How

to

Adjust

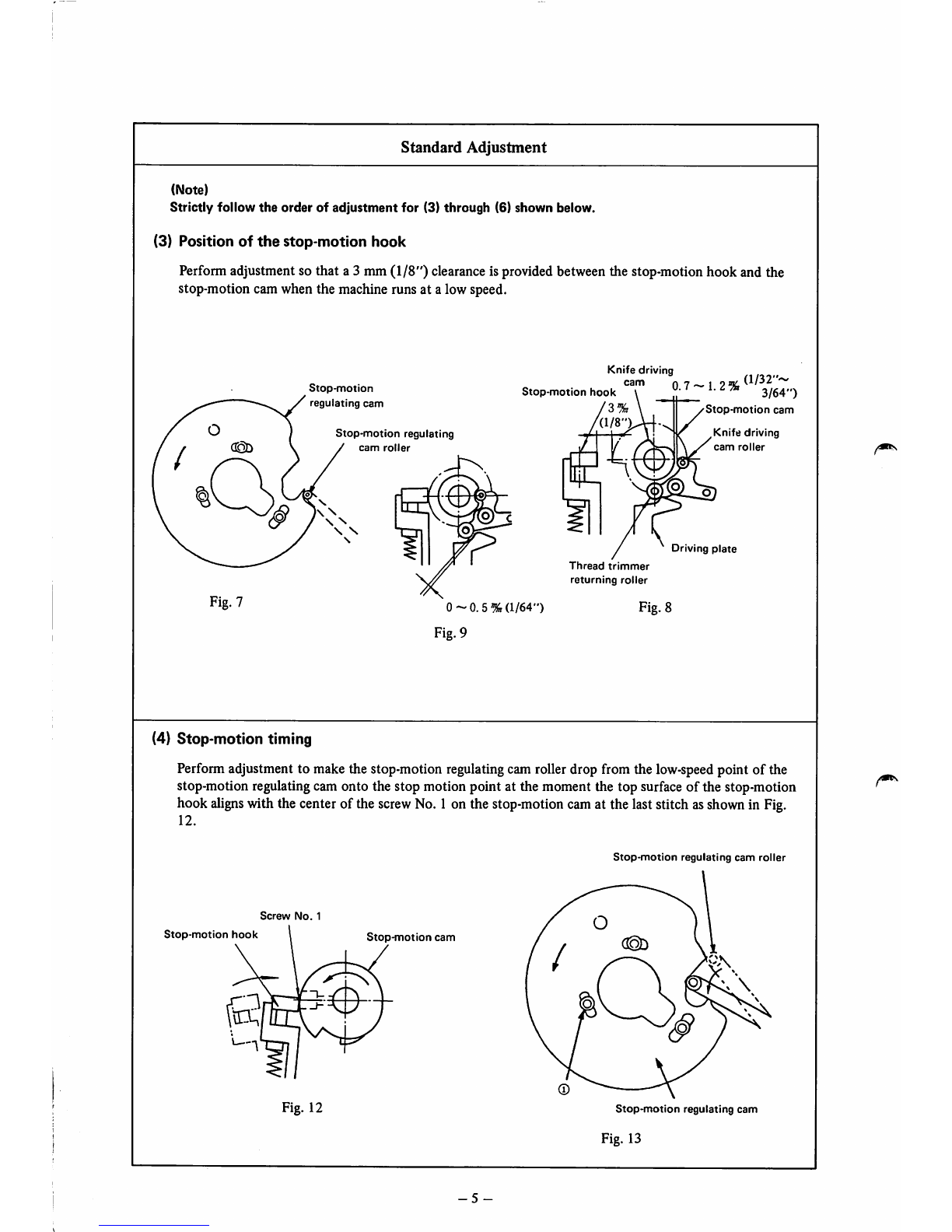

1)

Turn

the

main

shaftbyhandto obtainthestate

shown

in

Fig.

7.

(low-speed running)

2)

Remove

the

spring

(2)

and

spring

(D .

3)

Loosen

screw

(T),

and

perform

adjustment

to

allow

a3

mm

(1/8")

clearance

between

thestop-motion hookandthe

knife

driving

cam.

(Caution)

When

tightening

screw

(l),

be

careful

not to

cause

excessive

axial

sticking.

Fig. 10 Fig. 11

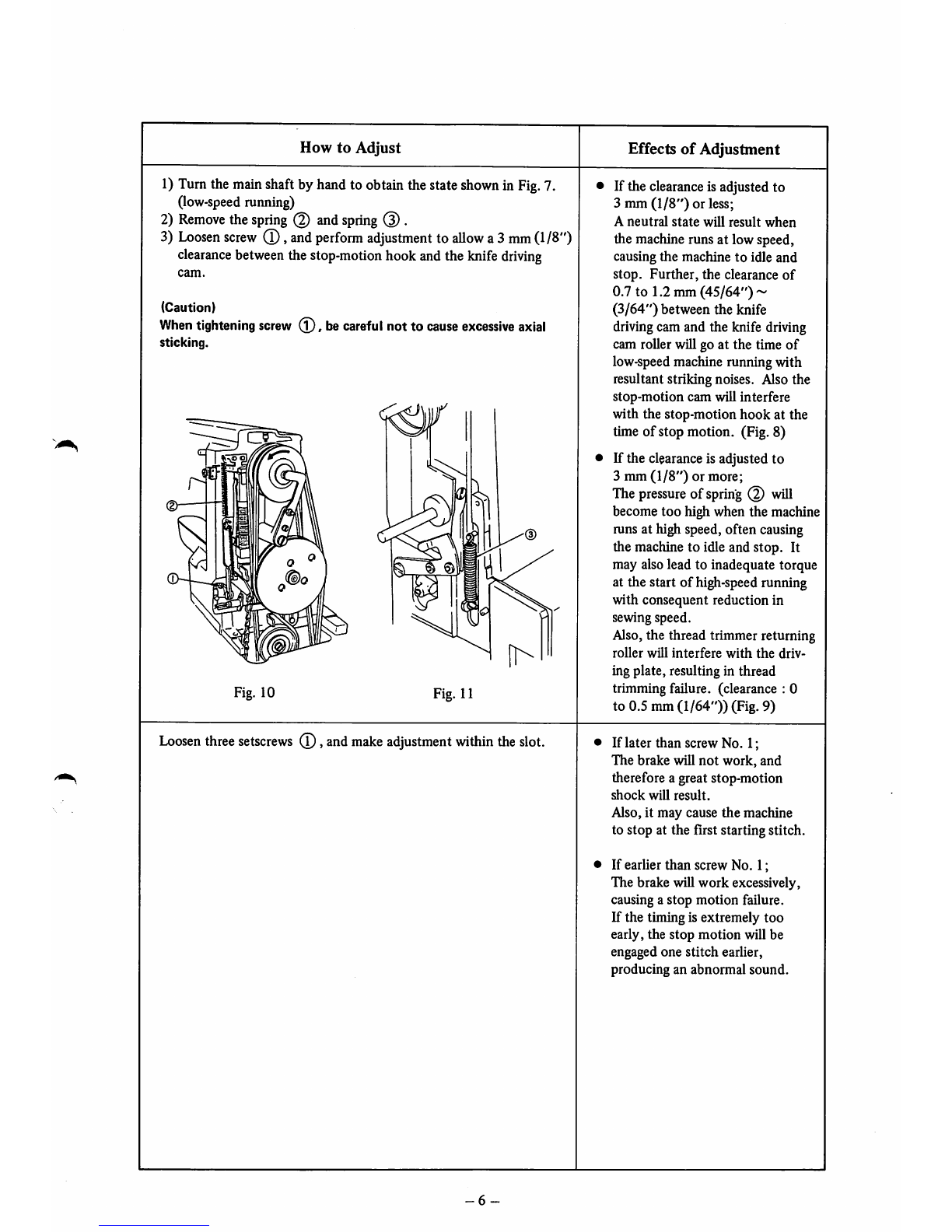

Loosen

three

setscrews

(D,

and

make

adjustment

within

the

slot.

-6

Effects

of

Adjustment

If the clearanceis adjusted to

3 mm (1/8") or less;

A

neutral

state

will

result

when

the machine runs at low speed,

causing the machine to idle and

stop.

Further,

the clearance

of

0.7 to 1.2 mm (45/64") ~

(3/64")

between the knife

drivingcam and the knife driving

cam roller willgo at the time of

low-speedmachine running with

resultant striking noises. Also the

stop-motion

cam

will interfere

with the stop-motion

hook

at the

time of stop motion. (Fig. 8)

If the clearanceis adjusted to

3 mm

(1/8")

or more;

The pressure of spring will

become too high when the machine

mns at high speed, often causing

the machine to idle and stop. It

may alsolead to inadequate torque

at the start of high-speedrunning

with consequent reduction in

sewing speed.

Also,the thread trimmer returning

roller

will

interfere

with

the

driv

ing plate, resulting in thread

trimming failure, (clearance : 0

to 0.5 mm

(1/64"))

(Fig. 9)

• If later than screw No. 1;

The brake will

not

work,

and

therefore a great stop-motion

shock

will

result.

Also, it may cause

the

machine

to stop at the first starting stitch.

• If earlier than screw No. 1;

The brake will work excessively,

causing a

stop

motion

failure.

If the timing is extremely

too

early, the stop motion will be

engaged one stitch earlier,

producing an abnormal sound.