i

CONTENTS

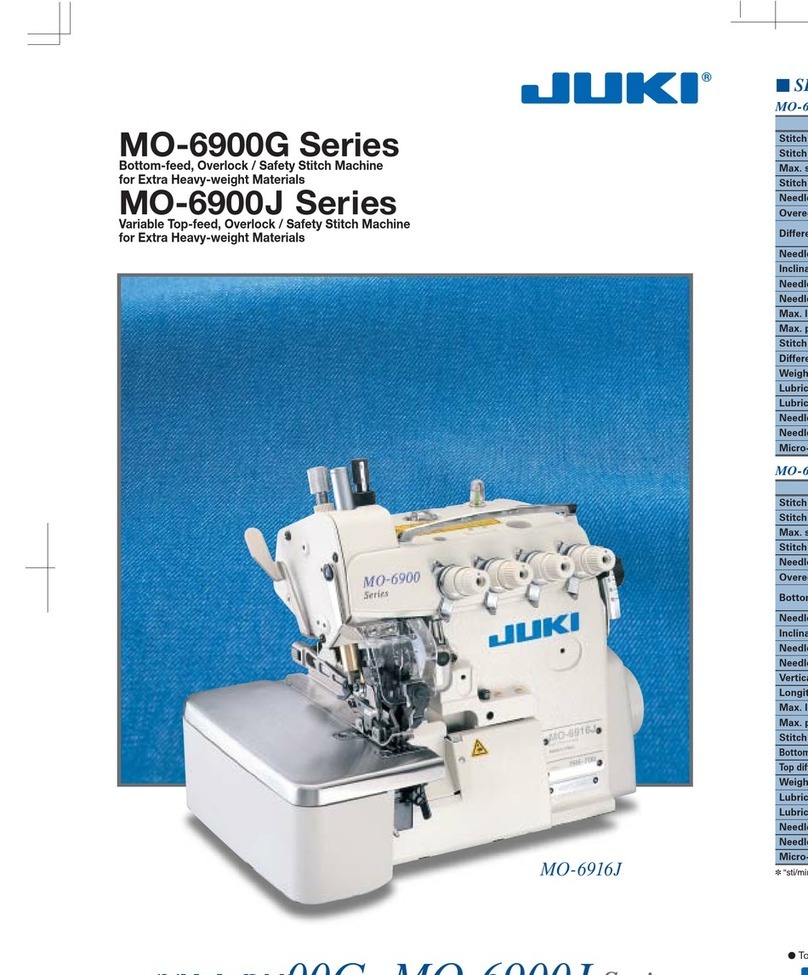

1. SPECIFICATIONS.......................................................................................................... 1

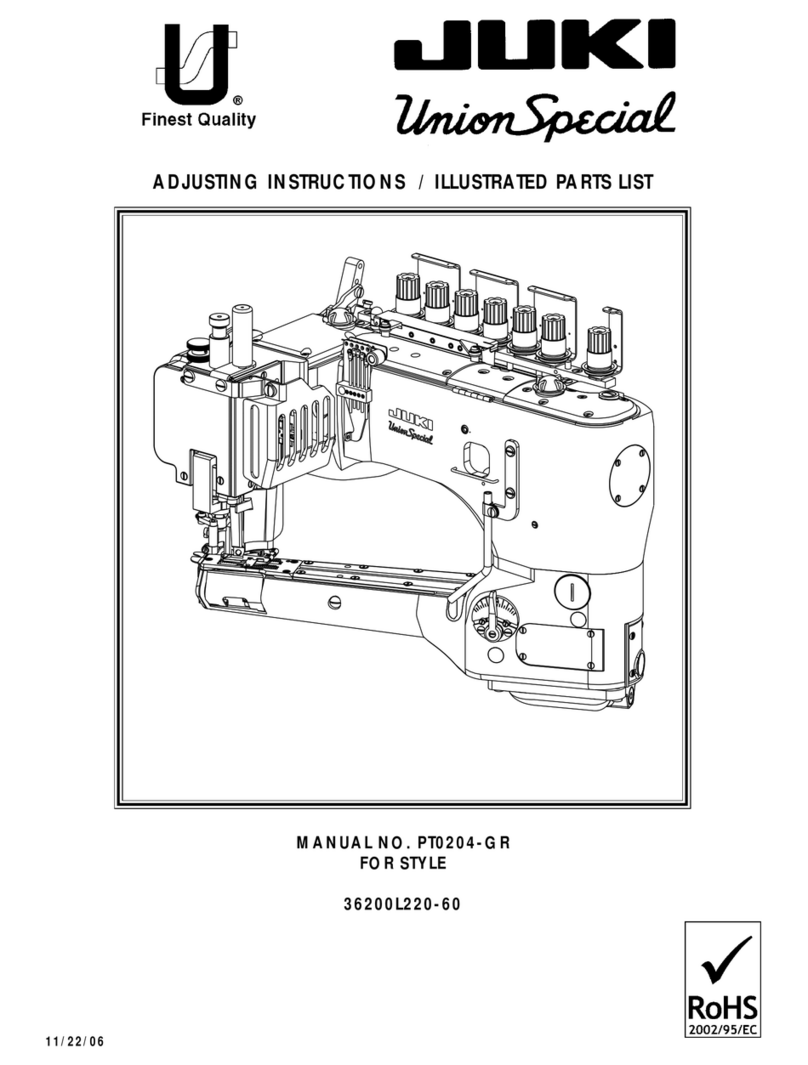

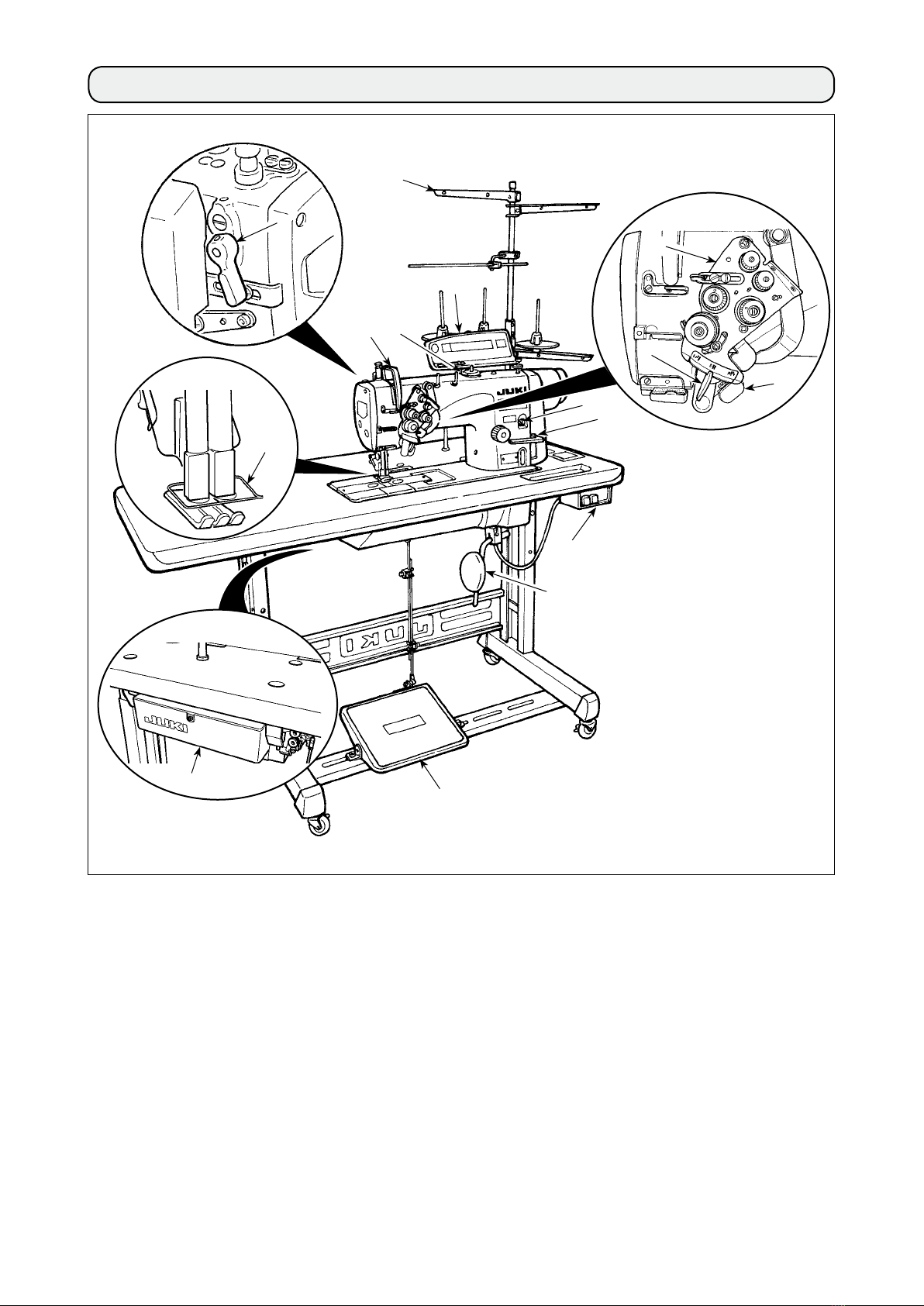

2. NAME OF EACH COMPONENT ................................................................................... 3

3. INSTALLATION.............................................................................................................. 4

3-1. Caution at the time of set-up............................................................................................................................ 4

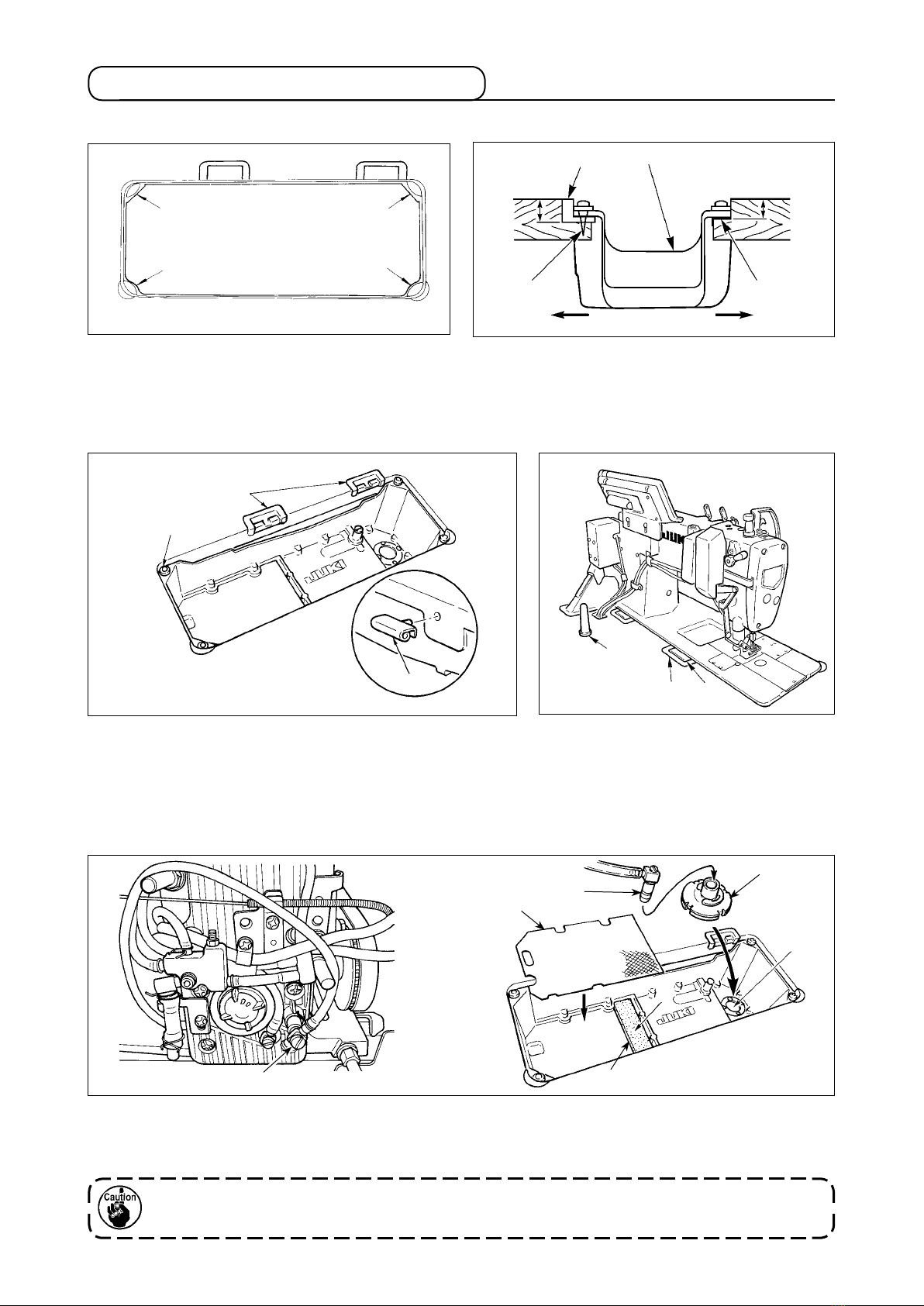

3-2. Installation of the sewing machine.................................................................................................................. 5

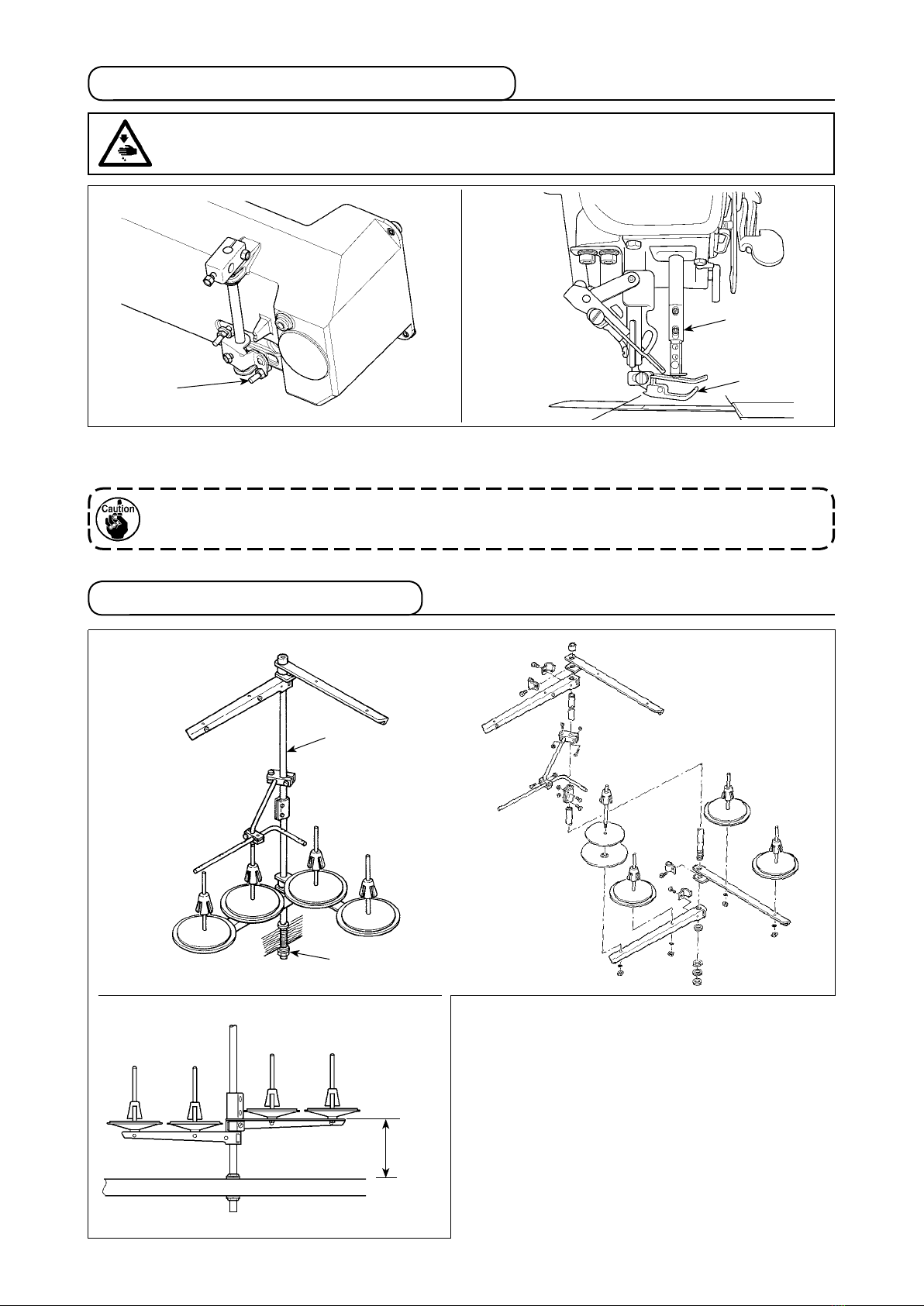

3-3. Adjusting the height of the knee lifter............................................................................................................. 6

3-4. Installation of thread stand............................................................................................................................... 6

4. PREPARATION OF THE SEWING MACHINE .............................................................. 7

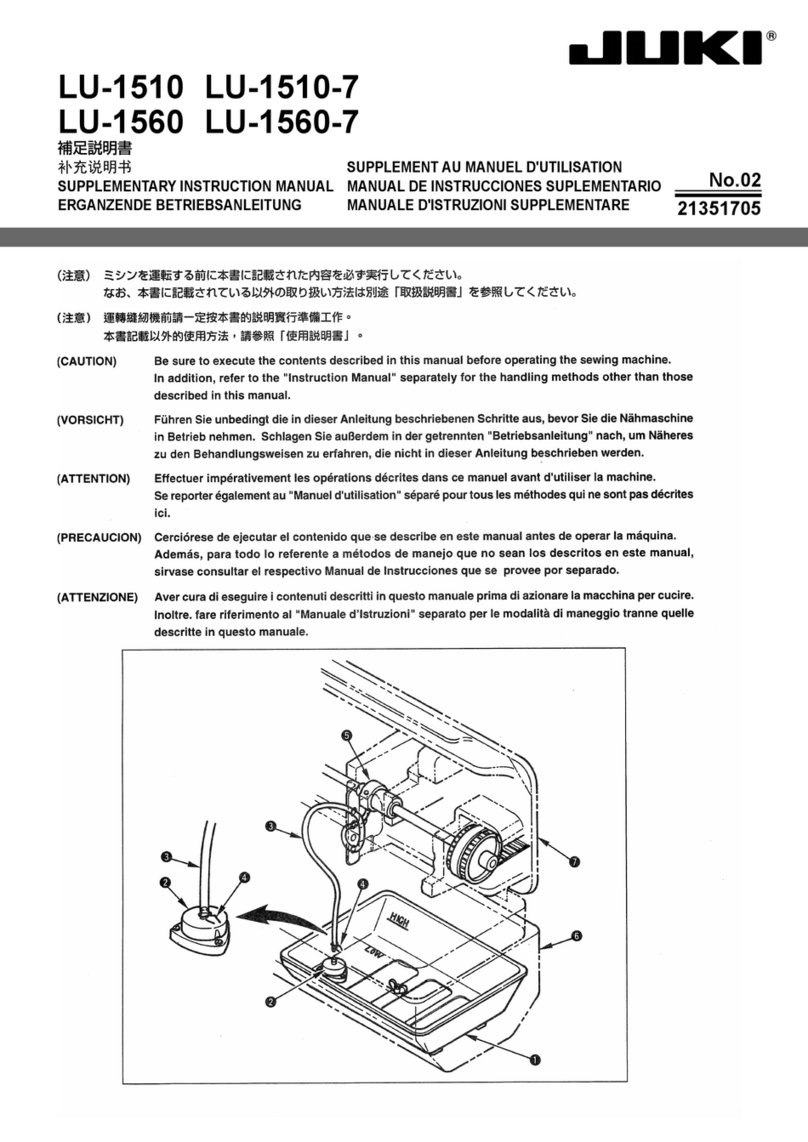

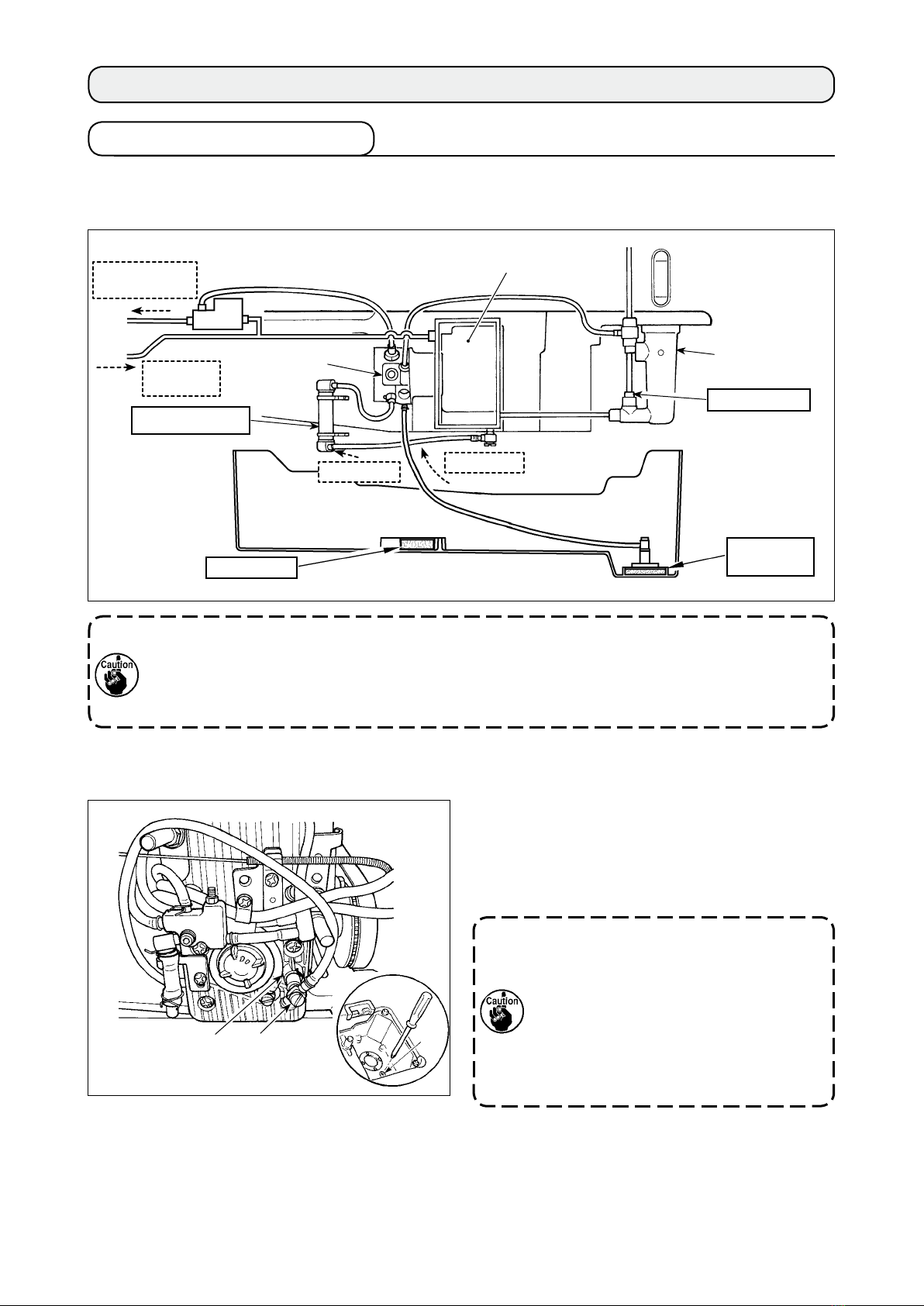

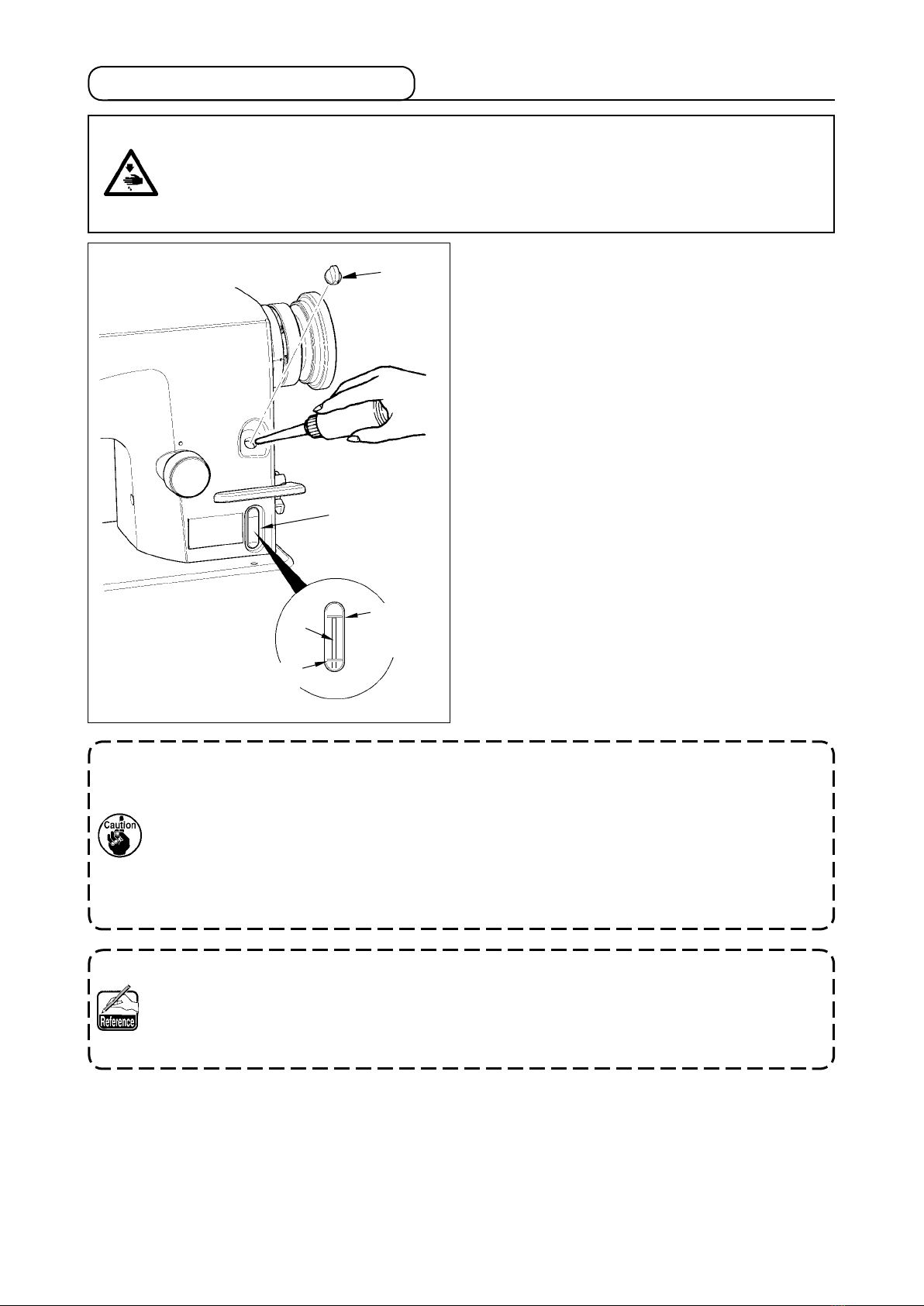

4-1. Method of lubrication........................................................................................................................................ 7

4-2. Lubrication to the oil tank................................................................................................................................. 8

4-3. Draining of oil from the oil tank ....................................................................................................................... 9

4-4. Adjusting the amount of oil in the hook.......................................................................................................... 9

4-5. Oil in the feed box ........................................................................................................................................... 10

4-6. Applying grease............................................................................................................................................... 11

4-7. Setting up the SC-920 ..................................................................................................................................... 14

4-8. Installing the belt cover (For LH-3528A, 3568A, 3578A and 3588A) ........................................................... 18

4-9. Attaching the needles ..................................................................................................................................... 18

4-10. How to take out the bobbin case ................................................................................................................... 19

4-11. Inserting a bobbin in a bobbin case .............................................................................................................. 19

4-12. Threading the machine head.......................................................................................................................... 20

4-13. Thread tension................................................................................................................................................. 23

4-14. Winding the bobbin thread............................................................................................................................. 24

4-15. Thread take-up spring..................................................................................................................................... 25

4-16. Adjusting the stitch length ............................................................................................................................. 27

4-17. Needle-to-hook relation .................................................................................................................................. 27

4-18. Pedal pressure and pedal stroke ................................................................................................................... 29

4-19. Adjustment of the pedal.................................................................................................................................. 29

5. OPERATION OF THE SEWING MACHINE ................................................................ 30

5-1. Pedal Operation............................................................................................................................................... 30

5-2. Hand lifter......................................................................................................................................................... 30

5-3. Adjusting the pressure of the presser foot................................................................................................... 31

5-4. Micro-lifter........................................................................................................................................................ 31

5-5. Thread tension release changeover when using the knee lifter................................................................. 32

5-6. One-touch manual reverse feed (One-touch reverse feed type)................................................................. 32

6. MAINTENANCE ........................................................................................................... 33

6-1. Procedure of changing over between bottom feed and needle feed and the adjustment (for LH-3528A

only).................................................................................................................................................................. 33

6-2. Changing the feed timing ............................................................................................................................... 35

6-3. Adjusting the thread trimming cam............................................................................................................... 36

6-4. Adjusting the hook needle guard................................................................................................................... 37

6-5. Adjusting the inner hook guide...................................................................................................................... 37

6-6. Adjusting the height and the inclination of the feed dog ............................................................................ 38

6-7. Replacing the gauge ....................................................................................................................................... 39

6-8. Adjusting the thread presser spring.............................................................................................................. 39

6-9. Adjusting the position of the moving knife................................................................................................... 40

6-10. Position of the wiper ....................................................................................................................................... 41

6-11. Caution when installing the attachments...................................................................................................... 41

6-12. Replacing the bobbin thread slack preventer spring (For LH-3568A, 3568A-7, 3588A and 3588A-7) ..... 42

6-13. Stop of the needle bars and angle of corners for corners stitching (For LH-3568A, 3568A-7, 3588A and

3588A-7)............................................................................................................................................................ 42

7. STITCH-TO-ANGLE TABLE BY GAUGE (PITCH AND mm CONVERSION TABLE) 43

8. GAUGE SETS.............................................................................................................. 44

9. TROUBLES AND CORRECTIVE MEASURES ........................................................... 53

10. MOTOR PULLEY AND BELT ...................................................................................... 55