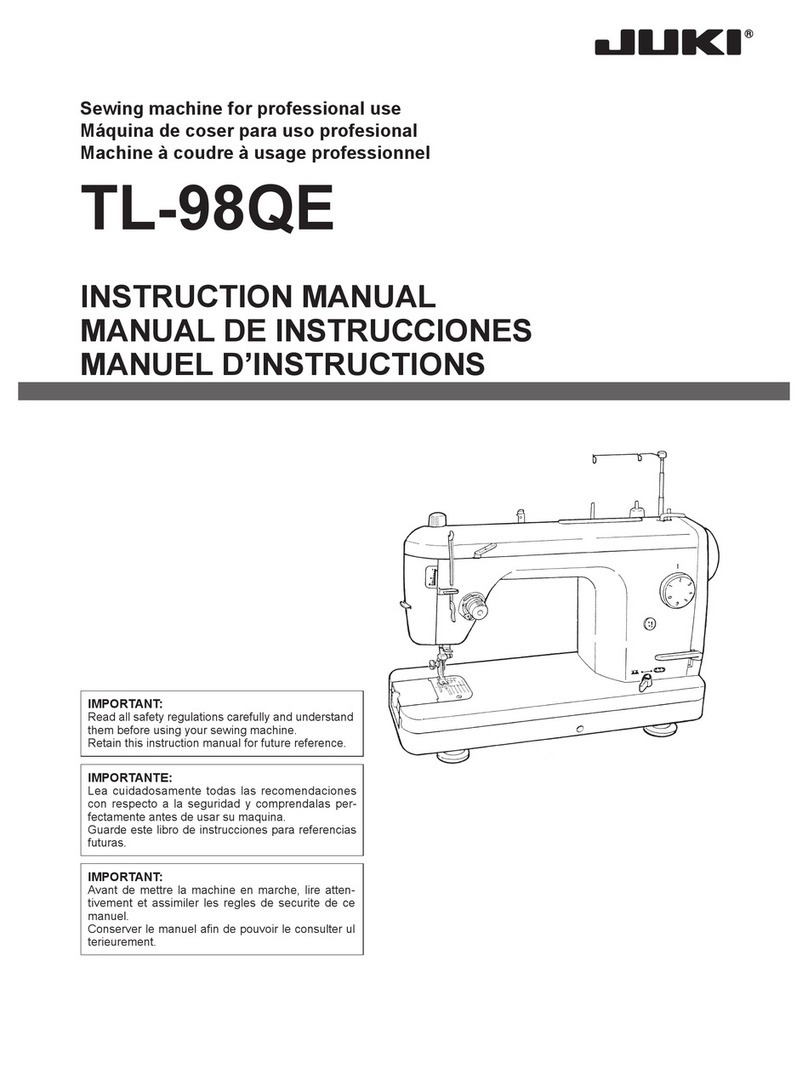

1. Turn the hand-wheel to bring the needle bar to the lowest dead point.

2. Loosen the clamping screw of the needle bar connecting bracket

.

3. Align the marker line Aengraved in the needle bar to the lower end

of the needle bar lower metal and fasten the clamping screw of

the needle bar connecting bracket .

(Cautions) 1. For the needle DP x 17 (Standard), use the second

marker line AA

AA

Afrom the lowest, engraved in the

needle bar.

2. For the needle DB x 1, use the fourth marker line BB

BB

B

from the lowest, engraved in the needle bar.

3. After adjustment, make sure that the outer presser

foot does not come in contact with the needle bar.

oStitch skipping or thread breakage

may be caused.

– 4 –

oIrregular stitches, stitch skipping

or thread breakage may be

caused.

oIrregular stitches, particularly

isolated idling loops, will occur

when the hook timing is too early

or too late.

oIrregular stitches can be improved

when the hook timing is

appropriately set later.

oWhen the hook timing is set too

late, the thread tension may be

lowered.

oIsolated idling loops can be

improved when the hook timing is

set appropriately earlier.

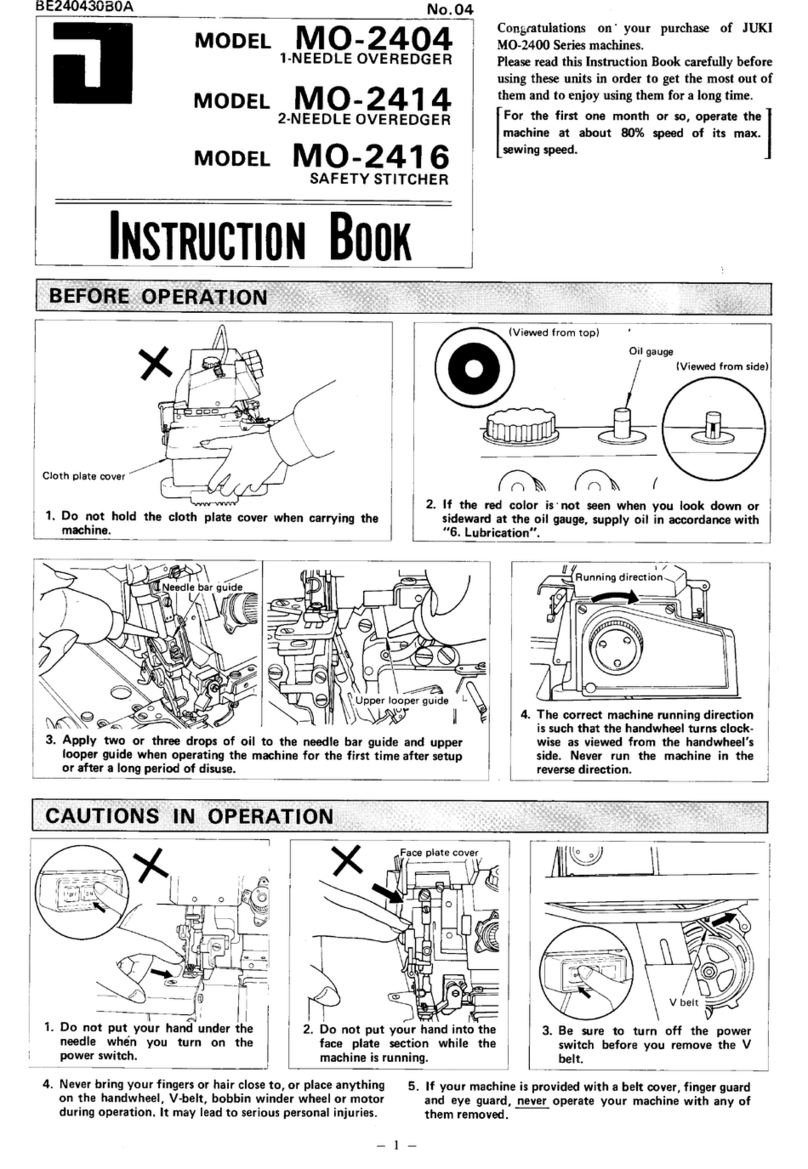

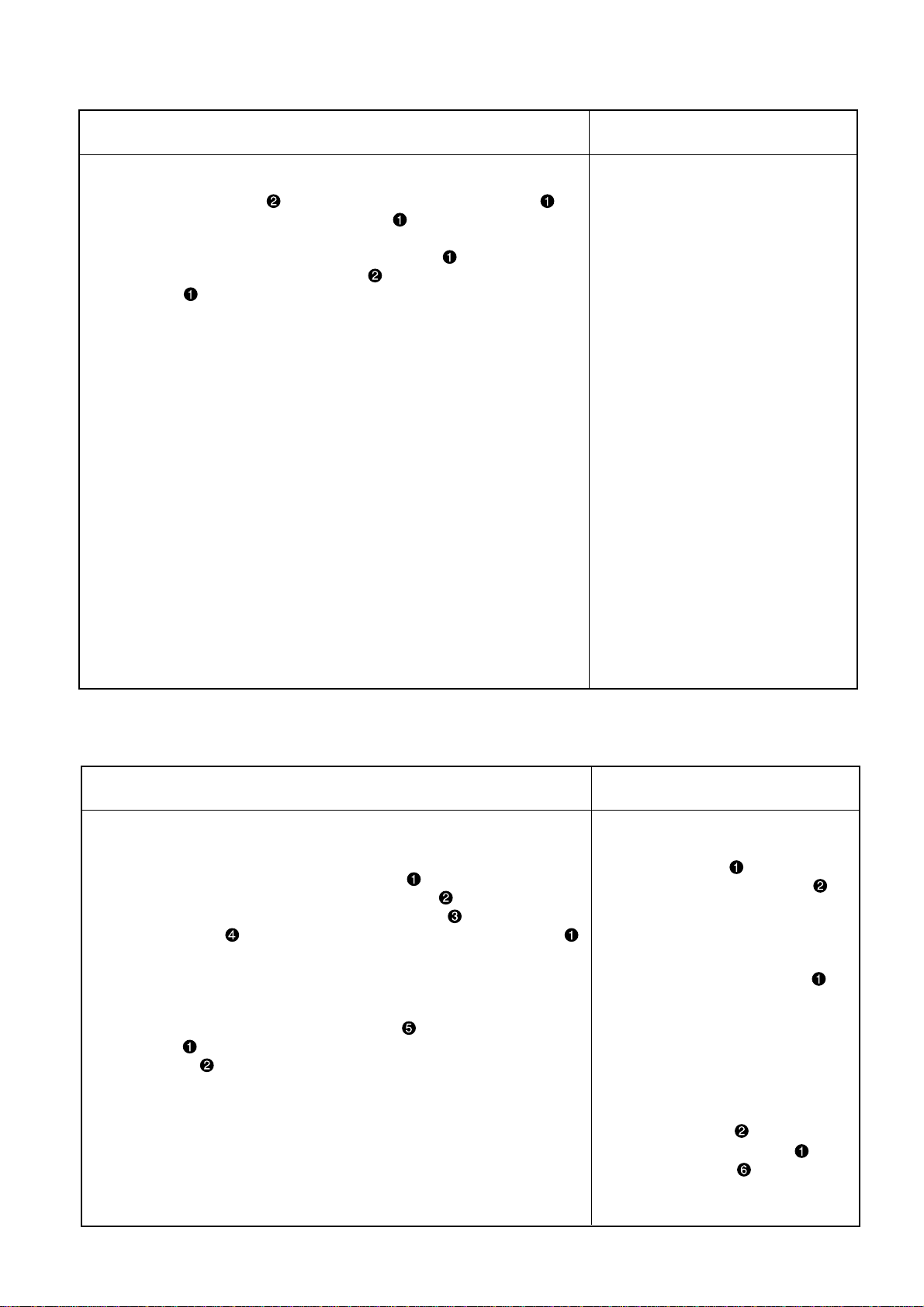

1) Needle Lifting Amount and Positions of the Needle and Blade

Point of the Hook

1. Loosen the set screw of the throat plate and remove the throat plate.

2. Lift the needle bar 2.5 mm up from the lowest dead point.

3. Align the marker line C(for DP x 17) to the lower end of the needle

bar lower metal .

For the needle DP x 17 (Standard), use the lowest engraved

marker line Con the needle bar.

For the needle DB x 1, use the third marker line Dfrom the

lowest engraved on the needle bar.

4. When the positions of the needle and the blade point of the

hook are adjusted, loosen the hook set screw and turn the hook

by hand. Then align the center of the needle with the blade point

of the hook.

2) Clearance between the Needle and the Blade Point of the Hook

1. When setting the clearance between the needle and the blade

point , loosen the hook set screw so taht the clearance of 0.02

to 0.07 mm is provided between the needle and the blade point

.

Adjustment Procedure Results of Improper Adjustment

Adjustment Procedure Results of Improper Adjustment