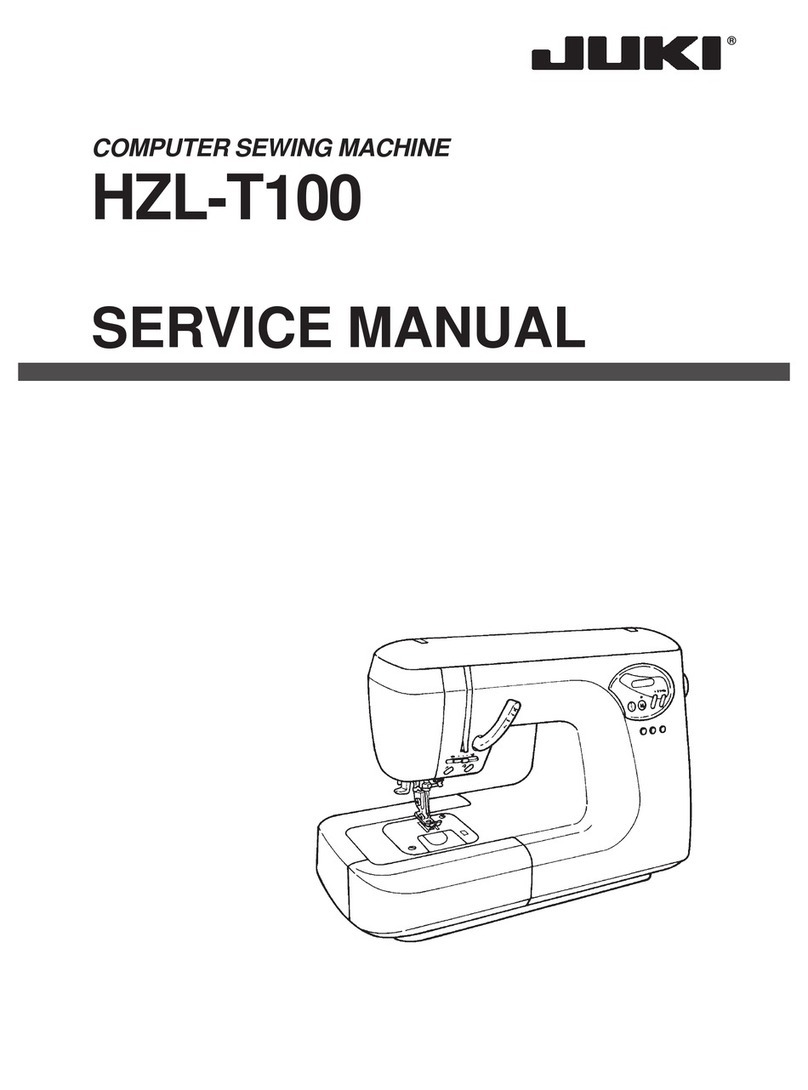

13. Using the machine

17. Threading

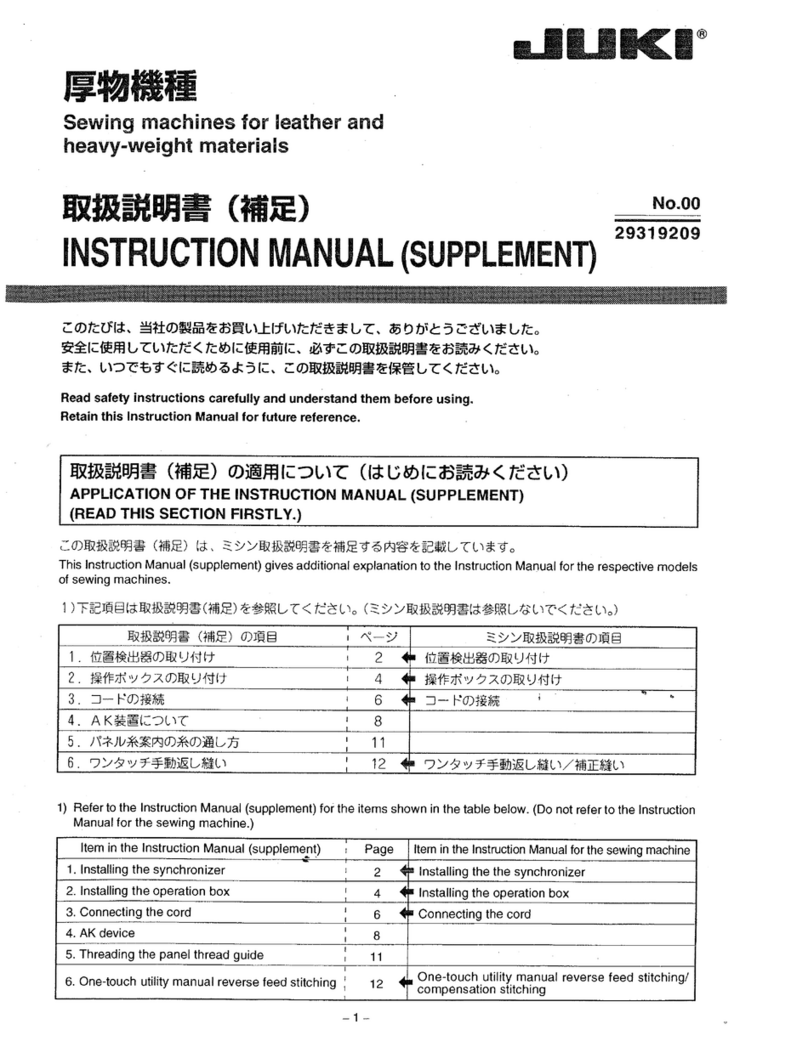

Contents

25. Trial sewing, thread tension

27. Adjusting the thread tension

29. Adjustments and settings

31. Differential feed*

33. Practical sewing

35. Maintenance

37. Trouble shooting guide

41. Technical data

1. Safety regulations

5. Contents

7. Details of the machine

9. Preparing the machine

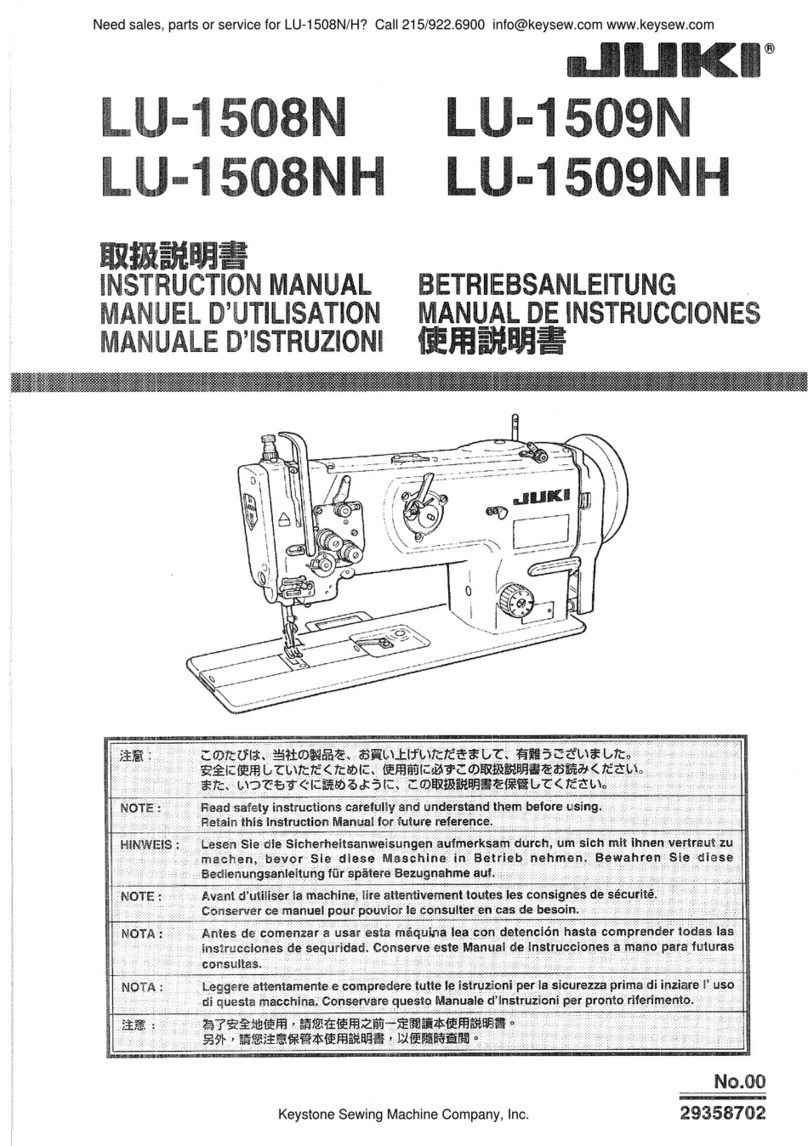

4C-315A221

4C-316B22

4C-326C22

4C-316C24

4C-316C26

4C-316C28

4C-326G22

4C-326C25

4C-326C23

Foot controller (100v) Japan

Foot controller (115v) U.S.A.

Foot controller (220v) South Africa

Foot controller (220v) Argentina

Foot controller (220v) Korea

Foot controller (220v) the Middle East

Foot controller (230v) Europe

Foot controller (240v) U.K.

Foot controller (240v) Australia

2